lock LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 3776 of 4087

TSIB

IntroductionA musty odor may be emitted from the air conditioning system of some vehicles which are

usually operated in areas with high temperature and humidity. It is most noticeable when

the air conditioner is first turned ªONº after the vehicle has bee\

n parked for several hours.

The odor could result from one or more of the following conditions:

1. Blockage of the evaporator housing drain pipe, resulting in the build up of cond\

ensation.

2. Microbial growth in the evaporator, arising from dampness in the evaporator housing

where the cooling air flow is dehumidified.

To address excessive air conditioning evaporator odor, check the evaporator housing drain

pipe for blockage. If no problems are found, the evaporator and housing\

should be cleaned

and disinfected using the general procedure given on page 2, and the model \

specific

procedure on the pages indicated in the Table of Contents at the bottom of this page.

Affected �While this procedure may be used on any Lexus vehicle, this bulletin giv\

es details

Vehicles specifically for the '92±'96 ES 300, all GS 300, '93±'94 LS 400, all SC 300/400 and the\

LX 450.

Tools &

PART NUMBER DESCRIPTION OF TOOLS & MATERIALS QUANTITY SOURCE

Materials08821±00810±01 Spray Gun Kit 1 OTC 08821±00811±01 Spray Gun (replacement) (1) OTC

08821±00812±01 Spray Gun Nozzle (replacement) (1) OTC

08821±00813±01 Freshener Mixing Container (replacement) (1) OTC

08821±00801±DS Air Conditioning Freshener 1 per vehicle TMS

CAUTION:

Wear safety glasses, protective mask, and gloves while working with the

freshener.

Warranty

OPCODE DESCRIPTION TIME OPN T1 T2

Information

N/A No applicable warranty information ± ± ± ±

Table ofMODEL PAGE MODEL PAGE MODEL PAGE MODEL PAGE

Contents

ES 300 3 GS 300 5 LS 400 7

GENERAL 2

SC 300 9 SC 400 9 LX 450 11

General Procedure applies to all models and model years.

The Specific Model Sections cover only the listed ªaffected models.º

HEATING & AIR CONDITIONING

September 12, 1997

Title:

AIR CONDITIONING EVAPORATOR ODOR

Models:

'92±96 ES 300, '93±'94 LS 400,

All GS 300, SC 300/400, LX 450.

Page 1 of 11

AC001±97

WhereEverybodyKnowsYourName

Page 3794 of 4087

SENSOR INSPECTION FOR AIR CONDITIONING SYSTEM ± AC005-04 December 16, 2004

Page 8 of 12

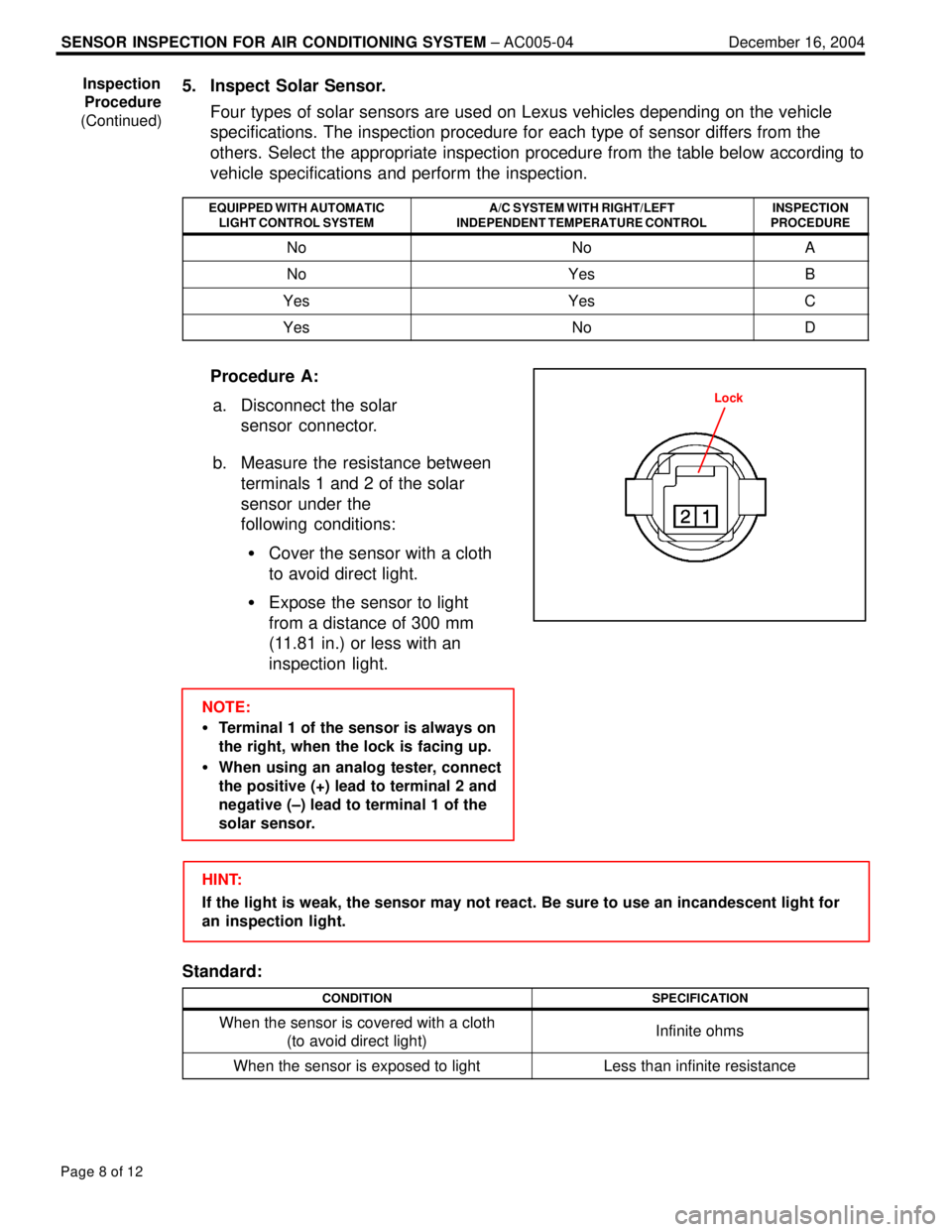

5. Inspect Solar Sensor.

Four types of solar sensors are used on Lexus vehicles depending on the \

vehicle

specifications. The inspection procedure for each type of sensor differs from the

others. Select the appropriate inspection procedure from the table below\

according to

vehicle specifications and perform the inspection.

