LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991,

Model line: SC400,

Model: LEXUS SC400 1991

Pages: 4087, PDF Size: 75.75 MB

LEXUS SC400 1991 Service Repair Manual

SC400 1991

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57051/w960_57051-0.png

LEXUS SC400 1991 Service Repair Manual

Trending: adding oil, headrest, engine oil, oil type, brakes, radio, fuel type

Page 951 of 4087

OKNG

NGOK

6Check for open and short in harness and connector between terminal VTA1 of ECM and main

throttle position sensor (See page IN±33

).

Repair or replace harness or connector.

Adjust or replace main throttle position sensor

(See page EG±333 or EG±205 ).

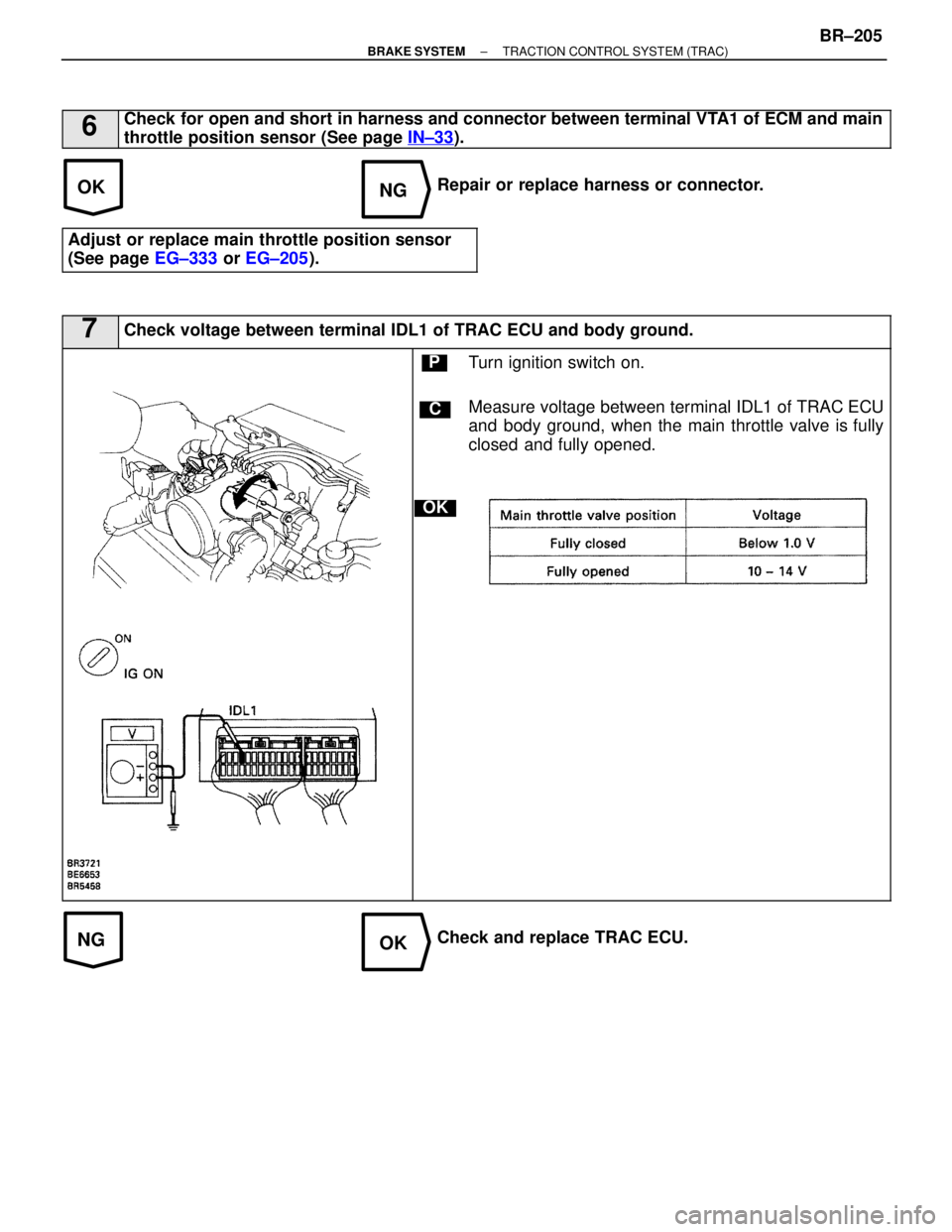

7Check voltage between terminal IDL1 of TRAC ECU and body ground.

C

OK

PTurn ignition switch on.

Measure voltage between terminal IDL1 of TRAC ECU

and body ground, when the main throttle valve is fully

closed and fully opened.

Check and replace TRAC ECU.

