LINCOLN MKX 2017 Owners Manual

Manufacturer: LINCOLN, Model Year: 2017, Model line: MKX, Model: LINCOLN MKX 2017Pages: 587, PDF Size: 5.4 MB

Page 371 of 587

This device complies with Part 15 of the FCC

Rules and with Industry Canada

license-exempt RSS standard(s). Operation

is subject to the following two conditions:

•

This device may not cause harmful

interference.

• This device must accept any interference

received, including interference that may

cause undesired operation.

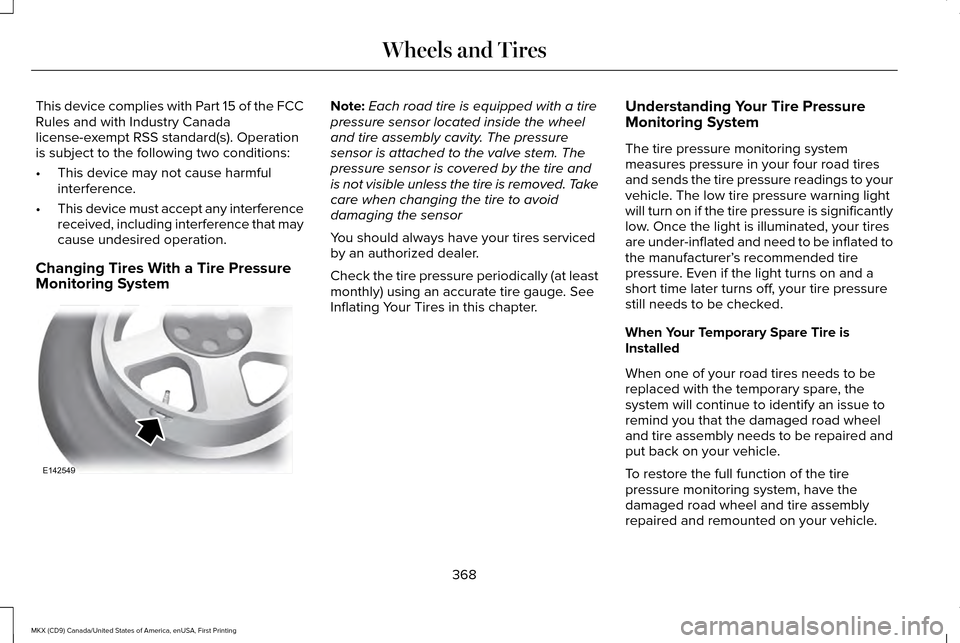

Changing Tires With a Tire Pressure

Monitoring System Note:

Each road tire is equipped with a tire

pressure sensor located inside the wheel

and tire assembly cavity. The pressure

sensor is attached to the valve stem. The

pressure sensor is covered by the tire and

is not visible unless the tire is removed. Take

care when changing the tire to avoid

damaging the sensor

You should always have your tires serviced

by an authorized dealer.

Check the tire pressure periodically (at least

monthly) using an accurate tire gauge. See

Inflating Your Tires in this chapter. Understanding Your Tire Pressure

Monitoring System

The tire pressure monitoring system

measures pressure in your four road tires

and sends the tire pressure readings to your

vehicle. The low tire pressure warning light

will turn on if the tire pressure is significantly

low. Once the light is illuminated, your tires

are under-inflated and need to be inflated to

the manufacturer’

s recommended tire

pressure. Even if the light turns on and a

short time later turns off, your tire pressure

still needs to be checked.

When Your Temporary Spare Tire is

Installed

When one of your road tires needs to be

replaced with the temporary spare, the

system will continue to identify an issue to

remind you that the damaged road wheel

and tire assembly needs to be repaired and

put back on your vehicle.

To restore the full function of the tire

pressure monitoring system, have the

damaged road wheel and tire assembly

repaired and remounted on your vehicle.

