engine LINCOLN MKZ 2015 Owners Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2015, Model line: MKZ, Model: LINCOLN MKZ 2015Pages: 516, PDF Size: 4.48 MB

Page 321 of 516

Air pressure gauge

D

Sealant bottle and canister

E

Dual purpose hose: air and repair

F

Tire valve connector

G

Accessory power plug

H

Casing/housing

I

Bike/raft/sports ball adapters

J

General Information WARNING

Failure to follow these guidelines could

result in an increased risk of loss of

vehicle control, injury or death. Note:

Do not use the kit if a tire has become

severely damaged. Only punctures located

within the tire tread can be sealed with the

kit.

Do not attempt to repair punctures larger

than ¼ inch (6 millimeters) or damage to the

tire's sidewall. The tire may not completely

seal. Loss of air pressure may adversely affect tire

performance. For this reason:

Note:

Do not drive the vehicle above 50 mph

(80 km/h).

Note: Do not drive further than

120 mi

(200 km). Drive only to the closest authorized

Ford dealer or tire repair shop to have your

tire inspected.

• Drive carefully and avoid abrupt steering

maneuvers.

• Periodically monitor tire inflation pressure

in the affected tire; if the tire is losing

pressure, have the vehicle towed.

• Read the information in the Tips for Use

of the Kit section to make sure safe

operation of the kit and your vehicle.

Tips for Use of the Kit

To ensure safe operation of the kit:

• Read all instructions and cautions fully.

• Before operating the kit, make sure your

vehicle is safely off the road and away

from moving traffic. Turn on the hazard

lights. •

Always set the parking brake to ensure

the vehicle doesn't move unexpectedly.

• Do not remove any foreign objects, such

as nails or screws, from the tire.

• When using the kit, leave the engine

running (only if the vehicle is outdoors or

in a well-ventilated area) so the

compressor does not drain the vehicle's

battery.

• Do not allow the compressor to operate

continuously for more than 15 minutes.

This will help prevent the compressor

from overheating.

• Never leave the kit unattended during

operation.

• Sealant compound contains latex. Those

with latex sensitivities should use

appropriate precautions to avoid an

allergic reaction.

• Keep the kit away from children.

• Only use the kit when the ambient

temperature is between -22°F (-30°C) and

158°F (70°C)

.

318

MKZ (), enUSA Wheels and Tires

Page 322 of 516

•

Only use the sealing compound before

the use-by date. The use-by date is on a

label on the sealant canister and can be

seen through the rectangular viewing

window on the bottom of the compressor.

Check the use-by date regularly and

replace the canister after four years of

non-use.

• Do not store the kit unsecured inside the

passenger compartment of the vehicle

as it may cause injury during a sudden

stop or crash. Always store the kit in its

original location.

• After sealant use, the tire pressure

monitoring system sensor and valve stem

on the wheel must be replaced by an

authorized Ford dealer.

• Operating the kit could cause an

electrical disturbance in radio, CD, and

DVD player operation. * When inflation only is required for

a tire or other objects, the selector

must be in the Air position. What to do when a Tire Is Punctured

A tire puncture within the tire's tread area

can be repaired in two stages with the kit.

•

In the first stage, the tire will be reinflated

with a sealing compound and air. After

the tire has been inflated, you will need

to drive the vehicle a short distance

(about 4 miles [6 kilometers]) to distribute

the sealant in the tire.

• In the second stage, you will need to

check the tire pressure and adjust, if

necessary, to the vehicle's specified tire

inflation pressure.

First Stage: Reinflating the Tire with

Sealing Compound and Air WARNINGS

Do not stand directly over the kit while

inflating the tire. If you notice any

unusual bulges or deformations in the tire's

sidewall during inflation, stop and call

roadside assistance. If the tire does not inflate to the

recommended tire pressure within 15

minutes, stop and call roadside assistance. WARNINGS

Do not run the engine during kit

operation unless the vehicle is

outdoors or in a well-ventilated area. Preparation: Park the vehicle in a safe, level

and secure area, away from moving traffic.

