lock LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 2295 of 4087

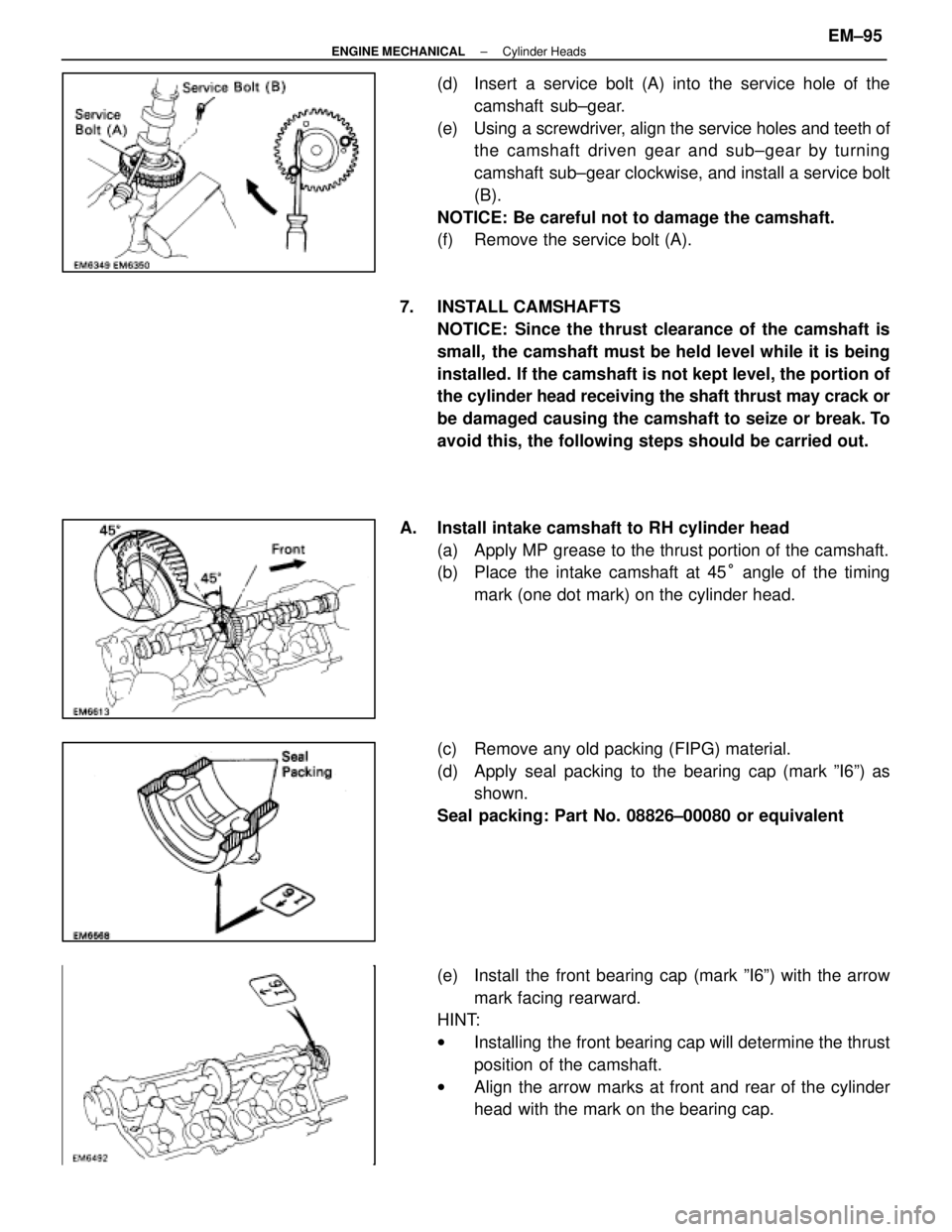

(d) Insert a service bolt (A) into the service hole of thecamshaft sub±gear.

(e) Using a screwdriver, align the service holes and teeth of the camshaft driven gear and sub±gear by turning

camshaft sub±gear clockwise, and install a service bolt

(B).

NOTICE: Be careful not to damage the camshaft.

(f) Remove the service bolt (A).

7. INSTALL CAMSHAFTS NOTICE: Since the thrust clearance of the camshaft is

small, the camshaft must be held level while it is being

installed. If the camshaft is not kept level, the portion of

the cylinder head receiving the shaft thrust may crack or

be damaged causing the camshaft to seize or break. To

avoid this, the following steps should be carried out.