EQUIPPED WITH AUTOMATICLIGHT CONTROL SYSTEMA/C SYSTEM WITH RIGHT/LEFT

INDEPENDENT TEMPERATURE CONTROLINSPECTION

PROCEDURE

NoNoA

NoYesB

YesYesC

YesNoD

Procedure A:

a. Disconnect the solar sensor connector.

b. Measure the resistance between terminals 1 and 2 of the solar

sensor under the

following conditions:

� Cover the sensor with a cloth

to avoid direct light.

� Expose the sensor to light

from a distance of 300 mm

(11.81 in.) or less with an

inspection light.

NOTE:

�Terminal 1 of the sensor is always on

the right, when the lock is facing up.

� When using an analog tester, connect

the positive (+) lead to terminal 2 and

negative (±) lead to terminal 1 of the

solar sensor.

HINT:

If the light is weak, the sensor may not react. Be sure to use an incand\

escent light for

an inspection light.

Standard:

CONDITIONSPECIFICATION

When the sensor is covered with a cloth

(to avoid direct light)Infinite ohms

When the sensor is exposed to lightLess than infinite resistance

InspectionProcedure

(Continued)

Lock

WhereEverybodyKnowsYourName

Page 3795 of 4087

SENSOR INSPECTION FOR AIR CONDITIONING SYSTEM ± AC005-04 December 16, 2004

Page 9 of 12

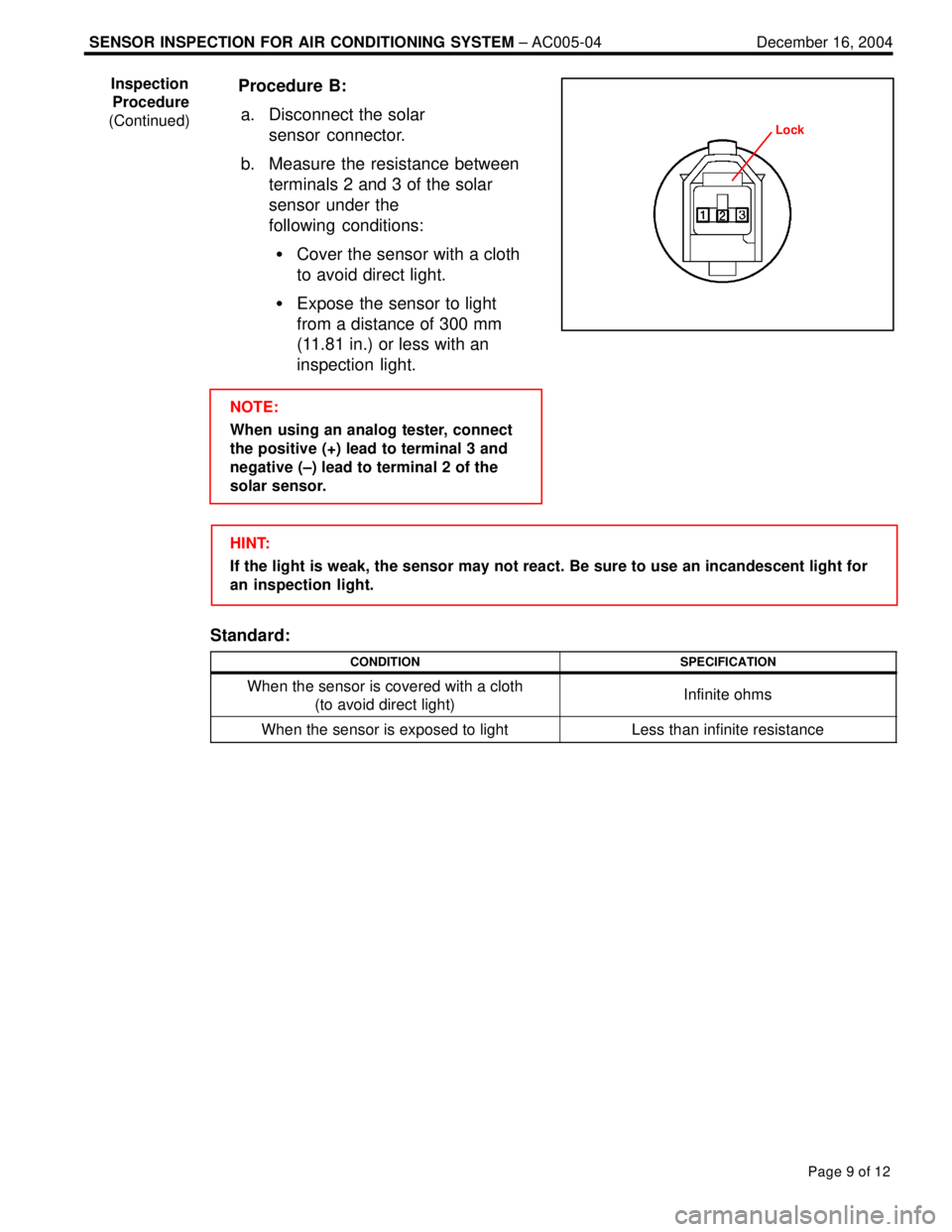

Procedure B:

a. Disconnect the solar sensor connector.

b. Measure the resistance between terminals 2 and 3 of the solar

sensor under the

following conditions:

� Cover the sensor with a cloth

to avoid direct light.

