LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991,

Model line: SC400,

Model: LEXUS SC400 1991

Pages: 4087, PDF Size: 75.75 MB

LEXUS SC400 1991 Service Repair Manual

SC400 1991

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57051/w960_57051-0.png

LEXUS SC400 1991 Service Repair Manual

Trending: radio, brake fluid, ignition buzzer, weight, exhaust, warning, instrument panel

Page 941 of 4087

±MEMO±

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)BR±195

WhereEverybodyKnowsYourName

Page 942 of 4087

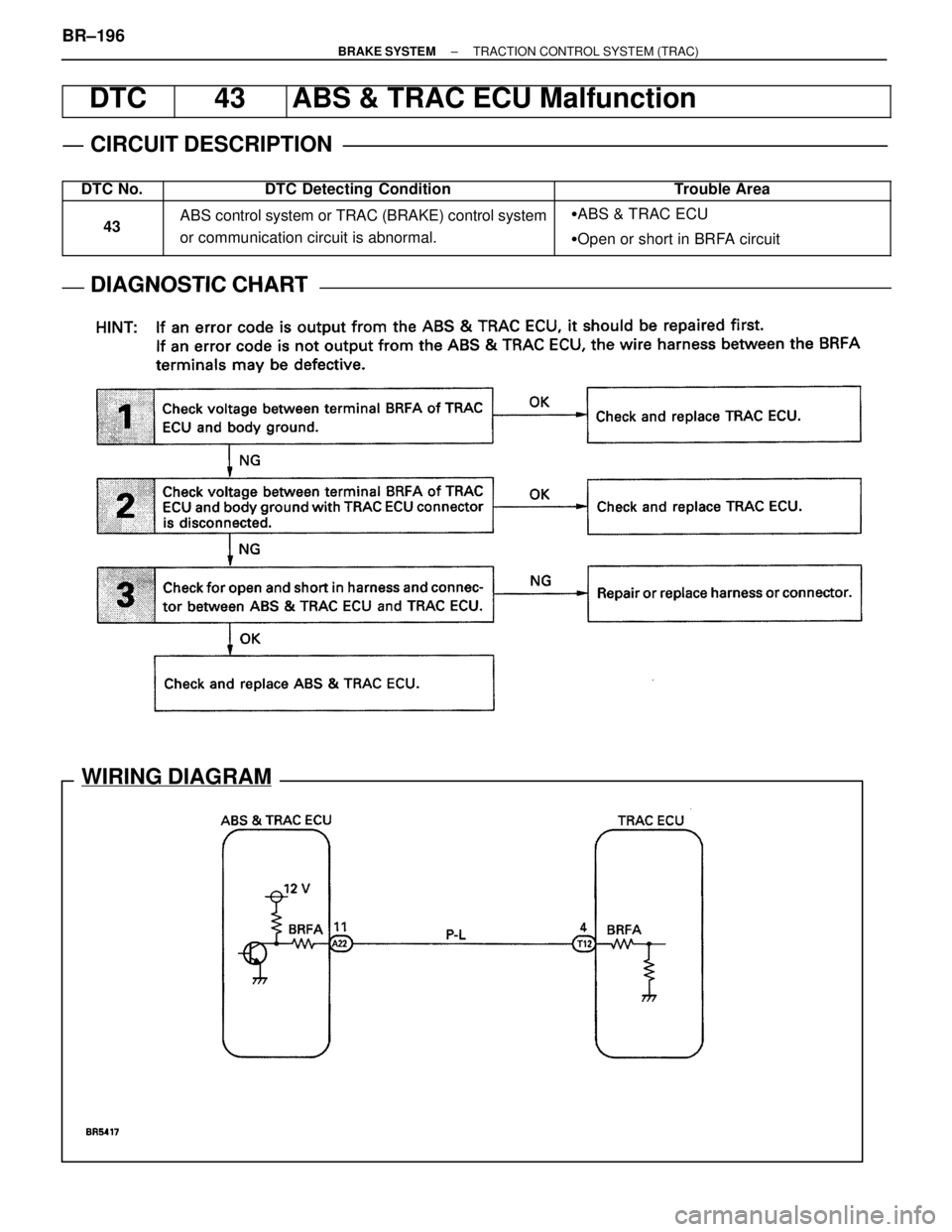

WIRING DIAGRAM

DTC43ABS & TRAC ECU Malfunction

CIRCUIT DESCRIPTION

DTC No.DTC Detecting ConditionTrouble Area

43ABS control system or TRAC (BRAKE) control system

or communication circuit is abnormal.

