lock LINCOLN MKZ 2015 Manual Online

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2015, Model line: MKZ, Model: LINCOLN MKZ 2015Pages: 516, PDF Size: 4.48 MB

Page 277 of 516

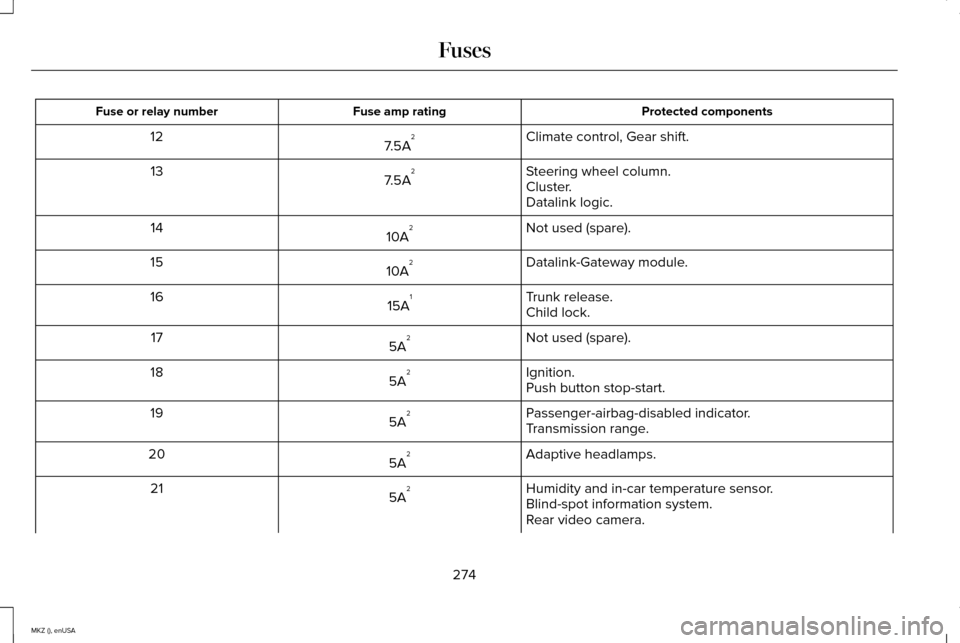

Protected components

Fuse amp rating

Fuse or relay number

Climate control, Gear shift.

7.5A 2

12

Steering wheel column.

7.5A 2

13

Cluster.

Datalink logic.

Not used (spare).

10A 2

14

Datalink-Gateway module.

10A 2

15

Trunk release.

15A 1

16

Child lock.

Not used (spare).

5A 2

17

Ignition.

5A 2

18

Push button stop-start.

Passenger-airbag-disabled indicator.

5A 2

19

Transmission range.

Adaptive headlamps.

5A 2

20

Humidity and in-car temperature sensor.

5A 2

21

Blind-spot information system.

Rear video camera.