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)BR±205

WhereEverybodyKnowsYourName

Page 952 of 4087

NGOK

OKNG

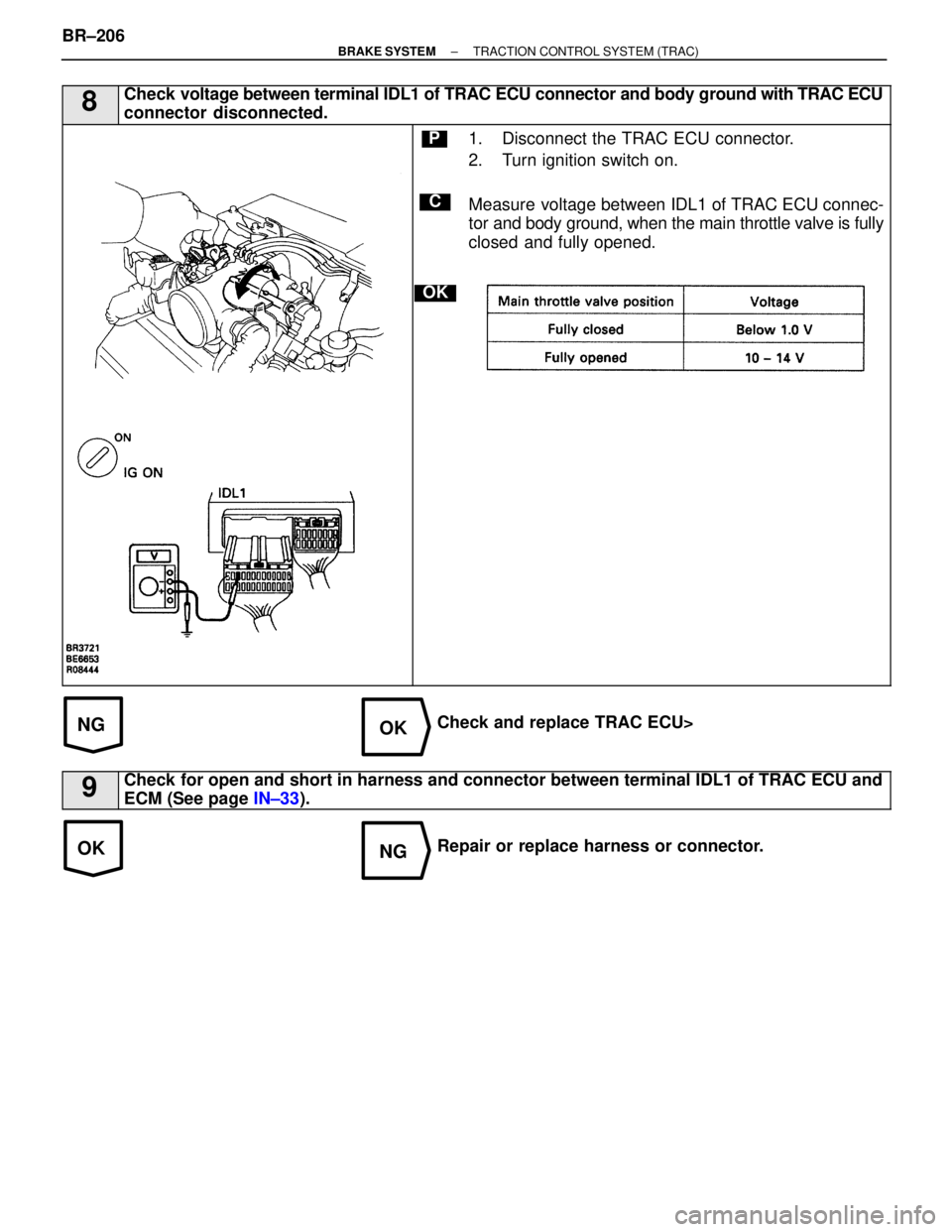

8Check voltage between terminal IDL1 of TRAC ECU connector and body ground with TRAC ECU

connector disconnected.

C

OK

P1. Disconnect the TRAC ECU connector.

2. Turn ignition switch on.

Measure voltage between IDL1 of TRAC ECU connec-

tor and body ground, when the main throttle valve is fully

closed and fully opened.

Check and replace TRAC ECU>

9Check for open and short in harness and connector between terminal IDL1 of TR\

AC ECU and

ECM (See page IN±33).

Repair or replace harness or connector.

BR±206

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)

WhereEverybodyKnowsYourName

Page 953 of 4087

OKNG

10Check main throttle position sensor (See page EG±609 or EG±389 ).

Adjust or replace main throttle position sensor (See

page EG±333 or EG±205).

Check and replace ECM.