ABS & TRAC ECU

Open or short in BRFA circuit

DIAGNOSTIC CHARTDIAGNOSTIC CHART

BR±196±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)

WhereEverybodyKnowsYourName

Page 943 of 4087

NGOK

NGOK

OKNG

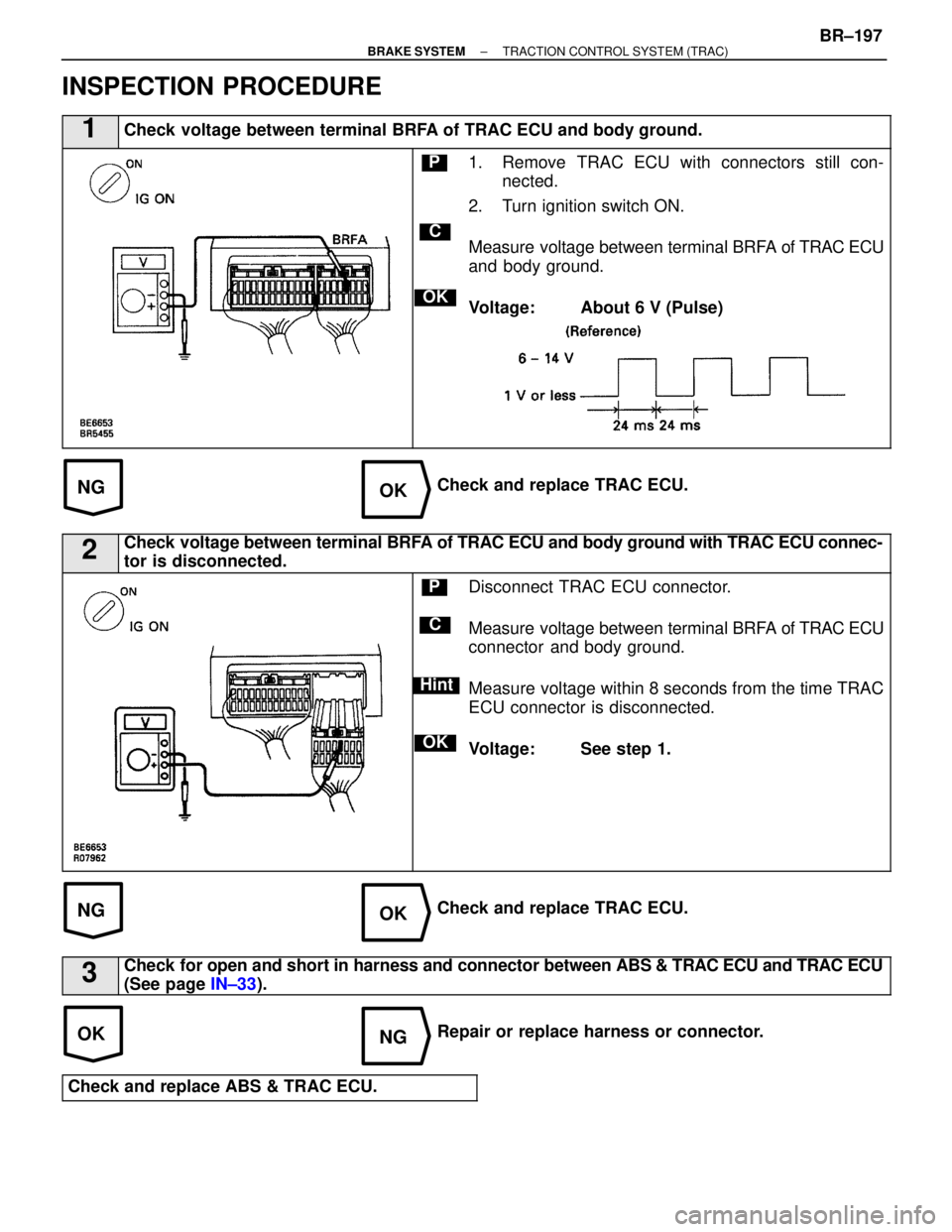

INSPECTION PROCEDURE

1Check voltage between terminal BRFA of TRAC ECU and body ground.

C

OK

P1. Remove TRAC ECU with connectors still con-nected.

2. Turn ignition switch ON.

Measure voltage between terminal BRFA of TRAC ECU

and body ground.

Voltage: About 6 V (Pulse)

Check and replace TRAC ECU.

2Check voltage between terminal BRFA of TRAC ECU and body ground with TRAC ECU connec-

tor is disconnected.

C

OK

Hint

PDisconnect TRAC ECU connector.

Measure voltage between terminal BRFA of TRAC ECU

connector and body ground.

Measure voltage within 8 seconds from the time TRAC

ECU connector is disconnected.

Voltage: See step 1.

Check and replace TRAC ECU.

3Check for open and short in harness and connector between ABS & TRAC ECU and TRAC ECU

(See page IN±33).

Repair or replace harness or connector.

Check and replace ABS & TRAC ECU.