274

MKZ (), enUSA Fuses

Page 278 of 516

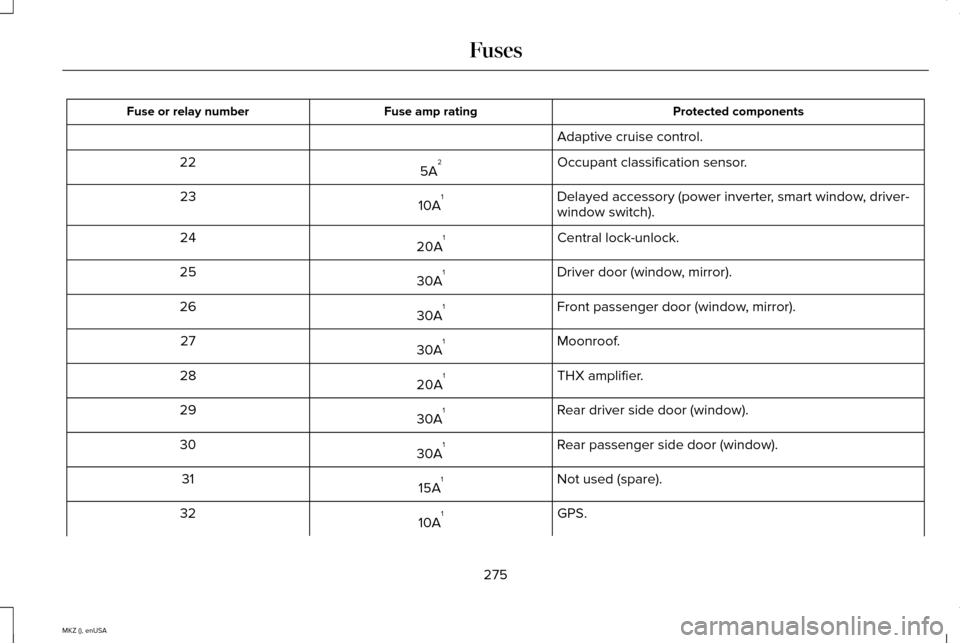

Protected components

Fuse amp rating

Fuse or relay number

Adaptive cruise control.

Occupant classification sensor.

5A 2

22

Delayed accessory (power inverter, smart window, driver-

window switch).

10A 1

23

Central lock-unlock.

20A 1

24

Driver door (window, mirror).

30A 1

25

Front passenger door (window, mirror).

30A 1

26

Moonroof.

30A 1

27

THX amplifier.

20A 1

28

Rear driver side door (window).

30A 1

29

Rear passenger side door (window).

30A 1

30

Not used (spare).

15A 1

31

GPS.

10A 1

32

275

MKZ (), enUSA Fuses

Page 281 of 516

GENERAL INFORMATION

Have your vehicle serviced regularly to help

maintain its roadworthiness and resale value.

There is a large network of Ford authorized

dealers that are there to help you with their

professional servicing expertise. We believe

that their specially trained technicians are

best qualified to service your vehicle properly

and expertly. They are supported by a wide

range of highly specialized tools developed

specifically for servicing your vehicle.

To help you service your vehicle, we provide

scheduled maintenance information which

makes tracking routine service easy. See

Scheduled Maintenance (page 478).

If your vehicle requires professional service,

your authorized dealer can provide the

necessary parts and service. Check your

warranty information to find out which parts

and services are covered.

Use only recommended fuels, lubricants,

fluids and service parts conforming to

specifications. Motorcraft® parts are

designed and built to provide the best

performance in your vehicle. Precautions

•

Do not work on a hot engine.

• Make sure that nothing gets caught in

moving parts.

• Do not work on a vehicle with the engine

running in an enclosed space, unless you

are sure you have enough ventilation.

• Keep all open flames and other burning

material (such as cigarettes) away from

the battery and all fuel related parts.

Working with the Engine Off

1. Set the parking brake and shift to

P

(Park).

2. Turn off the engine and remove the key (if equipped).

3. Block the wheels. Working with the Engine On WARNING

To reduce the risk of vehicle damage

and/or personal burn injuries, do not

start your engine with the air cleaner

removed and do not remove it while the

engine is running. 1. Set the parking brake and shift to

P

(Park).

2. Block the wheels

278

MKZ (), enUSA Maintenance

Page 292 of 516

6F50/6F55 Transmission (If Equipped)

WARNINGS

The dipstick cap and surrounding

components may be hot; gloves are

recommended. Use gloves when moving the air filter

assembly. Components will be hot.

Note:

Automatic transmission fluid expands

when warmed. To obtain an accurate fluid

check, drive the vehicle until it is warmed up

(approximately 20 miles [30 kilometers]). If

your vehicle has been operated for an

extended period at high speeds, in city traffic

during hot weather or pulling a trailer, the

vehicle should be turned off until normal

operating temperatures are reached to allow

the fluid to cool before checking. Depending

on vehicle use, cooling times could take up

to 30 minutes or longer. Refer to your scheduled maintenance

information for scheduled intervals for fluid

checks and changes. Your transmission does

not consume fluid. However, the fluid level

should be checked if the transmission is not

working properly. For example, if the

transmission slips or shifts slowly or if you

notice some sign of fluid leakage.

1.

Drive the vehicle 20 miles (30 kilometers)

or until it reaches normal operating

temperature

2. Park the vehicle on a level surface and engage the parking brake.

3. With the parking brake engaged and your

foot on the brake pedal, start the engine

and move the gearshift lever through all

of the gear ranges. Allow a minimum of

10 seconds for each gear to engage.

