maintenance LINCOLN LS 2000 User Guide

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2000, Model line: LS, Model: LINCOLN LS 2000Pages: 272, PDF Size: 2.36 MB

Page 128 of 272

attaching hardware, should be inspected after a collision. Ford

recommends that all safety belt assemblies used in vehicles involved in a

collision be replaced. However, if the collision was minor and a qualified

technician finds that the belts do not show damage and continue to

operate properly, they do not need to be replaced. Safety belt assemblies

not in use during a collision should also be inspected and replaced if

either damage or improper operation is noted.

Failure to inspect and if necessary replace the safety belt

assembly under the above conditions could result in severe

personal injuries in the event of a collision.

Refer toCleaning and maintaining the safety beltsin the

Maintenance and caresection.

AIR BAG SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Your vehicle is equipped with a crash sensing and diagnostic module

which records information about the air bag and sensor systems. In the

event of a collision this module may save information related to the

collision including information about the air bag system and impact

severity. This information will assist Ford in the servicing of your vehicle

and may help Ford better understand rear world collisions and further

improve the safety of future vehicles.

PU

LL AU

TORESUME

SET

CANCELO

NO

F

F

MUTE

VOL

MEDIA

HI

LO

INTINTOFF

MIST

P! BRAKEHC123456700204060801001201401604080120160

200240km/hRPMX1000RESETMPHFE

SEEKMUTEVOL

PUSH ON

CD TAPEEJBASS

TREBSELBAL

FADE

TUNESCANAUTOAM FMREW1FF2SIDE 1-23COMP5SHUFF6 4RDS

AUTO OFFA/C

R EXT

F CFF

Seating and safety restraints

128

Page 132 of 272

properly restrained as far away from the air bag module as possible while

maintaining vehicle control.

Several air bag system components get hot after inflation. Do not

touch them after inflation.

If the air bag is inflated,the air bag will not function again

and must be replaced immediately.If the air bag is not

replaced, the unrepaired area will increase the risk of injury in a

collision.

The SRS consists of:

²driver and passenger air bag modules (which include the inflators and

air bags).

²side air bags (if equipped). Refer toSide air bag systemlater in this

chapter.

²safety belt pretensioners.

²one or more impact and safing sensors.

²a readiness light and tone.

²and the electrical wiring which connects the components.

The diagnostic module monitors its own internal circuits and the

supplemental air bag electrical system warning (including the impact

sensors), the system wiring, the air bag system readiness light, the air

bag back up power, the air bag ignitors and safety belt pretensioners.

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster or a tone to

indicate the condition of the system. Refer to theAir bag readiness

section in theInstrumentationchapter. Routine maintenance of the air

bag is not required.

A difficulty with the system is indicated by one or more of the following:

²The readiness light will either

flash or stay lit.

²The readiness light will not

illuminate immediately after

ignition is turned to the RUN

position.