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)BR±197

WhereEverybodyKnowsYourName

Page 944 of 4087

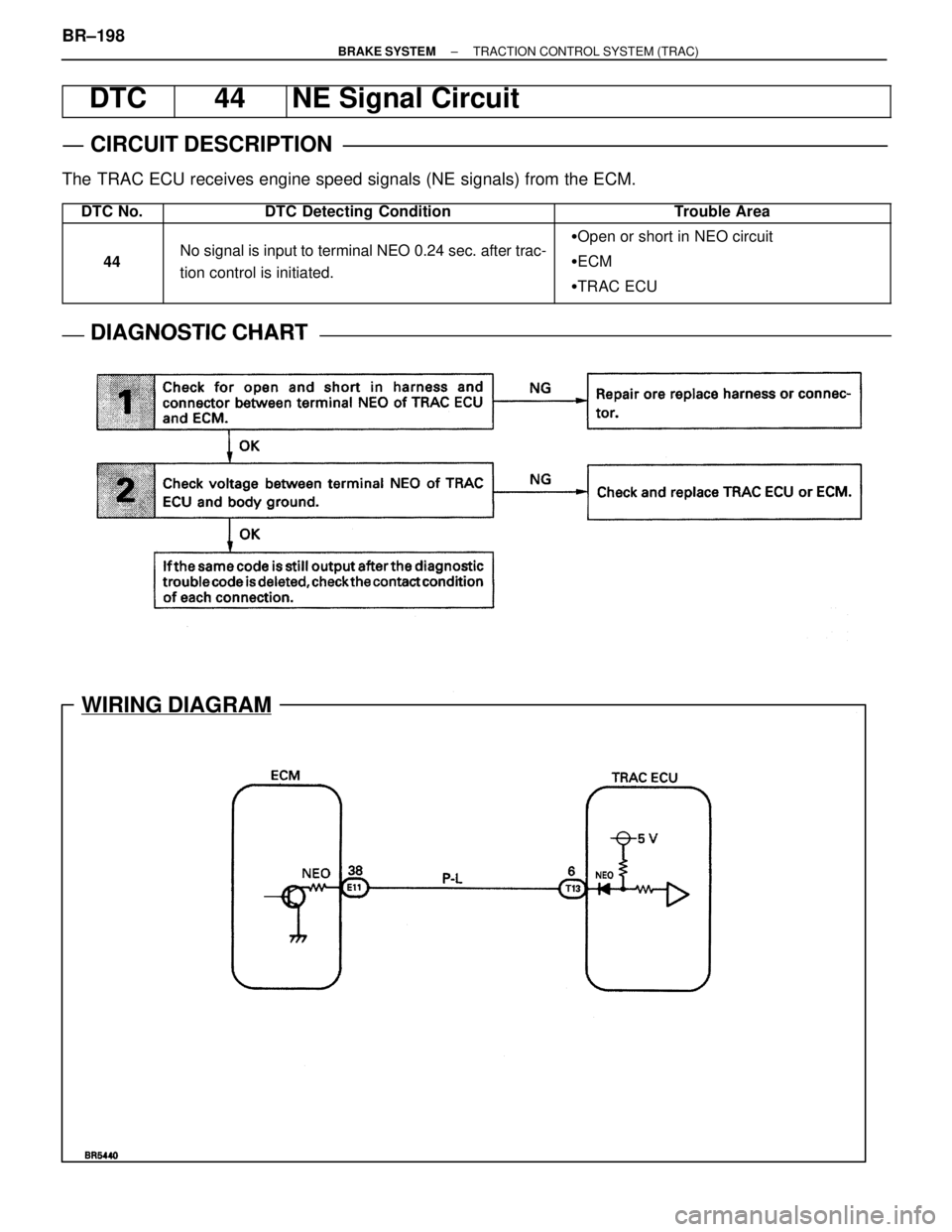

WIRING DIAGRAM

DTC44NE Signal Circuit

CIRCUIT DESCRIPTION

The TRAC ECU receives engine speed signals (NE signals) from the ECM.

DTC No.DTC Detecting ConditionTrouble Area

44No signal is input to terminal NEO 0.24 sec. after trac-

tion control is initiated.

Open or short in NEO circuit

ECM

TRAC ECU

DIAGNOSTIC CHARTDIAGNOSTIC CHART

BR±198±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)