Turn the hazard lights on. Apply the parking

brake and turn the engine off. Inspect the

flat tire for visible damage.

Sealant compound contains latex. Use

appropriate precautions to avoid any allergic

reactions.

Do not remove any foreign object that has

pierced the tire. If a puncture is located in

the tire sidewall, stop and call roadside

assistance.

1.

Remove the valve cap from the tire valve.

2. Unwrap the dual purpose hose (black tube) from the back of the compressor

housing.

3. Fasten the hose to the tire valve by turning the connector clockwise. Tighten

the connection securely.

319

MKZ (), enUSA Wheels and TiresE175978

Page 323 of 516

4. Plug the power cable into the 12-volt

power point in the vehicle. 5.

Remove the warning sticker found on the

casing/housing and place it on the top of

the instrument panel or the center of the

dash.

6. Start the vehicle leave the engine running

so the compressor does not drain the

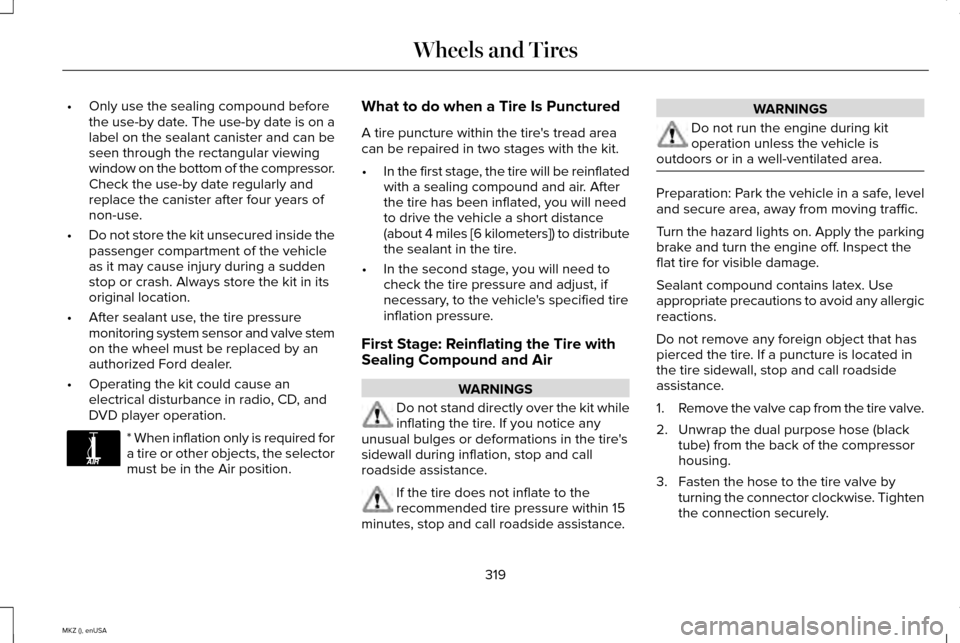

vehicle ’s battery. 7. Turn dial (A) clockwise to the sealant

position. Turn the kit on by pressing the

on/off button (B).

320

MKZ (), enUSA Wheels and TiresE175979 E175981

Page 348 of 516

•

Wet weather driving capability.

• All-wheel driving capability

When driving with the full-size dissimilar

spare wheel and tire assembly additional

caution should be given to:

• Towing a trailer.

• Driving vehicles equipped with a camper

body.

• Driving vehicles with a load on the cargo

rack.

Drive cautiously when using a full-size

dissimilar spare wheel and tire assembly and

seek service as soon as possible.

Tire Change Procedure (If Equipped) WARNINGS

When one of the front wheels is off the

ground, the transmission alone will not

prevent the vehicle from moving or slipping

off the jack, even if the transmission is in park

(P). WARNINGS

To help prevent your vehicle from

moving when you change a tire, be

sure to place the transmission in park (P), set

the parking brake and block (in both

directions) the wheel that is diagonally

opposite (other side and end of the vehicle)

to the tire being changed. Never get underneath a vehicle that is

supported only by a jack. If your vehicle

slips off the jack, you or someone else could

be seriously injured. Do not attempt to change a tire on the

side of the vehicle close to moving

traffic. Pull far enough off the road to avoid

the danger of being hit when operating the

jack or changing the wheel. Always use the jack provided as

original equipment with your vehicle.

