LINCOLN MKZ 2019 Owners Manual

Manufacturer: LINCOLN, Model Year: 2019, Model line: MKZ, Model: LINCOLN MKZ 2019Pages: 595, PDF Size: 4.95 MB

Page 331 of 595

Cooling system

•Protect against freezing temperatures.

•When removing your vehicle fromstorage, check coolant fluid level.Confirm that there are no cooling systemleaks and that fluid is at therecommended level.

Battery

•Check and recharge as necessary. Keepconnections clean.

•If storing your vehicle for more than 30days without recharging the battery, werecommend that you disconnect thebattery cables to maintain battery chargefor quick starting.

Note:It is necessary to reset memoryfeatures if battery cables are disconnected.

Brakes

•Make sure the brakes and parking brakerelease fully.

Tires

•Maintain recommended air pressure.

Miscellaneous

•Make sure all linkages, cables, levers andpins under your vehicle are covered withgrease to prevent rust.

•Move vehicles at least 25 ft (7.5 m) every15 days to lubricate working parts andprevent corrosion.

Removing Vehicle From Storage

When your vehicle is ready to come out ofstorage, do the following:

•Wash your vehicle to remove any dirt orgrease film build-up on window surfaces.

•Check windshield wipers for anydeterioration.

•Check under the hood for any foreignmaterial that may have collected duringstorage such as mice or squirrel nests.

•Check the exhaust for any foreignmaterial that may have collected duringstorage.

•Check tire pressures and set tire inflationper the Tire Label.

•Check brake pedal operation. Drive yourvehicle 15 ft (4.5 m) back and forth toremove rust build-up.

•Check fluid levels (including coolant, oiland gas) to make sure there are no leaks,and fluids are at recommended levels.

•If you remove the battery, clean thebattery cable ends and check fordamage.

Contact an authorized dealer if you have anyconcerns or issues.

BODY STYLING KITS

The distance between the underside of yourvehicle and the ground is less than that ofother models. Drive with extreme care toavoid damage to your vehicle.

328

MKZ (CC9) Canada/United States of America, enUSA, Edition date: 201805, First-Printing

Vehicle Care

Page 332 of 595

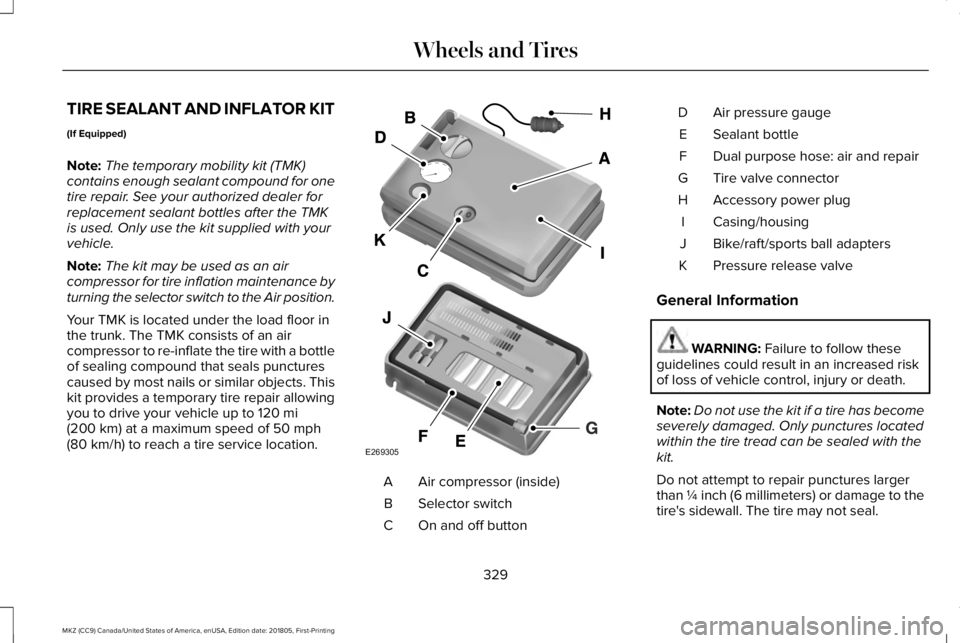

TIRE SEALANT AND INFLATOR KIT

(If Equipped)

Note:The temporary mobility kit (TMK)contains enough sealant compound for onetire repair. See your authorized dealer forreplacement sealant bottles after the TMKis used. Only use the kit supplied with yourvehicle.

