warning LINCOLN MKZ HYBRID 2013 Owners Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2013, Model line: MKZ HYBRID, Model: LINCOLN MKZ HYBRID 2013Pages: 475, PDF Size: 3.89 MB

Page 307 of 475

•

Only use the sealing compound

before the use by date. The use by

date is on the lower right hand

corner of the label located on the

sealant canister (bottle). Check

the use by date regularly and

replace the canister after four

years.

• Do not store the kit unsecured

inside the passenger compartment

of the vehicle as it may cause injury

during a sudden stop or crash.

Always store the kit in its original

location.

• After sealant use, the tire pressure

monitoring system sensor and

valve stem on the wheel must be

replaced by an authorized Ford

dealer.

• When inflating a tire or other

objects, use the black air hose only.

Do not use the transparent hose

which is designed for sealant

application only.

• Operating the kit could cause an

electrical disturbance in radio, CD,

and DVD player operation.

What to do when a Tire Is

Punctured

A tire puncture within the tire's tread

area can be repaired in two stages

with the kit. •

In the first stage, the tire will be

reinflated with a sealing

compound and air. After the tire

has been reinflated, you will need

to drive the vehicle a short

distance (about 4 miles [6

kilometers]) to distribute the

sealant in the tire.

• In the second stage, you will need

to check the tire pressure and

adjust, if necessary, to the vehicle's

tire inflation pressure.

First Stage: Reinflating the Tire

with Sealing Compound and Air WARNINGS

Do not stand directly over the kit

while inflating the tire. If you

notice any unusual bulges or

deformations in the tire's sidewall

during inflation, stop and call roadside

assistance. If the tire doesn't inflate to the

recommended tire pressure

within 15 minutes, stop and call

roadside assistance. Preparation: Park the vehicle in a safe,

level and secure area, away from

moving traffic. Turn the hazard lights

on. Apply the parking brake and turn

the engine off. Inspect the flat tire for

visible damage.

Sealant compound contains latex. To

avoid any allergic reactions, use the

non-latex gloves located in the

accessory box on the underside of the

kit housing.

305

MKZ (CC9) Wheels and Tires

Page 308 of 475

Do not remove any foreign object that

has pierced the tire. If a puncture is

located in the tire sidewall, stop and

call roadside assistance.

1.

Remove the valve cap from the tire

valve.

2. Unwrap the clear tube from the compressor housing.

3. Remove the tube cap and fasten the metal connector of the tube to

the tire valve, turning clockwise.