Seating and safety restraints

132

Page 135 of 272

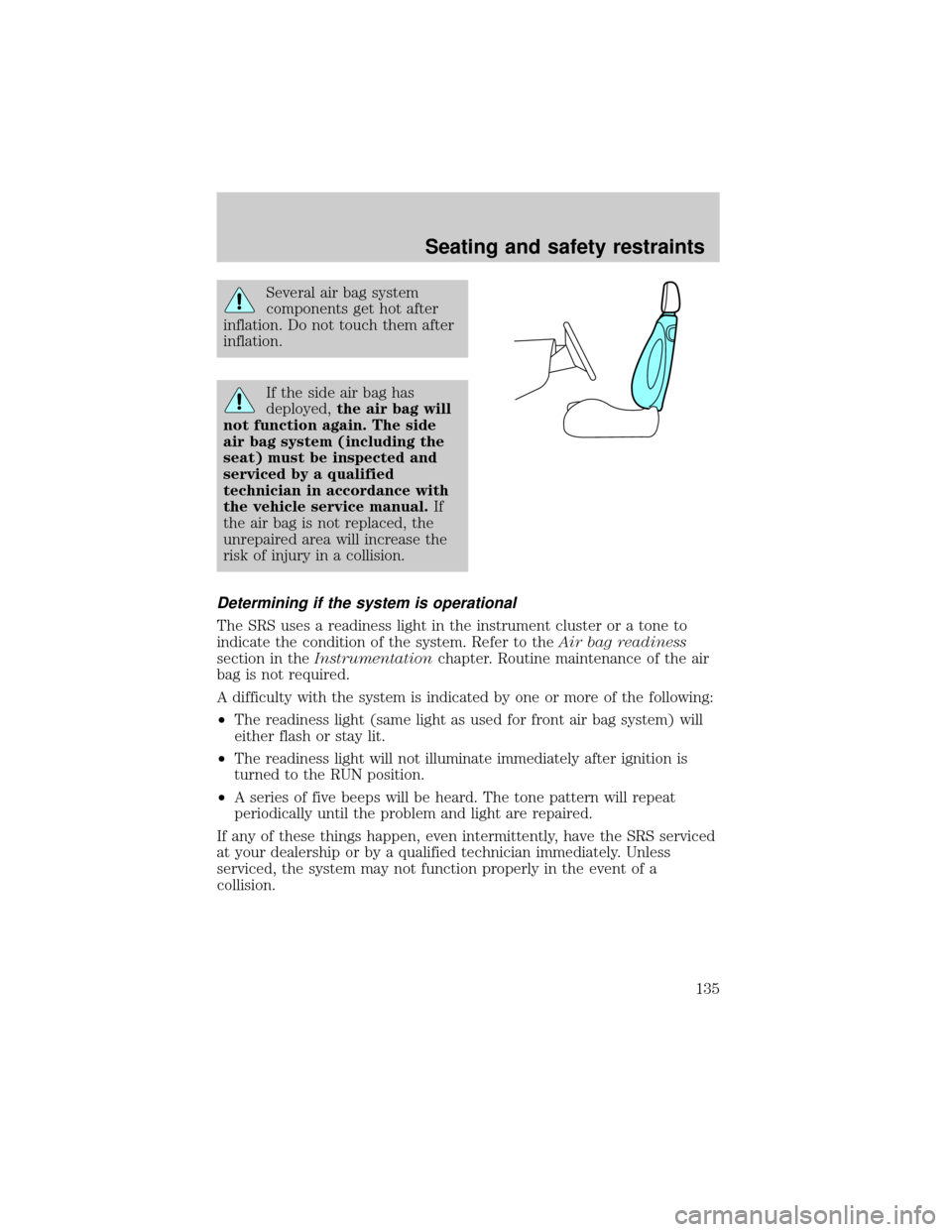

Several air bag system

components get hot after

inflation. Do not touch them after

inflation.

If the side air bag has

deployed,the air bag will

not function again. The side

air bag system (including the

seat) must be inspected and

serviced by a qualified

technician in accordance with

the vehicle service manual.If

the air bag is not replaced, the

unrepaired area will increase the

risk of injury in a collision.

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster or a tone to

indicate the condition of the system. Refer to theAir bag readiness

section in theInstrumentationchapter. Routine maintenance of the air

bag is not required.

A difficulty with the system is indicated by one or more of the following:

²The readiness light (same light as used for front air bag system) will

either flash or stay lit.

²The readiness light will not illuminate immediately after ignition is

turned to the RUN position.

²A series of five beeps will be heard. The tone pattern will repeat

periodically until the problem and light are repaired.

If any of these things happen, even intermittently, have the SRS serviced

at your dealership or by a qualified technician immediately. Unless

serviced, the system may not function properly in the event of a

collision.

Seating and safety restraints

135

Page 149 of 272

BRAKES

Your service brakes are self-adjusting. Refer to the scheduled

maintenance guide for scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a ªmetal-to-metalº, ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

Anti-lock brake system (ABS)

On vehicles equipped with an anti-lock braking system (ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. The ABS performs a self-check after you start

the engine and begin to drive away. A brief mechanical noise may be

heard during this test. This is normal. If a malfunction is found, the ABS

warning light will come on. If the vehicle has continuous vibration or

shudder in the steering wheel while braking, the vehicle should be

inspected by a qualified service technician.