� Expose the sensor to light

from a distance of 300 mm

(11.81 in.) or less with an

inspection light.

NOTE:

When using an analog tester, connect

the positive (+) lead to terminal 3 and

negative (±) lead to terminal 2 of the

solar sensor.

HINT:

If the light is weak, the sensor may not react. Be sure to use an incand\

escent light for

an inspection light.

Standard:

CONDITIONSPECIFICATION

When the sensor is covered with a cloth

(to avoid direct light)Infinite ohms

When the sensor is exposed to lightLess than infinite resistance

InspectionProcedure

(Continued)

Lock

WhereEverybodyKnowsYourName

Page 3807 of 4087

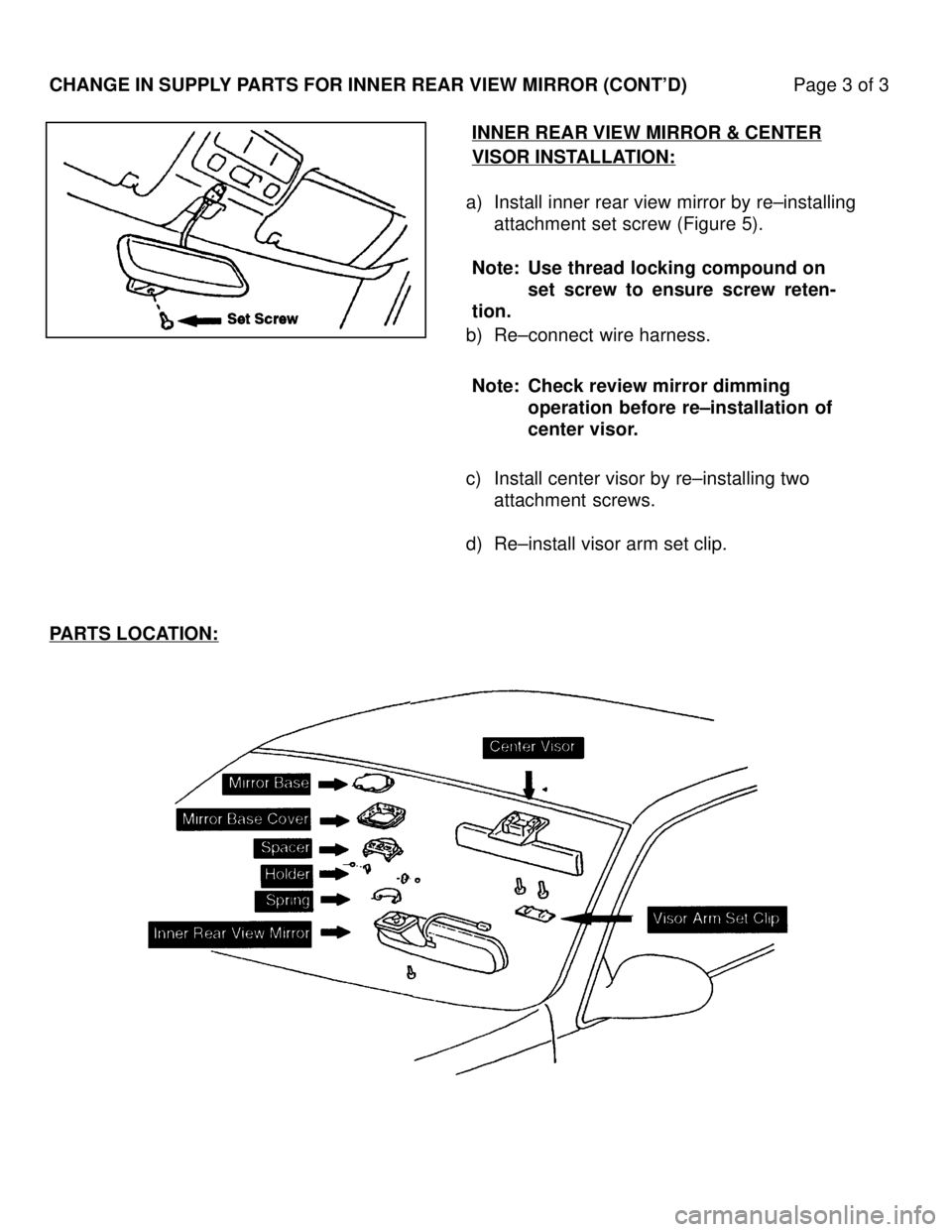

CHANGE IN SUPPLY PARTS FOR INNER REAR VIEW MIRROR (CONT'D)Page 3 of 3

a) Install inner rear view mirror by re±installing

attachment set screw (Figure 5).

INNER REAR VIEW MIRROR & CENTER

VISOR INSTALLATION:

PARTS LOCATION:

Note: Use thread locking compound on

set screw to ensure screw reten-

tion.

b) Re±connect wire harness.

Note: Check review mirror dimming operation before re±installation of

center visor.

c) Install center visor by re±installing two attachment screws.

d) Re±install visor arm set clip.

