Door LINCOLN AVIATOR 2004 Service Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2004, Model line: AVIATOR, Model: LINCOLN AVIATOR 2004Pages: 336, PDF Size: 3.69 MB

Page 219 of 336

Tires, Replacement Requirements

Do not use a size and type of tire and wheel other than that

originally provided by Ford Motor Company because it can affect

the safety and performance of your vehicle, which could result in an

increased risk of loss of vehicle control, vehicle rollover, and/or serious

personal injury or death.

AWD vehicles are equipped with tires designed to provide for safe ride

and handling capability.

Make sure all tires and wheels on the vehicle are of the same size, type,

tread design and load-carrying capacity. If you have questions regarding

tire replacement, see an authorized Ford or Lincoln Mercury dealer.

If you nevertheless decide to equip your AWD for off-road use with tires

larger than what Ford Motor Company recommends, you should not use

these tires for highway driving.

If you use any tire/wheel combination not recommended by Ford Motor

Company, it may adversely affect vehicle handling and could cause

steering, suspension, axle or transfer case failure as well as the increased

risk of loss of vehicle control.

Do not use ªaftermarket lift kitsº or other suspension modifications,

whether or not they are used with larger tires and wheels.

These ªaftermarket lift kitsº could adversely affect the vehicle's handling

characteristics, which could lead to loss of vehicle control or rollover and

serious injury.

Tires can be damaged during off-road use. For your safety, tires that are

damaged should not be used for highway driving because they are more

likely to blow out or fail.

You should carefully observe the recommended tire inflation pressure

found on the safety compliance certification label attached to the left

front door lock facing or door latch post pillar. Failure to follow tire

pressure recommendations can adversely affect the way your vehicle

handles. Do not exceed the Ford Motor Company recommended pressure

even if it is less than the maximum pressure allowed for the tire.