Note:The kit may be used as an aircompressor for tire inflation maintenance byturning the selector switch to the Air position.

Your TMK is located under the load floor inthe trunk. The TMK consists of an aircompressor to re-inflate the tire with a bottleof sealing compound that seals puncturescaused by most nails or similar objects. Thiskit provides a temporary tire repair allowingyou to drive your vehicle up to 120 mi(200 km) at a maximum speed of 50 mph(80 km/h) to reach a tire service location.

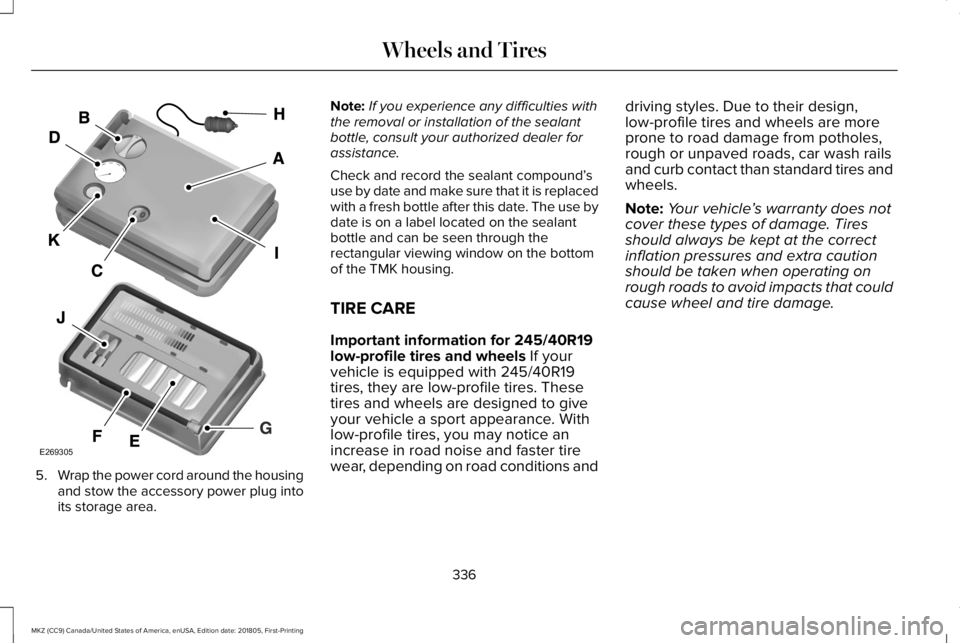

Air compressor (inside)A

Selector switchB

On and off buttonC

Air pressure gaugeD

Sealant bottleE

Dual purpose hose: air and repairF

Tire valve connectorG

Accessory power plugH

Casing/housingI

Bike/raft/sports ball adaptersJ

Pressure release valveK

General Information

WARNING: Failure to follow theseguidelines could result in an increased riskof loss of vehicle control, injury or death.

Note:Do not use the kit if a tire has becomeseverely damaged. Only punctures locatedwithin the tire tread can be sealed with thekit.

Do not attempt to repair punctures largerthan ¼ inch (6 millimeters) or damage to thetire's sidewall. The tire may not seal.

329

MKZ (CC9) Canada/United States of America, enUSA, Edition date: 201805, First-Printing

Wheels and TiresE269305

Page 333 of 595

Loss of air pressure may adversely affect tireperformance. For this reason:

Note:Do not drive the vehicle above 50 mph(80 km/h).

Note:Do not drive further than 120 mi(200 km). Drive only to the closest authorizedLincoln dealer or tire repair shop to haveyour tire inspected.

•Drive carefully and avoid abrupt steeringmaneuvers.

•Periodically monitor tire inflation pressurein the affected tire; if the tire is losingpressure, have the vehicle towed.

•Read the information in the Tips for Useof the Kit section to make sure safeoperation of the kit and your vehicle.

Tips for Use of your TMK

To ensure safe operation of the TMK:

•Read all instructions and cautions fully.

•Do not remove any foreign objects, suchas nails or screws, from the tire.

•Before operating the kit, make sure yourvehicle is safely off the road and awayfrom moving traffic. Turn on the hazardlights.