368

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and TiresE142549

Page 372 of 587

When You Believe Your System is Not

Operating Properly

The main function of the tire pressure

monitoring system is to warn you when your

tires need air. It can also warn you in the

event the system is no longer capable of

functioning as intended. See the following

chart for information concerning your tire

pressure monitoring system:

369

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 373 of 587

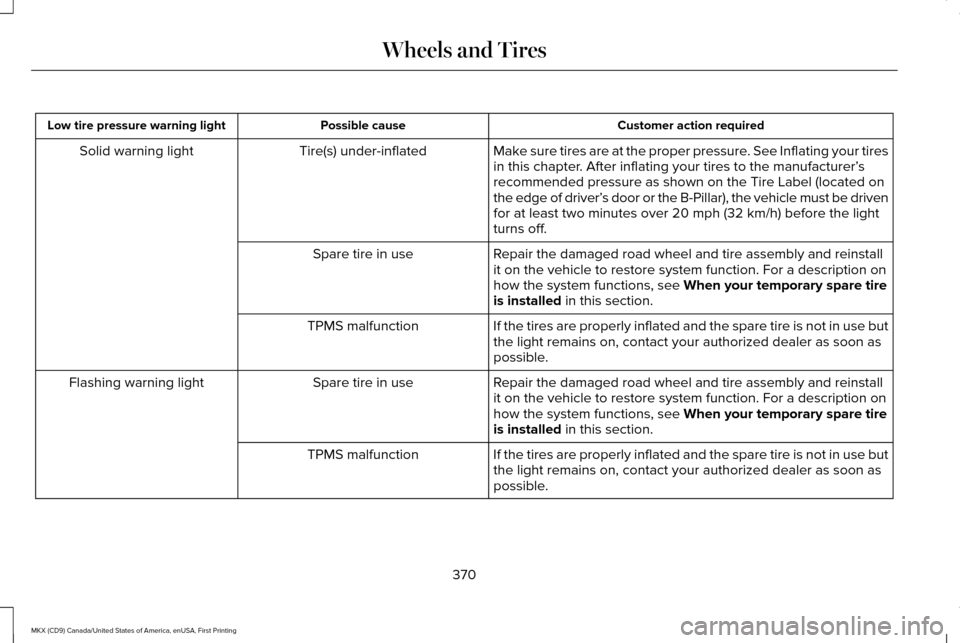

Customer action required

Possible cause

Low tire pressure warning light

Make sure tires are at the proper pressure. See Inflating your tires

in this chapter. After inflating your tires to the manufacturer’s

recommended pressure as shown on the Tire Label (located on

the edge of driver’ s door or the B-Pillar), the vehicle must be driven

for at least two minutes over 20 mph (32 km/h) before the light

turns off.

Tire(s) under-inflated

Solid warning light

Repair the damaged road wheel and tire assembly and reinstall

it on the vehicle to restore system function. For a description on

how the system functions, see

When your temporary spare tire

is installed in this section.

Spare tire in use

If the tires are properly inflated and the spare tire is not in use but

the light remains on, contact your authorized dealer as soon as

possible.

TPMS malfunction

Repair the damaged road wheel and tire assembly and reinstall

it on the vehicle to restore system function. For a description on

how the system functions, see

When your temporary spare tire

is installed in this section.

Spare tire in use

Flashing warning light

If the tires are properly inflated and the spare tire is not in use but

the light remains on, contact your authorized dealer as soon as

possible.

TPMS malfunction

370

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 374 of 587

When Inflating Your Tires

When putting air into your tires (such as at a

gas station or in your garage), the tire

pressure monitoring system may not respond

immediately to the air added to your tires.