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)BR±207

WhereEverybodyKnowsYourName

Page 954 of 4087

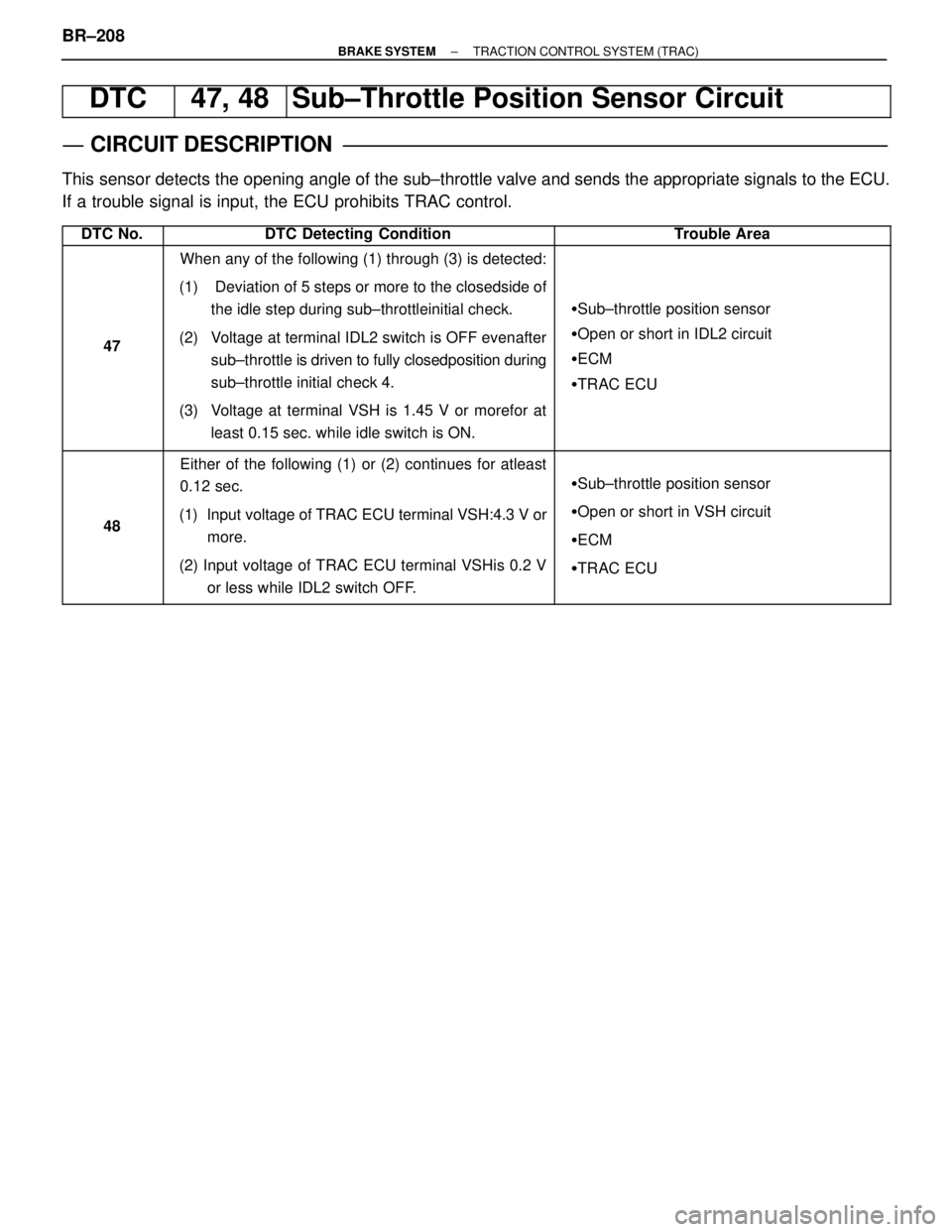

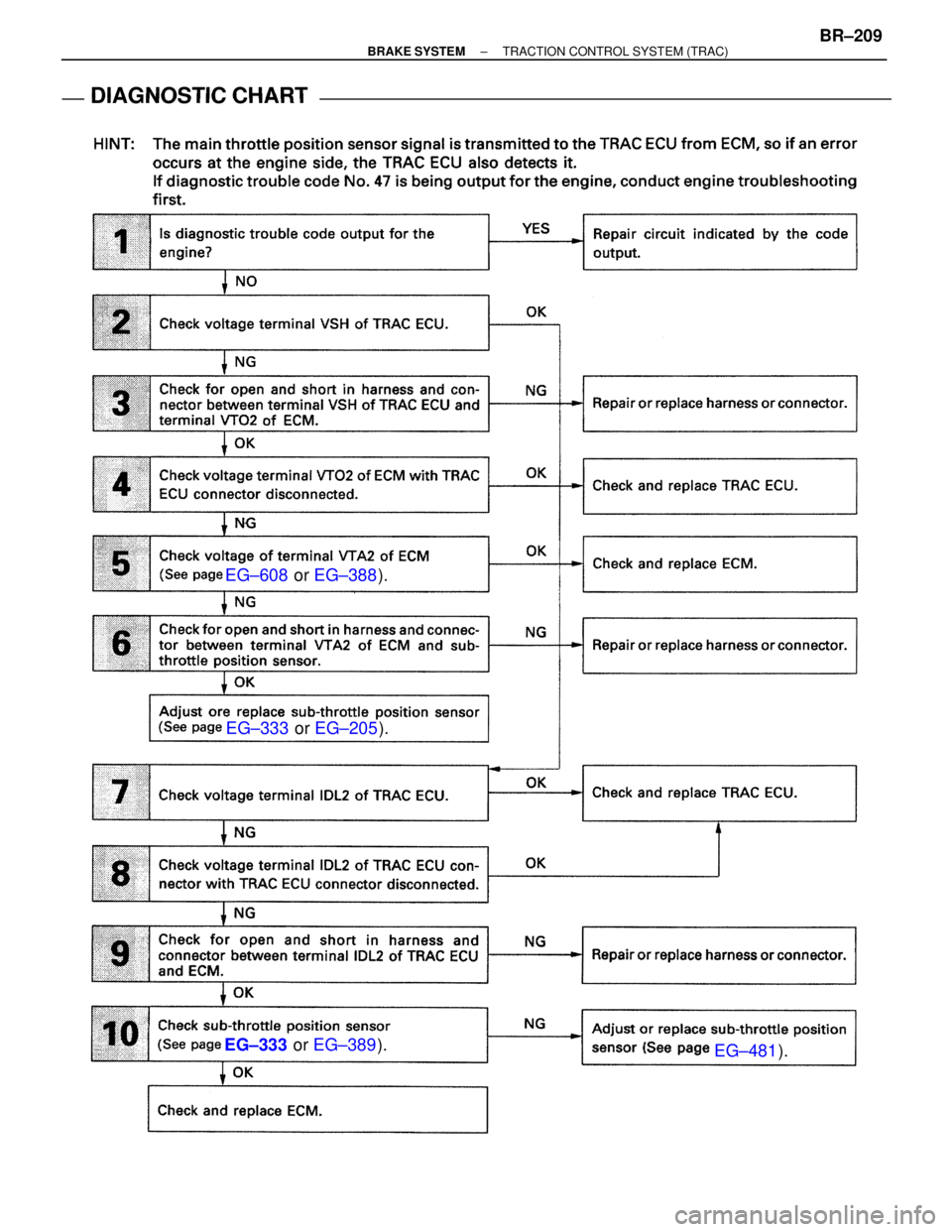

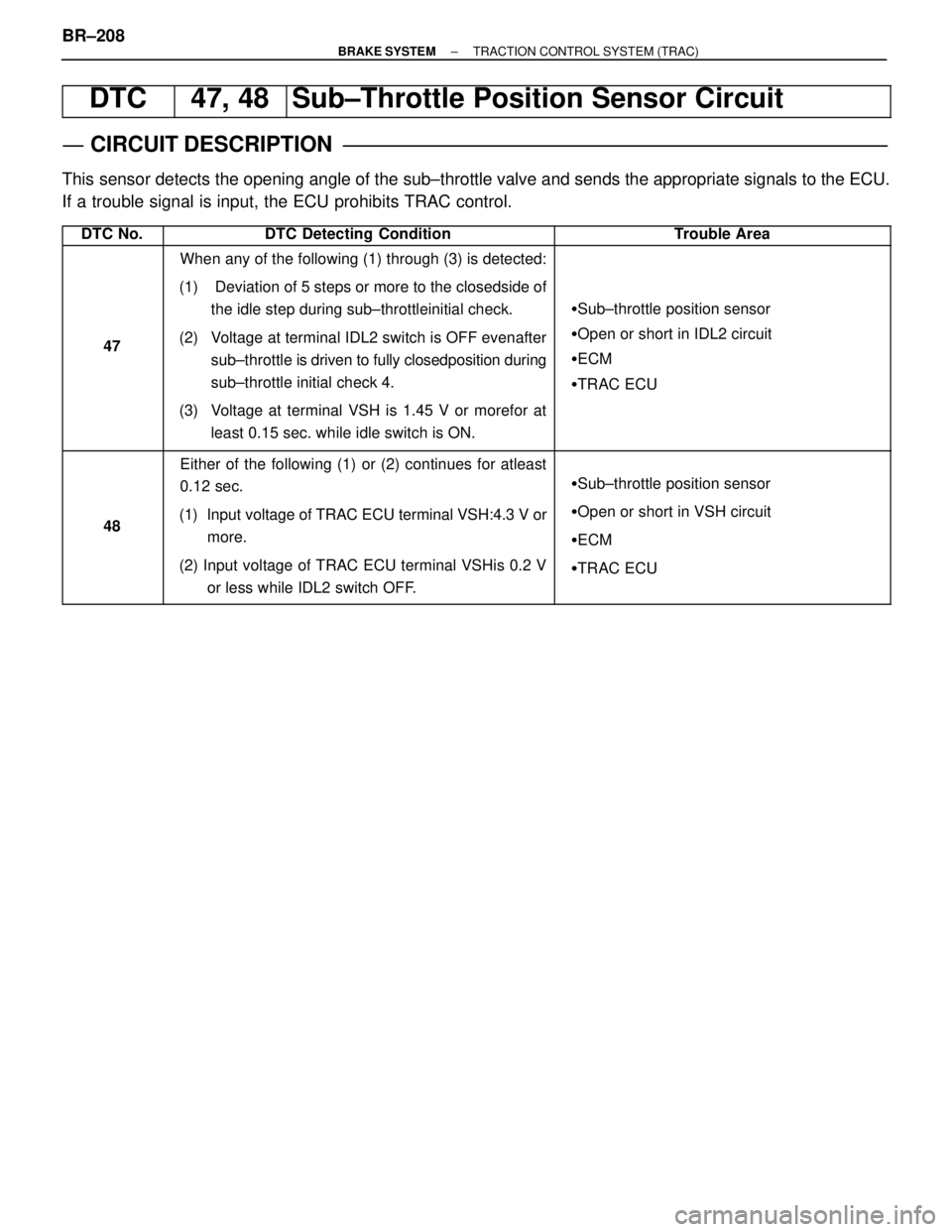

DTC47, 48Sub±Throttle Position Sensor Circuit

CIRCUIT DESCRIPTION

This sensor detects the opening angle of the sub±throttle valve and sends the appropriate signals to the ECU.

If a trouble signal is input, the ECU prohibits TRAC control.

DTC No.DTC Detecting ConditionTrouble Area

47

When any of the following (1) through (3) is detected:

(1) Deviation of 5 steps or more to the closedside of the idle step during sub±throttleinitial check.

(2) Voltage at terminal IDL2 switch is OFF evenafter sub±throttle is driven to fully closedposition during

sub±throttle initial check 4.

(3) Voltage at terminal VSH is 1.45 V or morefor at least 0.15 sec. while idle switch is ON.

Sub±throttle position sensor

Open or short in IDL2 circuit

ECM

TRAC ECU

48

Either of the following (1) or (2) continues for atleast

0.12 sec.

(1) Input voltage of TRAC ECU terminal VSH:4.3 V or more.

(2) Input voltage of TRAC ECU terminal VSHis 0.2 V or less while IDL2 switch OFF.

Sub±throttle position sensor

Open or short in VSH circuit

ECM

TRAC ECU

BR±208±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)

WhereEverybodyKnowsYourName

Page 955 of 4087

EG±608 or EG±388 ).

EG±333 or EG±205 ).

EG±333 or EG±389 ).