•Always set the parking brake to ensurethe vehicle doesn't move unexpectedly.

•When using the kit, leave the enginerunning (only if the vehicle is outdoors orin a well-ventilated area) so thecompressor does not drain the vehicle'sbattery.

•Do not allow the compressor to operatecontinuously for more than 15 minutes.This helps prevent the compressor fromoverheating.

•Never leave the kit unattended duringoperation.

•Sealant compound contains latex. Thosewith latex sensitivities should useappropriate precautions to avoid anallergic reaction.

•Keep the kit away from children.

•Only use the kit when the ambienttemperature is between -22°F (-30°C) and158°F (70°C).

•Only use the sealing compound beforethe use-by date. The use-by date is on alabel on the sealant bottle and can beseen through the rectangular viewingwindow on the bottom of the compressorhousing. Check the use-by date regularlyand replace the bottle when the fluid hasexpired.

•Do not store the kit unsecured inside thepassenger compartment of the vehicleas it may cause injury during a suddenstop or crash. Always store the kit in itsoriginal location.

•After sealant use, the tire pressuremonitoring system sensor and valve stemon the wheel must be replaced by anauthorized Lincoln dealer.

•Operating the kit could cause anelectrical disturbance in radio, CD, andDVD player operation.

* When inflation only is required fora tire or other objects, the selectormust be in the Air position.

330

MKZ (CC9) Canada/United States of America, enUSA, Edition date: 201805, First-Printing

Wheels and TiresE175978

Page 334 of 595

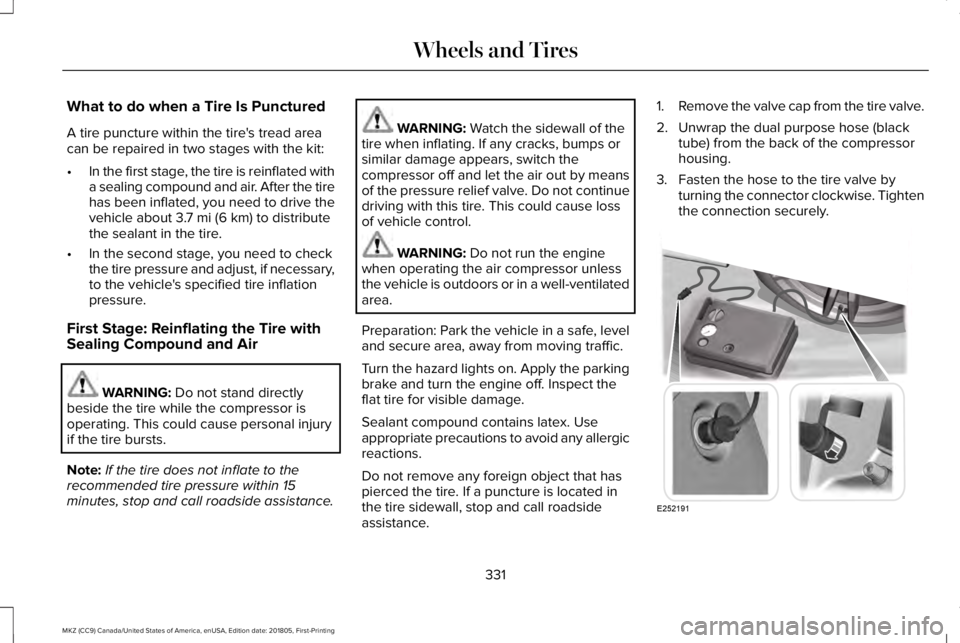

What to do when a Tire Is Punctured

A tire puncture within the tire's tread areacan be repaired in two stages with the kit:

•In the first stage, the tire is reinflated witha sealing compound and air. After the tirehas been inflated, you need to drive thevehicle about 3.7 mi (6 km) to distributethe sealant in the tire.

•In the second stage, you need to checkthe tire pressure and adjust, if necessary,to the vehicle's specified tire inflationpressure.

First Stage: Reinflating the Tire withSealing Compound and Air

WARNING: Do not stand directlybeside the tire while the compressor isoperating. This could cause personal injuryif the tire bursts.

Note:If the tire does not inflate to therecommended tire pressure within 15minutes, stop and call roadside assistance.