It may take up to two minutes of driving over

20 mph (32 km/h) for the light to turn off after

you have filled your tires to the

recommended inflation pressure

How Temperature Affects Your Tire

Pressure

The tire pressure monitoring system monitors

tire pressure in each pneumatic tire. While

driving in a normal manner, a typical

passenger tire inflation pressure may

increase about 2–4 psi (14–28 kPa) from a

cold start situation. If the vehicle is stationary

overnight with the outside temperature

significantly lower than the daytime

temperature, the tire pressure may decrease

about

3 psi (21 kPa) for a drop of 30°F (17°C)

in ambient temperature. This lower pressure

value may be detected by the tire pressure

monitoring system as being significantly

lower than the recommended inflation pressure and activate the system warning

light for low tire pressure. If the low tire

pressure warning light is on, visually check

each tire to verify that no tire is flat. If one or

more tires are flat, repair as necessary.

Check the air pressure in the road tires. If

any tire is under-inflated, carefully drive the

vehicle to the nearest location where air can

be added to the tires. Inflate all the tires to

the recommended inflation pressure.

CHANGING A ROAD WHEEL

WARNINGS

Do not use tire sealants as they may

damage the tire pressure monitoring

system. If the tire pressure monitor sensor

becomes damaged it may not function. Note:

The use of tire sealant may damage

your tire pressure monitoring system and

should only be used in roadside

emergencies. If you must use a sealant, the

Ford Tire Mobility Kit sealant should be used.

The tire pressure monitoring system sensor

and valve stem on the wheel must be

replaced by an authorized dealer after use

of the sealant.

Note: The tire pressure monitoring system

indicator light will illuminate when the spare

tire is in use. To restore the full function of

the monitoring system, all road wheels

equipped with tire pressure monitoring

sensors must be mounted on the vehicle.

If you get a flat tire while driving, do not apply

the brake heavily. Instead, gradually

decrease your speed. Hold the steering

wheel firmly and slowly move to a safe place

on the side of the road.

371

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 375 of 587

Have a flat serviced by an authorized dealer

in order to prevent damage to the tire

pressure monitoring system sensors. See

Tire Pressure Monitoring System (page 367).

Replace the spare tire with a road tire as

soon as possible. During repairing or

replacing of the flat tire, have an authorized

dealer inspect the tire pressure monitoring

system sensor for damage.

Dissimilar Spare Wheel and Tire

Assembly Information WARNING

Failure to follow these guidelines could

result in an increased risk of loss of

vehicle control, injury or death. If you have a dissimilar spare wheel and tire,

then it is intended for temporary use only.

This means that if you need to use it, you

should replace it as soon as possible with a

road wheel and tire assembly that is the

same size and type as the road tires and

wheels that were originally provided by Ford.

If the dissimilar spare tire or wheel is

damaged, it should be replaced rather than

repaired.

A dissimilar spare wheel and tire assembly

is defined as a spare wheel and tire assembly

that is different in brand, size or appearance

from the road tires and wheels and can be

one of three types:

1.

T-type mini-spare: This spare tire begins

with the letter T for tire size and may have

Temporary Use Only molded in the sidewall.

2.

Full-size dissimilar spare with label on

wheel: This spare tire has a label on the

wheel that states: THIS WHEEL AND TIRE

ASSEMBLY FOR TEMPORARY USE ONLY.

When driving with one of the dissimilar spare

tires listed above, do not: •

Exceed

50 mph (80 km/h).

• Load the vehicle beyond maximum

vehicle load rating listed on the Safety

Compliance Label.

• Tow a trailer.

• Use snow chains on the end of the

vehicle with the dissimilar spare tire.

• Use more than one dissimilar spare tire

at a time.

• Use commercial car washing equipment.

• Try to repair the dissimilar spare tire.

Use of one of the dissimilar spare tires listed

above at any one wheel location can lead to

impairment of the following:

• Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability.

• Wet weather driving capability.

• All-wheel driving capability (if applicable).

3.

Full-size dissimilar spare without label

on wheel

372

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 376 of 587

When driving with the full-size dissimilar

spare wheel and tire assembly, do not:

•

Exceed 70 mph (113 km/h).

• Use more than one dissimilar spare

wheel and tire assembly at a time.