EG±481).

DIAGNOSTIC CHARTDIAGNOSTIC CHART

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)BR±209

WhereEverybodyKnowsYourName

Page 956 of 4087

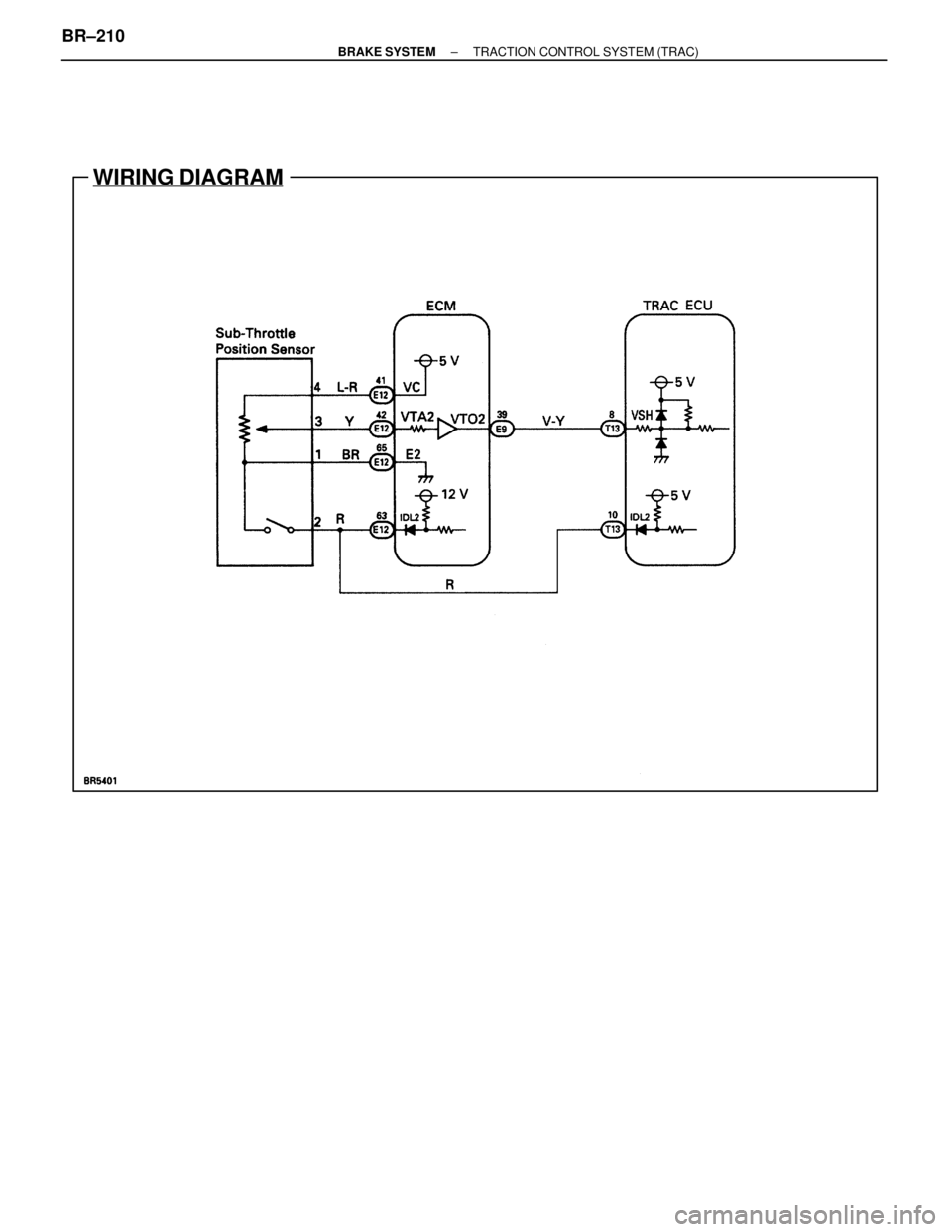

WIRING DIAGRAM

BR±210±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)