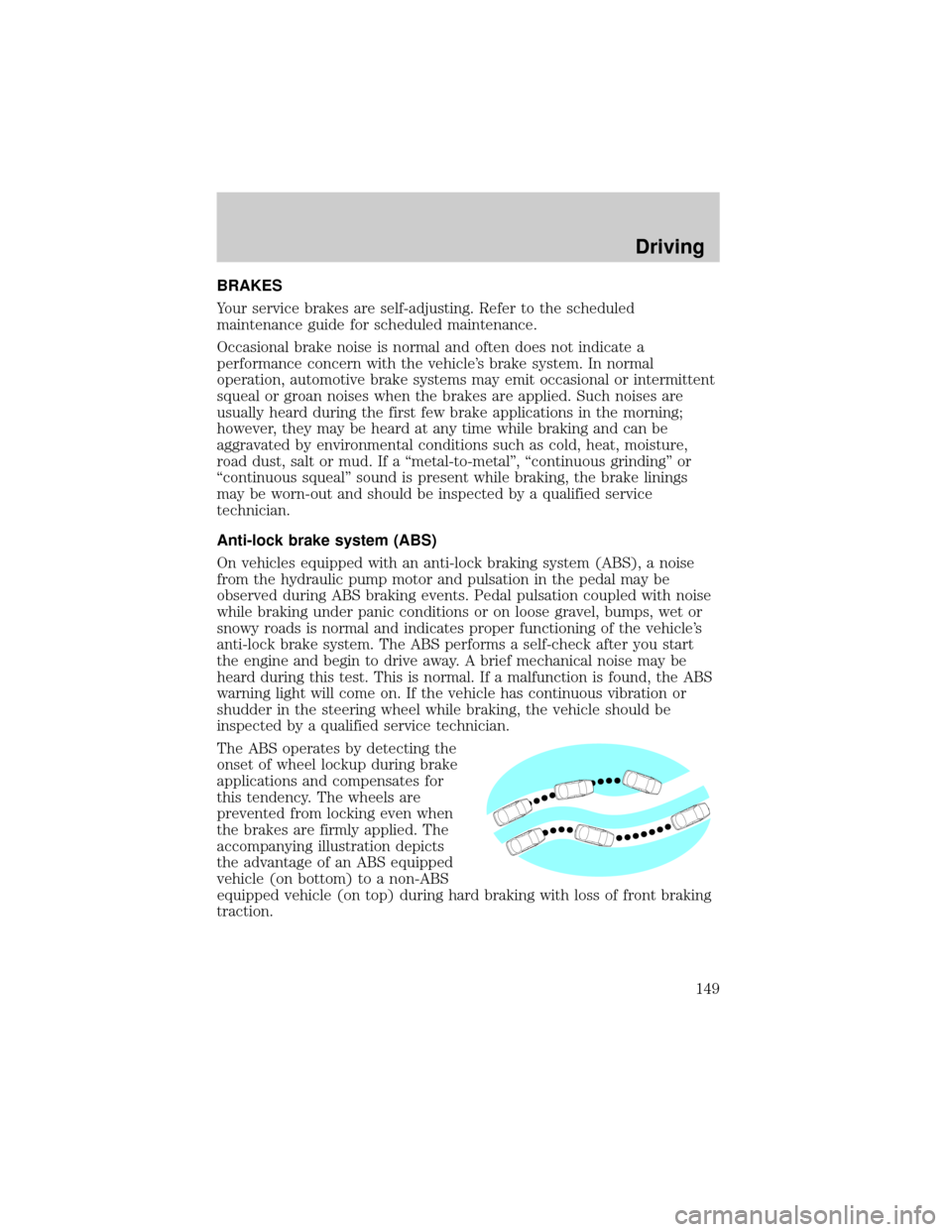

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensates for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

Driving

149

Page 169 of 272

²Use extra caution when driving while trailer towing. Refer toDriving

while you towin this chapter.

²Service your vehicle more frequently if you tow a trailer. Refer to the

severe duty schedule in the Scheduled Maintenance Guide.

²Do not tow a trailer until your vehicle has been driven at least 800 km

(500 miles).

²Refer to the instructions included with towing accessories for the

proper installation and adjustment specifications.

To ensure that the electrical system is not damaged, you will require a

trailer tow package which includes a trailer tow module and the

necessary wiring to connect the trailer tow module to the electrical

system and to the trailer. This option is available through your dealer or

through Ford Customer Service Division. Please refer toPreparing to

towfor further information.