Driving

219

Page 222 of 336

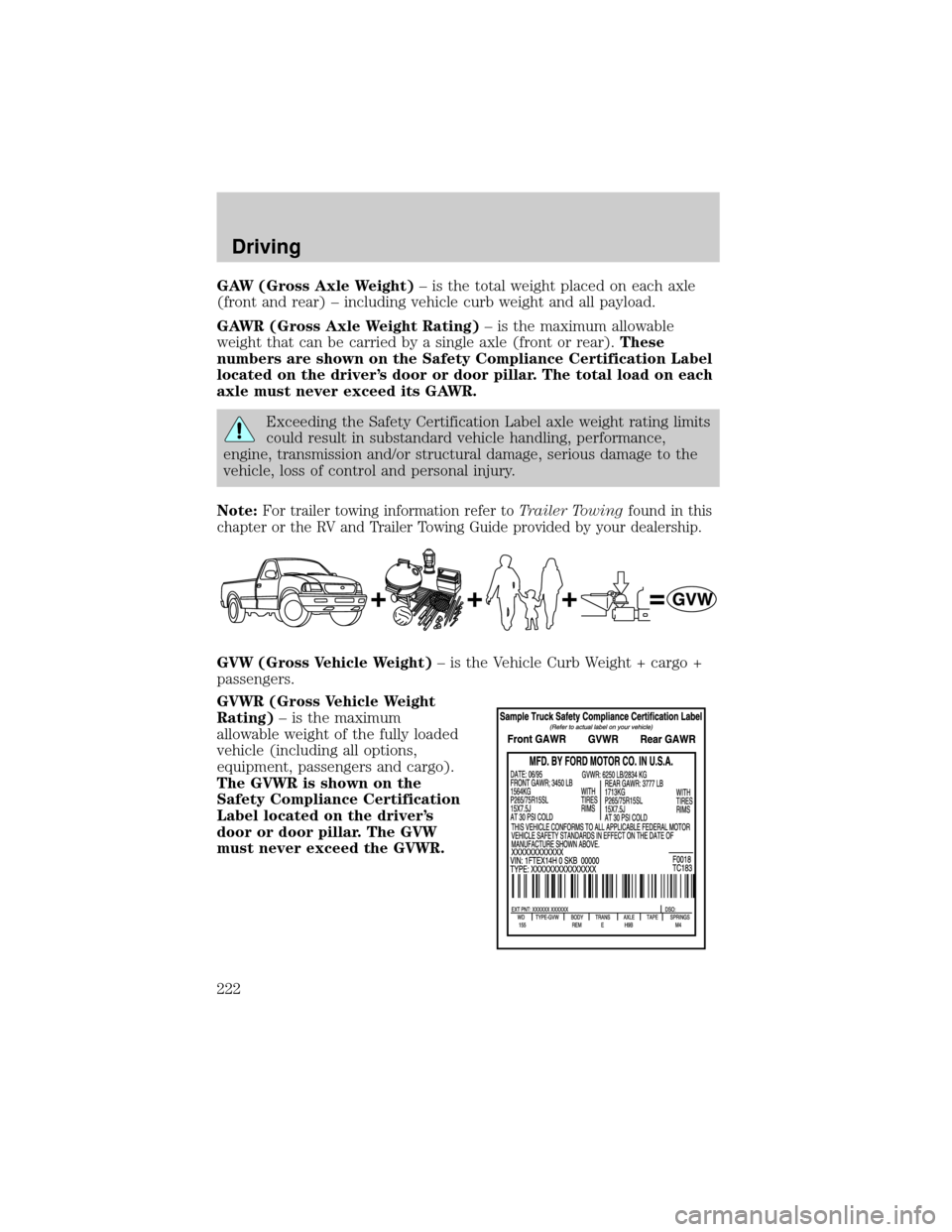

GAW (Gross Axle Weight)± is the total weight placed on each axle

(front and rear) ± including vehicle curb weight and all payload.

GAWR (Gross Axle Weight Rating)± is the maximum allowable

weight that can be carried by a single axle (front or rear).These

numbers are shown on the Safety Compliance Certification Label

located on the driver's door or door pillar. The total load on each

axle must never exceed its GAWR.

Exceeding the Safety Certification Label axle weight rating limits

could result in substandard vehicle handling, performance,

engine, transmission and/or structural damage, serious damage to the

vehicle, loss of control and personal injury.

Note:

For trailer towing information refer toTrailer Towingfound in this

chapter or the RV and Trailer Towing Guide provided by your dealership.

GVW (Gross Vehicle Weight)± is the Vehicle Curb Weight + cargo +

passengers.

GVWR (Gross Vehicle Weight

Rating)± is the maximum

allowable weight of the fully loaded

vehicle (including all options,

equipment, passengers and cargo).

The GVWR is shown on the

Safety Compliance Certification

Label located on the driver's

door or door pillar. The GVW

must never exceed the GVWR.