4. Put the gearshift lever in

P (Park) and

leave the engine running.

Note: You will need to move the air filter

assembly to access the transmission

dipstick. 5.

Remove the dipstick, wiping it clean with

a clean, dry lint free rag. If necessary,

refer to Under hood overview in this

chapter for the location of the dipstick.

6. Install the dipstick making sure it is fully seated in the filler tube by turning it to

the locked position.

7. Remove the dipstick and inspect the fluid

level. The fluid should be in the

designated areas for normal operating

temperature.

Moving the Air Filter Assembly (Accessing

the Dipstick) WARNING

Do not run engine with the air filter

disconnected.

289

MKZ (), enUSA Maintenance

Page 293 of 516

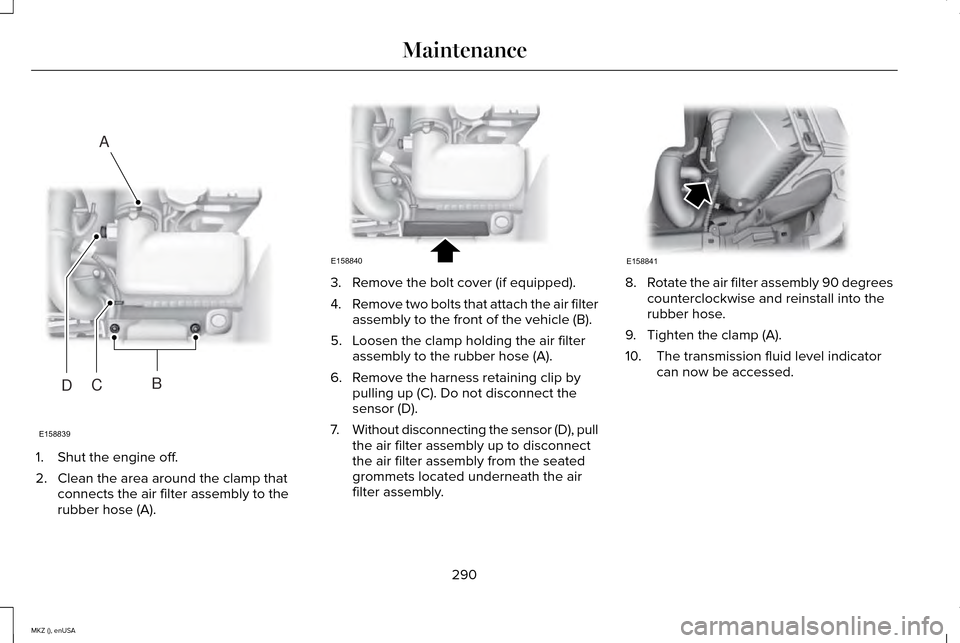

1. Shut the engine off.

2. Clean the area around the clamp that

connects the air filter assembly to the

rubber hose (A). 3. Remove the bolt cover (if equipped).

4.

Remove two bolts that attach the air filter

assembly to the front of the vehicle (B).

5. Loosen the clamp holding the air filter assembly to the rubber hose (A).

6. Remove the harness retaining clip by pulling up (C). Do not disconnect the

sensor (D).

7. Without disconnecting the sensor (D), pull

the air filter assembly up to disconnect

the air filter assembly from the seated

grommets located underneath the air

filter assembly. 8.

Rotate the air filter assembly 90 degrees

counterclockwise and reinstall into the

rubber hose.