Make sure the connection is tightly

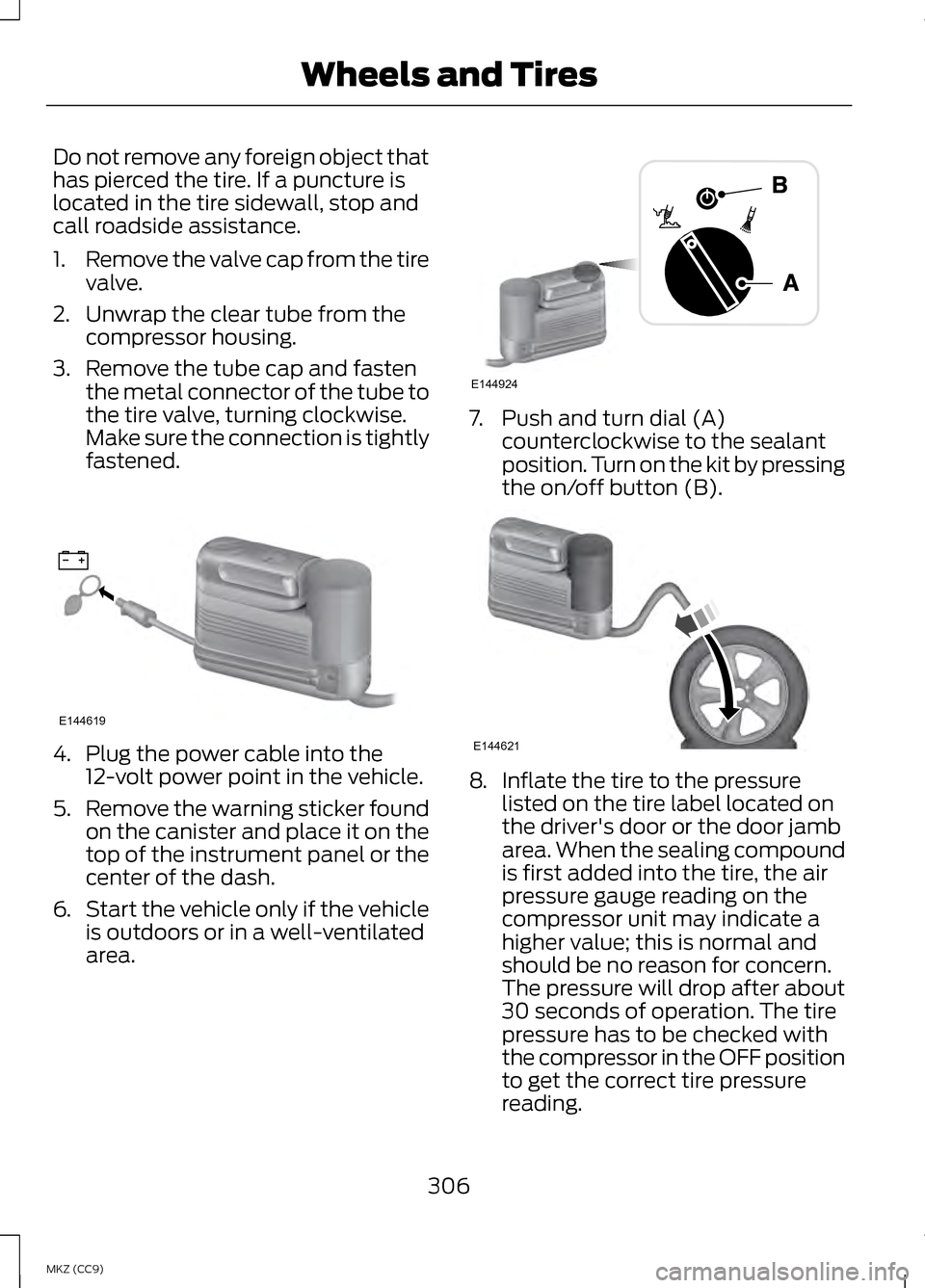

fastened. 4. Plug the power cable into the

12-volt power point in the vehicle.

5. Remove the warning sticker found

on the canister and place it on the

top of the instrument panel or the

center of the dash.