WhereEverybodyKnowsYourName

Page 957 of 4087

NOYES

NGOK

OKNG

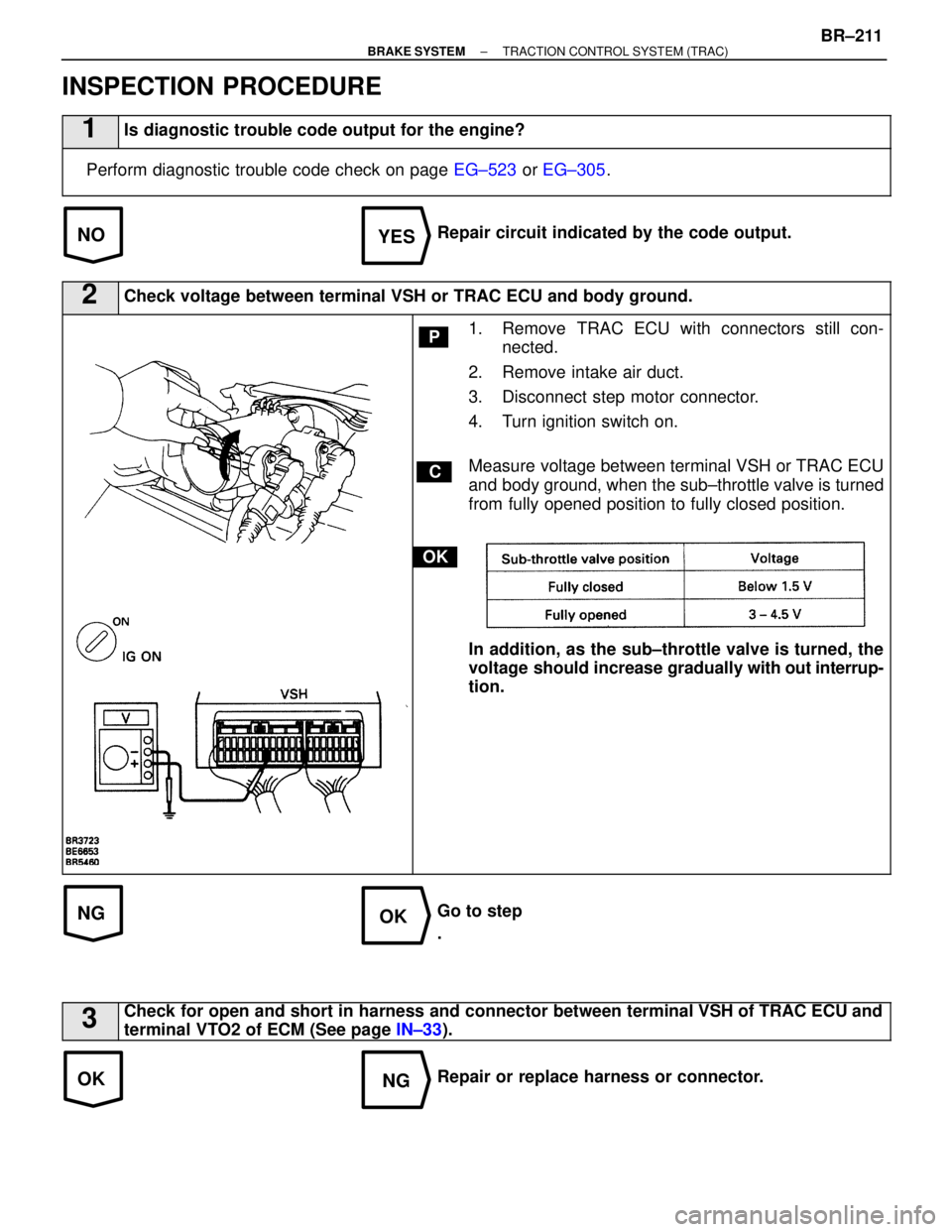

INSPECTION PROCEDURE

1Is diagnostic trouble code output for the engine?

Perform diagnostic trouble code check on page EG±523 or EG±305 .

Repair circuit indicated by the code output.

2Check voltage between terminal VSH or TRAC ECU and body ground.

C

OK

P1. Remove TRAC ECU with connectors still con-

nected.

2. Remove intake air duct.

3. Disconnect step motor connector.

4. Turn ignition switch on.

Measure voltage between terminal VSH or TRAC ECU

and body ground, when the sub±throttle valve is turned

from fully opened position to fully closed position.

In addition, as the sub±throttle valve is turned, the

voltage should increase gradually w ith out interrup-

tion.

Go to step

.

3Check for open and short in harness and connector between terminal VSH of TRAC ECU and

terminal VTO2 of ECM (See page IN±33).

Repair or replace harness or connector.