If using a jack other than the one provided

as original equipment with your vehicle,

make sure the jack capacity is adequate for

the vehicle weight, including any vehicle

cargo or modifications. Note:

Passengers should not remain in your

vehicle when the vehicle is being jacked.

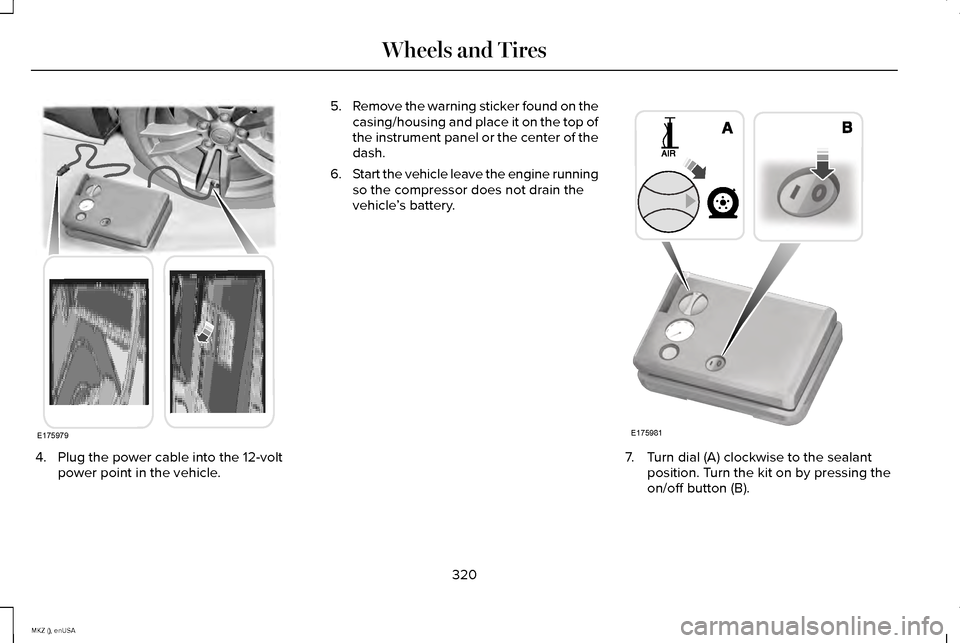

Type 1

1. Park on a level surface, set the parking brake and activate the hazard flashers.

2. Place the transmission in park (P) and turn the engine off. For vehicles with a

manual transmission, place the

transmission in reverse (R) after the

engine is turned off. 3.

Block both the front and rear of the wheel

diagonally opposite the flat tire. For

example, if the left front tire is flat, block

the right rear wheel.

345

MKZ (), enUSA Wheels and TiresE175447

Page 350 of 516

11. Remove the lug nuts with the lug

wrench.

12. Replace the flat tire with the spare tire,

making sure the valve stem is facing

outward. Reinstall the lug nuts until the

wheel is snug against the hub. Do not

fully tighten the lug nuts until the wheel

has been lowered. If you are using the

temporary tire, the lug nut washers will

not appear to be flush with the rim. This

is normal only when using the

temporary spare tire.