6. Start the vehicle only if the vehicle

is outdoors or in a well-ventilated

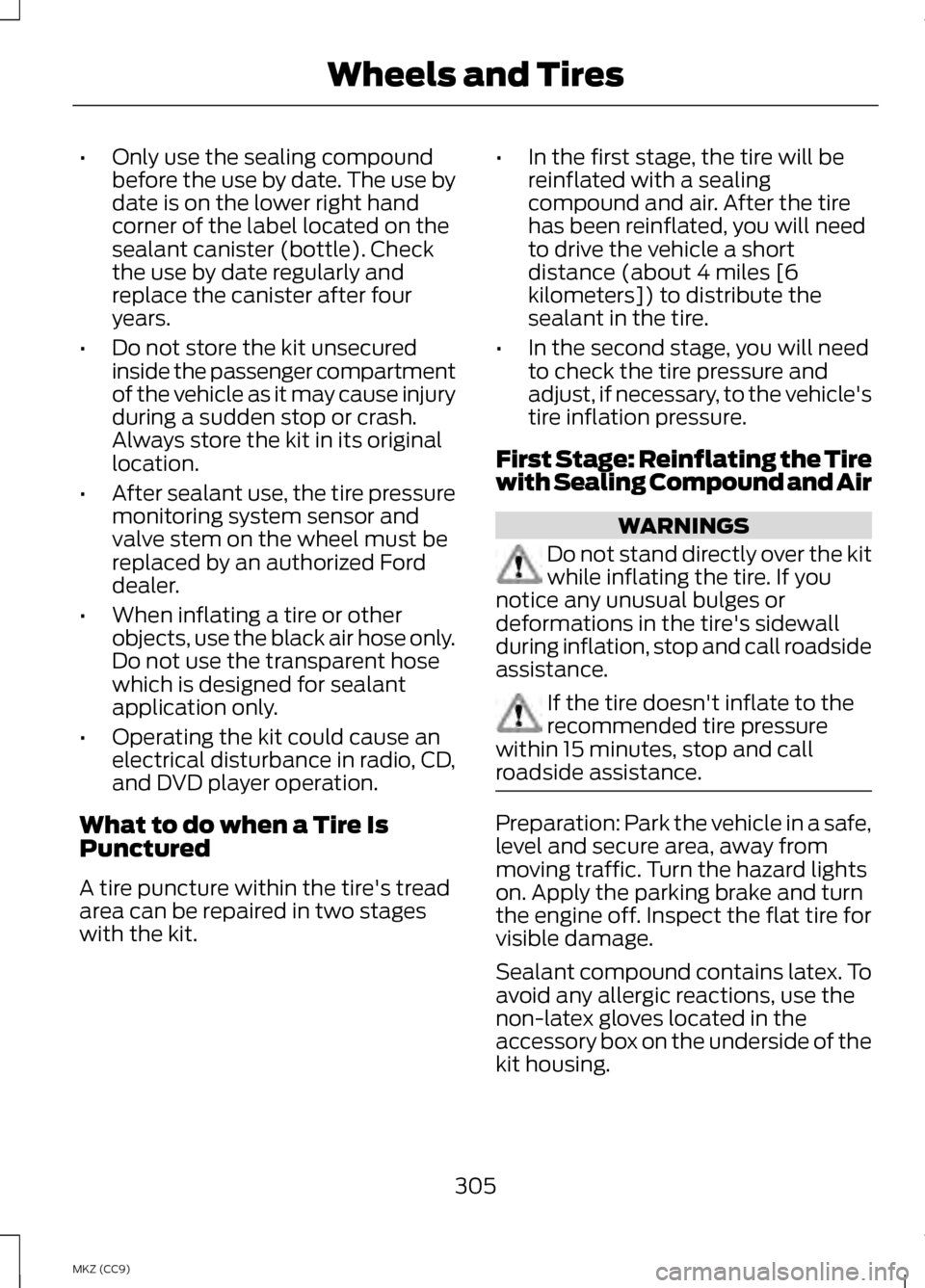

area. 7. Push and turn dial (A)

counterclockwise to the sealant

position. Turn on the kit by pressing

the on/off button (B). 8.

Inflate the tire to the pressure

listed on the tire label located on

the driver's door or the door jamb

area. When the sealing compound

is first added into the tire, the air

pressure gauge reading on the

compressor unit may indicate a

higher value; this is normal and

should be no reason for concern.

The pressure will drop after about

30 seconds of operation. The tire

pressure has to be checked with

the compressor in the OFF position

to get the correct tire pressure

reading.

306

MKZ (CC9) Wheels and TiresE144619 E144924 E144621

Page 309 of 475

9. When the recommended tire

pressure is reached, turn off the kit

by pressing the on button;

disconnect the kit from the tire

valve and the power point.

Re-install the valve cap on the tire

valve, place the tube cap on the

metal connector, and return the kit

to the stowage area

10. Immediately and cautiously, drive

the vehicle 4 miles (6 kilometers)

to distribute the sealant evenly

inside the tire. Do not exceed 50

mph (80 km/h).

11. After 4 miles (6 kilometers), stop

and check the tire pressure. See

Second stage: Checking tire

pressure.

Note: If you experience any unusual

vibration, ride disturbance or noise

while driving, reduce your speed until

you can safely pull off to the side of the

road to call for roadside assistance.