WhereEverybodyKnowsYourName

Page 945 of 4087

OKNG

OKNG

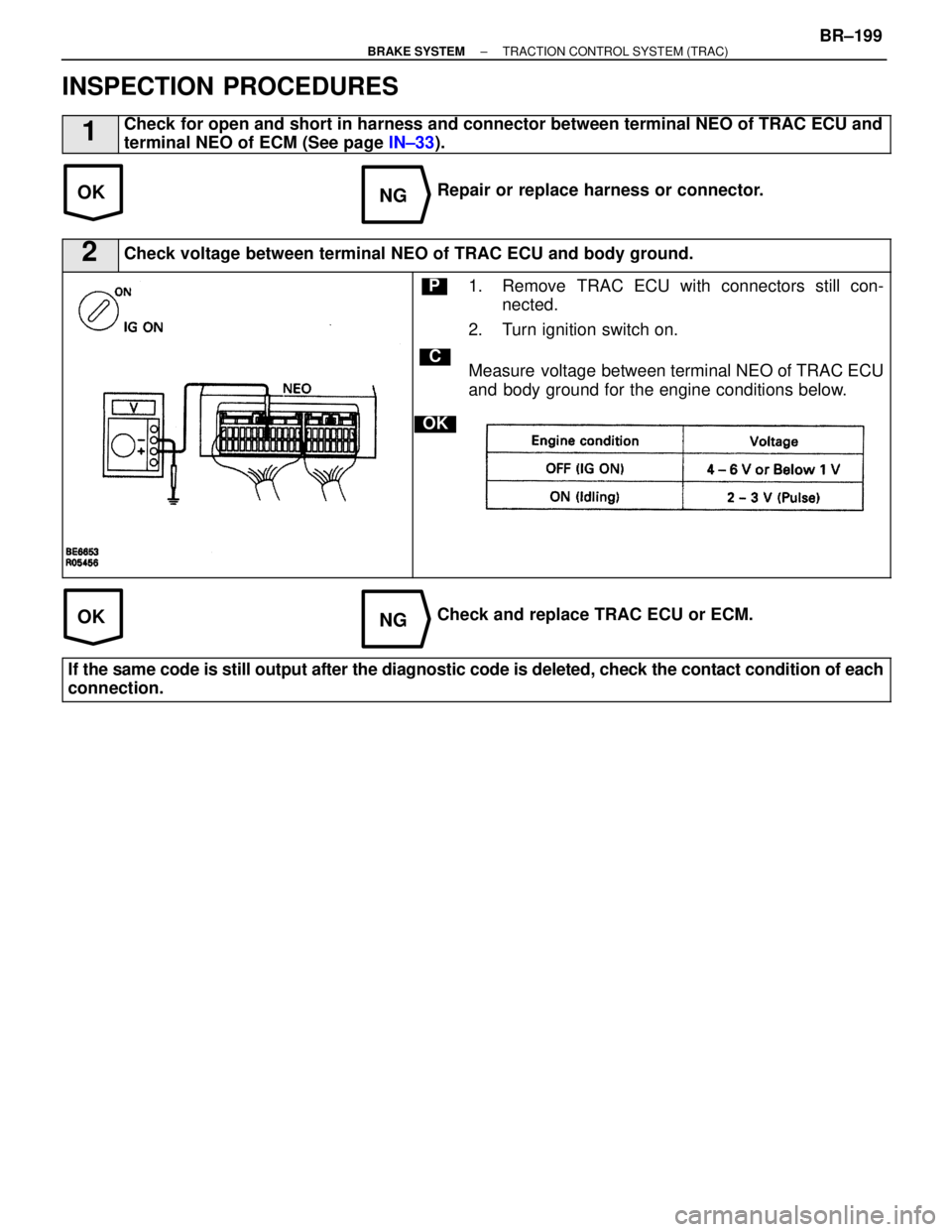

INSPECTION PROCEDURES

1Check for open and short in harness and connector between terminal NEO of TRA\

C ECU and

terminal NEO of ECM (See page IN±33).

Repair or replace harness or connector.

2Check voltage between terminal NEO of TRAC ECU and body ground.

C

OK

P1. Remove TRAC ECU with connectors still con-

nected.

2. Turn ignition switch on.

Measure voltage between terminal NEO of TRAC ECU

and body ground for the engine conditions below.

Check and replace TRAC ECU or ECM.

If the same code is still output after the diagnostic code is deleted, che\

ck the contact condition of each

connection.

