lock LINCOLN MKT 2019 Owners Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2019, Model line: MKT, Model: LINCOLN MKT 2019Pages: 575, PDF Size: 4.66 MB

Page 301 of 575

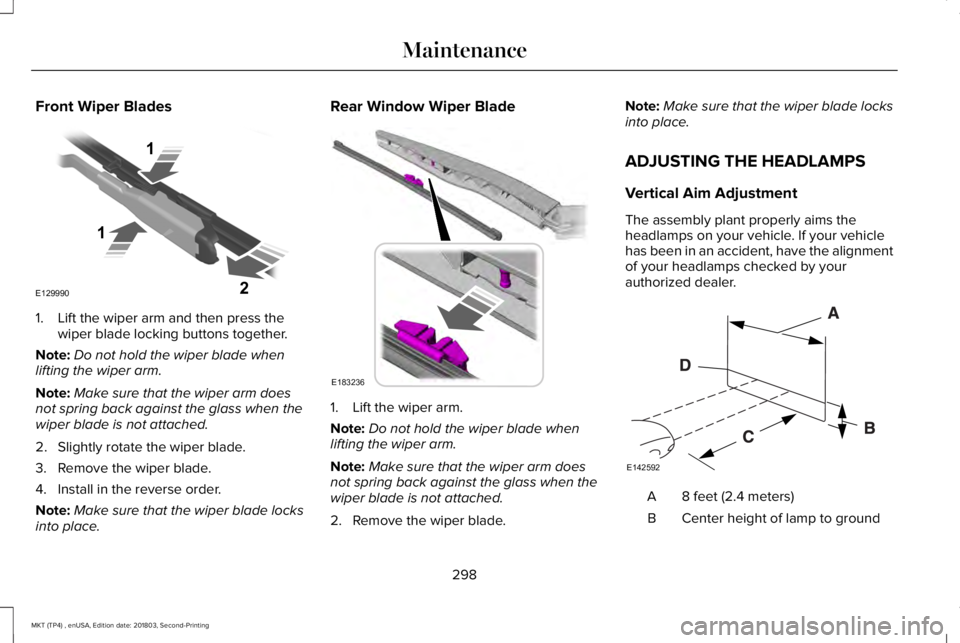

Front Wiper Blades

1. Lift the wiper arm and then press thewiper blade locking buttons together.

Note:Do not hold the wiper blade whenlifting the wiper arm.

Note:Make sure that the wiper arm doesnot spring back against the glass when thewiper blade is not attached.

2. Slightly rotate the wiper blade.

3. Remove the wiper blade.

4. Install in the reverse order.

Note:Make sure that the wiper blade locksinto place.

Rear Window Wiper Blade

1. Lift the wiper arm.

Note:Do not hold the wiper blade whenlifting the wiper arm.

Note:Make sure that the wiper arm doesnot spring back against the glass when thewiper blade is not attached.

2. Remove the wiper blade.

Note:Make sure that the wiper blade locksinto place.