WhereEverybodyKnowsYourName

Page 3810 of 4087

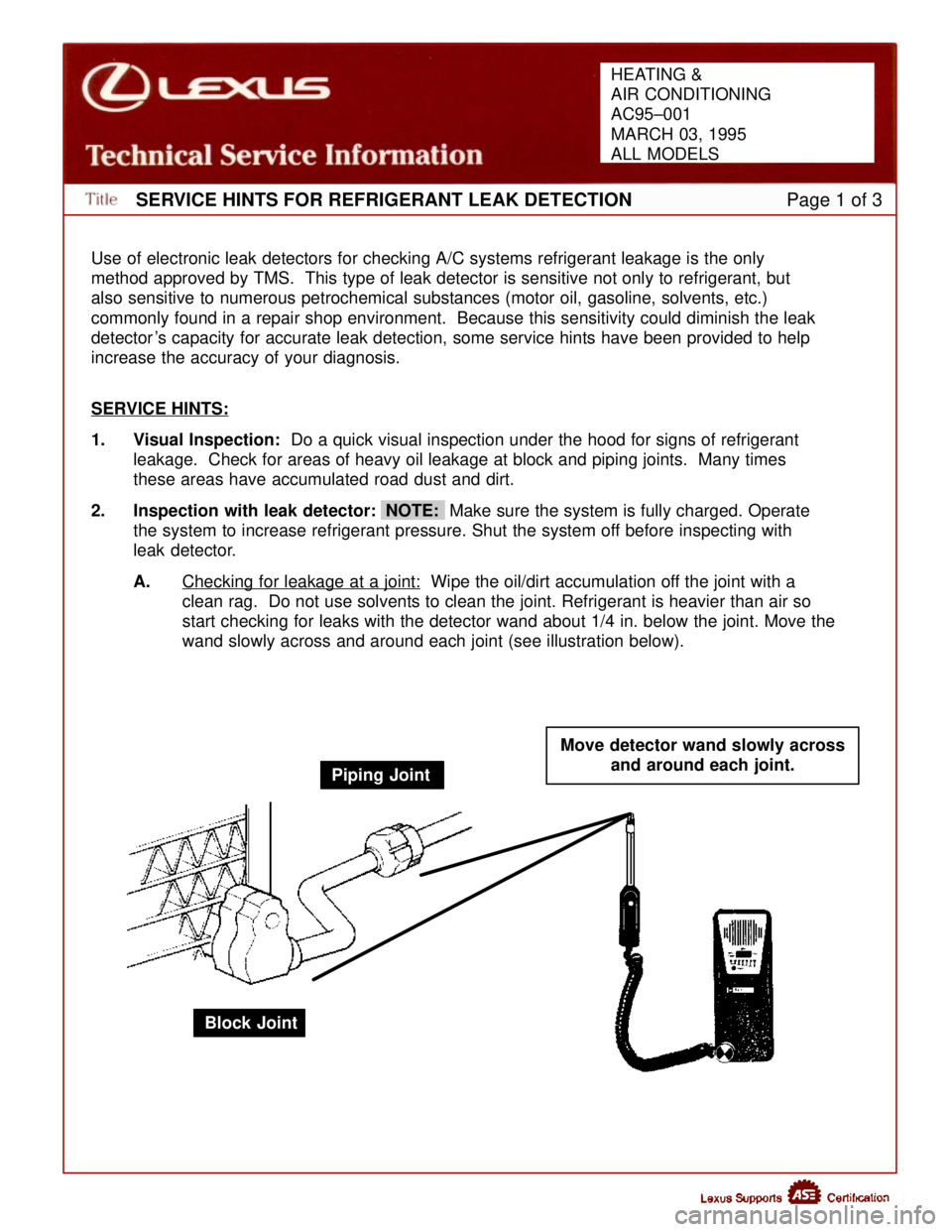

SERVICE HINTS FOR REFRIGERANT LEAK DETECTIONPage 1 of 3

Use of electronic leak detectors for checking A/C systems refrigerant leaka\

ge is the only

method approved by TMS. This type of leak detector is sensitive not onl\

y to refrigerant, but

also sensitive to numerous petrochemical substances (motor oil, gasolin\

e, solvents, etc.)

commonly found in a repair shop environment. Because this sensitivity c\

ould diminish the leak

detector 's capacity for accurate leak detection, some service hints have been pro\

vided to help

increase the accuracy of your diagnosis.

SERVICE HINTS:

1. Visual Inspection: Do a quick visual inspection under the hood for signs of refrigerant

leakage. Check for areas of heavy oil leakage at block and piping joint\

s. Many times

these areas have accumulated road dust and dirt.

2. Inspection with leak detector: NOTE: Make sure the system is fully charged. Operate

the system to increase refrigerant pressure. Shut the system off before inspecting with

leak detector.

A. Checking for leakage at a joint:

Wipe the oil/dirt accumulation off the joint with a

clean rag. Do not use solvents to clean the joint. Refrigerant is heavi\

er than air so

start checking for leaks with the detector wand about 1/4 in. below the \

joint. Move the

wand slowly across and around each joint (see illustration below).

Piping Joint Move detector wand slowly across

and around each joint.

Block Joint

HEATING &

AIR CONDITIONING

AC95±001

MARCH 03, 1995

ALL MODELS

WhereEverybodyKnowsYourName

Page 3819 of 4087

11 8

WIRELESS DOOR LOCK REMOTE CONTROL

7 6 10 542931

2 1

2

1E

11

1D

84

1J

1

1B

5

1I

64

1H

13

1D10 3E

7

3A 6

2

3

BY17

IP 1 20

BX1

2 BX1 11 BX1 8 BX19BX116 BX1 15 BX1 3

I8

I15

I7

B4 B7

9

10

6 3 6

3

BL IF IJ IP1

15

E KSW DSW D L1 LSWD1

UL1 LSWD2 LSWP

P±B

W±L

G± W

G±Y

L±W

W±B

W±B

W±B

W±B

W±B G±L

R±L

R

R

R

R±L

P±B

W±L L±W

G±W G±Y

G±W L±W G±Y

G±Y

G±W G±L

R±W Y

G±LY

W±B

G±L

R±W

R±W

W±B

W±B

W±B

W±B

W±B W±B

FROM POWER SOURCE SYSTEM

(

SEE PAGE 56 )

10A

DOME

+B

WIRE LES S DOOR LOCK E CU

WIRE LES S DOOR LOCK

MAIN SW

UNLOCK WARNING SW

[IGNITION SW]