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)BR±199

WhereEverybodyKnowsYourName

Page 946 of 4087

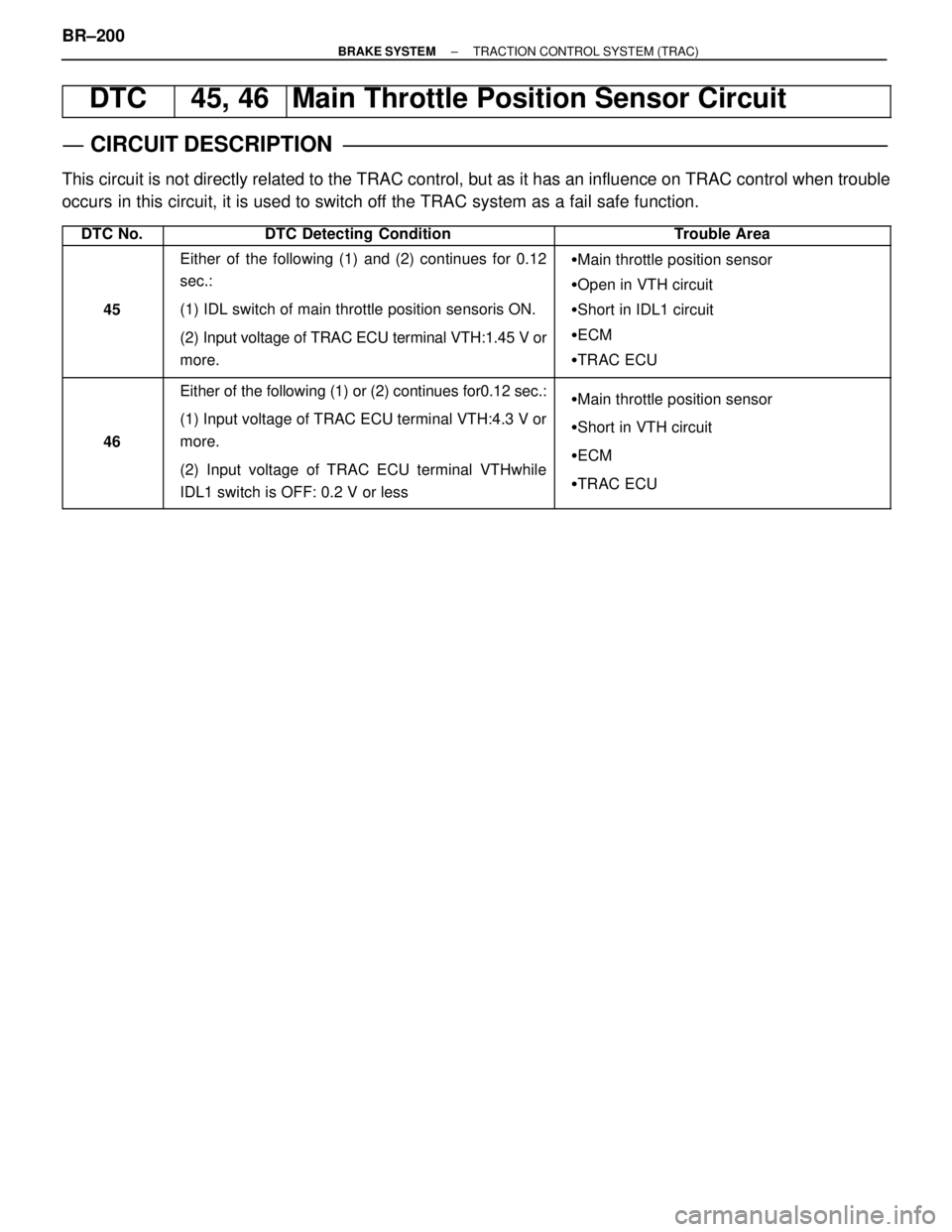

DTC45, 46Main Throttle Position Sensor Circuit

CIRCUIT DESCRIPTION

This circuit is not directly related to the TRAC control, but as it has an i\

nfluence on TRAC control when trouble

occurs in this circuit, it is used to switch off the TRAC system as a fail safe function.

DTC No.DTC Detecting ConditionTrouble Area

45

Either of the following (1) and (2) continues for 0.12

sec.:

(1) IDL switch of main throttle position sensoris ON.

(2) Input voltage of TRAC ECU terminal VTH:1.45 V or

more.

Main throttle position sensor

Open in VTH circuit

Short in IDL1 circuit

ECM

TRAC ECU

46

Either of the following (1) or (2) continues for0.12 sec.:

(1) Input voltage of TRAC ECU terminal VTH:4.3 V or

more.

(2) Input voltage of TRAC ECU terminal VTHwhile

IDL1 switch is OFF: 0.2 V or less

Main throttle position sensor

Short in VTH circuit

ECM

TRAC ECU

BR±200±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)

WhereEverybodyKnowsYourName

Page 947 of 4087

EG±608 or EG±388 ).

EG±333 or EG±205 ).

EG±609 or EG±389 ).

EG±481).