Driving

222

Page 239 of 336

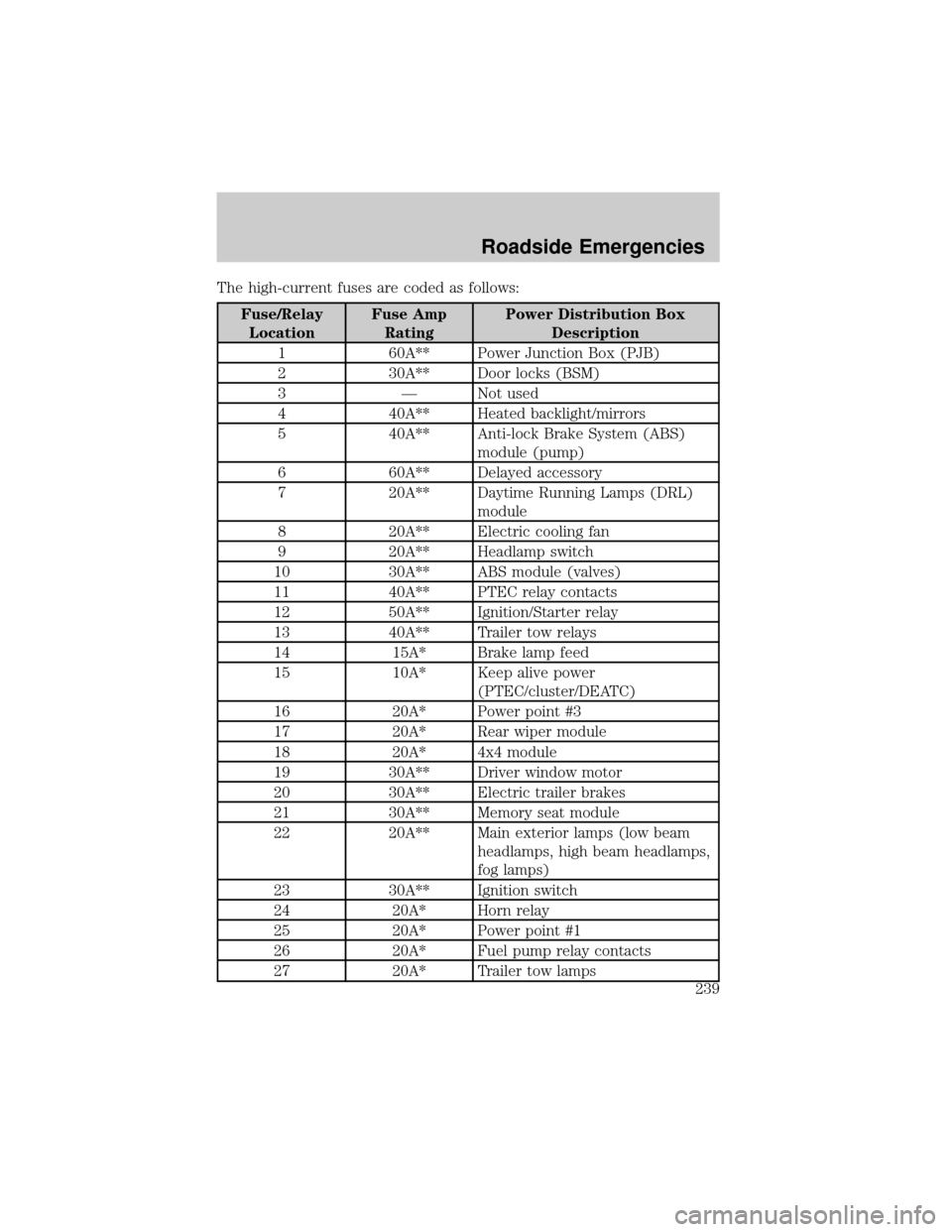

The high-current fuses are coded as follows:

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box

Description

1 60A** Power Junction Box (PJB)

2 30A** Door locks (BSM)

3 Ð Not used

4 40A** Heated backlight/mirrors

5 40A** Anti-lock Brake System (ABS)

module (pump)

6 60A** Delayed accessory

7 20A** Daytime Running Lamps (DRL)

module

8 20A** Electric cooling fan

9 20A** Headlamp switch

10 30A** ABS module (valves)

11 40A** PTEC relay contacts

12 50A** Ignition/Starter relay

13 40A** Trailer tow relays

14 15A* Brake lamp feed

15 10A* Keep alive power

(PTEC/cluster/DEATC)

16 20A* Power point #3

17 20A* Rear wiper module

18 20A* 4x4 module

19 30A** Driver window motor

20 30A** Electric trailer brakes

21 30A** Memory seat module

22 20A** Main exterior lamps (low beam

headlamps, high beam headlamps,

fog lamps)

23 30A** Ignition switch

24 20A* Horn relay

25 20A* Power point #1

26 20A* Fuel pump relay contacts

27 20A* Trailer tow lamps

Roadside Emergencies

239

Page 266 of 336

WASHING THE EXTERIOR

Wash your vehicle regularly with cool or lukewarm water and a neutral

Ph shampoo, such as Motorcraft Detail Wash (ZC-3±A), which is available

from your dealer.