WARNING: Watch the sidewall of thetire when inflating. If any cracks, bumps orsimilar damage appears, switch thecompressor off and let the air out by meansof the pressure relief valve. Do not continuedriving with this tire. This could cause lossof vehicle control.

WARNING: Do not run the enginewhen operating the air compressor unlessthe vehicle is outdoors or in a well-ventilatedarea.

Preparation: Park the vehicle in a safe, leveland secure area, away from moving traffic.

Turn the hazard lights on. Apply the parkingbrake and turn the engine off. Inspect theflat tire for visible damage.

Sealant compound contains latex. Useappropriate precautions to avoid any allergicreactions.

Do not remove any foreign object that haspierced the tire. If a puncture is located inthe tire sidewall, stop and call roadsideassistance.

1.Remove the valve cap from the tire valve.

2. Unwrap the dual purpose hose (blacktube) from the back of the compressorhousing.

3. Fasten the hose to the tire valve byturning the connector clockwise. Tightenthe connection securely.

331

MKZ (CC9) Canada/United States of America, enUSA, Edition date: 201805, First-Printing

Wheels and TiresE252191

Page 335 of 595

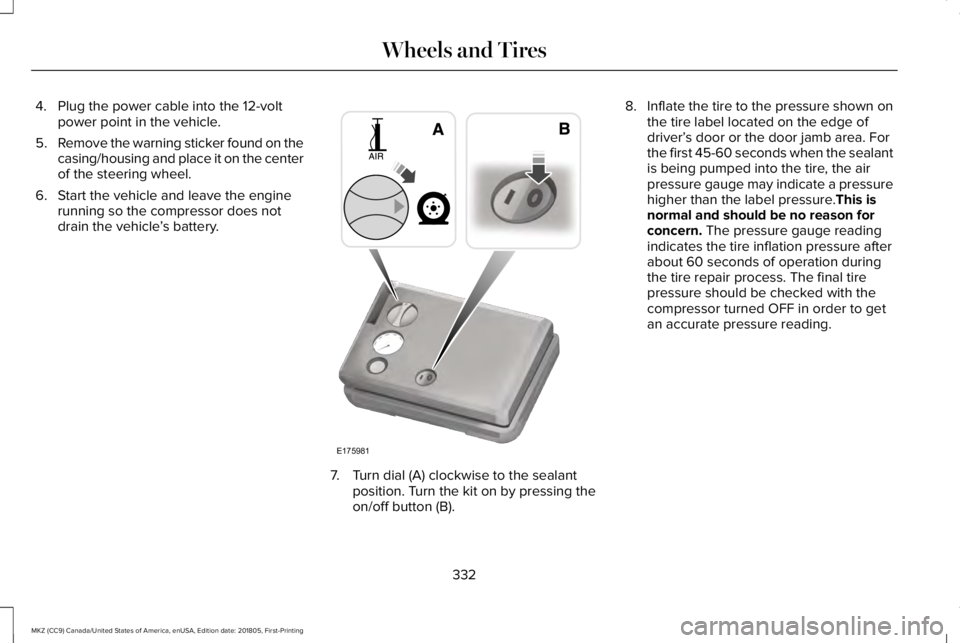

4. Plug the power cable into the 12-voltpower point in the vehicle.

5.Remove the warning sticker found on thecasing/housing and place it on the centerof the steering wheel.

6. Start the vehicle and leave the enginerunning so the compressor does notdrain the vehicle’s battery.

7. Turn dial (A) clockwise to the sealantposition. Turn the kit on by pressing theon/off button (B).

8.Inflate the tire to the pressure shown onthe tire label located on the edge ofdriver’s door or the door jamb area. Forthe first 45-60 seconds when the sealantis being pumped into the tire, the airpressure gauge may indicate a pressurehigher than the label pressure.This isnormal and should be no reason forconcern. The pressure gauge readingindicates the tire inflation pressure afterabout 60 seconds of operation duringthe tire repair process. The final tirepressure should be checked with thecompressor turned OFF in order to getan accurate pressure reading.

332

MKZ (CC9) Canada/United States of America, enUSA, Edition date: 201805, First-Printing

Wheels and TiresE175981

Page 336 of 595

9.When the recommended tire pressure isreached, turn off the kit, unplug thepower cable, and disconnect the hosefrom the tire valve. Re-install the valvecap on the tire valve and return the kit tothe stowage area.