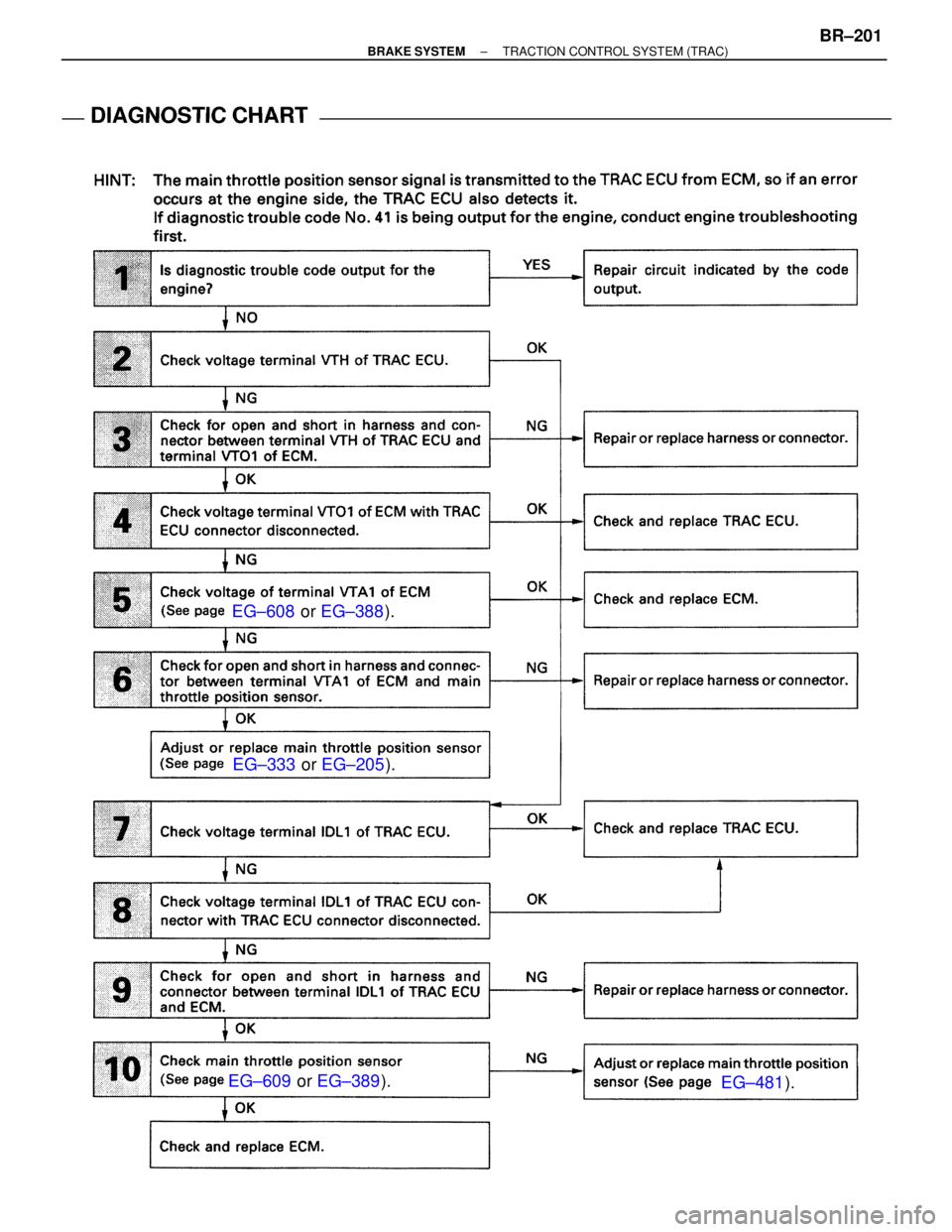

DIAGNOSTIC CHARTDIAGNOSTIC CHART

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)BR±201

WhereEverybodyKnowsYourName

Page 948 of 4087

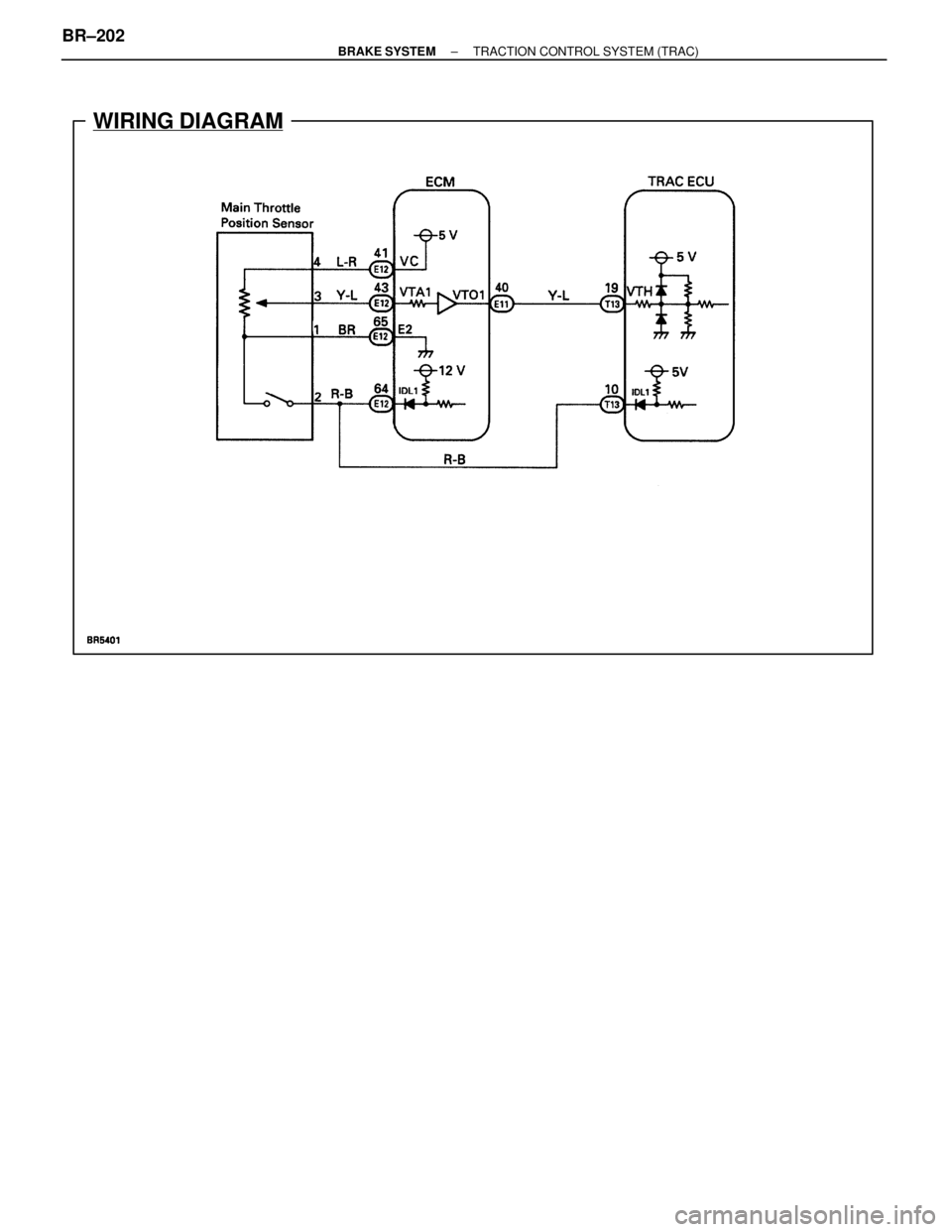

WIRING DIAGRAM

BR±202±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)