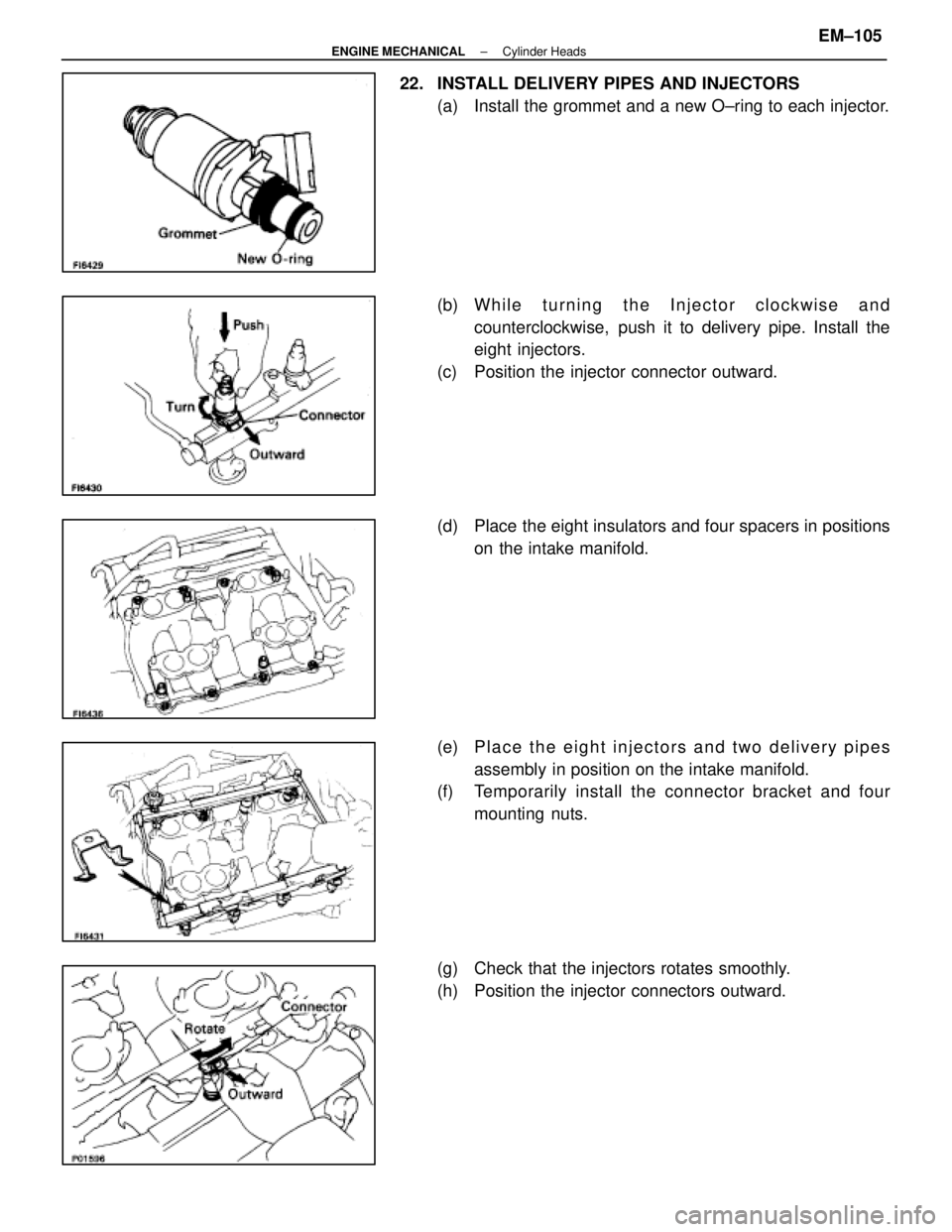

A. Install intake camshaft to RH cylinder head (a) Apply MP grease to the thrust portion of the camshaft.

(b) Place the intake camshaft at 45 ° angle of the timing

mark (one dot mark) on the cylinder head.

(c) Remove any old packing (FIPG) material.

(d) Apply seal packing to the bearing cap (mark ºI6º) as shown.

Seal packing: Part No. 08826±00080 or equivalent

(e) Install the front bearing cap (mark ºI6º) with the arrow mark facing rearward.

HINT:

w Installing the front bearing cap will determine the thrust

position of the camshaft.

w Align the arrow marks at front and rear of the cylinder

head with the mark on the bearing cap.