DOOR OPEN

DE TE CTION SW LH

DOOR OPEN

DE TE CTION SW RH

INTEGRATION

RELAY DIODE

TO DOOR LOCK

AND UNLOCK SW LH

TO DOOR LOCK

AND UNLOCK SW RH

W8

I15

D10

D11

W7

2

1

4

6 IF2

15

IP 1

19

G±Y

G±W

I15

G±Y

TO DOOR LOCK

AND UNLOCK SW RH

IP1

8

G±Y

G±Y

WhereEverybodyKnowsYourName

Page 3820 of 4087

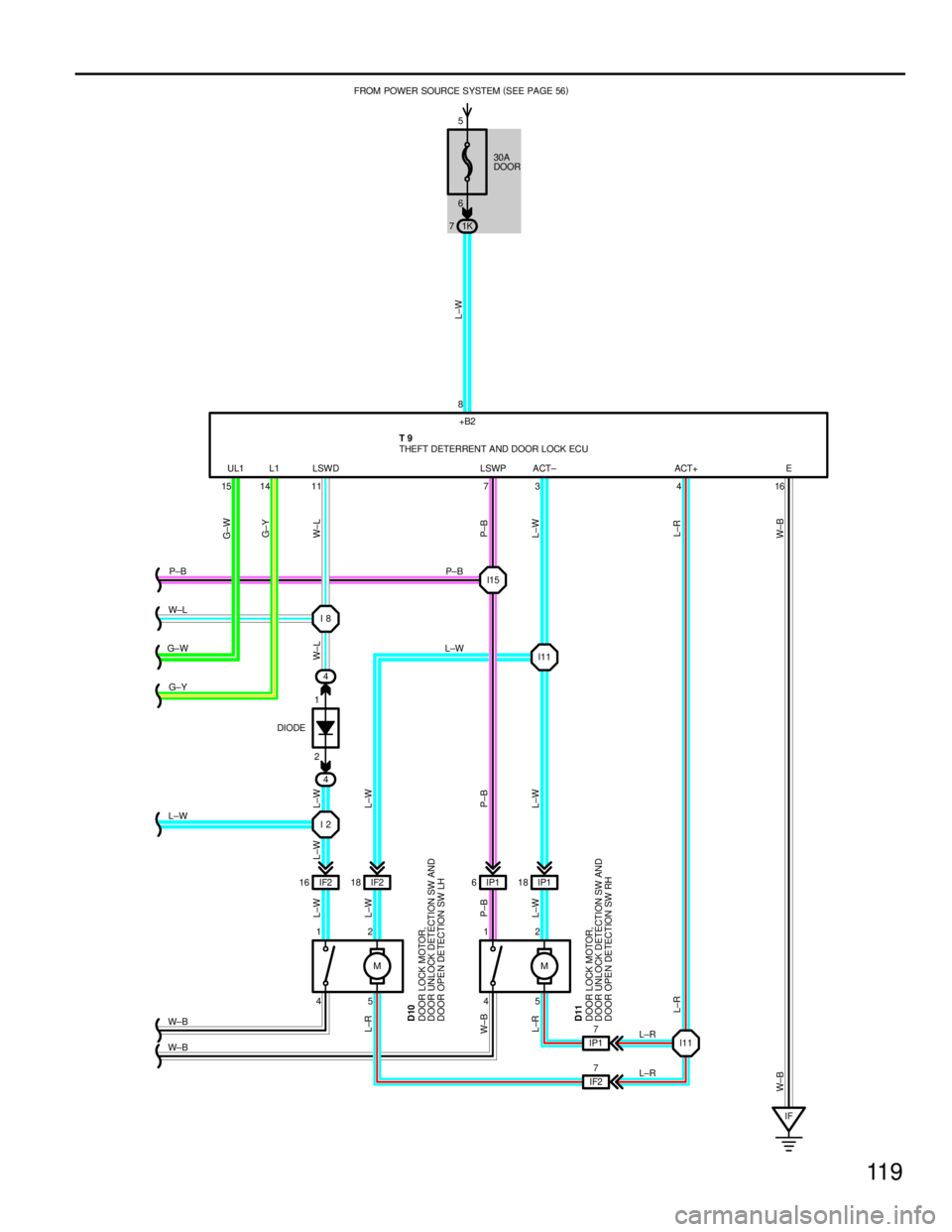

11 9

1K

7

15 14 11 7 3 4 16 8

2 1 4 4

IP17

IF2 7

I2 I8

I11

I11IF

IF2

16 IF2 18 IP1 6IP118

4 1 M

5

2

4

1 M

5

2

UL1 L1 LSWD LSWP ACT± ACT+ E

P±B

L±W

P±B

W±L

G±W

G±Y

L±W

W±B

W±B L±R

L±R

L±W

G±W

G±Y

W±L

P±B

L±W

L±R

W±B

L±W

L±W

L±W

P±B

L±W

W±B

L±R L±R W±L

L±R

W±B

FROM POWER SOURCE SYSTEM (

SEE PAGE 56 )