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)BR±211

WhereEverybodyKnowsYourName

Page 958 of 4087

NGOK

NGOK

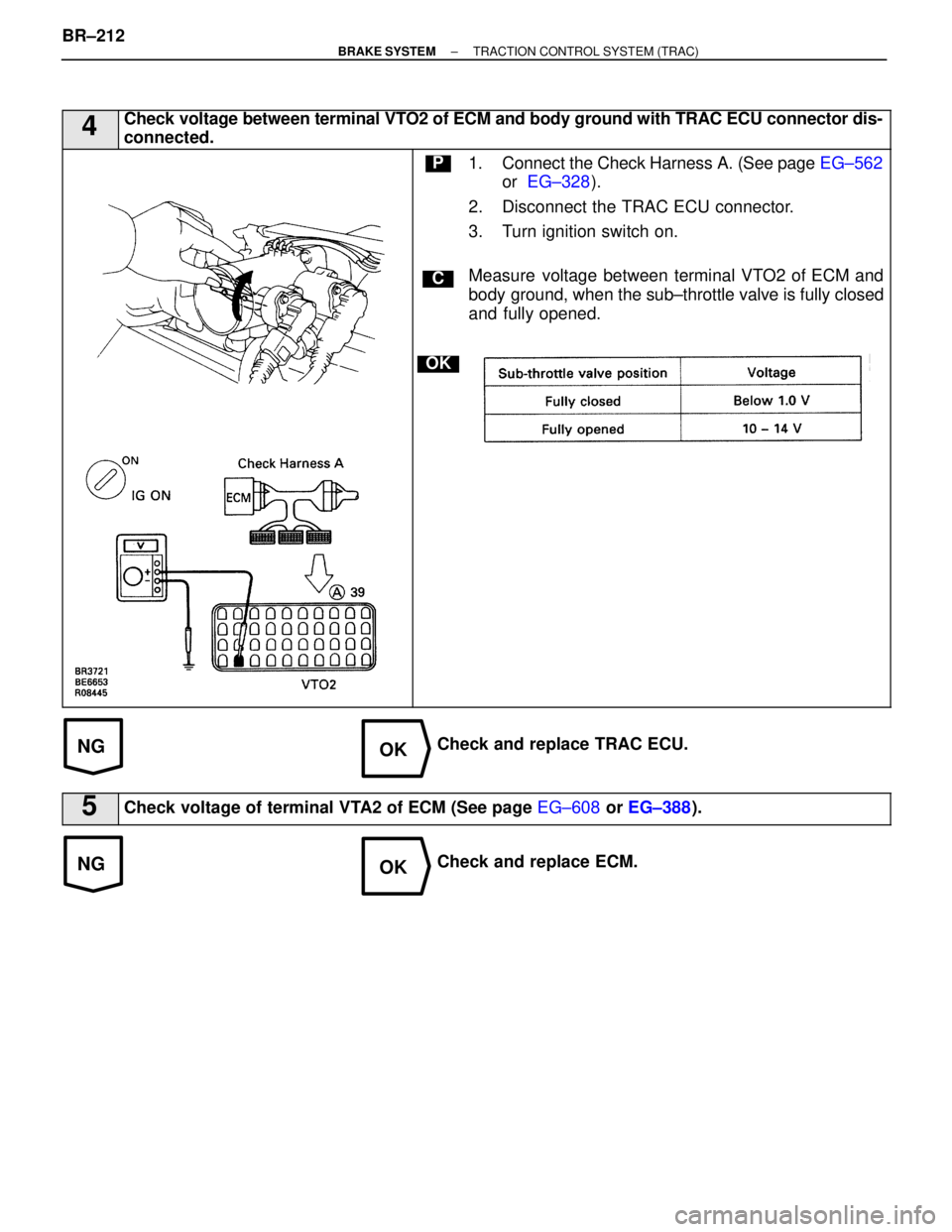

4Check voltage between terminal VTO2 of ECM and body ground with TRAC ECU connector dis-

connected.

C

OK

P1. Connect the Check Harness A. (See page EG±562

or EG±328 ).

2. Disconnect the TRAC ECU connector.

3. Turn ignition switch on.

Measure voltage between terminal VTO2 of ECM and

body ground, when the sub±throttle valve is fully closed

and fully opened.

Check and replace TRAC ECU.

5Check voltage of terminal VTA2 of ECM (See page EG±608 or EG±388 ).

Check and replace ECM.

BR±212

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)

WhereEverybodyKnowsYourName

Page 959 of 4087

OKNG

NGOK

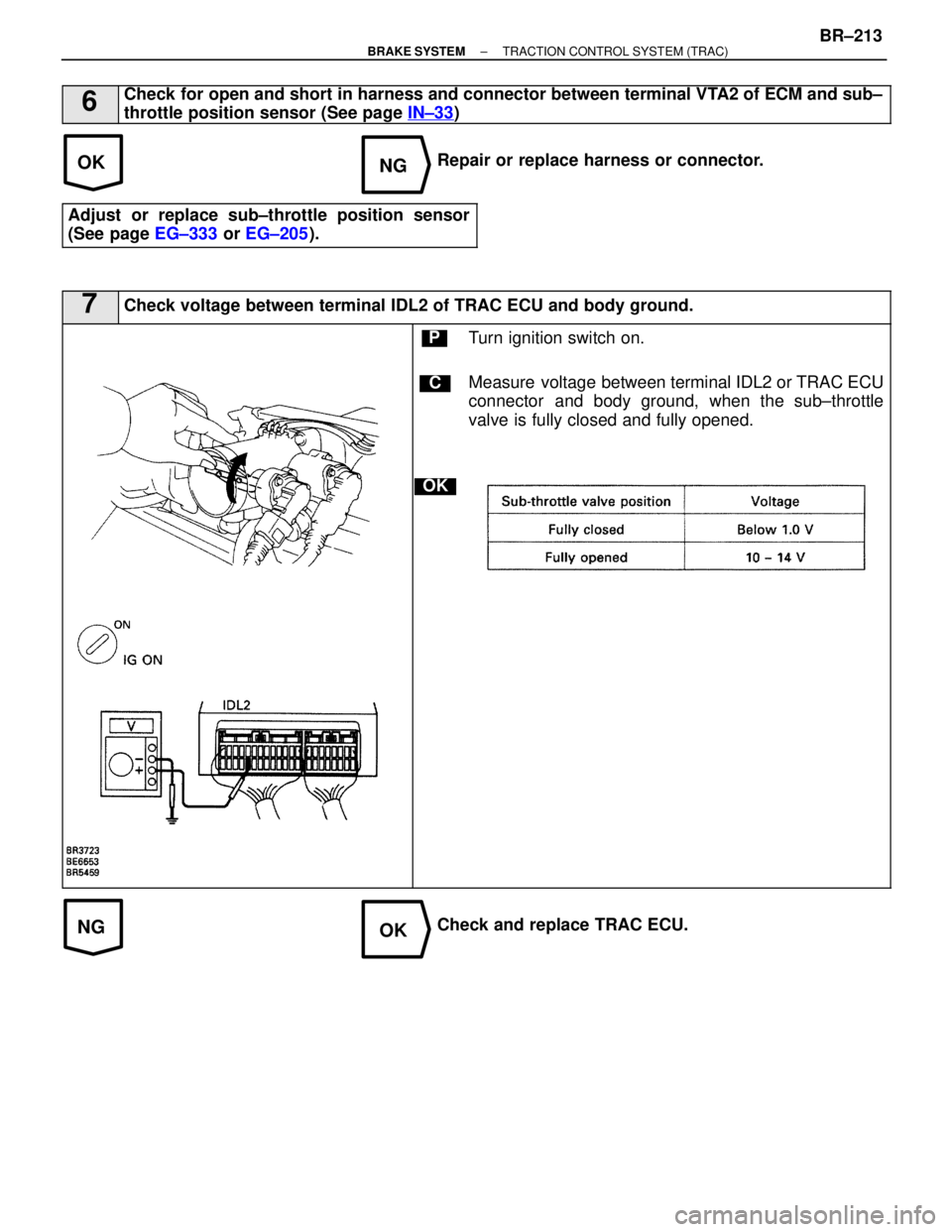

6Check for open and short in harness and connector between terminal VTA2 of ECM and sub±

throttle position sensor (See page IN±33

)

Repair or replace harness or connector.