±

ENGINE MECHANICAL Cylinder HeadsEM±95

WhereEverybodyKnowsYourName

Page 2305 of 4087

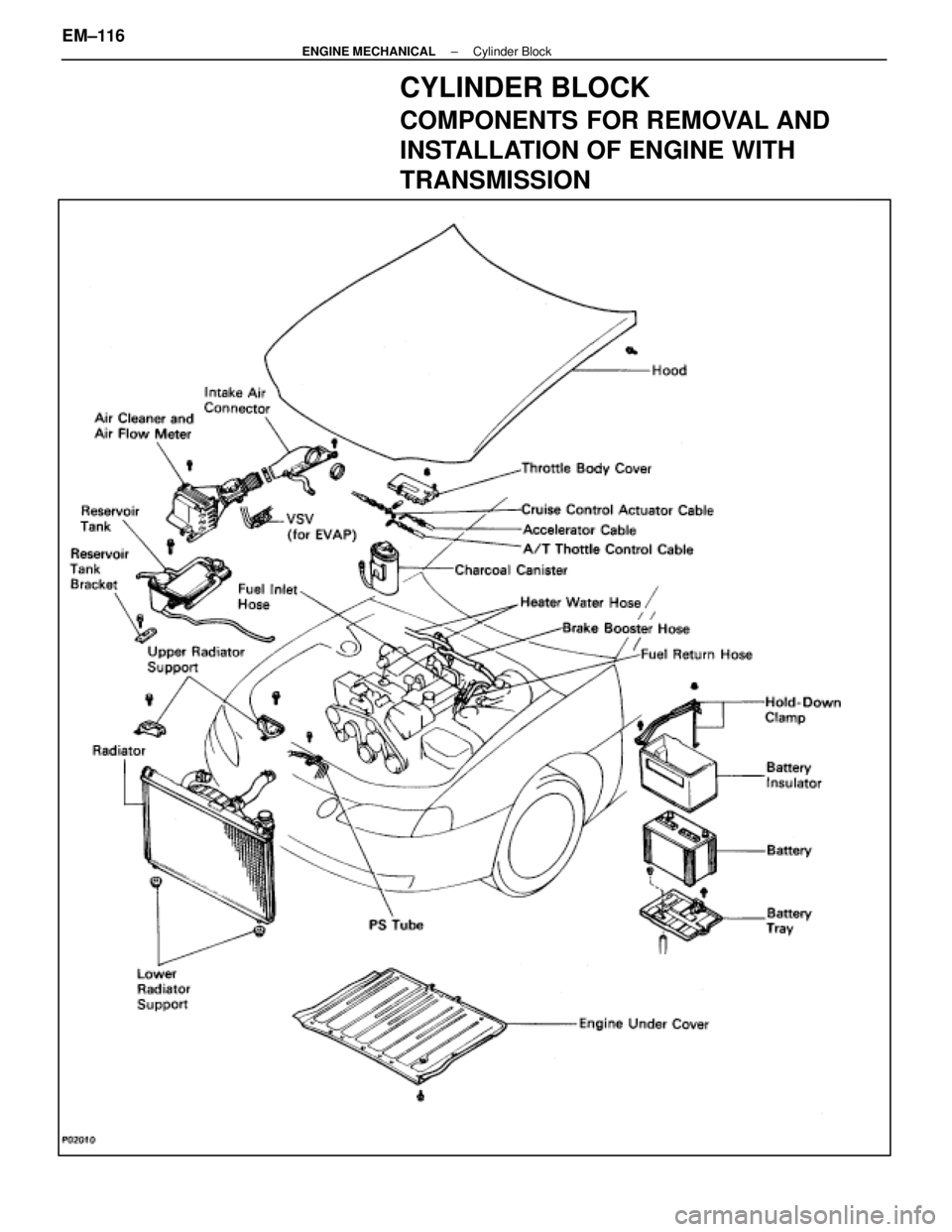

22. INSTALL DELIVERY PIPES AND INJECTORS(a) Install the grommet and a new O±ring to each injector.

(b) W h i l e t u r n i n g t h e I n j e c t o r c l o c k w i s e a n dcounterclockwise, push it to delivery pipe. Install the

eight injectors.

(c) Position the injector connector outward.

(d) Place the eight insulators and four spacers in positions on the intake manifold.

(e) P l a c e t h e e i g h t i n j e c t o r s a n d t w o d e l i v e r y p i p e s assembly in position on the intake manifold.

(f) Temporarily install the c onnector bracket and four

mounting nuts.

(g) Check that the injectors rotates smoothly.

(h) Position the injector connectors outward.

±

ENGINE MECHANICAL Cylinder HeadsEM±105

WhereEverybodyKnowsYourName

Page 2316 of 4087

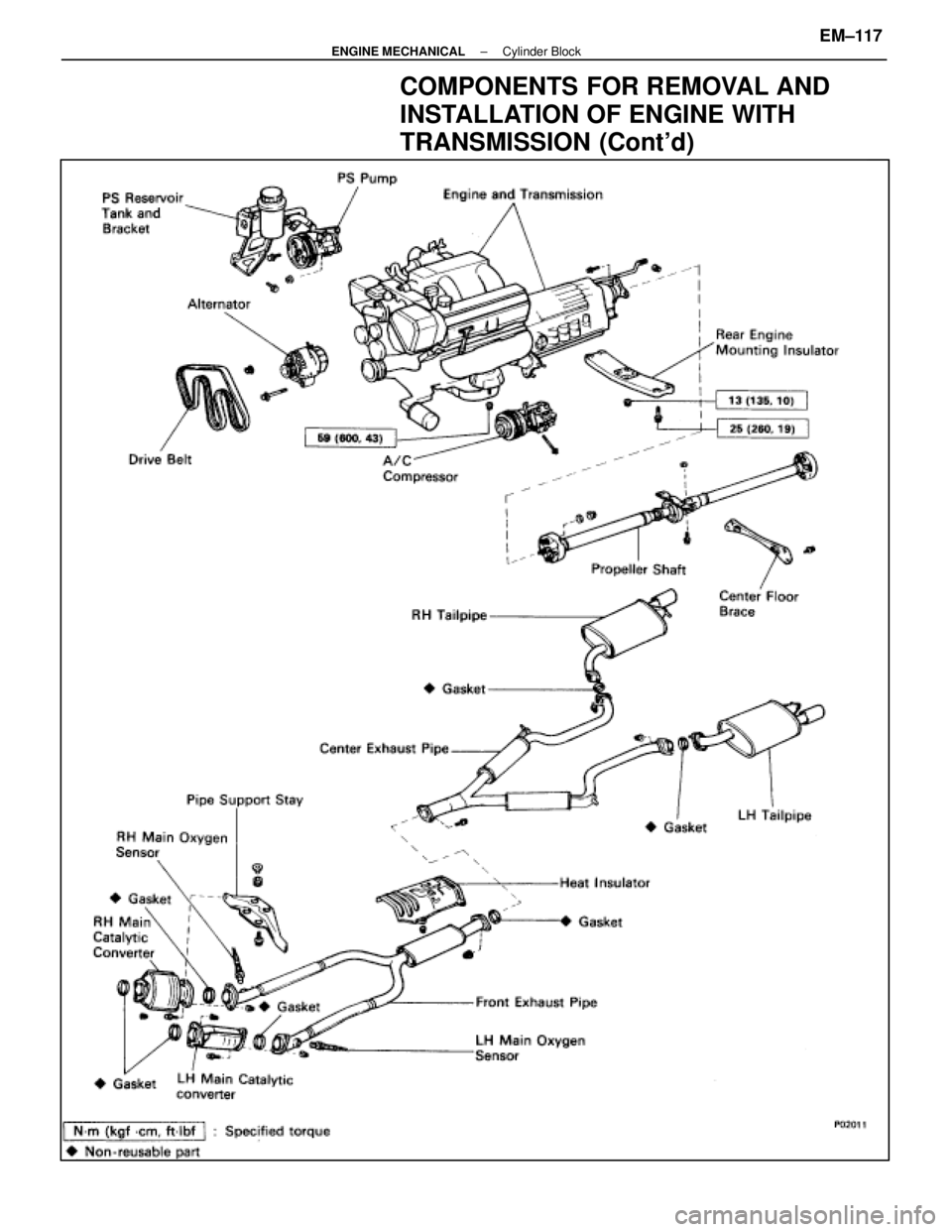

CYLINDER BLOCK

COMPONENTS FOR REMOVAL AND

INSTALLATION OF ENGINE WITH

TRANSMISSION

EM±116±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 2317 of 4087

COMPONENTS FOR REMOVAL AND

INSTALLATION OF ENGINE WITH

TRANSMISSION (Cont'd)