9. Tighten the clamp (A).

10. The transmission fluid level indicator can now be accessed.

290

MKZ (), enUSA MaintenanceE158839

A

BCD E158840 E158841

Page 295 of 516

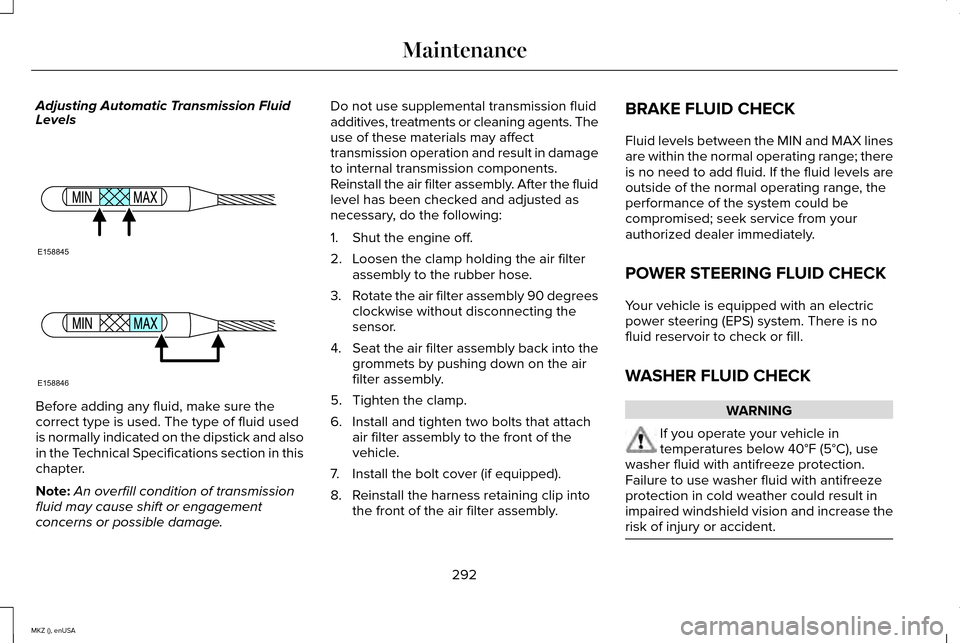

Adjusting Automatic Transmission Fluid

Levels

Before adding any fluid, make sure the

correct type is used. The type of fluid used

is normally indicated on the dipstick and also

in the Technical Specifications section in this

chapter.

Note:

An overfill condition of transmission

fluid may cause shift or engagement

concerns or possible damage. Do not use supplemental transmission fluid

additives, treatments or cleaning agents. The

use of these materials may affect

transmission operation and result in damage

to internal transmission components.

Reinstall the air filter assembly. After the fluid

level has been checked and adjusted as

necessary, do the following:

1. Shut the engine off.

2. Loosen the clamp holding the air filter

assembly to the rubber hose.

3. Rotate the air filter assembly 90 degrees

clockwise without disconnecting the

sensor.

4. Seat the air filter assembly back into the

grommets by pushing down on the air

filter assembly.

5. Tighten the clamp.

6. Install and tighten two bolts that attach air filter assembly to the front of the

vehicle.

7. Install the bolt cover (if equipped).

8. Reinstall the harness retaining clip into the front of the air filter assembly. BRAKE FLUID CHECK

Fluid levels between the MIN and MAX lines

are within the normal operating range; there

is no need to add fluid. If the fluid levels are

outside of the normal operating range, the

performance of the system could be

compromised; seek service from your

authorized dealer immediately.

POWER STEERING FLUID CHECK

Your vehicle is equipped with an electric

power steering (EPS) system. There is no

fluid reservoir to check or fill.

WASHER FLUID CHECK

WARNING

If you operate your vehicle in

temperatures below 40°F (5°C), use

washer fluid with antifreeze protection.

Failure to use washer fluid with antifreeze

protection in cold weather could result in

impaired windshield vision and increase the

risk of injury or accident. 292

MKZ (), enUSA MaintenanceE158845 E158846

Page 297 of 516

When a low voltage battery replacement is

necessary, see an authorized dealer to

replace the low voltage battery with a Ford

recommended replacement low voltage

battery that matches the electrical

requirements of the vehicle

To ensure proper operation of the battery

management system (BMS), do not allow a

technician to connect any electrical device

ground connection directly to the low voltage

battery negative post. A connection at the

low voltage battery negative post can cause

inaccurate measurements of the battery

condition and potential incorrect system

operation.

Note:

If a person adds electrical or electronic

accessories or components to the vehicle,

the accessories or components may

adversely affect the low voltage battery

performance and durability and may also

affect the performance of other electrical

systems in the vehicle.