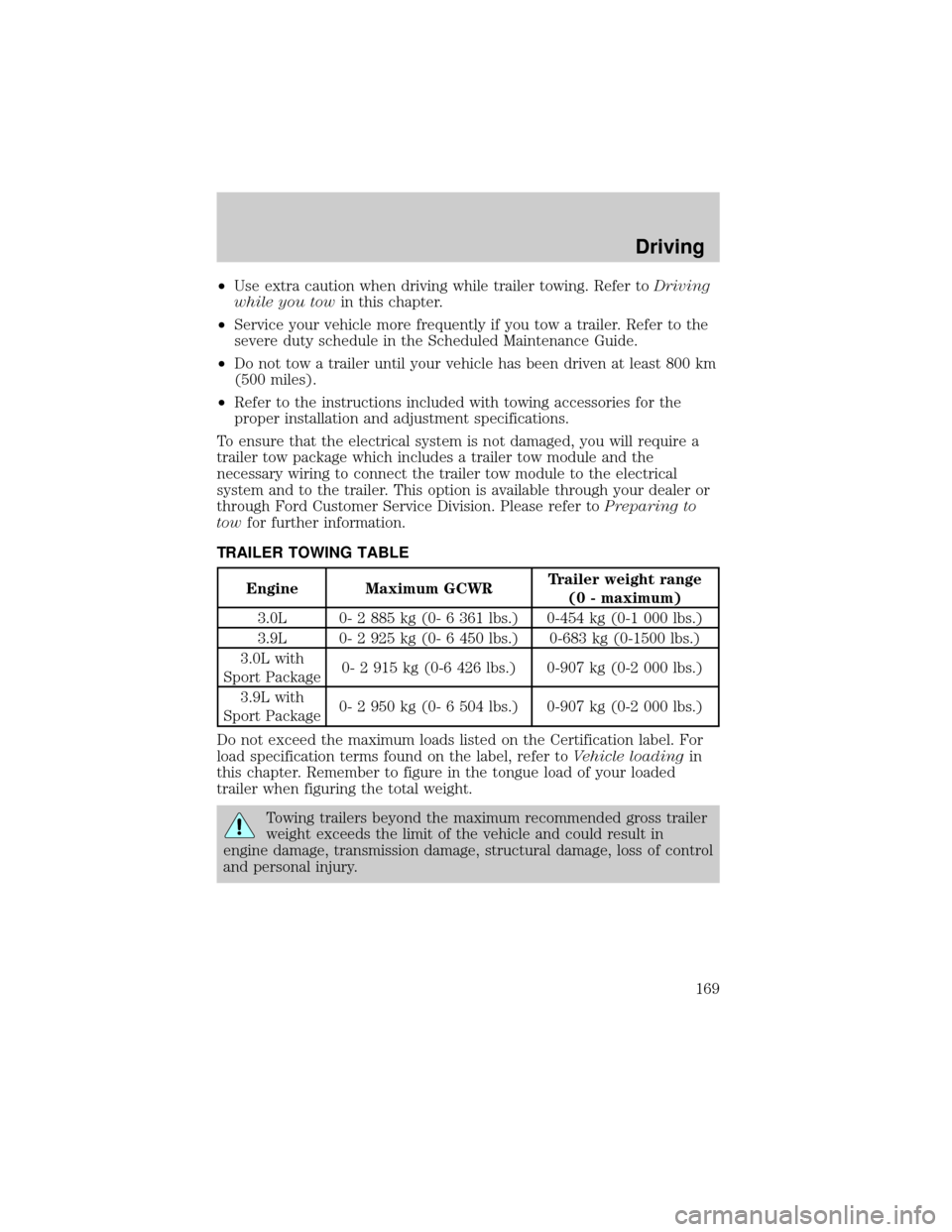

TRAILER TOWING TABLE

Engine Maximum GCWRTrailer weight range

(0 - maximum)

3.0L 0- 2 885 kg (0- 6 361 lbs.) 0-454 kg (0-1 000 lbs.)

3.9L 0- 2 925 kg (0- 6 450 lbs.) 0-683 kg (0-1500 lbs.)

3.0L with

Sport Package0- 2 915 kg (0-6 426 lbs.) 0-907 kg (0-2 000 lbs.)

3.9L with

Sport Package0- 2 950 kg (0- 6 504 lbs.) 0-907 kg (0-2 000 lbs.)