±

ENGINE MECHANICAL Cylinder BlockEM±117

WhereEverybodyKnowsYourName

Page 2318 of 4087

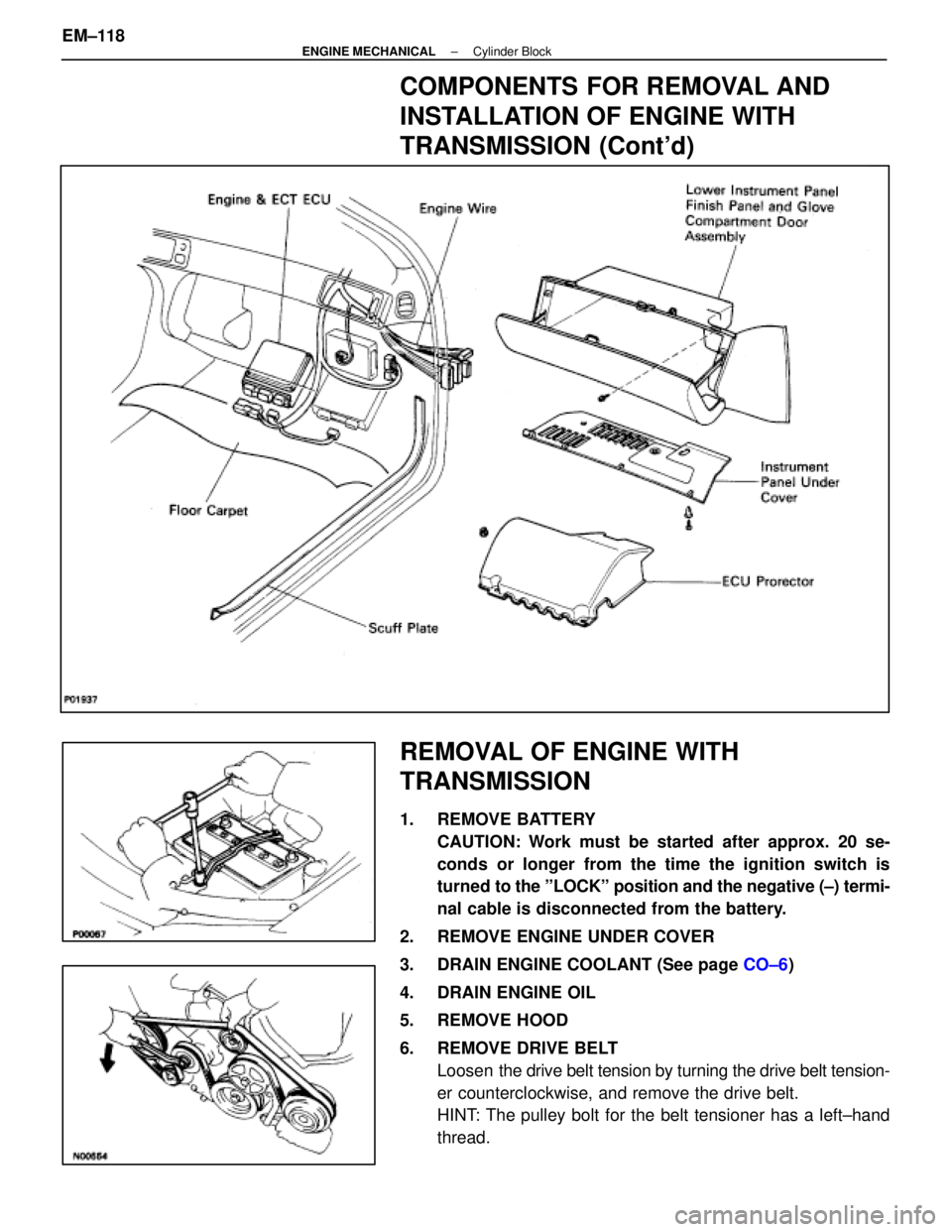

COMPONENTS FOR REMOVAL AND

INSTALLATION OF ENGINE WITH

TRANSMISSION (Cont'd)

REMOVAL OF ENGINE WITH

TRANSMISSION

1. REMOVE BATTERYCAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. REMOVE ENGINE UNDER COVER

3. DRAIN ENGINE COOLANT (See page CO±6)

4. DRAIN ENGINE OIL

5. REMOVE HOOD

6. REMOVE DRIVE BELT Loosen the drive belt tension by turning the drive belt tension-

er counterclockwise, and remove the drive belt.

HINT: The pulley bolt for the belt tensioner has a left±hand

thread.