For longer, trouble-free operation, keep the

top of the battery clean and dry. Also, make

certain the battery cables are always tightly

fastened to the battery terminals. If you see any corrosion on the battery or

terminals, remove the cables from the

terminals and clean with a wire brush. You

can neutralize the acid with a solution of

baking soda and water.

When a battery replacement is required, the

battery should only be replaced with a Ford

recommended replacement battery that

matches the electrical requirements of the

vehicle.

Because your vehicle

’s engine is

electronically-controlled by a computer,

some engine control settings are maintained

by power from the low voltage battery. Some

engine computer settings, like the idle trim

and fuel trim strategy, optimize the

driveability and performance of the engine.

Some other computer settings, like the clock

and radio station presets, are also maintained

in memory by power from the low voltage

battery. When a technician disconnects and

connects the low voltage battery, these

settings are erased. Note:

Until you switch the ignition to the on

position, you will receive a message in your

information display stating that your vehicle

is not in park.

Complete the following procedure in order

to restore the settings:

1. With the vehicle at a complete stop, set the parking brake.

2. Shift the transmission into P.

3. Turn off all accessories.

4. Step on the brake pedal and start the vehicle.

5. Run the engine until it reaches normal operating temperature. While the engine

is warming up, complete the following:

Reset the clock. See Audio System

(page 370). Reset the power windows

bounce-back feature. See Windows and

Mirrors (page 93). Reset the radio station

presets.

See Audio System (page 370).

6. Allow the engine to idle for at least one minute. If the engine turns off, step on

the accelerator to start the engine.

294

MKZ (), enUSA Maintenance

Page 298 of 516

7. While the engine is running, step on the

brake pedal and shift the transmission to

N.

8. Allow the engine to run for at least one minute by pressing on the accelerator

pedal.

9. Drive your vehicle at least 10 miles (16 kilometers) to completely relearn the idle

and fuel trim strategy.

Note: Certain features may not operate if

the Battery Monitor System is not reset with

a scan tool following a jump start or battery

replacement. Normal electrical accessory

operation should resume after your vehicle

is left undisturbed for 8 hours.

Note: If you do not allow the engine to

relearn the idle and fuel trim strategy, the

idle quality of your vehicle may be adversely

affected until the engine computer

eventually relearns the idle trim and fuel trim

strategy. Note:

Always dispose of automotive

batteries in a responsible manner. Follow

your local authorized standards for disposal.

Call your local authorized recycling center

to find out more about recycling automotive

batteries.

Note: It is recommended that the negative

battery cable terminal be disconnected from

the battery if you plan to store your vehicle

for an extended period of time.

CHECKING THE WIPER BLADES Run the tip of your fingers over the edge of

the blade to check for roughness.