Do not exceed the maximum loads listed on the Certification label. For

load specification terms found on the label, refer toVehicle loadingin

this chapter. Remember to figure in the tongue load of your loaded

trailer when figuring the total weight.

Towing trailers beyond the maximum recommended gross trailer

weight exceeds the limit of the vehicle and could result in

engine damage, transmission damage, structural damage, loss of control

and personal injury.

Driving

169

Page 171 of 272

vehicle lamps from functioning. Your lamp outage feature will also be

disabled or provide incorrect information.

Your vehicle is ready to install a Trailer Tow module that will provide the

proper communication with the vehicle electrical system so your trailer

lamps will function properly. See your dealer or trailer rental agency for

proper instructions and equipment for hooking up trailer lamps.

Driving while you tow

When towing a trailer:

²Ensure that you turn off your speed control. The speed control may

shut off automatically when you are towing on long, steep grades.

²Consult your local motor vehicle speed regulations for towing a trailer.

²Shift out of D5 (Overdrive) and into D4 (Drive) or a lower gear when

towing up or down steep hills. This will eliminate excessive

downshifting and upshifting for optimum fuel economy and

transmission cooling.

²Anticipate stops and brake gradually.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to your Scheduled Maintenance Guide

for more information.

Trailer towing tips

²Practice turning, stopping and backing up in an area before starting on

a trip to get the feel of the vehicle trailer combination. When turning,

make wider turns so the trailer wheels will clear curbs and other

obstacles.

²Allow more distance for stopping with a trailer attached.

²The trailer tongue weight should be 10% of the loaded trailer weight.

²After you have traveled 80 km (50 miles), thoroughly check your

hitch, electrical connections and trailer wheel lug nuts.

²When stopped in traffic for long periods of time in hot weather, place

the gearshift in P (Park) or N (Neutral) and increase idle speed. This

aids engine cooling and air conditioner efficiency.

²Vehicles with trailers should not be parked on a grade. If you must

park on a grade, place wheel chocks under the trailer's wheels.