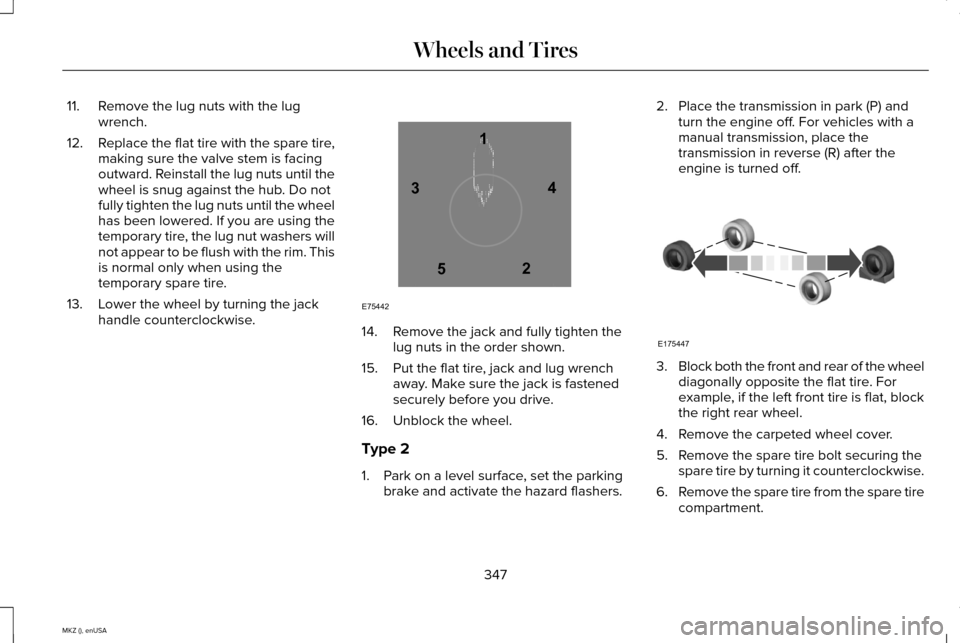

13. Lower the wheel by turning the jack handle counterclockwise. 14. Remove the jack and fully tighten the

lug nuts in the order shown.

15. Put the flat tire, jack and lug wrench away. Make sure the jack is fastened

securely before you drive.

16. Unblock the wheel.

Type 2

1. Park on a level surface, set the parking brake and activate the hazard flashers. 2. Place the transmission in park (P) and

turn the engine off. For vehicles with a

manual transmission, place the

transmission in reverse (R) after the

engine is turned off. 3.

Block both the front and rear of the wheel

diagonally opposite the flat tire. For

example, if the left front tire is flat, block

the right rear wheel.

4. Remove the carpeted wheel cover.

5. Remove the spare tire bolt securing the spare tire by turning it counterclockwise.

6. Remove the spare tire from the spare tire

compartment.

347

MKZ (), enUSA Wheels and Tires12

3

4

5

E75442 E175447

Page 356 of 516

ENGINE SPECIFICATIONS

3.7L V6 Engine

2.0L EcoBoost engine

Engine

227

122

Cubic inches

Minimum 87 octane

Minimum 87 octane

Required fuel

10.5:1

9.3:1

Compression ratio

0.049-0.053 in. (1.25-1.35 mm)

0.027-0.031 in. (0.70-0.80 mm)