10. Immediately and cautiously, drive thevehicle 3.7 mi (6 km) to distribute thesealant evenly inside the tire. Do notexceed 50 mph (80 km/h).

11. After 3.7 mi (6 km), stop and check thetire pressure. See Second stage:Checking tire pressure.

WARNING: If you experience anyunusual vibration, ride disturbance or noisewhile driving, reduce your speed until youcan safely pull off to the side of the road andcall for roadside assistance. Failure to do socould cause you to lose control of yourvehicle and increase the risk of personalinjury or death.

Note:If you experience any unusualvibration, ride disturbance or noise whendriving, do not proceed to the second stageof this operation.

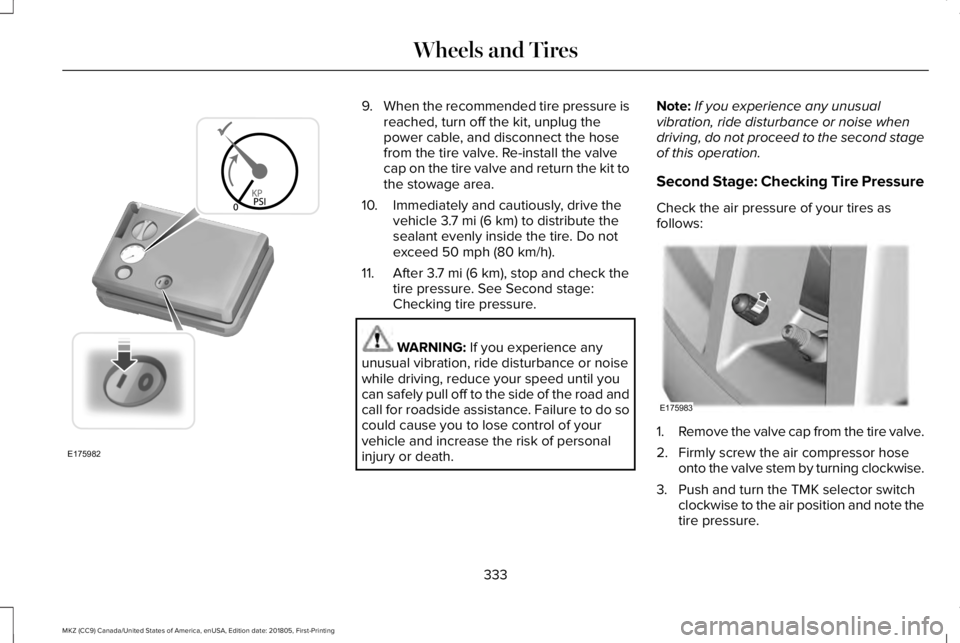

Second Stage: Checking Tire Pressure

Check the air pressure of your tires asfollows:

1.Remove the valve cap from the tire valve.

2. Firmly screw the air compressor hoseonto the valve stem by turning clockwise.

3. Push and turn the TMK selector switchclockwise to the air position and note thetire pressure.

333

MKZ (CC9) Canada/United States of America, enUSA, Edition date: 201805, First-Printing