• Use commercial car washing equipment.

• Use snow chains on the end of the

vehicle with the dissimilar spare wheel

and tire assembly.

The usage of a full-size dissimilar spare

wheel and tire assembly can lead to

impairment of the following:

• Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability.

• Wet weather driving capability.

• All-wheel driving capability. When driving with the full-size dissimilar

spare wheel and tire assembly additional

caution should be given to:

•

Towing a trailer.

• Driving vehicles equipped with a camper

body.

• Driving vehicles with a load on the cargo

rack.

Drive cautiously when using a full-size

dissimilar spare wheel and tire assembly and

seek service as soon as possible.

Tire Change Procedure

(If Equipped) WARNINGS

When one of the front wheels is off the

ground, the transmission alone will not

prevent the vehicle from moving or slipping

off the jack, even if the transmission is in park

(P). WARNINGS

To help prevent your vehicle from

moving when changing a wheel, shift

the transmission into park (P), set the parking

brake and use an appropriate block or wheel

chock to secure the wheel diagonally

opposite to the wheel being changed. For

example, when changing the front left wheel,

place an appropriate block or wheel chock

on the right rear wheel. No person should place any portion of

their body under a vehicle that is

supported by a jack. Do not attempt to change a tire on the

side of the vehicle close to moving

traffic. Pull far enough off the road to avoid

the danger of being hit when operating the

jack or changing the wheel. Always use the jack provided as

original equipment with your vehicle.

If using a jack other than the one provided,

make sure the jack capacity is adequate for

the vehicle weight, including any vehicle

cargo or modifications. If you are unsure if

the jack capacity is adequate, contact the

authorized dealer. 373

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 377 of 587

Note:

Passengers should not remain in your

vehicle when the vehicle is being jacked.

1. Park on a level surface, set the parking brake and activate the hazard flashers.

2. Place the transmission in park (P) and turn the engine off. 3.

Block both the front and rear of the wheel

diagonally opposite the flat tire. For

example, if the left front tire is flat, block

the right rear wheel.

4. Lift and remove the carpeted load floor panel to access the minispare and jack

kit. 5. Remove the steel winged washer nut

securing the spare tire by turning it

counterclockwise.

6. Remove the spare tire from the spare tire

compartment.

7. Remove plastic wing nut and jack and lug wrench assembly. Detach lug wrench

from jack by turning the jack hex nut

drive screw counterclockwise.