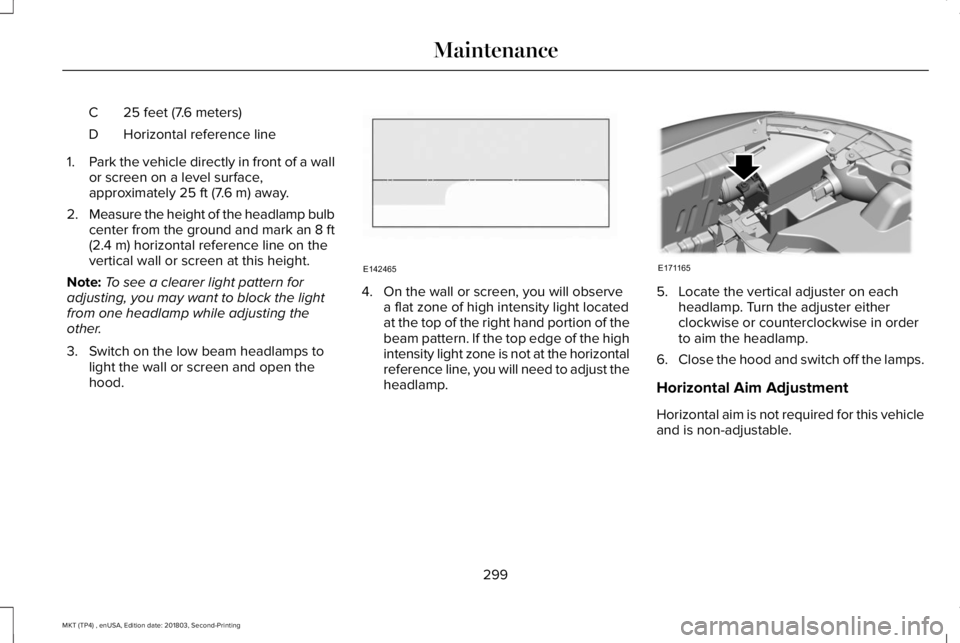

ADJUSTING THE HEADLAMPS

Vertical Aim Adjustment

The assembly plant properly aims theheadlamps on your vehicle. If your vehiclehas been in an accident, have the alignmentof your headlamps checked by yourauthorized dealer.

8 feet (2.4 meters)A

Center height of lamp to groundB

298

MKT (TP4) , enUSA, Edition date: 201803, Second-Printing

MaintenanceE129990

1

1 2 E183236 E142592

Page 302 of 575

25 feet (7.6 meters)C

Horizontal reference lineD

1.Park the vehicle directly in front of a wallor screen on a level surface,approximately 25 ft (7.6 m) away.

2.Measure the height of the headlamp bulbcenter from the ground and mark an 8 ft(2.4 m) horizontal reference line on thevertical wall or screen at this height.

Note:To see a clearer light pattern foradjusting, you may want to block the lightfrom one headlamp while adjusting theother.

3. Switch on the low beam headlamps tolight the wall or screen and open thehood.

4. On the wall or screen, you will observea flat zone of high intensity light locatedat the top of the right hand portion of thebeam pattern. If the top edge of the highintensity light zone is not at the horizontalreference line, you will need to adjust theheadlamp.

5. Locate the vertical adjuster on eachheadlamp. Turn the adjuster eitherclockwise or counterclockwise in orderto aim the headlamp.

6.Close the hood and switch off the lamps.

Horizontal Aim Adjustment

Horizontal aim is not required for this vehicleand is non-adjustable.

299

MKT (TP4) , enUSA, Edition date: 201803, Second-Printing

MaintenanceE142465 E171165

Page 303 of 575

REMOVING A HEADLAMP

To gain access to the headlamp securingbolts and to remove the headlamp assembly,you must first remove the front fascia andfront bumper assemblies. We recommendyou see an authorized dealer.

CHANGING A BULB

WARNING: Switch the lamps and theignition off. Failure to do so could result inserious personal injury.

WARNING: Bulbs can become hot.Let the bulb cool down before removingit. Failure to do so could result in personalinjury.

Use the correct specification bulb. See BulbSpecification Chart (page 362).

Install in the reverse order unless otherwisestated.

High Intensity Discharge Headlamp

These lamps operate at a high voltage. Seean authorized dealer if they fail.