Spark plug gap

Drivebelt Routing

3.7L Engine 353

MKZ (), enUSA Capacities and SpecificationsE146428

Page 357 of 516

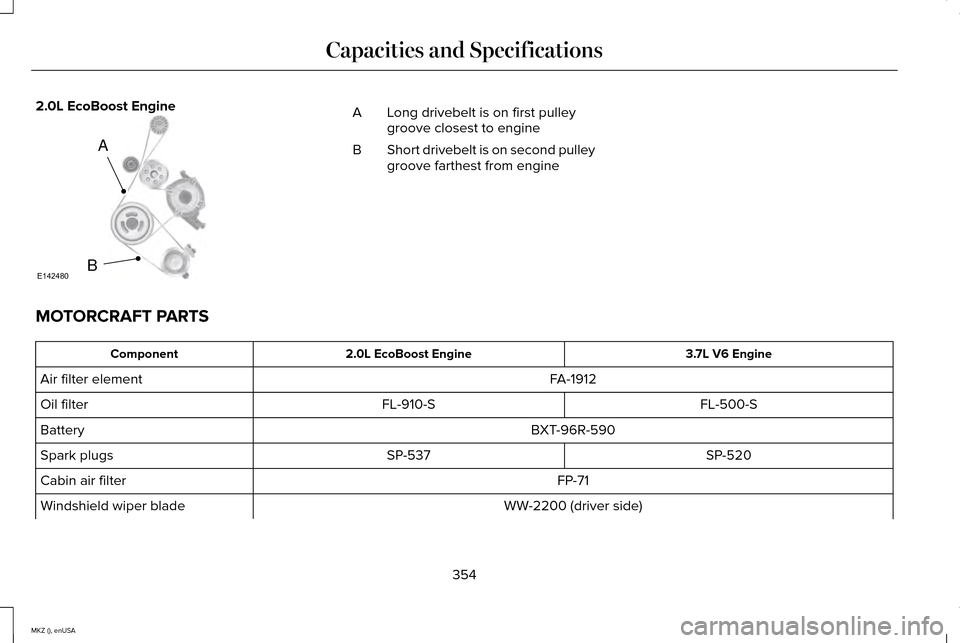

2.0L EcoBoost Engine

Long drivebelt is on first pulley

groove closest to engine

A

Short drivebelt is on second pulley

groove farthest from engine

B

MOTORCRAFT PARTS 3.7L V6 Engine

2.0L EcoBoost Engine

Component

FA-1912

Air filter element

FL-500-S

FL-910-S

Oil filter

BXT-96R-590

Battery

SP-520

SP-537

Spark plugs

FP-71

Cabin air filter

WW-2200 (driver side)

Windshield wiper blade

354

MKZ (), enUSA Capacities and SpecificationsA

BE142480

Page 358 of 516

3.7L V6 Engine

2.0L EcoBoost Engine

Component

WW-1900 (passenger side)

We recommend Motorcraft replacement parts available at your Lincoln deale\

r or at fordparts.com for scheduled maintenance. These parts

meet or exceed Ford Motor Company’ s specifications and are engineered for your vehicle. Use of other parts may impact vehicle performance,

emissions and durability. Your warranty may be void for any damage related to use of other parts.

If a Motorcraft oil filter is not available, use an oil filter that meets industry performance specification SAE/USCAR-36.

For spark plug replacement, contact an authorized dealer. Replace the spark plugs at the appropriate intervals. See Scheduled Maintenance

(page 478).

355

MKZ (), enUSA Capacities and Specifications

Page 359 of 516

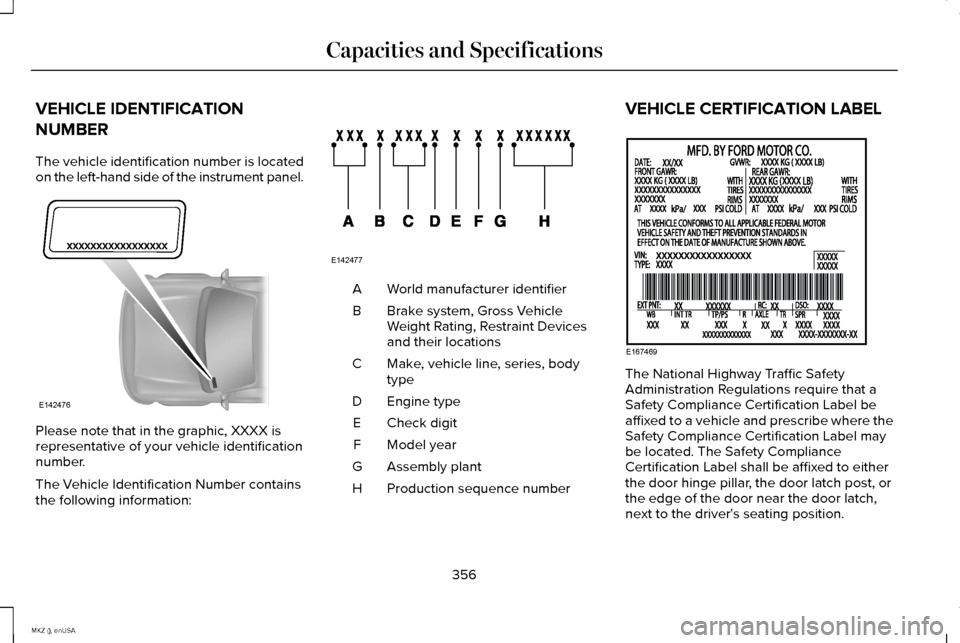

VEHICLE IDENTIFICATION

NUMBER

The vehicle identification number is located

on the left-hand side of the instrument panel.