EM±118

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 2319 of 4087

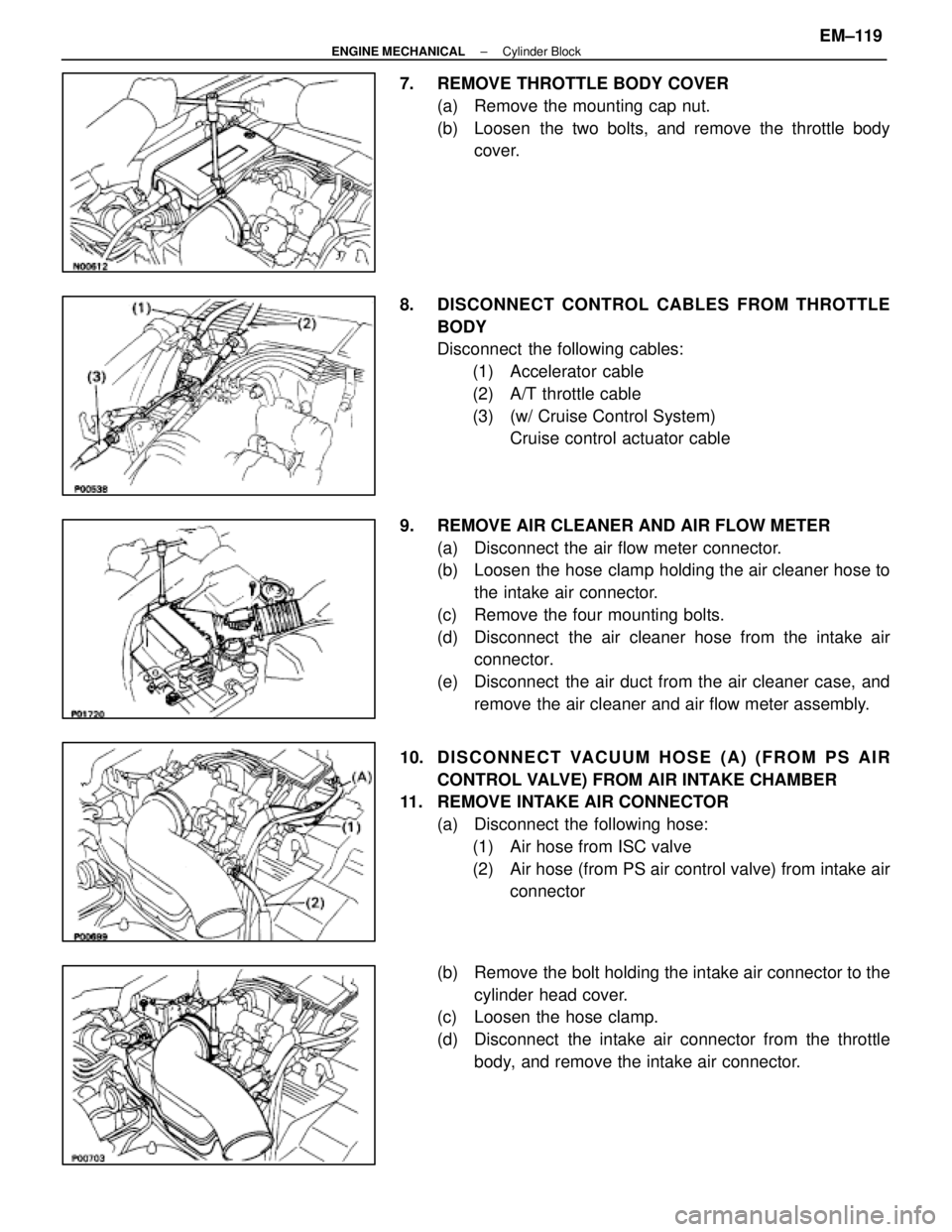

7. REMOVE THROTTLE BODY COVER(a) Remove the mounting cap nut.

(b) Loosen the two bolts, and remove the throttle bodycover.

8. DISCONNECT CONTROL CABLES FROM THROTTLE BODY

Disconnect the following cables:(1) Accelerator cable

(2) A/T throttle cable

(3) (w/ Cruise Control System) Cruise control actuator cable

9. REMOVE AIR CLEANER AND AIR FLOW METER (a) Disconnect the air flow meter connector.

(b) Loosen the hose clamp holding the air cleaner hose tothe intake air connector.

(c) Remove the four mounting bolts.

(d) Disconnect the air cleaner hose from the intake air connector.

(e) Disconnect the air duct from the air cleaner case, and remove the air cleaner and air flow meter assembly.

10. D I S C O N N E C T VA CUUM HOSE (A) (FROM PS AIR

CONTROL VALVE) FROM AIR INTAKE CHAMBER

11. REMOVE INTAKE AIR CONNECTOR

(a) Disconnect the following hose:(1) Air hose from ISC valve

(2) Air hose (from PS air control valve) from intake air connector

(b) Remove the bolt holding the intake air connector to the cylinder head cover.

(c) Loosen the hose clamp.

(d) Disconnect the intake air connector from the throttle

body, and remove the intake air connector.