Note: Do not proceed to the second

stage of this operation.

Second Stage: Checking Tire

Pressure WARNINGS

If you are proceeding from the

First stage: Re–inflating the tire

with sealing compound and air section

and have injected sealant in the tire

and the pressure is below 20 psi (1.4

bar), stop and call roadside

assistance. If tire pressure is above 20

psi (1.4 bar), continue to the next step. The power plug may get hot

after use and should be handled

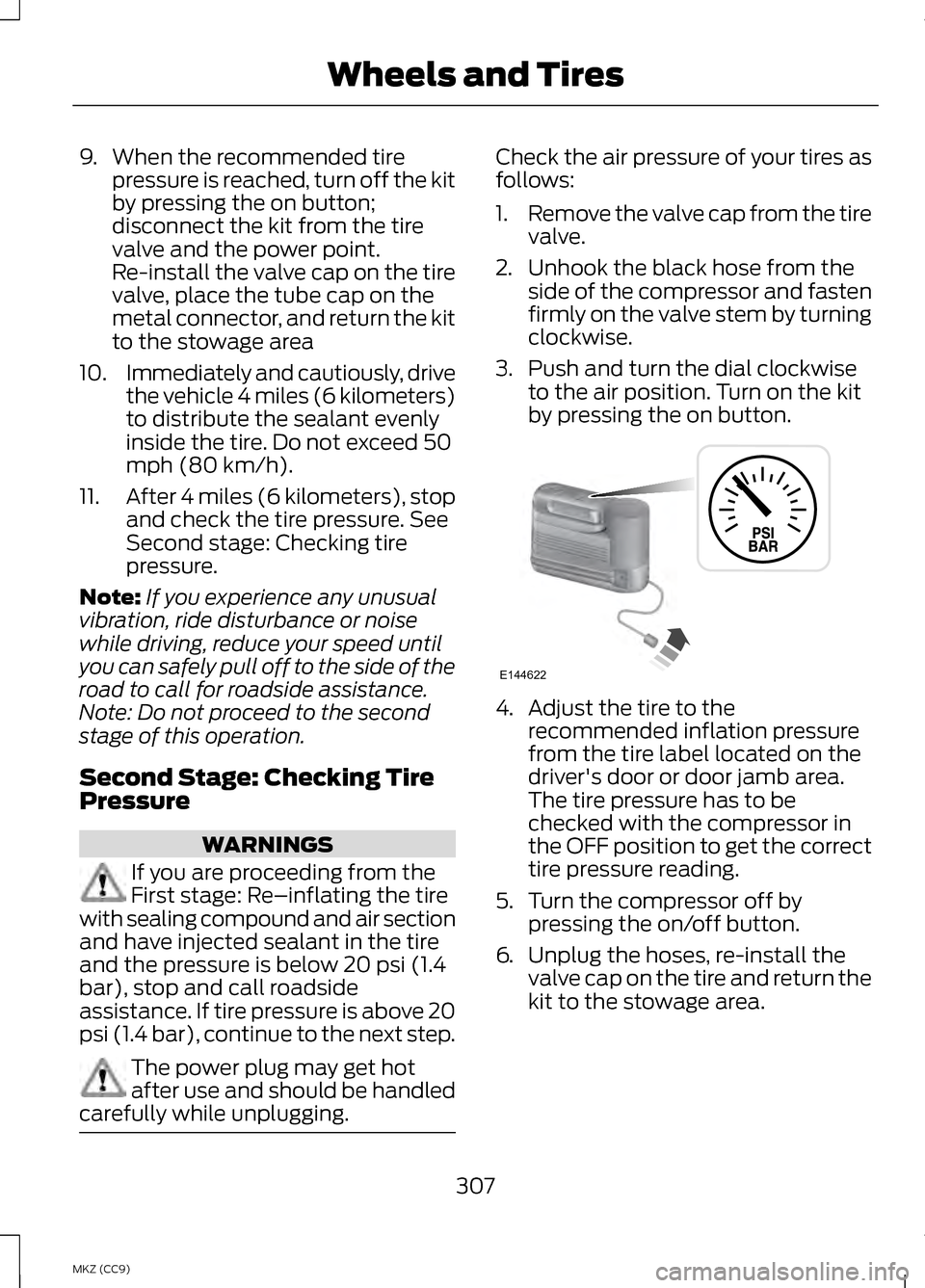

carefully while unplugging. Check the air pressure of your tires as

follows:

1.