8. Loosen each wheel lug nut one-half turn

counterclockwise, but do not remove

them until the wheel is raised off the

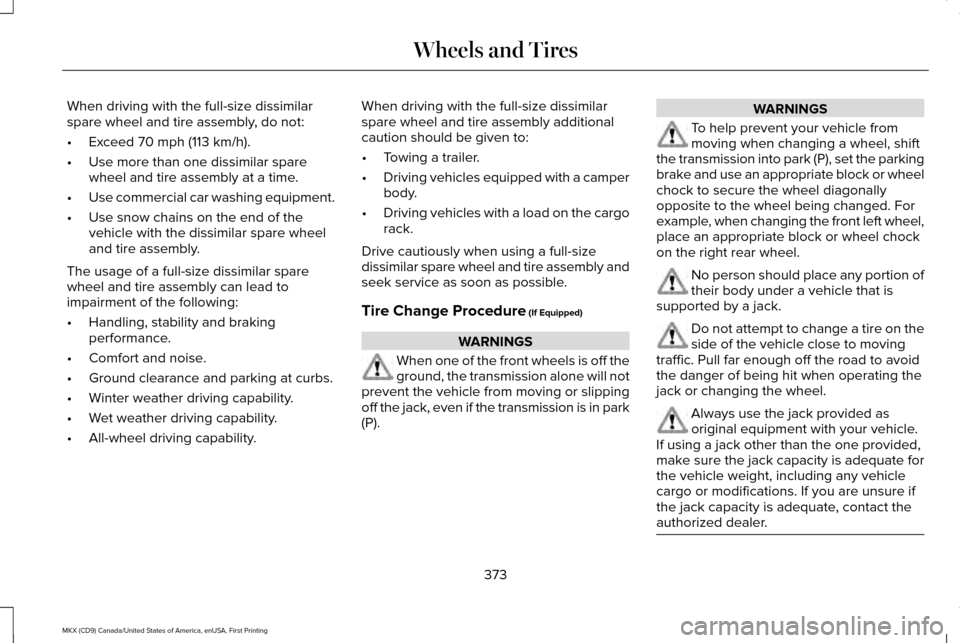

ground. 9. The vehicle jacking points are depicted

by arrows on the underside of the vehicle

at the locations shown above. 10. Position the jack so that the vehicle

downward flange rests in the jack

saddle flange as shown above. Raise

the vehicle by using the lug wrench to

turn the jack nut clockwise. Once the

flat tire is raised above the ground,

remove the lug nuts with the lug

wrench.

374

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and TiresE175447 E242877 E201100

Page 378 of 587

11.

Replace the flat tire with the spare tire,

making sure the valve stem is facing

outward. Reinstall the lug nuts until the

wheel is snug against the hub. Do not

fully tighten the lug nuts until the wheel

has been lowered.

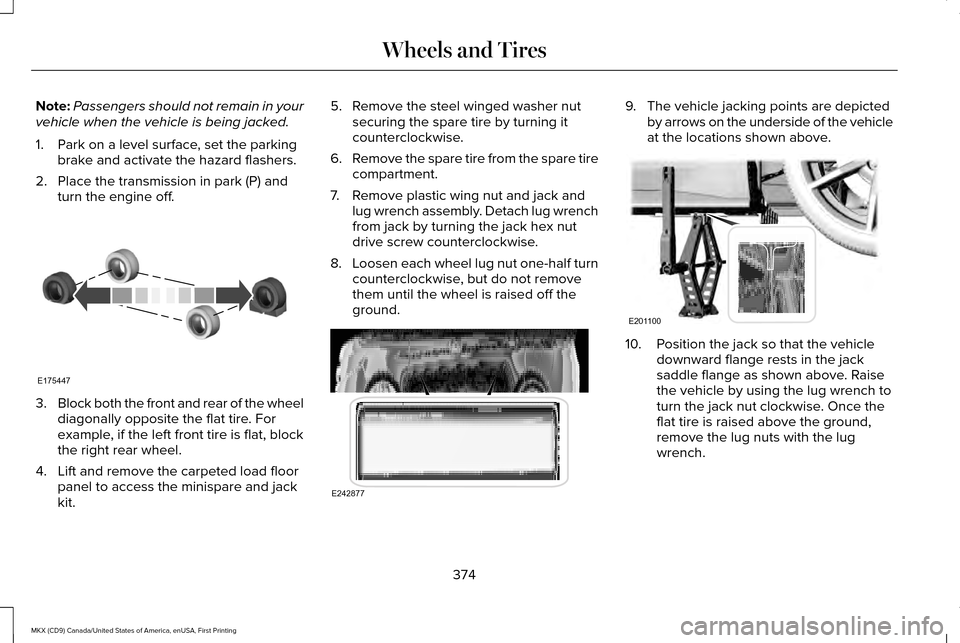

12. Lower the wheel by turning the jack handle counterclockwise. 13. Remove the jack and fully tighten the

lug nuts in the order shown. See

Technical Specifications (page 377).

14. Fold up the wrench/jack handle and re-attach to the jack. Re-position

jack/wrench assembly into the original

vehicle position and secure with the

plastic wing nut. Make sure the jack is

fastened securely before you drive.

15. Unblock the wheel.

Stowing the flat tire

You cannot store the full-sized road wheel

in the temporary spare tire well.