Adjust or replace sub±throttle position sensor

(See page EG±333 or EG±205 ).

7Check voltage between terminal IDL2 of TRAC ECU and body ground.

C

OK

PTurn ignition switch on.

Measure voltage between terminal IDL2 or TRAC ECU

connector and body ground, when the sub±throttle

valve is fully closed and fully opened.

Check and replace TRAC ECU.

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)BR±213

WhereEverybodyKnowsYourName

Page 960 of 4087

NGOK

OKNG

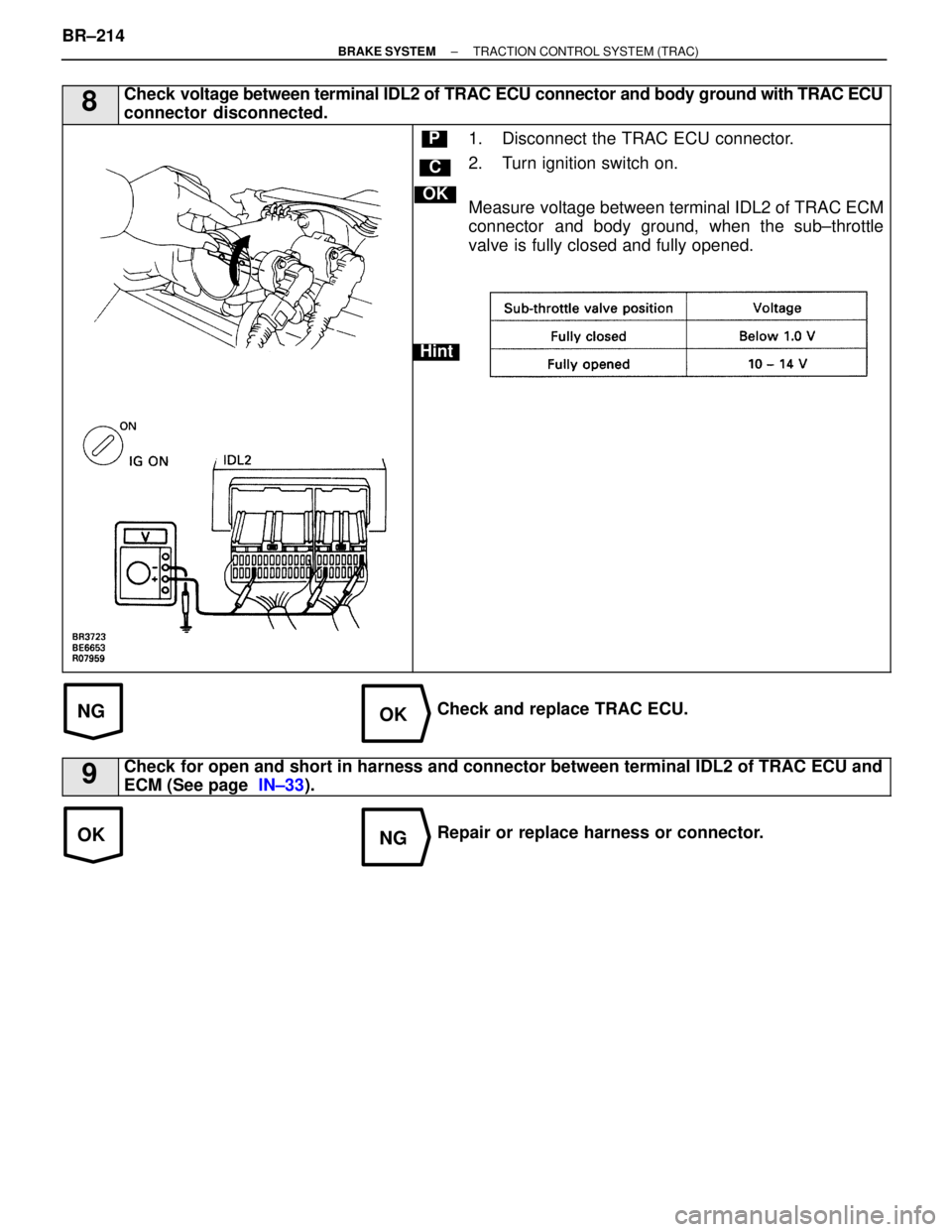

8Check voltage between terminal IDL2 of TRAC ECU connector and body ground with TRAC ECU

connector disconnected.

C

OK

Hint

P1. Disconnect the TRAC ECU connector.

2. Turn ignition switch on.

Measure voltage between terminal IDL2 of TRAC ECM

connector and body ground, when the sub±throttle

valve is fully closed and fully opened.

Check and replace TRAC ECU.

9Check for open and short in harness and connector between terminal IDL2 of TR\

AC ECU and

ECM (See page IN±33).

Repair or replace harness or connector.

BR±214

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)

WhereEverybodyKnowsYourName

Trending: cooling, torque, airbag, turn signal bulb, check transmission fluid, horn, warning light