Driving

171

Page 179 of 272

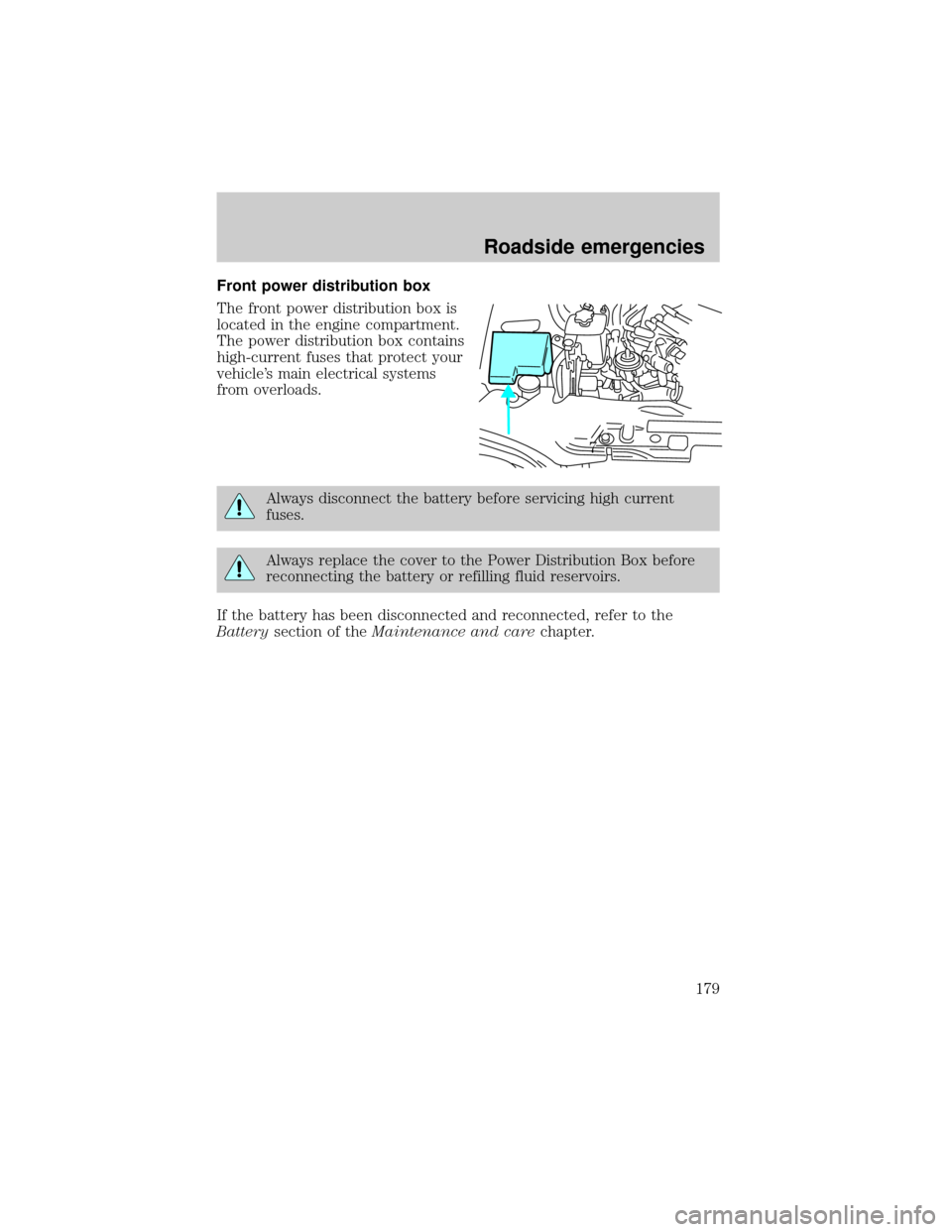

Front power distribution box

The front power distribution box is

located in the engine compartment.

The power distribution box contains

high-current fuses that protect your

vehicle's main electrical systems

from overloads.

Always disconnect the battery before servicing high current

fuses.

Always replace the cover to the Power Distribution Box before

reconnecting the battery or refilling fluid reservoirs.

If the battery has been disconnected and reconnected, refer to the

Batterysection of theMaintenance and carechapter.