Clean the wiper blades with washer fluid or

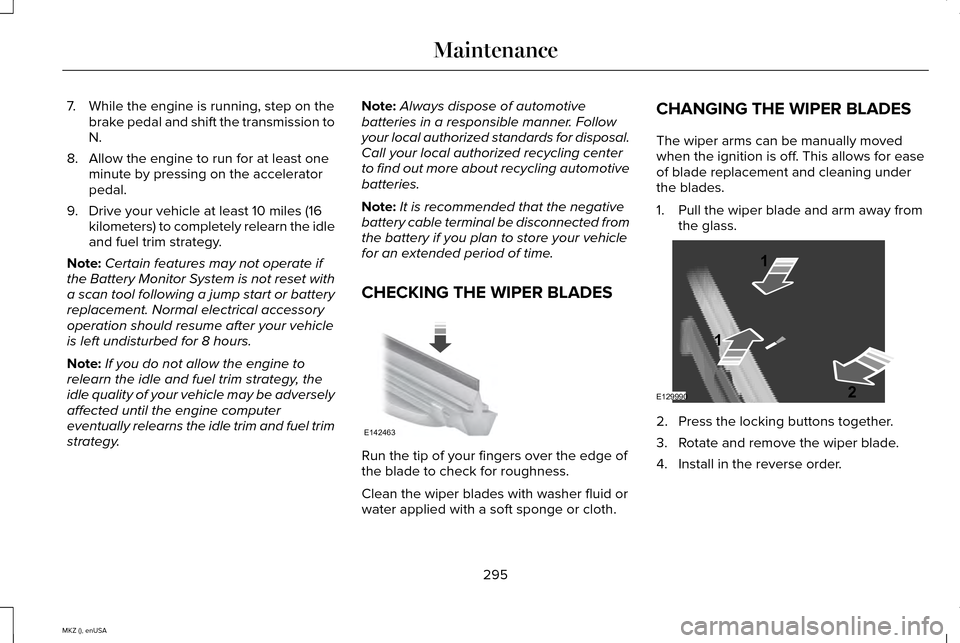

water applied with a soft sponge or cloth.CHANGING THE WIPER BLADES

The wiper arms can be manually moved

when the ignition is off. This allows for ease

of blade replacement and cleaning under

the blades.

1. Pull the wiper blade and arm away from

the glass. 2. Press the locking buttons together.

3. Rotate and remove the wiper blade.

4. Install in the reverse order.

295

MKZ (), enUSA MaintenanceE142463 E129990

1

1 2

Page 299 of 516

Note:

Make sure that the wiper blade locks

into place. Lower the wiper arm and blade

back to the windshield. The wiper arms will

automatically return to their normal position

when the ignition is turned on.

Replace wiper blades at least once per year

for optimum performance.

Poor wiper quality can be improved by

cleaning the wiper blades and the

windshield.

ADJUSTING THE HEADLAMPS

Vertical Aim Adjustment

The headlamps on your vehicle are properly

aimed at the assembly plant. If your vehicle

has been in an accident, the alignment of

your headlamps should be checked by your

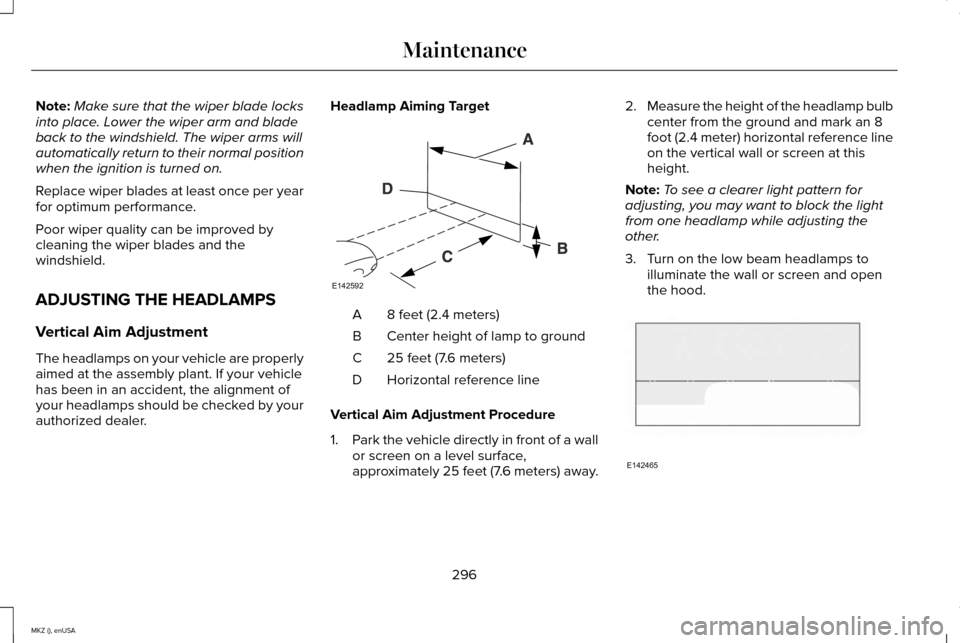

authorized dealer. Headlamp Aiming Target

8 feet (2.4 meters)

A

Center height of lamp to ground

B

25 feet (7.6 meters)

C

Horizontal reference line

D

Vertical Aim Adjustment Procedure

1. Park the vehicle directly in front of a wall

or screen on a level surface,

approximately 25 feet (7.6 meters) away. 2.

Measure the height of the headlamp bulb

center from the ground and mark an 8

foot (2.4 meter) horizontal reference line

on the vertical wall or screen at this

height.

Note: To see a clearer light pattern for

adjusting, you may want to block the light

from one headlamp while adjusting the

other.