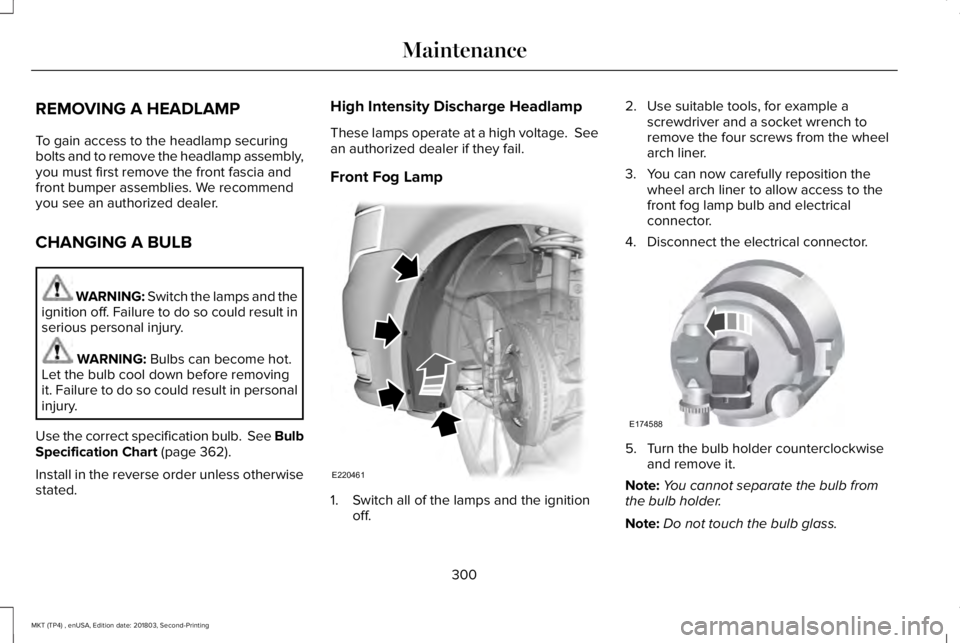

Front Fog Lamp

1. Switch all of the lamps and the ignitionoff.

2. Use suitable tools, for example ascrewdriver and a socket wrench toremove the four screws from the wheelarch liner.

3. You can now carefully reposition thewheel arch liner to allow access to thefront fog lamp bulb and electricalconnector.

4. Disconnect the electrical connector.

5. Turn the bulb holder counterclockwiseand remove it.

Note:You cannot separate the bulb fromthe bulb holder.

Note:Do not touch the bulb glass.

300

MKT (TP4) , enUSA, Edition date: 201803, Second-Printing

MaintenanceE220461 E174588

Page 309 of 575

•Do not allow wax to come in contact withany non-body (low-gloss black) coloredtrim. The wax will discolor or stain theparts over time.

•Roof racks.

•Bumpers.

•Grained door handles.

•Side moldings.

•Mirror housings.

•Windshield cowl area.

•Do not apply wax to glass areas.

•After waxing, your car's paint should feelsmooth, and be free of streaks andsmudges.

CLEANING THE ENGINE

Engines are more efficient when they areclean because grease and dirt buildup keepthe engine warmer than normal.

When washing:

•Take care when using a power washerto clean the engine. The high-pressurefluid could penetrate the sealed partsand cause damage.

•Do not spray a hot engine with cold waterto avoid cracking the engine block orother engine components.

•Spray Motorcraft Engine Shampoo andDegreaser on all parts that requirecleaning and pressure rinse clean. InCanada, use Motorcraft Engine Shampoo.

•Never wash or rinse the engine while itis hot or running; water in the runningengine may cause internal damage.

•Never wash or rinse any ignition coil,spark plug wire or spark plug well, or thearea in and around these locations.

•Cover the battery, power distribution box,and air filter assembly to prevent waterdamage when cleaning the engine.

CLEANING THE WINDOWS AND

WIPER BLADES

Car wash chemicals and environmentalfallout can result in windshield and wiperblade contamination. Dirty windshield andwipers will result in poor windshield wiperoperation. Keep the windshield and wiperblades clean to maintain windshield wiperperformance.

To clean the windshield and wiper blades:

•Clean the windshield with a non-abrasiveglass cleaner. When cleaning the interiorof the windshield, avoid getting any glasscleaner on the instrument panel or doorpanels. Wipe any glass cleaner off thesesurfaces immediately.

•For windshields contaminated with treesap, chemicals, wax or bugs, clean theentire windshield using steel wool (nogreater than 0000 grade) in a circularmotion and rinse with water.

•Clean the wiper blades with isopropylrubbing alcohol or windshield washerconcentrate.

306

MKT (TP4) , enUSA, Edition date: 201803, Second-Printing

Vehicle Care

Page 338 of 575

The usage of a full-size dissimilar sparewheel and tire assembly can lead toimpairment of the following:

•Handling, stability and brakingperformance.

•Comfort and noise.

•Ground clearance and parking at curbs.

•Winter weather driving capability.

•Wet weather driving capability.

•All-wheel driving capability.

When driving with the full-size dissimilarspare wheel and tire assembly additionalcaution should be given to:

•Towing a trailer.

•Driving vehicles equipped with a camperbody.

•Driving vehicles with a load on the cargorack.

Drive cautiously when using a full-sizedissimilar spare wheel and tire assembly andseek service as soon as possible.

Tire Change Procedure

WARNING: When one of the frontwheels is off the ground, the transmissionalone will not prevent the vehicle frommoving or slipping off the jack, even if thetransmission is in park (P).