1. Find the flat tire retainer strap tucked inside the jack channel. Lower the

carpeted load floor.

2. Stow the flat tire in the cargo area on the

load floor with the wheel facing up.

Secure the flat tire with the retainer strap

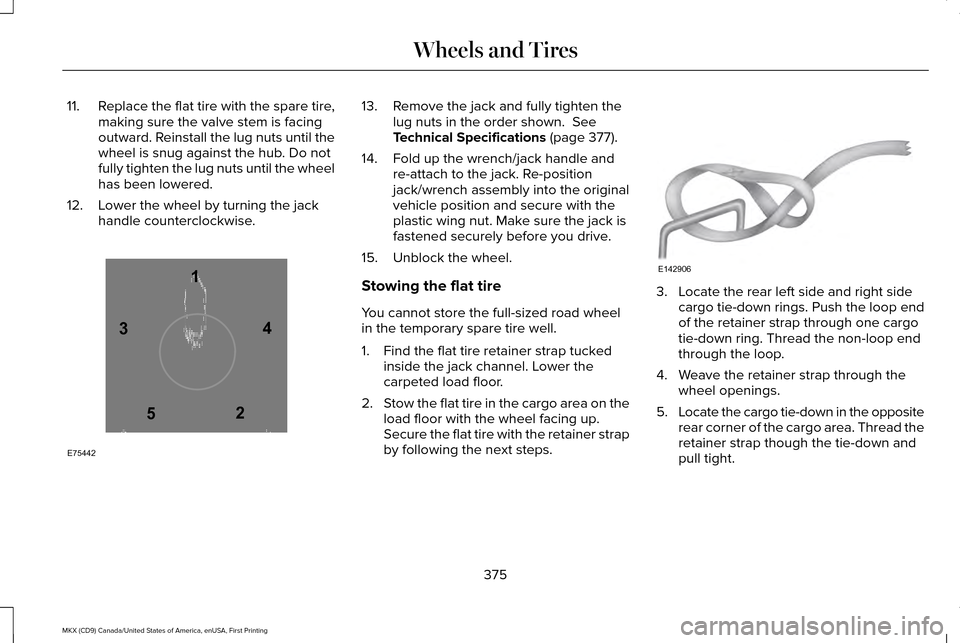

by following the next steps. 3. Locate the rear left side and right side

cargo tie-down rings. Push the loop end

of the retainer strap through one cargo

tie-down ring. Thread the non-loop end

through the loop.

4. Weave the retainer strap through the wheel openings.

5. Locate the cargo tie-down in the opposite

rear corner of the cargo area. Thread the

retainer strap though the tie-down and

pull tight.