±

ENGINE MECHANICAL Cylinder BlockEM±119

WhereEverybodyKnowsYourName

Page 2320 of 4087

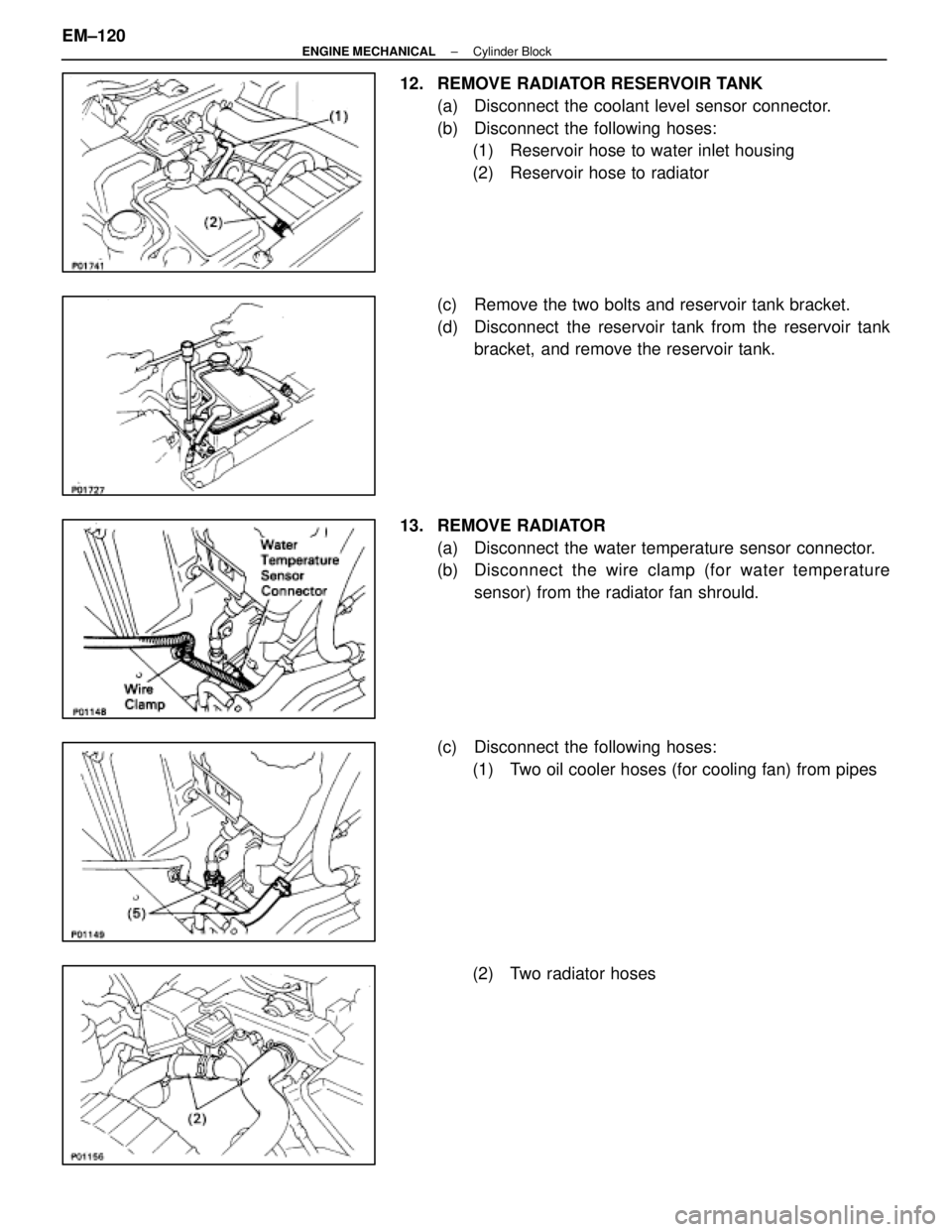

12. REMOVE RADIATOR RESERVOIR TANK(a) Disconnect the coolant level sensor connector.

(b) Disconnect the following hoses:(1) Reservoir hose to water inlet housing

(2) Reservoir hose to radiator

(c) Remove the two bolts and reservoir tank bracket.

(d) Disconnect the reservoir tank from the reservoir tank bracket, and remove the reservoir tank.

13. REMOVE RADIATOR (a) Disconnect the water temperature sensor connector.

(b) Disc onnect the wire clamp (for water temperature

sensor) from the radiator fan shrould.

(c) Disconnect the following hoses: (1) Two oil cooler hoses (for cooling fan) from pipes