Remove the valve cap from the tire

valve.

2. Unhook the black hose from the side of the compressor and fasten

firmly on the valve stem by turning

clockwise.

3. Push and turn the dial clockwise to the air position. Turn on the kit

by pressing the on button. 4. Adjust the tire to the

recommended inflation pressure

from the tire label located on the

driver's door or door jamb area.

The tire pressure has to be

checked with the compressor in

the OFF position to get the correct

tire pressure reading.

5. Turn the compressor off by pressing the on/off button.

6. Unplug the hoses, re-install the

valve cap on the tire and return the

kit to the stowage area.

307

MKZ (CC9) Wheels and TiresE144622

Page 311 of 475

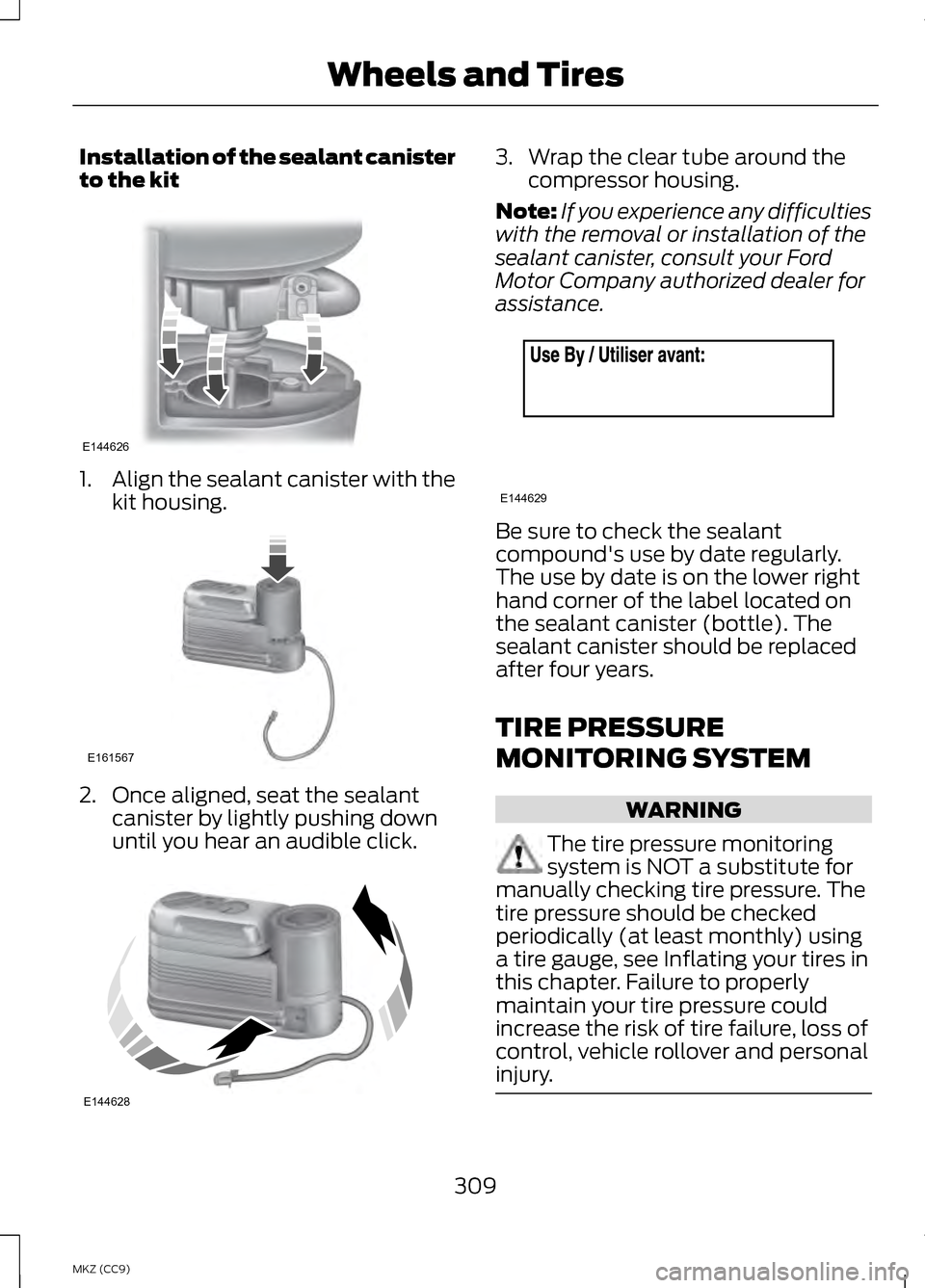

Installation of the sealant canister

to the kit

1.

Align the sealant canister with the

kit housing. 2. Once aligned, seat the sealant

canister by lightly pushing down

until you hear an audible click. 3. Wrap the clear tube around the

compressor housing.

Note: If you experience any difficulties

with the removal or installation of the

sealant canister, consult your Ford

Motor Company authorized dealer for

assistance. Be sure to check the sealant

compound's use by date regularly.

The use by date is on the lower right

hand corner of the label located on

the sealant canister (bottle). The

sealant canister should be replaced

after four years.

TIRE PRESSURE

MONITORING SYSTEM

WARNING

The tire pressure monitoring

system is NOT a substitute for

manually checking tire pressure. The

tire pressure should be checked

periodically (at least monthly) using

a tire gauge, see Inflating your tires in

this chapter. Failure to properly

maintain your tire pressure could

increase the risk of tire failure, loss of

control, vehicle rollover and personal

injury. 309

MKZ (CC9) Wheels and TiresE144626 E161567 E144628 E144629

Page 313 of 475

Changing Tires with a Tire

Pressure Monitoring System