WhereEverybodyKnowsYourName

Page 949 of 4087

NOYES

NGOK

OKNG

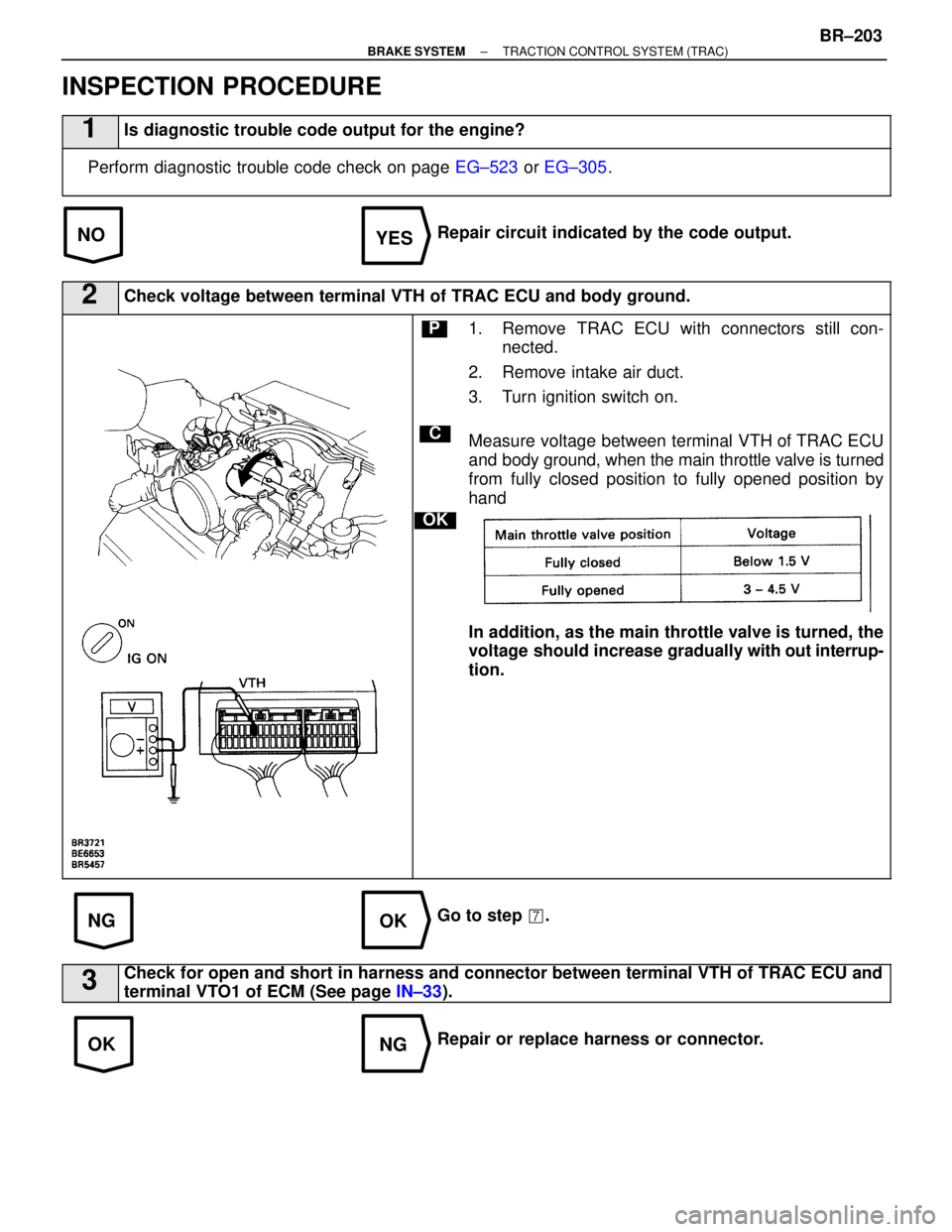

INSPECTION PROCEDURE

1Is diagnostic trouble code output for the engine?

Perform diagnostic trouble code check on page EG±523 or EG±305 .

Repair circuit indicated by the code output.

2Check voltage between terminal VTH of TRAC ECU and body ground.

C

OK

P1. Remove TRAC ECU with connectors still con-

nected.