WARNING: To help prevent yourvehicle from moving when changing awheel, shift the transmission into park (P),set the parking brake and use anappropriate block or wheel chock tosecure the wheel diagonally opposite tothe wheel being changed. For example,when changing the front left wheel, placean appropriate block or wheel chock onthe right rear wheel.

WARNING: No person should placeany portion of their body under a vehiclethat is supported by a jack.

WARNING: Do not attempt to changea tire on the side of the vehicle close tomoving traffic. Pull far enough off the roadto avoid the danger of being hit whenoperating the jack or changing the wheel.

WARNING: Always use the jackprovided as original equipment with yourvehicle. If using a jack other than the oneprovided, make sure the jack capacity isadequate for the vehicle weight, includingany vehicle cargo or modifications. If youare unsure if the jack capacity is adequate,contact the authorized dealer.

Note:Passengers should not remain in yourvehicle when the vehicle is being jacked.

Note:Jack at the specified locations to avoiddamage to the vehicle.

Note:If your vehicle came equipped with anextra full size wheel and tire assembly(placed in the cargo area), be sure to storethe wheel and tire assembly outside of thevehicle after delivery (livery vehicles only).

335

MKT (TP4) , enUSA, Edition date: 201803, Second-Printing

Wheels and Tires

Page 339 of 575

Non-Limousine

Note:If the third row seat is stowed in thefloor, you will need to unstow it to accessthe spare tire.

1. Park on a level surface, set the parkingbrake and activate the hazard flashers.

2. Place the transmission in park (P) andturn the engine off.

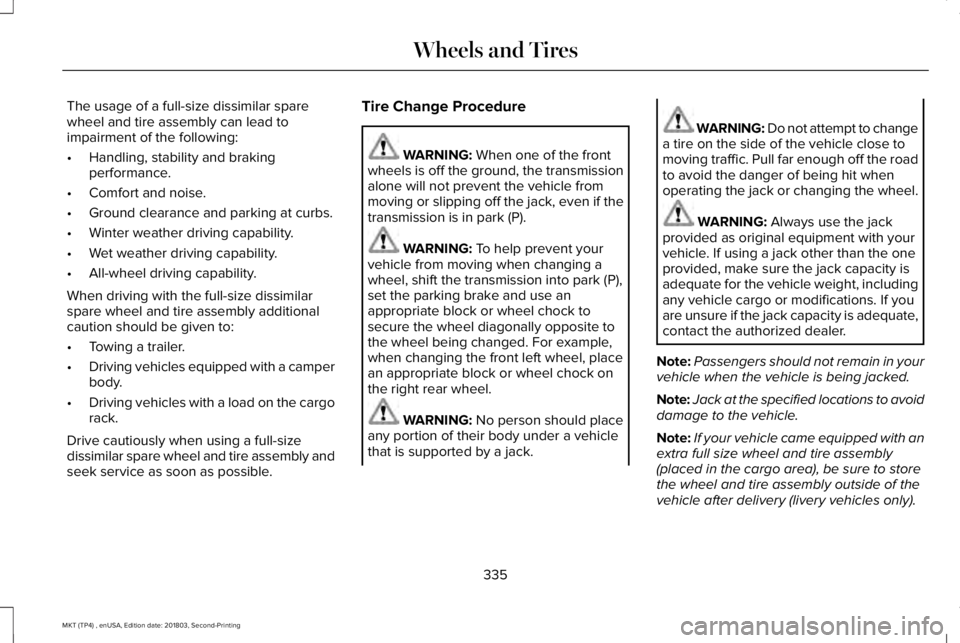

3. Block the diagonally opposite wheel.

4.Remove the carpeted floor panel locatedin the rear of the vehicle, then removethe wing nut that secures the spare tireby turning it counterclockwise.

5. Lift and remove the spare tire from thetrunk.

6. Remove the second wing nut thatsecures the jack retention bracket byturning it counterclockwise. Then removethe jack kit from the vehicle.

7.Remove the jack, L-shaped bolt, and thewrench from the felt bag. Fold down thewrench socket to use to loosen the lugnuts and to operate the jack.

8. Remove the wheel cover with the lugwrench tip and loosen each wheel lugnut one-half turn counterclockwise, butdo not remove them until the wheel israised off the ground.