Wheels and TiresE175982 E175983

Page 337 of 595

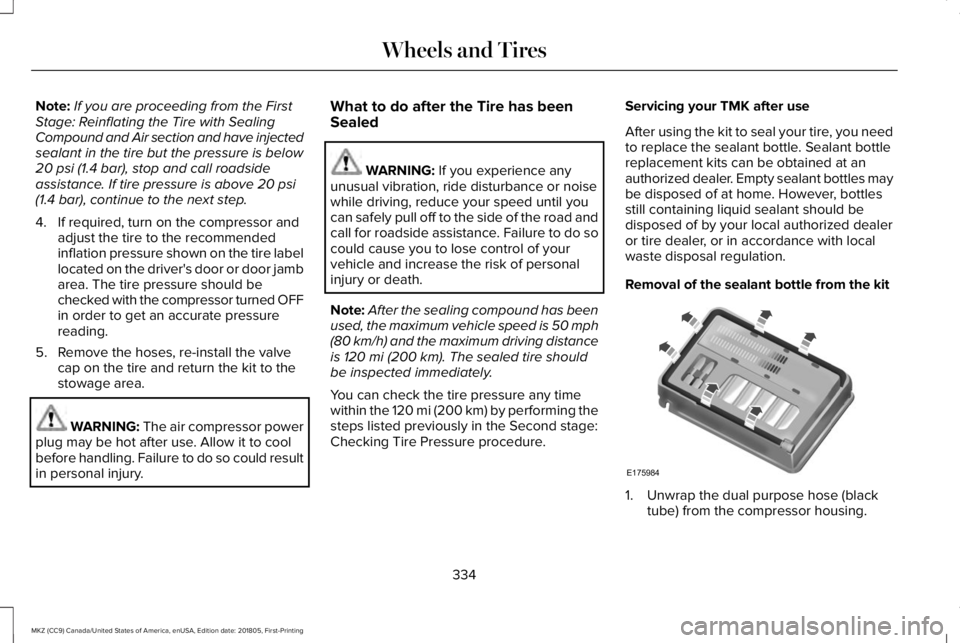

Note:If you are proceeding from the FirstStage: Reinflating the Tire with SealingCompound and Air section and have injectedsealant in the tire but the pressure is below20 psi (1.4 bar), stop and call roadsideassistance. If tire pressure is above 20 psi(1.4 bar), continue to the next step.

4. If required, turn on the compressor andadjust the tire to the recommendedinflation pressure shown on the tire labellocated on the driver's door or door jambarea. The tire pressure should bechecked with the compressor turned OFFin order to get an accurate pressurereading.

5. Remove the hoses, re-install the valvecap on the tire and return the kit to thestowage area.

WARNING: The air compressor powerplug may be hot after use. Allow it to coolbefore handling. Failure to do so could resultin personal injury.

What to do after the Tire has beenSealed

WARNING: If you experience anyunusual vibration, ride disturbance or noisewhile driving, reduce your speed until youcan safely pull off to the side of the road andcall for roadside assistance. Failure to do socould cause you to lose control of yourvehicle and increase the risk of personalinjury or death.

Note:After the sealing compound has beenused, the maximum vehicle speed is 50 mph(80 km/h) and the maximum driving distanceis 120 mi (200 km). The sealed tire shouldbe inspected immediately.

You can check the tire pressure any timewithin the 120 mi (200 km) by performing thesteps listed previously in the Second stage:Checking Tire Pressure procedure.

Servicing your TMK after use

After using the kit to seal your tire, you needto replace the sealant bottle. Sealant bottlereplacement kits can be obtained at anauthorized dealer. Empty sealant bottles maybe disposed of at home. However, bottlesstill containing liquid sealant should bedisposed of by your local authorized dealeror tire dealer, or in accordance with localwaste disposal regulation.

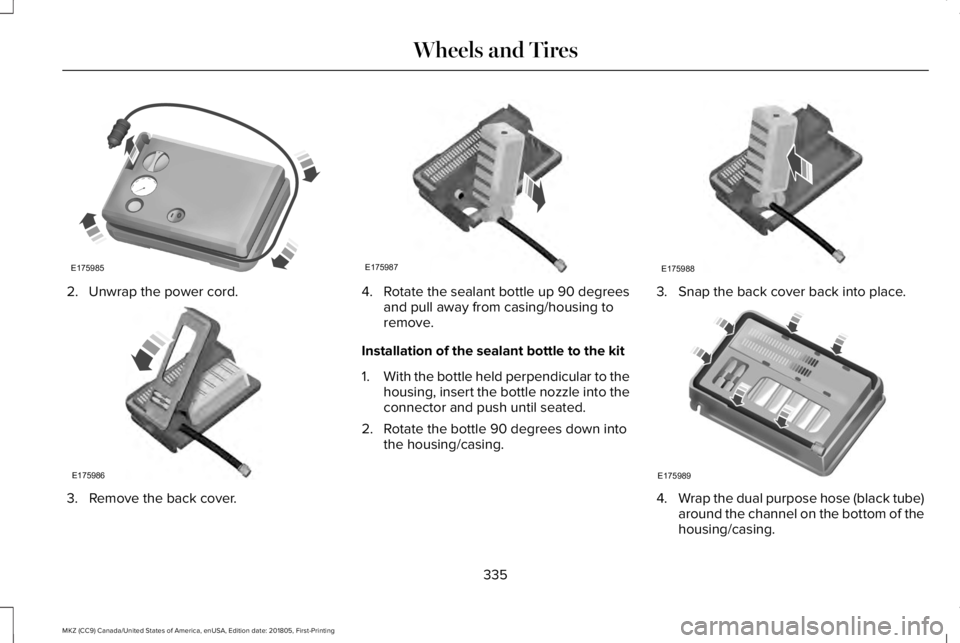

Removal of the sealant bottle from the kit

1. Unwrap the dual purpose hose (blacktube) from the compressor housing.

334

MKZ (CC9) Canada/United States of America, enUSA, Edition date: 201805, First-Printing