²Never use strong household detergents or soap, such as dish washing

or laundry liquid. These products can discolor and spot painted

surfaces.

²Never wash a vehicle that is ªhot to the touchº or during exposure to

strong, direct sunlight.

²Always use a clean sponge or carwash mitt with plenty of water for

best results.

²Dry the vehicle with a chamois or soft terry cloth towel in order to

eliminate water spotting.

²It is especially important to wash the vehicle regularly during the

winter months, as dirt and road salt are difficult to remove and cause

damage to the vehicle.

²Immediately remove items such as gasoline, diesel fuel, bird droppings

and insect deposits because they can cause damage to the vehicle's

paintwork and trim over time.

²Remove any exterior accessories, such as antennas, before entering a

car wash.

²Suntan lotions and insect repellents can damage any painted

surface; if these substances come in contact with your vehicle,

wash off as soon as possible.

²If your vehicle is equipped with running boards, do not use

rubber, plastic and vinyl protectant products on the running

board surface, as the area may become slippery.

WAXING

Applying a polymer paint sealant to your vehicle every six months will

assist in reducing minor scratches and paint damage.

²Wash the vehicle first.

²Do not use waxes that contain abrasives.

²Do not allow paint sealant to come in contact with any non-body

(low-gloss black) colored trim, such as grained door handles, roof

racks, bumpers, side moldings, mirror housings or the windshield cowl

area. The paint sealant will ªgrayº or stain the parts over time.

Cleaning

Cleaning

266

Page 267 of 336

PAINT CHIPS

Your dealer has touch-up paint and sprays to match your vehicle's color.

Take your color code (printed on a sticker in the driver's door jam) to

your dealer to ensure you get the correct color.

²Remove particles such as bird droppings, tree sap, insect deposits, tar

spots, road salt and industrial fallout before repairing paint chips.

²Always read the instructions before using the products.

ALUMINUM WHEELS AND WHEEL COVERS

Aluminum wheels and wheel covers are coated with a clearcoat paint

finish. In order to maintain their shine:

²Clean weekly with Motorcraft Wheel and Tire Cleaner (ZC-37±A),

which is available from your dealer. Heavy dirt and brake dust

accumulation may require agitation with a sponge. Rinse thoroughly

with a strong stream of water.

²Never apply any cleaning chemical to hot or warm wheel rims or

covers.

²Some automatic car washes may cause damage to the finish on your

wheel rims or covers. Chemical-strength cleaners, or cleaning

chemicals, in combination with brush agitation to remove brake dust

and dirt, could wear away the clearcoat finish over time.

²Do not use hydrofluoric acid-based or high caustic-based wheel

cleaners, steel wool, fuels or strong household detergent.

²To remove tar and grease, use Motorcraft Bug and Tar Remover

(ZC-42), available from your dealer.

ENGINE

Engines are more efficient when they are clean because grease and dirt

buildup keep the engine warmer than normal. When washing:

²Take care when using a power washer to clean the engine. The

high-pressure fluid could penetrate the sealed parts and cause

damage.

²Do not spray a hot engine with cold water to avoid cracking the

engine block or other engine components.

²Spray Motorcraft Engine Shampoo and Degreaser (ZC-20) on all parts

that require cleaning and pressure rinse clean.

Cleaning

267

Page 270 of 336

CLEANING THE CLIMATE CONTROLLED SEATS (IF EQUIPPED)

Remove dust and loose dirt with a whisk broom or a vacuum cleaner.

Remove fresh spots immediately. Clean the seat with a damp cloth, using

a mild soap and water solution, if necessary.