9. The vehicle jacking points are shownabove, and are depicted on the warninglabel on the jack.

336

MKT (TP4) , enUSA, Edition date: 201803, Second-Printing

Wheels and TiresE142551 E211099 E145908

Page 340 of 575

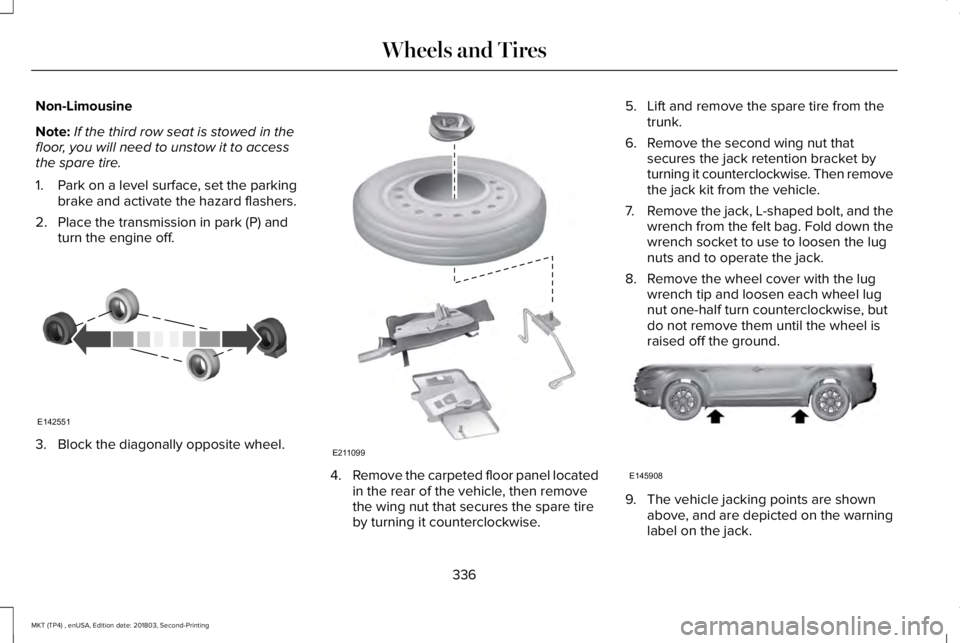

10. Put the jack in the jack notch next tothe tire you are changing. Turn the jackhandle clockwise until the wheel iscompletely off the ground.

11. Remove the lug nuts with the lugwrench.

12.Replace the flat tire with the spare tire,making sure the valve stem is facingoutward. Reinstall the lug nuts until thewheel is snug against the hub. Do notfully tighten the lug nuts until the wheelhas been lowered.