30A

DOOR

+B2

THEFT DETERRENT AND DOOR LOCK ECU

L±W

L±W

P±B

L±W

DOOR LOCK MOTOR,

DOOR UNLOCK DETECTION SW AND

DOOR OPEN DETECTION SW LH

DOOR LOCK MOTOR,

DOOR UNLOCK DETECTION SW AND

DOOR OPEN DETECTION SW RH

DIODE

D10

D11

T9 6 5

I15

WhereEverybodyKnowsYourName

Page 3821 of 4087

120

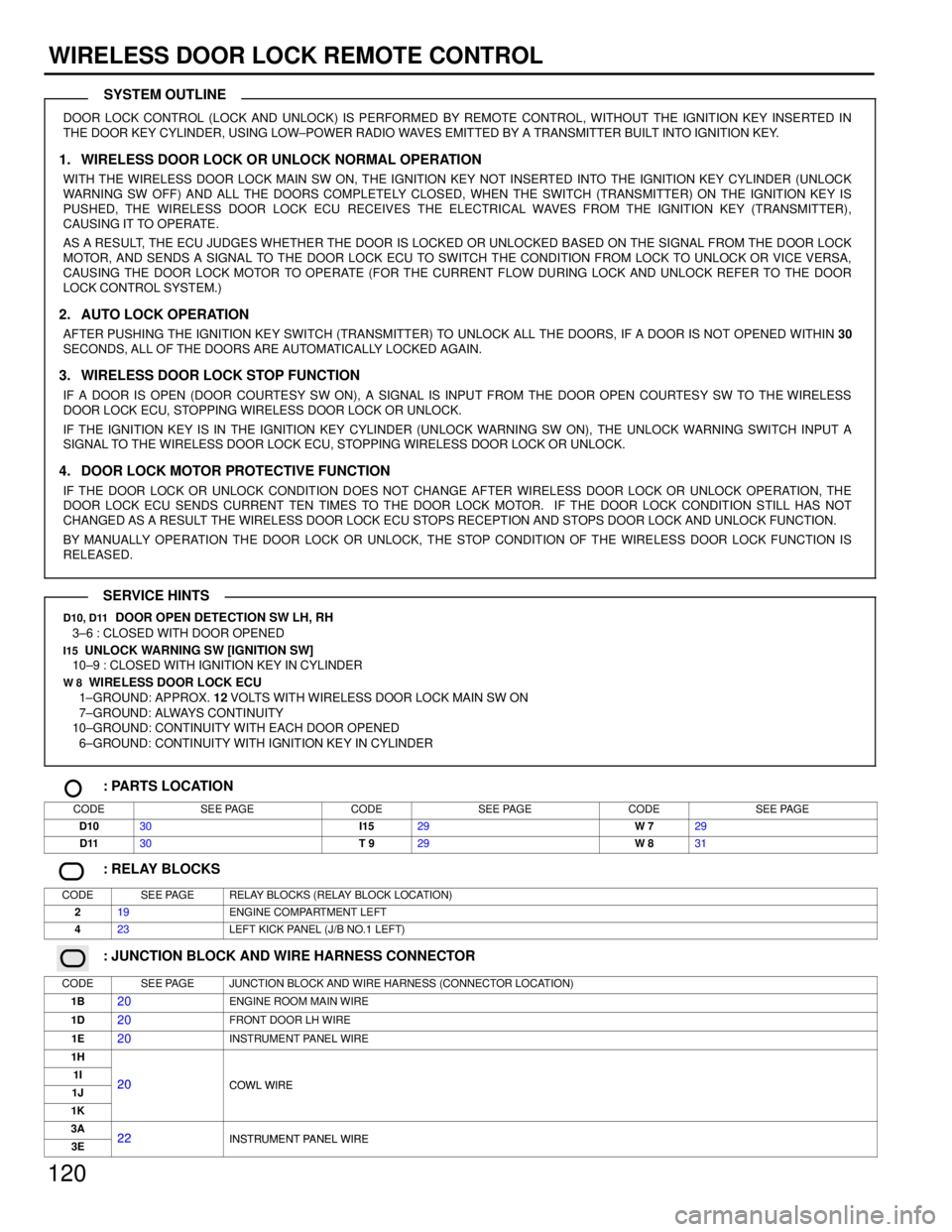

WIRELESS DOOR LOCK REMOTE CONTROL

DOOR LOCK CONTROL (LOCK AND UNLOCK) IS PERFORMED BY REMOTE CONTROL, WI\

THOUT THE IGNITION KEY INSERTED IN

THE DOOR KEY CYLINDER, USING LOW±POWER RADIO WAVES EMITTED BY A TRANSMITTER BUILT INTO IGNITION KEY.

1. WIRELESS DOOR LOCK OR UNLOCK NORMAL OPERATION

WITH THE WIRELESS DOOR LOCK MAIN SW ON, THE IGNITION KEY NOT INSERTED INTO THE IGNITION KEY CYLINDER (UNLOCK

WARNING SW OFF) AND ALL THE DOORS COMPLETELY CLOSED, WHEN THE SWITCH (TRANSMITTER) ON THE IGNITION KEY IS

PUSHED, THE WIRELESS DOOR LOCK ECU RECEIVES THE ELECTRICAL WAVES FROM THE IGNITION KEY (TRANSMITTER),

CAUSING IT TO OPERATE.

AS A RESULT, THE ECU JUDGES WHETHER THE DOOR IS LOCKED OR UNLOCKED BASED ON THE SIGNAL FROM THE DOOR LOCK

MOTOR, AND SENDS A SIGNAL TO THE DOOR LOCK ECU TO SWITCH THE CONDITION FROM LOCK TO UNLOCK OR VICE VERSA,

CAUSING THE DOOR LOCK MOTOR TO OPERATE (FOR THE CURRENT FLOW DURING LOCK AND UNLOCK REFER TO THE DOOR

LOCK CONTROL SYSTEM.)

2. AUTO LOCK OPERATION

AFTER PUSHING THE IGNITION KEY SWITCH (TRANSMITTER) TO UNLOCK ALL THE DOORS, IF A DOOR IS NOT OPENED WITHIN 30

SECONDS, ALL OF THE DOORS ARE AUTOMATICALLY LOCKED AGAIN.

3. WIRELESS DOOR LOCK STOP FUNCTION

IF A DOOR IS OPEN (DOOR COURTESY SW ON), A SIGNAL IS INPUT FROM THE DOOR OPEN COURTESY SW TO THE WIRELESS

DOOR LOCK ECU, STOPPING WIRELESS DOOR LOCK OR UNLOCK.

IF THE IGNITION KEY IS IN THE IGNITION KEY CYLINDER (UNLOCK WARNING SW ON), THE UNLOCK WARNING SWITCH INPUT A

SIGNAL TO THE WIRELESS DOOR LOCK ECU, STOPPING WIRELESS DOOR LOCK OR UNLOCK.