(2) Two radiator hoses

EM±120

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 2321 of 4087

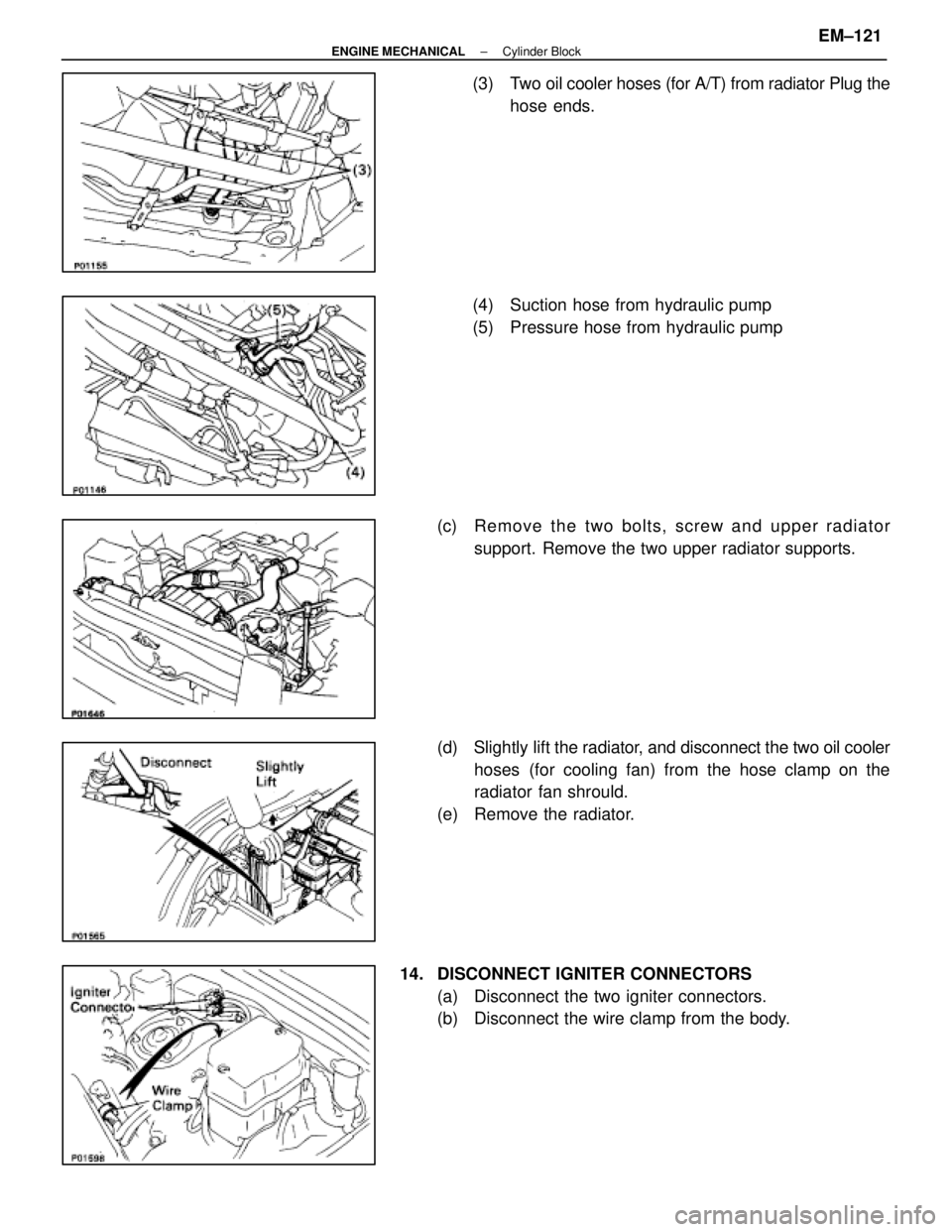

(3) Two oil cooler hoses (for A/T) from radiator Plug thehose ends.

(4) Suction hose from hydraulic pump

(5) Pressure hose from hydraulic pump

(c) Re mo ve th e two bo lts, scre w an d u pper radiator

support. Remove the two upper radiator supports.

(d) Slightly lift the radiator, and d isconnect the two oil cooler

hoses (for cooling fan) from the hose clamp on the

radiator fan shrould.

(e) Remove the radiator.

14. DISCONNECT IGNITER CONNECTORS (a) Disconnect the two igniter connectors.

(b) Disconnect the wire clamp from the body.

±

ENGINE MECHANICAL Cylinder BlockEM±121

WhereEverybodyKnowsYourName

Page 2322 of 4087

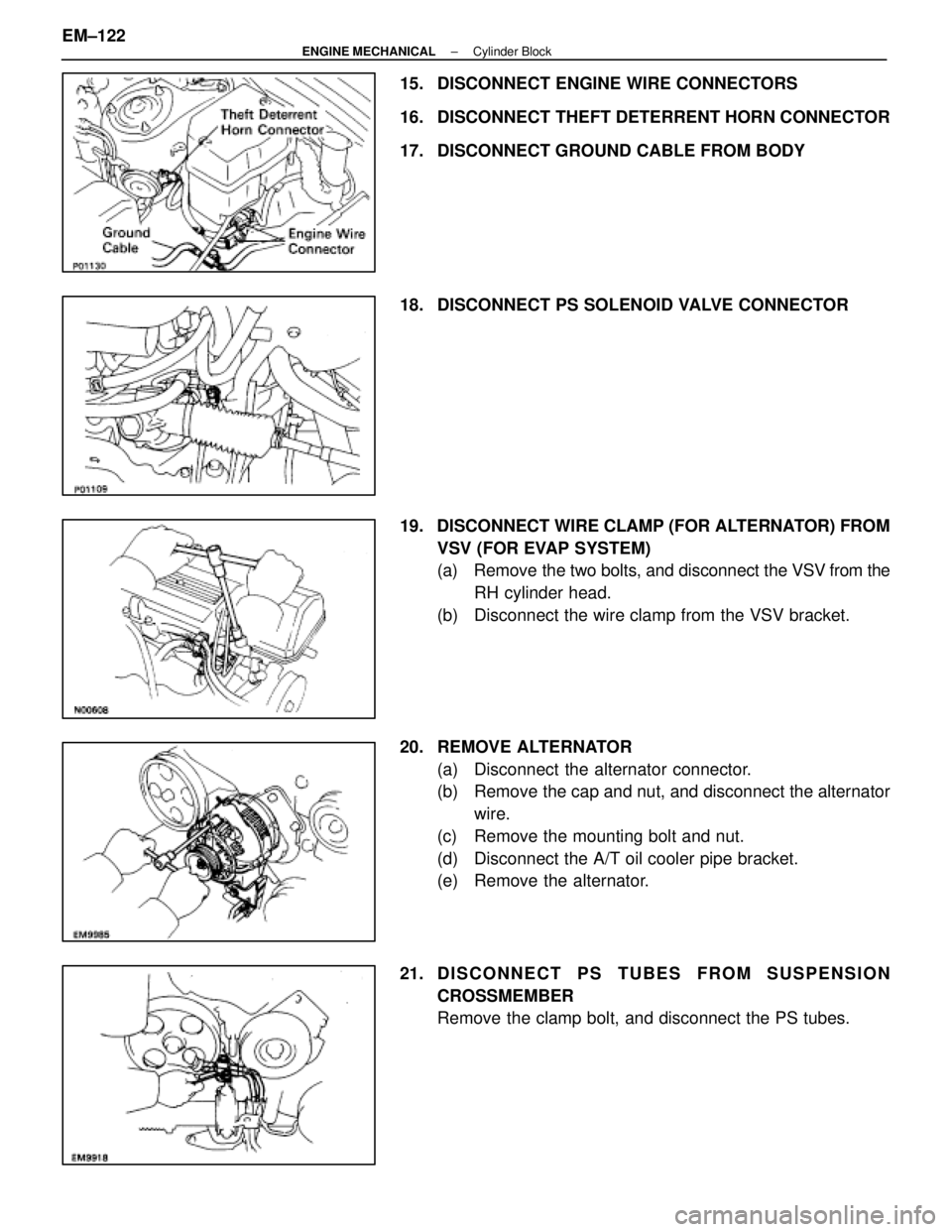

15. DISCONNECT ENGINE WIRE CONNECTORS

16. DISCONNECT THEFT DETERRENT HORN CONNECTOR

17. DISCONNECT GROUND CABLE FROM BODY

18. DISCONNECT PS SOLENOID VALVE CONNECTOR

19. DISCONNECT WIRE CLAMP (FOR ALTERNATOR) FROMVSV (FOR EVAP SYSTEM)

(a) Remove the two bolts, and disconnect the VSV from the

RH cylinder head.