13. Lower the wheel by turning the jackhandle counterclockwise.

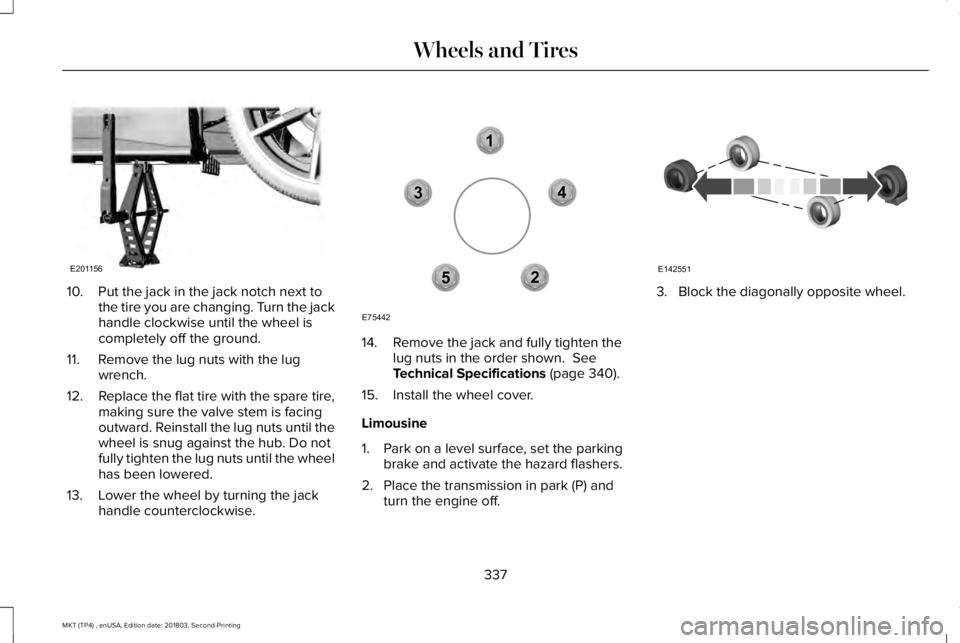

14. Remove the jack and fully tighten thelug nuts in the order shown. SeeTechnical Specifications (page 340).

15. Install the wheel cover.

Limousine

1. Park on a level surface, set the parkingbrake and activate the hazard flashers.

2. Place the transmission in park (P) andturn the engine off.

3. Block the diagonally opposite wheel.

337

MKT (TP4) , enUSA, Edition date: 201803, Second-Printing

Wheels and TiresE201156 12

3

4

5

E75442 E142551

Page 341 of 575

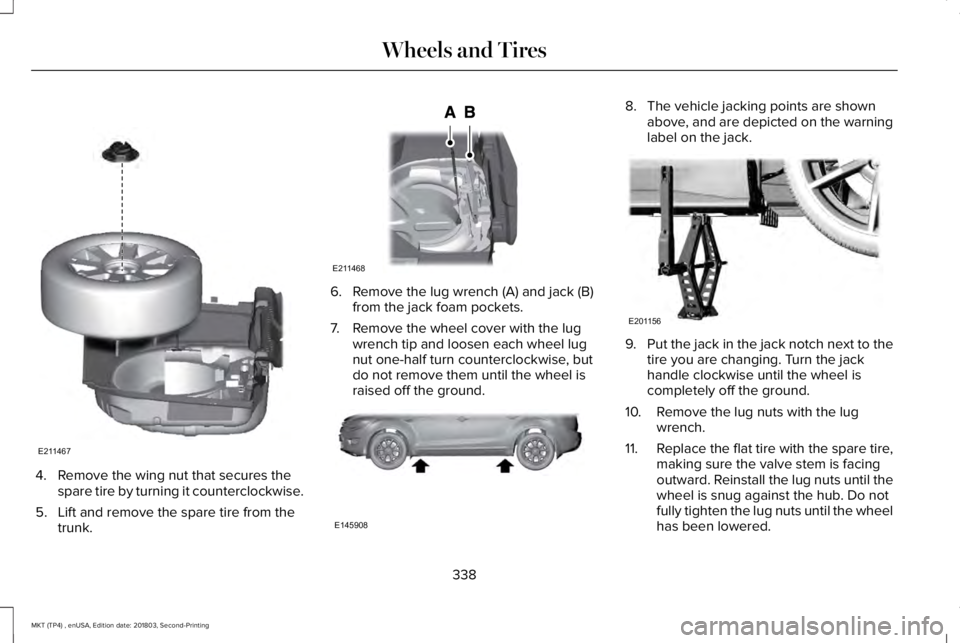

4. Remove the wing nut that secures thespare tire by turning it counterclockwise.

5. Lift and remove the spare tire from thetrunk.

6. Remove the lug wrench (A) and jack (B)from the jack foam pockets.

7. Remove the wheel cover with the lugwrench tip and loosen each wheel lugnut one-half turn counterclockwise, butdo not remove them until the wheel israised off the ground.

8. The vehicle jacking points are shownabove, and are depicted on the warninglabel on the jack.

9.Put the jack in the jack notch next to thetire you are changing. Turn the jackhandle clockwise until the wheel iscompletely off the ground.

10. Remove the lug nuts with the lugwrench.

11.Replace the flat tire with the spare tire,making sure the valve stem is facingoutward. Reinstall the lug nuts until thewheel is snug against the hub. Do notfully tighten the lug nuts until the wheelhas been lowered.