2. Remove intake air duct.

3. Turn ignition switch on.

Measure voltage between terminal VTH of TRAC ECU

and body ground, when the main throttle valve is turned

from fully closed position to fully opened position by

hand

In addition, as the main throttle valve is turned, the

voltage should increase gradually w ith out interrup-

tion.

Go to step �.

3Check for open and short in harness and connector between terminal VTH o\

f TRAC ECU and

terminal VTO1 of ECM (See page IN±33).

Repair or replace harness or connector.

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)BR±203

WhereEverybodyKnowsYourName

Page 950 of 4087

NGOK

NGOK

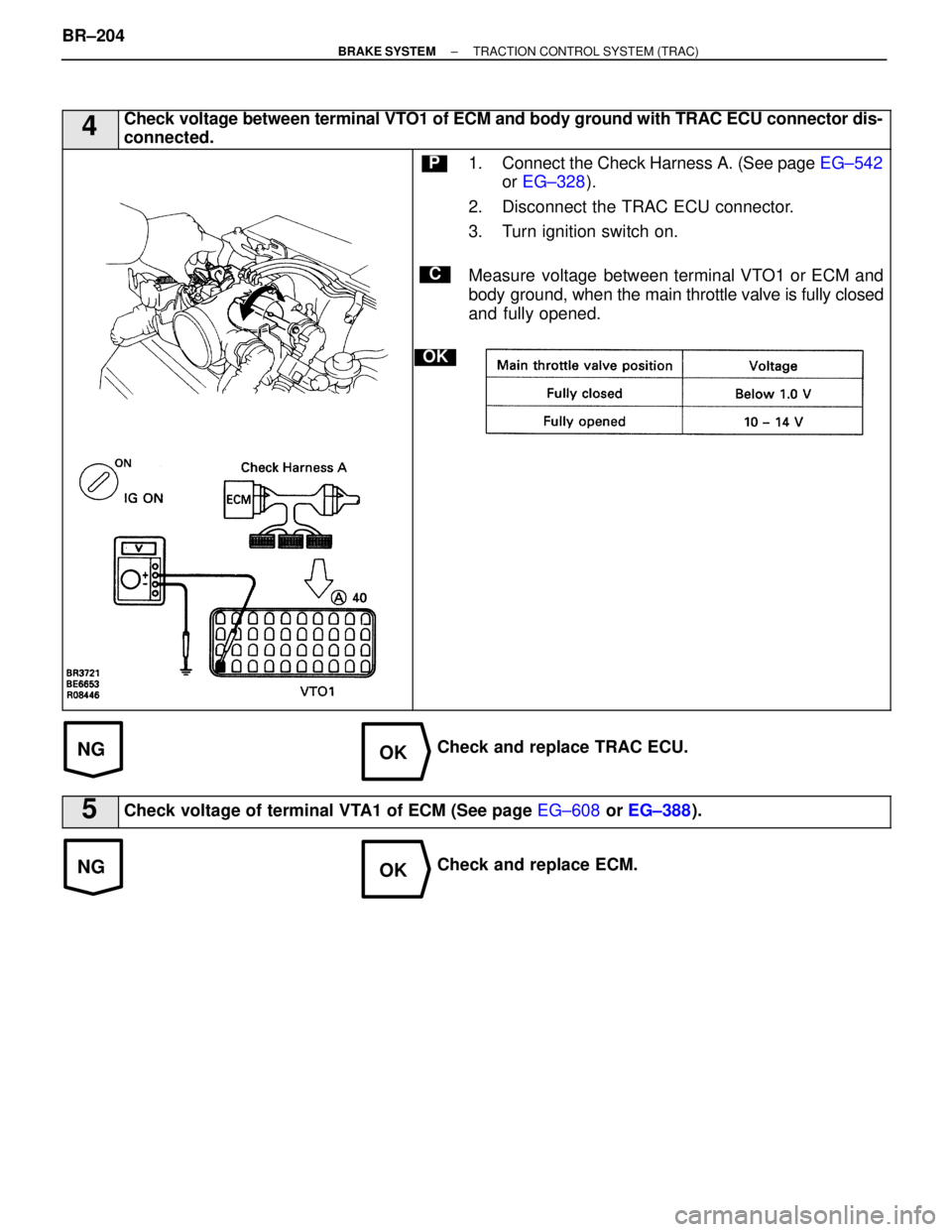

4Check voltage between terminal VTO1 of ECM and body ground with TRAC ECU connector dis-

connected.

C

OK

P1. Connect the Check Harness A. (See page EG±542

or EG±328 ).

2. Disconnect the TRAC ECU connector.

3. Turn ignition switch on.

Measure voltage between terminal VTO1 or ECM and

body ground, when the main thro ttle valve is fully closed

and fully opened.

Check and replace TRAC ECU.

5Check voltage of terminal VTA1 of ECM (See page EG±608 or EG±388 ).

Check and replace ECM.

BR±204

±

BRAKE SYSTEM TRACTION CONTROL SYSTEM (TRAC)

WhereEverybodyKnowsYourName

Trending: fold seats, lumbar support, oil capacity, brake light, low oil pressure, coolant level, headrest