(b) Disconnect the wire clamp from the VSV bracket.

20. REMOVE ALTERNATOR (a) Disconnect the alternator connector.

(b) Remove the cap and nut, and disconnect the alternatorwire.

(c) Remove the mounting bolt and nut.

(d) Disconnect the A/T oil cooler pipe bracket.

(e) Remove the alternator.

21. D I S C O N N E C T P S T U B E S F R O M S U SPENSION

CROSSMEMBER

Remove the clamp bolt, and disconnect the PS tubes.

EM±122

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 2323 of 4087

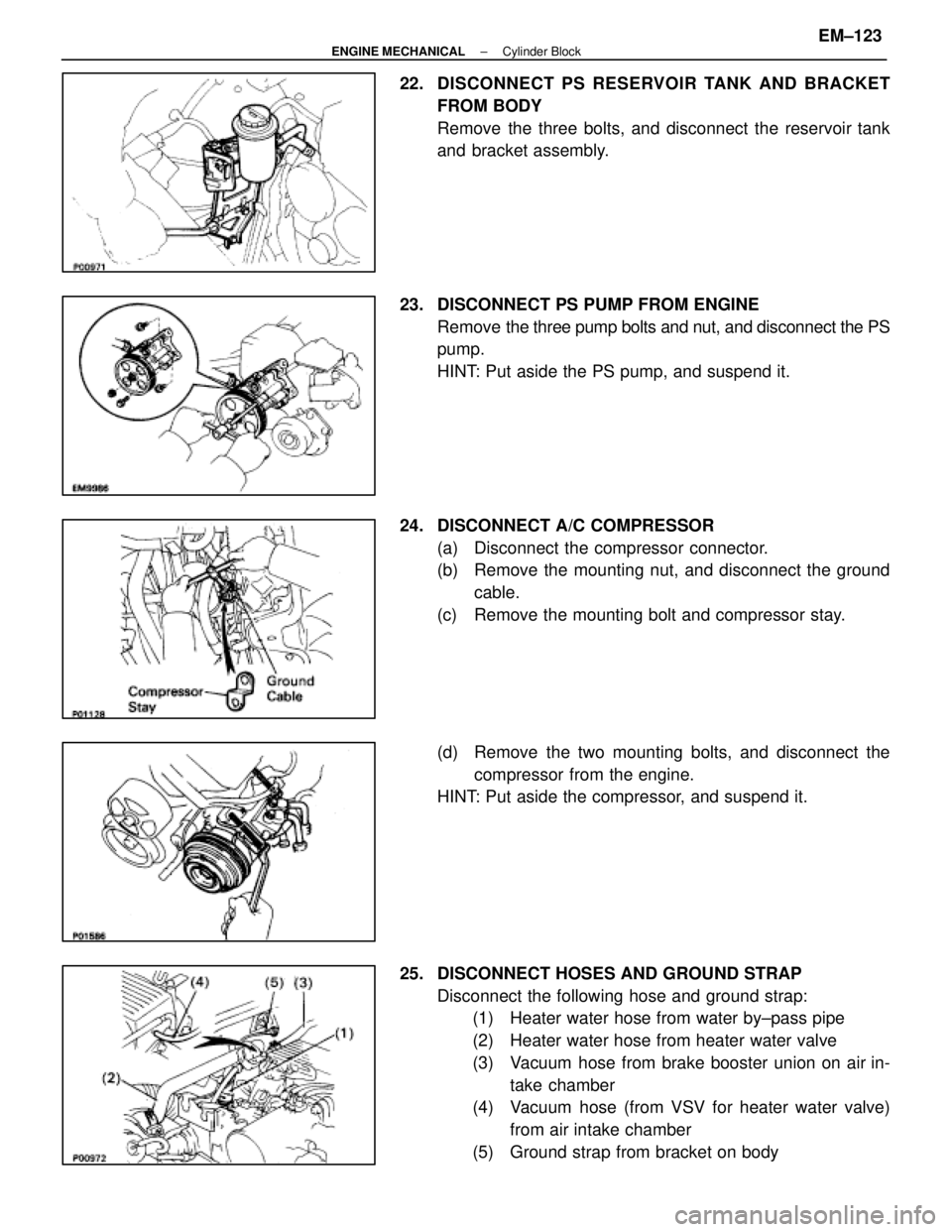

22. DISCONNECT PS RESERVOIR TANK AND BRACKET

FROM BODY

Remove the three bolts, and disconnect the reservoir tank

and bracket assembly.

23. DISCONNECT PS PUMP FROM ENGINE Remove the three pump bolts and nut, and disconnect the PS

pump.

HINT: Put aside the PS pump, and suspend it.

24. DISCONNECT A/C COMPRESSOR (a) Disconnect the compressor connector.

(b) Remove the mounting nut, and disconnect the groundcable.

(c) Remove the mounting bolt and compressor stay.

(d) Remove the two mounting bolts, and disconnect the compressor from the engine.

HINT: Put aside the compressor, and suspend it.

25. DISCONNECT HOSES AND GROUND STRAP Disconnect the following hose and ground strap:(1) Heater water hose from water by±pass pipe

(2) Heater water hose from heater water valve

(3) Vacuum hose from brake booster union on air in-

take chamber

(4) Vacuum hose (from VSV for heater water valve)

from air intake chamber

(5) Ground strap from bracket on body

±

ENGINE MECHANICAL Cylinder BlockEM±123

WhereEverybodyKnowsYourName