338

MKT (TP4) , enUSA, Edition date: 201803, Second-Printing

Wheels and TiresE211467 E211468 E145908 E201156

Page 342 of 575

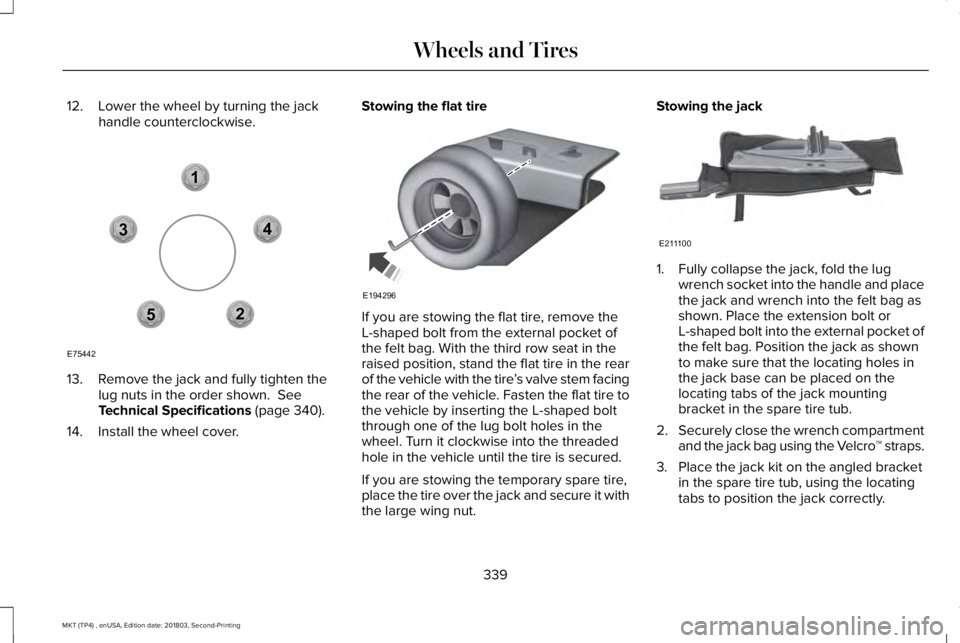

12. Lower the wheel by turning the jackhandle counterclockwise.

13. Remove the jack and fully tighten thelug nuts in the order shown. SeeTechnical Specifications (page 340).

14. Install the wheel cover.

Stowing the flat tire

If you are stowing the flat tire, remove theL-shaped bolt from the external pocket ofthe felt bag. With the third row seat in theraised position, stand the flat tire in the rearof the vehicle with the tire’s valve stem facingthe rear of the vehicle. Fasten the flat tire tothe vehicle by inserting the L-shaped boltthrough one of the lug bolt holes in thewheel. Turn it clockwise into the threadedhole in the vehicle until the tire is secured.

If you are stowing the temporary spare tire,place the tire over the jack and secure it withthe large wing nut.

Stowing the jack

1. Fully collapse the jack, fold the lugwrench socket into the handle and placethe jack and wrench into the felt bag asshown. Place the extension bolt orL-shaped bolt into the external pocket ofthe felt bag. Position the jack as shownto make sure that the locating holes inthe jack base can be placed on thelocating tabs of the jack mountingbracket in the spare tire tub.

2.Securely close the wrench compartmentand the jack bag using the Velcro™ straps.

3. Place the jack kit on the angled bracketin the spare tire tub, using the locatingtabs to position the jack correctly.

339

MKT (TP4) , enUSA, Edition date: 201803, Second-Printing

Wheels and Tires12

3

4

5

E75442 E194296 E211100

Page 356 of 575

SpecificationName

ESB-M1C93-BMulti-purpose grease:Motorcraft® Multi-Purpose Grease SprayXL-5-A

-Lock cylinders (U.S.):Penetrating and Lock LubricantXL-1

-Lock cylinders (Canada):Penetrating FluidCXC-51-A

If you use oil and fluids that do not meet thedefined specification and viscosity grade,this may lead to:

•Component damage which is notcovered by the vehicle warranty.

•Longer engine cranking periods.

•Increased emission levels.

•Reduced engine performance.

•Reduced fuel economy.

•Degraded brake performance.

We recommend Motorcraft® motor oil foryour vehicle. If Motorcraft® oil is notavailable, use motor oils of therecommended viscosity grade that meet APISN requirements and display the APICertification Mark for gasoline engines. Donot use oil labeled with API SN servicecategory unless the label also displays theAPI certification mark.

353

MKT (TP4) , enUSA, Edition date: 201803, Second-Printing

Capacities and SpecificationsE142732