LEATHER SEATS

Your leather seating surfaces have a clear, protective coating over the

leather.

²To clean, use a soft cloth with Motorcraft Deluxe Leather and Vinyl

Cleaner (ZC-11±A). Dry the area with a soft cloth.

²To help maintain its resiliency and color, use the Motorcraft Deluxe

Leather Care Kit (ZC-11±D), available from your authorized dealer.

²Do not use household cleaning products, alcohol solutions, solvents or

cleaners intended for rubber, vinyl and plastics, or oil/petroleum-based

leather conditioners. These products may cause premature wearing of

the clear, protective coating.

Note:In some instances, color or dye transfer can occur when wet

clothing comes in contact with leather upholstery. If this occurs, the

leather should be cleaned immediately to avoid permanent staining.

INTERIOR TRIM

²Clean the interior trim areas with a damp cloth, then dry by wiping

with a dry, soft, clean cloth.

²Do not use household or glass cleaners as these may damage the

finish.

UNDERBODY

Flush the complete underside of your vehicle frequently. Keep body and

door drain holes free from packed dirt.

Cleaning

270

Page 297 of 336

space-saver or temporary use spare tires, tires with nominal rim

diameters of 10 to 12 inches or limited production tires as defined in

Title 49 Code of Federal Regulations Part 575.104(c)(2).

U.S. Department of Transportation-Tire quality grades:The U.S.

Department of Transportation requires Ford to give you the following

information about tire grades exactly as the government has written it.

Treadwear

The treadwear grade is a comparative rating based on the wear rate of

the tire when tested under controlled conditions on a specified

government test course. For example, a tire graded 150 would wear one

and one-half (1 1/2) times as well on the government course as a tire

graded 100. The relative performance of tires depends upon the actual

conditions of their use, however, and may depart significantly from the

norm due to variations in driving habits, service practices, and

differences in road characteristics and climate.

Traction AA A B C

The traction grades, from highest to lowest are AA, A, B, and C. The

grades represent the tire's ability to stop on wet pavement as measured

under controlled conditions on specified government test surfaces of

asphalt and concrete. A tire marked C may have poor traction

performance.

The traction grade assigned to this tire is based on

straight-ahead braking traction tests, and does not include

acceleration, cornering, hydroplaning or peak traction characteristics.

Temperature A B C

The temperature grades are A (the highest), B and C, representing the

tire's resistance to the generation of heat and its ability to dissipate heat

when tested under controlled conditions on a specified indoor laboratory

test wheel. Sustained high temperature can cause the material of the tire

to degenerate and reduce tire life, and excessive temperature can lead to

sudden tire failure. The grade C corresponds to a level of performance

which all passenger car tires must meet under the Federal Motor Vehicle

Safety Standard No. 109. Grades B and A represent higher levels of

performance on the laboratory test wheel than the minimum required by

law.

Maintenance and Specifications

297

Page 298 of 336

The temperature grade for this tire is established for a tire that

is properly inflated and not overloaded. Excessive speed,

underinflation, or excessive loading, either separately or in

combination, can cause heat buildup and possible tire failure.

TIRES

Tires are designed to give many thousands of miles of service, but they

must be maintained in order to get the maximum benefit from them.

Glossary of tire terminology

²Tire label:A label showing the OE (Original Equipment) tire sizes,

recommended inflation pressure and the maximum weight the vehicle

can carry.

²Tire Identification Number (TIN):A number on the sidewall of

each tire providing information about the tire brand and

manufacturing plant, tire size and date of manufacturer.

²Inflation pressure:A measure of the amount of air in a tire.

²Standard load:A class of P-metric or Metric tires designed to carry a

maximum load at 35 psi [37 psi (2.5 bar) for Metric tires]. Increasing

the inflation pressure beyond this pressure will not increase the tires

load carrying capability.