7

Roadside emergencies

179

Page 182 of 272

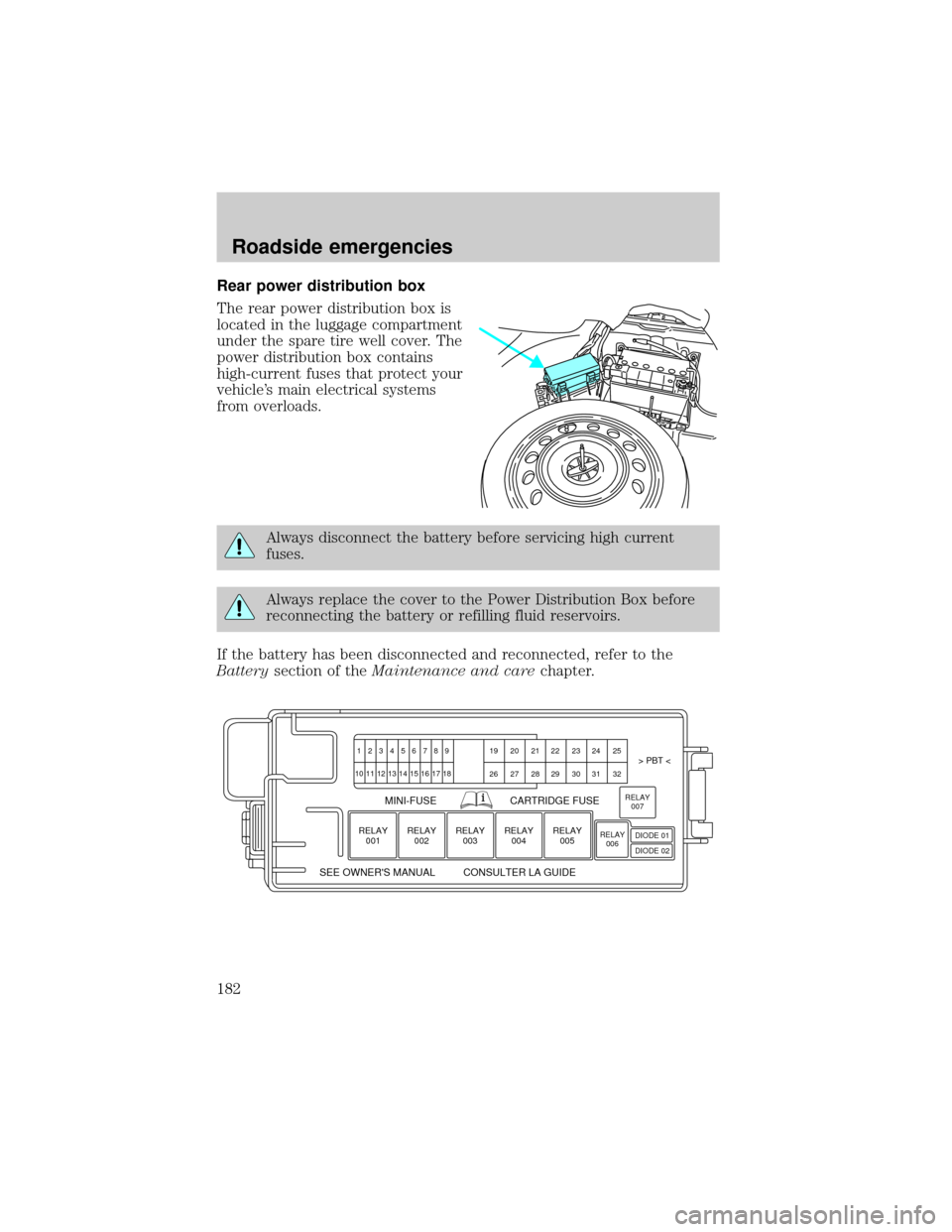

Rear power distribution box

The rear power distribution box is

located in the luggage compartment

under the spare tire well cover. The

power distribution box contains

high-current fuses that protect your

vehicle's main electrical systems

from overloads.

Always disconnect the battery before servicing high current

fuses.

Always replace the cover to the Power Distribution Box before

reconnecting the battery or refilling fluid reservoirs.

If the battery has been disconnected and reconnected, refer to the

Batterysection of theMaintenance and carechapter.

123456789 19 20 21 22 23 24 25> PBT <

MINI-FUSE

SEE OWNER'S MANUAL CONSULTER LA GUIDECARTRIDGE FUSE

26 27 28 29 30 31 32 10 11

RELAY

001

12 13 14 15 16 17 18

RELAY

002RELAY

003RELAY

004RELAY

005RELAY

006RELAY

007

DIODE 01

DIODE 02

Roadside emergencies

182

Page 195 of 272

SERVICE RECOMMENDATIONS

To help you service your vehicle:

²We highlight do-it-yourself items in the engine compartment for easy

location.

²We provide a Scheduled Maintenance Guide which makes tracking

routine service easy.

If your vehicle requires professional service, your dealership can provide

necessary parts and service. Check your ªWarranty Guideº to find out

which parts and services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

Be especially careful when inspecting or servicing your vehicle.

²Do not work on a hot engine.

²When the engine is running, keep loose clothing, jewelry or long hair

away from moving parts.

²Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

²Keep all lit cigarettes, open flames and other lit material away from

the battery and all fuel related parts.

If you disconnect the battery, the engine must ªrelearnº its idle

conditions before your vehicle will drive properly, as explained in the

Batterysection in this chapter.

Working with the engine off

²Automatic transmission:

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Turn off the engine and remove the key.

3. Block the wheels to prevent the vehicle from moving unexpectedly.

²Manual transmission:

1. Set the parking brake.

2. Depress the clutch and place the gearshift in 1 (First).

Maintenance and care

195

Page 196 of 272

3. Turn off the engine and remove the key.

4. Block the wheels to prevent the vehicle from moving unexpectedly.

Working with the engine on

²Automatic transmission:

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Block the wheels to prevent the vehicle from moving unexpectedly.

Do not start your engine with the air cleaner removed and do

not remove it while the engine is running.

²Manual transmission:

1. Set the parking brake, depress the clutch and place the gearshift in N

(Neutral).

2. Block the wheels to prevent the vehicle from moving unexpectedly.

Do not start your engine with the air cleaner removed and do

not remove it while the engine is running.

OPENING THE HOOD

1. Inside the vehicle, pull the hood

release handle located at the bottom

left of the instrument panel.

2. Go to the front of the vehicle and

release the auxiliary latch that is

located under the front center of

the hood by pushing upward on the

handle.

3. Lift the hood until the lift cylinders hold it open.

Maintenance and care

196