375

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and Tires12

3

4

5

E75442 E142906

Page 379 of 587

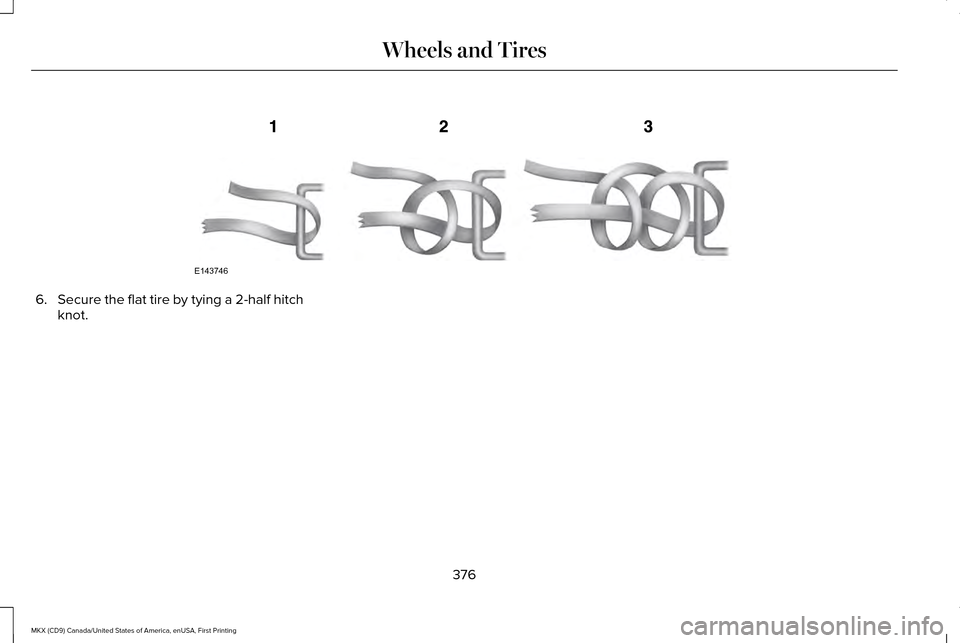

6.

Secure the flat tire by tying a 2-half hitch

knot.

376

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and TiresE143746

Page 380 of 587

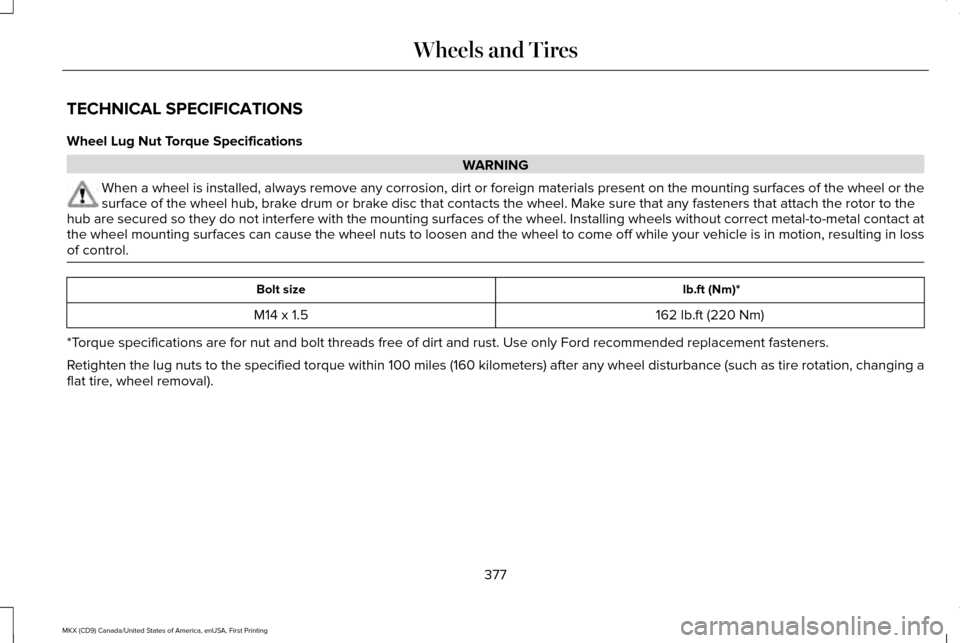

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications

WARNING

When a wheel is installed, always remove any corrosion, dirt or foreign \

materials present on the mounting surfaces of the wheel or the

surface of the wheel hub, brake drum or brake disc that contacts the wheel. Make sure that any fasteners that attach the rotor to the

hub are secured so they do not interfere with the mounting surfaces of t\

he wheel. Installing wheels without correct metal-to-metal contact at

the wheel mounting surfaces can cause the wheel nuts to loosen and the w\

heel to come off while your vehicle is in motion, resulting in loss

of control. lb.ft (Nm)*

Bolt size

162 lb.ft (220 Nm)

M14 x 1.5

*Torque specifications are for nut and bolt threads free of dirt and rust.\

Use only Ford recommended replacement fasteners.

Retighten the lug nuts to the specified torque within 100 miles (160 kil\

ometers) after any wheel disturbance (such as tire rotation, changing \

a

flat tire, wheel removal).

377

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and Tires