4. DOOR LOCK MOTOR PROTECTIVE FUNCTION

IF THE DOOR LOCK OR UNLOCK CONDITION DOES NOT CHANGE AFTER WIRELESS DOOR L\

OCK OR UNLOCK OPERATION, THE

DOOR LOCK ECU SENDS CURRENT TEN TIMES TO THE DOOR LOCK MOTOR. IF THE DOOR LOCK CONDITION STILL HAS NOT

CHANGED AS A RESULT THE WIRELESS DOOR LOCK ECU STOPS RECEPTION AND STOPS DOOR LOCK AND UNLOCK FUNCTION.

BY MANUALLY OPERATION THE DOOR LOCK OR UNLOCK, THE STOP CONDITION OF THE WIRELESS DOOR LOCK FUNCTION IS

RELEASED.

D10, D11 DOOR OPEN DETECTION SW LH, RH

3±6 : CLOSED WITH DOOR OPENED

I15 UNLOCK WARNING SW [IGNITION SW]

10±9 : CLOSED WITH IGNITION KEY IN CYLINDER

W 8 WIRELESS DOOR LOCK ECU

1±GROUND: APPROX. 12 VOLTS WITH WIRELESS DOOR LOCK MAIN SW ON

7±GROUND: ALWAYS CONTINUITY

10±GROUND: CONTINUITY WITH EACH DOOR OPENED

6±GROUND: CONTINUITY WITH IGNITION KEY IN CYLINDER

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

D1030I1529W 729

D1130T 929W 831

: RELAY BLOCKS

CODESEE PAGERELAY BLOCKS (RELAY BLOCK LOCATION)

219ENGINE COMPARTMENT LEFT

423LEFT KICK PANEL (J/B NO.1 LEFT)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1B20ENGINE ROOM MAIN WIRE

1D20FRONT DOOR LH WIRE

1E20INSTRUMENT PANEL WIRE

1H

1I20COWL WIRE1J20COWL WIRE

1K

3A22INSTRUMENT PANEL WIRE3E22INSTRUMENT PANEL WIRE

SYSTEM OUTLINE

SERVICE HINTS

WhereEverybodyKnowsYourName

Page 3823 of 4087

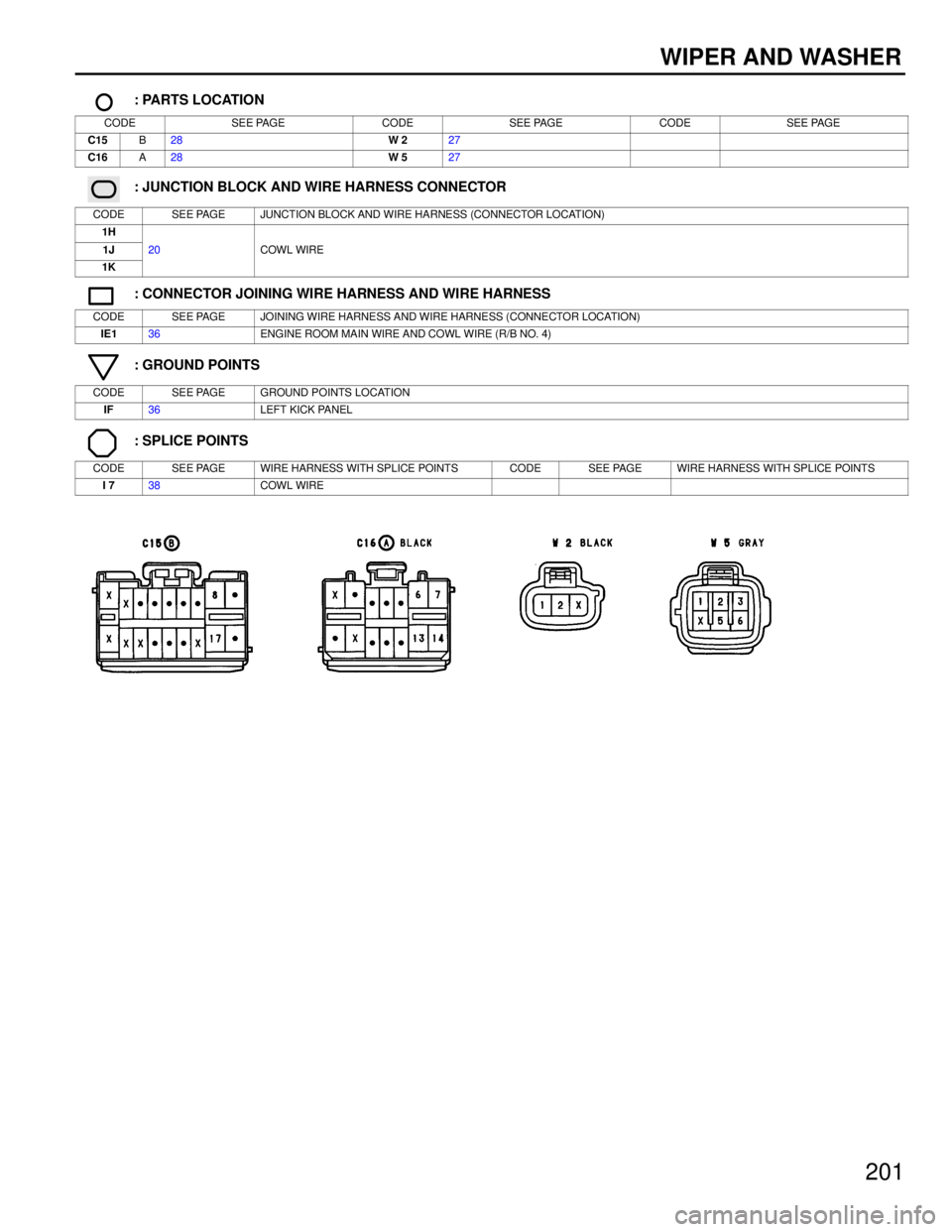

201

WIPER AND WASHER

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

C15B28W 227

C16A28W 527

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1H

1J20COWL WIRE

1K

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

IE136ENGINE ROOM MAIN WIRE AND COWL WIRE (R/B NO. 4)