²Extra load:A class of P-metric or Metric tires designed to carry a

heavier maximum load at 41 psi [43 psi (2.9 bar) for Metric tires].

Increasing the inflation pressure beyond this pressure will not increase

the tires load carrying capability.

²kPa:Kilopascal, a metric unit of air pressure.

²PSI:Pounds per square inch, a standard unit of air pressure.

²B-pillar:The structural member at the side of the vehicle behind the

front door.

²Bead area of the tire:Area of the tire next to the rim.

²Sidewall of the tire:Area between the bead area and the tread.

²Tread area of the tire:Area of the perimeter of the tire that

contacts the road when mounted on the vehicle.

²Rim:The metal support (wheel) for a tire or a tire and tube assembly

upon which the tire beads are seated.

Maintenance and Specifications

298

Page 302 of 336

Note:You may not find this information on all tires because it is not

required by federal law.

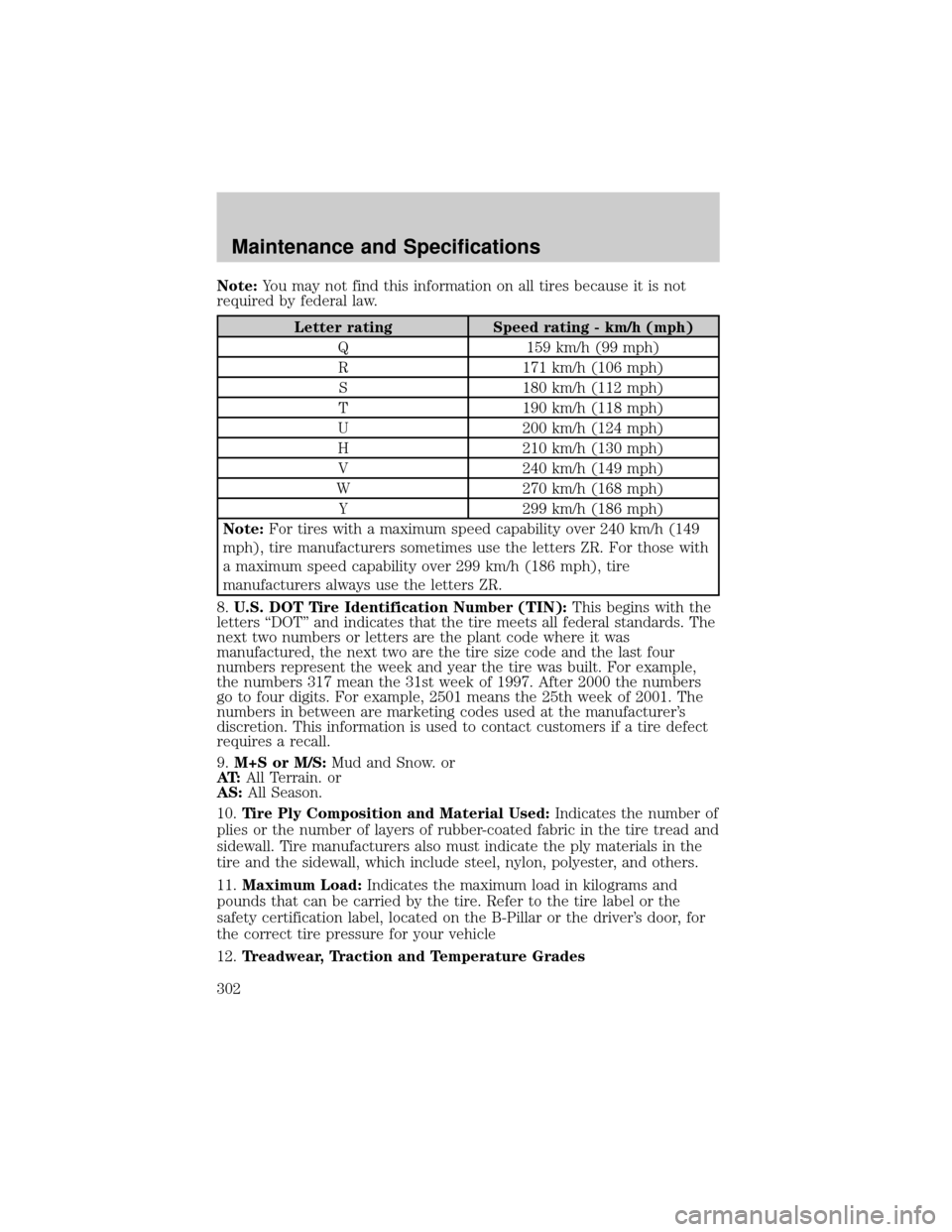

Letter rating Speed rating - km/h (mph)

Q 159 km/h (99 mph)

R 171 km/h (106 mph)

S 180 km/h (112 mph)

T 190 km/h (118 mph)

U 200 km/h (124 mph)

H 210 km/h (130 mph)

V 240 km/h (149 mph)

W 270 km/h (168 mph)

Y 299 km/h (186 mph)

Note:For tires with a maximum speed capability over 240 km/h (149

mph), tire manufacturers sometimes use the letters ZR. For those with

a maximum speed capability over 299 km/h (186 mph), tire

manufacturers always use the letters ZR.

8.U.S. DOT Tire Identification Number (TIN):This begins with the

letters ªDOTº and indicates that the tire meets all federal standards. The

next two numbers or letters are the plant code where it was

manufactured, the next two are the tire size code and the last four

numbers represent the week and year the tire was built. For example,

the numbers 317 mean the 31st week of 1997. After 2000 the numbers

go to four digits. For example, 2501 means the 25th week of 2001. The

numbers in between are marketing codes used at the manufacturer's

discretion. This information is used to contact customers if a tire defect

requires a recall.

9.M+S or M/S:Mud and Snow. or

AT:All Terrain. or

AS:All Season.

10.Tire Ply Composition and Material Used:Indicates the number of