3. Turn on the low beam headlamps to illuminate the wall or screen and open

the hood. 296

MKZ (), enUSA MaintenanceE142592 E142465

Page 300 of 516

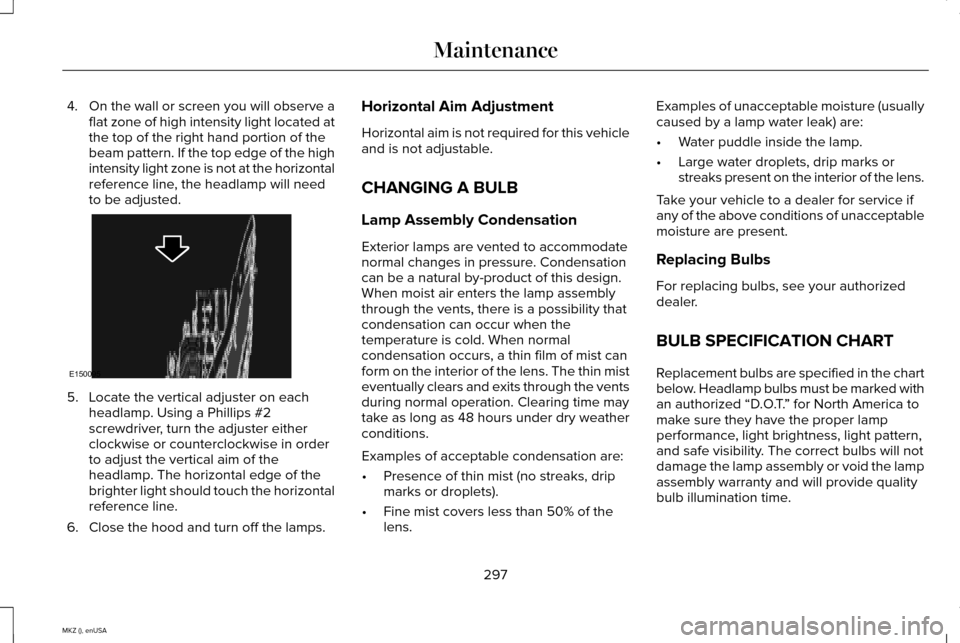

4.

On the wall or screen you will observe a

flat zone of high intensity light located at

the top of the right hand portion of the

beam pattern. If the top edge of the high

intensity light zone is not at the horizontal

reference line, the headlamp will need

to be adjusted. 5. Locate the vertical adjuster on each

headlamp. Using a Phillips #2

screwdriver, turn the adjuster either

clockwise or counterclockwise in order

to adjust the vertical aim of the

headlamp. The horizontal edge of the

brighter light should touch the horizontal

reference line.

6. Close the hood and turn off the lamps. Horizontal Aim Adjustment

Horizontal aim is not required for this vehicle

and is not adjustable.

CHANGING A BULB

Lamp Assembly Condensation

Exterior lamps are vented to accommodate

normal changes in pressure. Condensation

can be a natural by-product of this design.

When moist air enters the lamp assembly

through the vents, there is a possibility that

condensation can occur when the

temperature is cold. When normal

condensation occurs, a thin film of mist can

form on the interior of the lens. The thin mist

eventually clears and exits through the vents

during normal operation. Clearing time may

take as long as 48 hours under dry weather

conditions.

Examples of acceptable condensation are:

•

Presence of thin mist (no streaks, drip

marks or droplets).

• Fine mist covers less than 50% of the

lens. Examples of unacceptable moisture (usually

caused by a lamp water leak) are:

•

Water puddle inside the lamp.

• Large water droplets, drip marks or

streaks present on the interior of the lens.

Take your vehicle to a dealer for service if

any of the above conditions of unacceptable

moisture are present.

Replacing Bulbs

For replacing bulbs, see your authorized

dealer.

BULB SPECIFICATION CHART

Replacement bulbs are specified in the chart

below. Headlamp bulbs must be marked with

an authorized “D.O.T. ” for North America to

make sure they have the proper lamp

performance, light brightness, light pattern,

and safe visibility. The correct bulbs will not

damage the lamp assembly or void the lamp

assembly warranty and will provide quality

bulb illumination time.

297

MKZ (), enUSA MaintenanceE150095