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

IF36LEFT KICK PANEL

: SPLICE POINTS

CODESEE PAGEWIRE HARNESS WITH SPLICE POINTSCODESEE PAGEWIRE HARNESS WITH SPLICE POINTS

I 738COWL WIRE

WhereEverybodyKnowsYourName

Page 3826 of 4087

15

ABBREVIATIONS

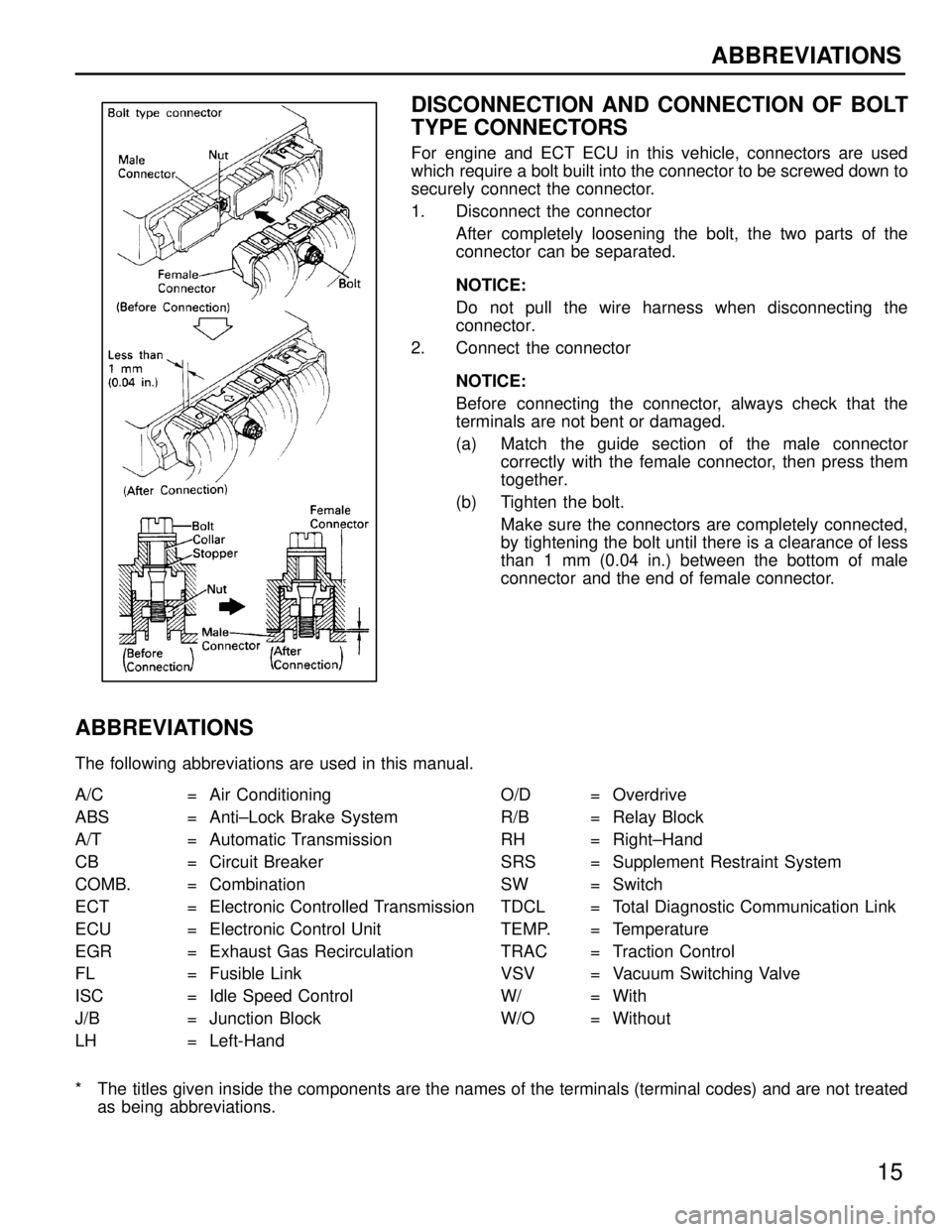

DISCONNECTION AND CONNECTION OF BOLT

TYPE CONNECTORS

For engine and ECT ECU in this vehicle, connectors are used

which require a bolt built into the connector to be screwed down to

securely connect the connector.

1. Disconnect the connectorAfter completely loosening the bolt, the two parts of the

connector can be separated.

NOTICE:

Do not pull the wire harness when disconnecting the

connector.

2. Connect the connector

NOTICE:

Before connecting the connector, always check that the

terminals are not bent or damaged.

(a) Match the guide section of the male connectorcorrectly with the female connector, then press them

together.

(b) Tighten the bolt. Make sure the connectors are completely connected,

by tightening the bolt until there is a clearance of less

than 1 mm (0.04 in.) between the bottom of male

connector and the end of female connector.

ABBREVIATIONS

The following abbreviations are used in this manual.

A/C = Air Conditioning O/D = Overdrive

ABS = Anti±Lock Brake System R/B = Relay Block

A/T = Automatic Transmission RH = Right±Hand

CB = Circuit Breaker SRS = Supplement Restraint System

COMB. = Combination SW = Switch

ECT = Electronic Controlled Transmission TDCL = Total Diagnostic Communication Link

ECU = Electronic Control Unit TEMP. = Temperature

EGR = Exhaust Gas Recirculation TRAC = Traction Control

FL = Fusible Link VSV = Vacuum Switching Valve

ISC = Idle Speed Control W/ = With

J/B = Junction Block W/O = Without

LH = Left-Hand

* The titles given inside the components are the names of the terminals (ter\

minal codes) and are not treatedas being abbreviations.

WhereEverybodyKnowsYourName