Please note that in the graphic, XXXX is

representative of your vehicle identification

number.

The Vehicle Identification Number contains

the following information: World manufacturer identifier

A

Brake system, Gross Vehicle

Weight Rating, Restraint Devices

and their locations

B

Make, vehicle line, series, body

type

C

Engine type

D

Check digit

E

Model year

F

Assembly plant

G

Production sequence number

H VEHICLE CERTIFICATION LABEL

The National Highway Traffic Safety

Administration Regulations require that a

Safety Compliance Certification Label be

affixed to a vehicle and prescribe where the

Safety Compliance Certification Label may

be located. The Safety Compliance

Certification Label shall be affixed to either

the door hinge pillar, the door latch post, or

the edge of the door near the door latch,

next to the driver's seating position.

356

MKZ (), enUSA Capacities and SpecificationsE142476 E142477 E167469

Page 361 of 516

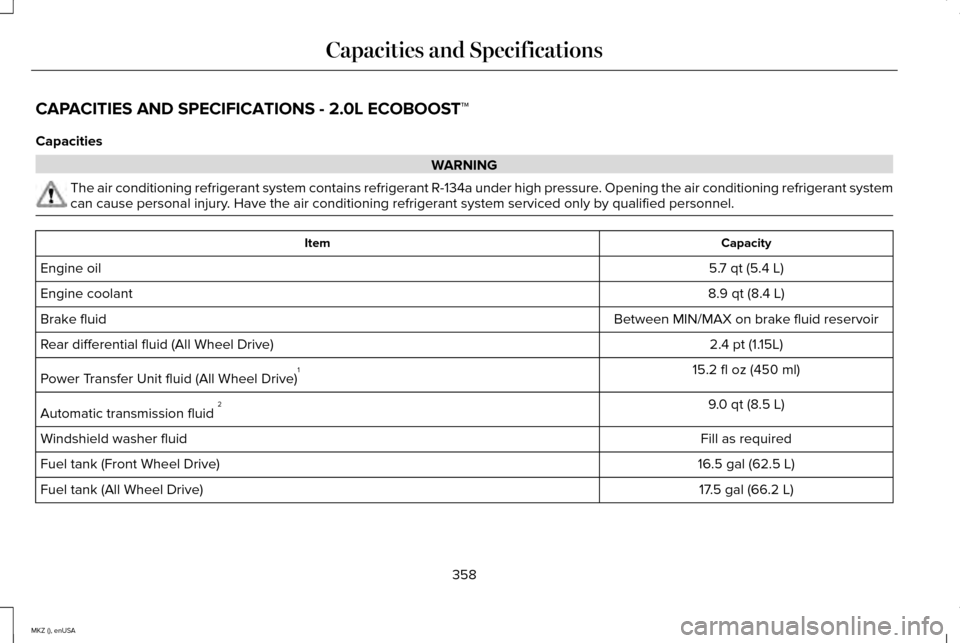

CAPACITIES AND SPECIFICATIONS - 2.0L ECOBOOST™

Capacities

WARNING

The air conditioning refrigerant system contains refrigerant R-134a unde\

r high pressure. Opening the air conditioning refrigerant system

can cause personal injury. Have the air conditioning refrigerant system serviced only by qualifie\

d personnel.

Capacity

Item

5.7 qt (5.4 L)

Engine oil

8.9 qt (8.4 L)

Engine coolant

Between MIN/MAX on brake fluid reservoir

Brake fluid

2.4 pt (1.15L)

Rear differential fluid (All Wheel Drive)

15.2 fl oz (450 ml)

Power Transfer Unit fluid (All Wheel Drive) 1

9.0 qt (8.5 L)

Automatic transmission fluid 2

Fill as required

Windshield washer fluid

16.5 gal (62.5 L)

Fuel tank (Front Wheel Drive)

17.5 gal (66.2 L)

Fuel tank (All Wheel Drive)

358

MKZ (), enUSA Capacities and Specifications