Wheels and TiresE175984

Page 338 of 595

2. Unwrap the power cord.

3. Remove the back cover.

4.Rotate the sealant bottle up 90 degreesand pull away from casing/housing toremove.

Installation of the sealant bottle to the kit

1.With the bottle held perpendicular to thehousing, insert the bottle nozzle into theconnector and push until seated.

2. Rotate the bottle 90 degrees down intothe housing/casing.

3. Snap the back cover back into place.

4.Wrap the dual purpose hose (black tube)around the channel on the bottom of thehousing/casing.

335

MKZ (CC9) Canada/United States of America, enUSA, Edition date: 201805, First-Printing

Wheels and TiresE175985 E175986 E175987 E175988 E175989

Page 339 of 595

5.Wrap the power cord around the housingand stow the accessory power plug intoits storage area.

Note:If you experience any difficulties withthe removal or installation of the sealantbottle, consult your authorized dealer forassistance.

Check and record the sealant compound’suse by date and make sure that it is replacedwith a fresh bottle after this date. The use bydate is on a label located on the sealantbottle and can be seen through therectangular viewing window on the bottomof the TMK housing.

TIRE CARE

Important information for 245/40R19low-profile tires and wheels If yourvehicle is equipped with 245/40R19tires, they are low-profile tires. Thesetires and wheels are designed to giveyour vehicle a sport appearance. Withlow-profile tires, you may notice anincrease in road noise and faster tirewear, depending on road conditions and

driving styles. Due to their design,low-profile tires and wheels are moreprone to road damage from potholes,rough or unpaved roads, car wash railsand curb contact than standard tires andwheels.

Note:Your vehicle’s warranty does notcover these types of damage. Tiresshould always be kept at the correctinflation pressures and extra cautionshould be taken when operating onrough roads to avoid impacts that couldcause wheel and tire damage.

336

MKZ (CC9) Canada/United States of America, enUSA, Edition date: 201805, First-Printing

Wheels and TiresE269305

Page 340 of 595

Information About Uniform Tire QualityGrading

Tire Quality Grades apply to newpneumatic passenger car tires. TheQuality grades can be found whereapplicable on the tire sidewall betweentread shoulder and maximum sectionwidth. For example: Treadwear 200Traction AA Temperature A.

These Tire Quality Grades aredetermined by standards that the UnitedStates Department of Transportation hasset.

Tire Quality Grades apply to newpneumatic passenger car tires. They donot apply to deep tread, winter-typesnow tires, space-saver or temporaryuse spare tires, light truck or LT typetires, tires with nominal rim diameters of10 to 12 inches or limited production tiresas defined in Title 49 Code of FederalRegulations Part 575.104 ©)(2).

U.S. Department of Transportation Tirequality grades: The U.S. Department ofTransportation requires Ford MotorCompany to give you the followinginformation about tire grades exactly asthe government has written it.

Treadwear

The treadwear grade is a comparative

rating based on the wear rate of the tirewhen tested under controlled conditionson a specified government test course.For example, a tire graded 150 wouldwear 1 ½ times as well on thegovernment course as a tire graded 100.The relative performance of tires

depends upon the actual conditions oftheir use, however, and may departsignificantly from the norm due tovariations in driving habits, servicepractices, and differences in roadcharacteristics and climate.

Traction AA A B C

WARNING: The traction gradeassigned to this tire is based onstraight-ahead braking traction tests, anddoes not include acceleration, cornering,hydroplaning or peak tractioncharacteristics.

The traction grades, from highest tolowest are AA, A, B, and C. The gradesrepresent the tire’s ability to stop on wetpavement as measured under controlledconditions on specified government testsurfaces of asphalt and concrete. A tiremarked C may have poor tractionperformance.

337

MKZ (CC9) Canada/United States of America, enUSA, Edition date: 201805, First-Printing

Wheels and TiresE142542