plies or the number of layers of rubber-coated fabric in the tire tread and

sidewall. Tire manufacturers also must indicate the ply materials in the

tire and the sidewall, which include steel, nylon, polyester, and others.

11.Maximum Load:Indicates the maximum load in kilograms and

pounds that can be carried by the tire. Refer to the tire label or the

safety certification label, located on the B-Pillar or the driver's door, for

the correct tire pressure for your vehicle

12.Treadwear, Traction and Temperature Grades

Maintenance and Specifications

302

Page 303 of 336

²Treadwear:The treadwear grade is a comparative rating based on the

wear rate of the tire when tested under controlled conditions on a

specified government test course. For example, a tire graded 150

would wear one and one-half (1

1¤2) times as well on the government

course as a tire graded 100.

²Traction:The traction grades, from highest to lowest are AA, A, B,

and C. The grades represent the tire's ability to stop on wet pavement

as measured under controlled conditions on specified government test

surfaces of asphalt and concrete. A tire marked C may have poor

traction performance.

²Temperature:The temperature grades are A (the highest), B and C,

representing the tire's resistance to the generation of heat and its

ability to dissipate heat when tested under controlled conditions on a

specified indoor laboratory test wheel.

13.Maximum Permissible Inflation Pressure:Tire manufactures

maximum permissible pressure and/or the pressure at which the

maximum load can be carried by the tire. This pressure is normally

higher than the manufacturer's recommended cold inflation pressure

which can be found on either the tire label or certification label which is

located on the structure by the trailing edge of the driver's door or the

edge of the driver's door. The cold inflation pressure should never be set

lower than the recommended pressure on the label.

Note:You may not find this information on all tires because it is not

required by federal law.

The tire suppliers may have additional markings, notes or warnings such

as standard load, radial tubeless, etc.

Maintenance and Specifications

303