Note:

Each road tire is equipped with

a tire pressure sensor located inside the

wheel and tire assembly cavity. The

pressure sensor is attached to the valve

stem. The pressure sensor is covered

by the tire and is not visible unless the

tire is removed. Care must be taken

when changing the tire to avoid

damaging the sensor

It is recommended that you always

have your tires serviced by an

authorized dealer.

The tire pressure should be checked

periodically (at least monthly) using

an accurate tire gauge. See Inflating

Your Tires in this chapter.

Understanding Your Tire

Pressure Monitoring System

The tire pressure monitoring system

measures pressure in your four road

tires and sends the tire pressure

readings to your vehicle. The low tire

pressure warning light will turn on if

the tire pressure is significantly low. Once the light is illuminated, your tires

are under-inflated and need to be

inflated to the manufacturer

’s

recommended tire pressure. Even if

the light turns on and a short time

later turns off, your tire pressure still

needs to be checked.

When your Temporary Spare Tire

is Installed (If Equipped)

When one of your road tires needs to

be replaced with the temporary spare,

the tire pressure monitoring system

will continue to identify an issue to

remind you that the damaged road

wheel and tire assembly needs to be

repaired and put back on your vehicle.

To restore the full functionality of the

tire pressure monitoring system, have

the damaged road wheel and tire

assembly repaired and remounted on

your vehicle.

When you Believe your System is

not Operating Properly

The main function of the tire pressure

monitoring system is to warn you

when your tires need air. It can also

warn you in the event the system is no

longer capable of functioning as

intended. See the following chart for

information concerning your tire

pressure monitoring system:

311

MKZ (CC9) Wheels and TiresE142549

Page 314 of 475

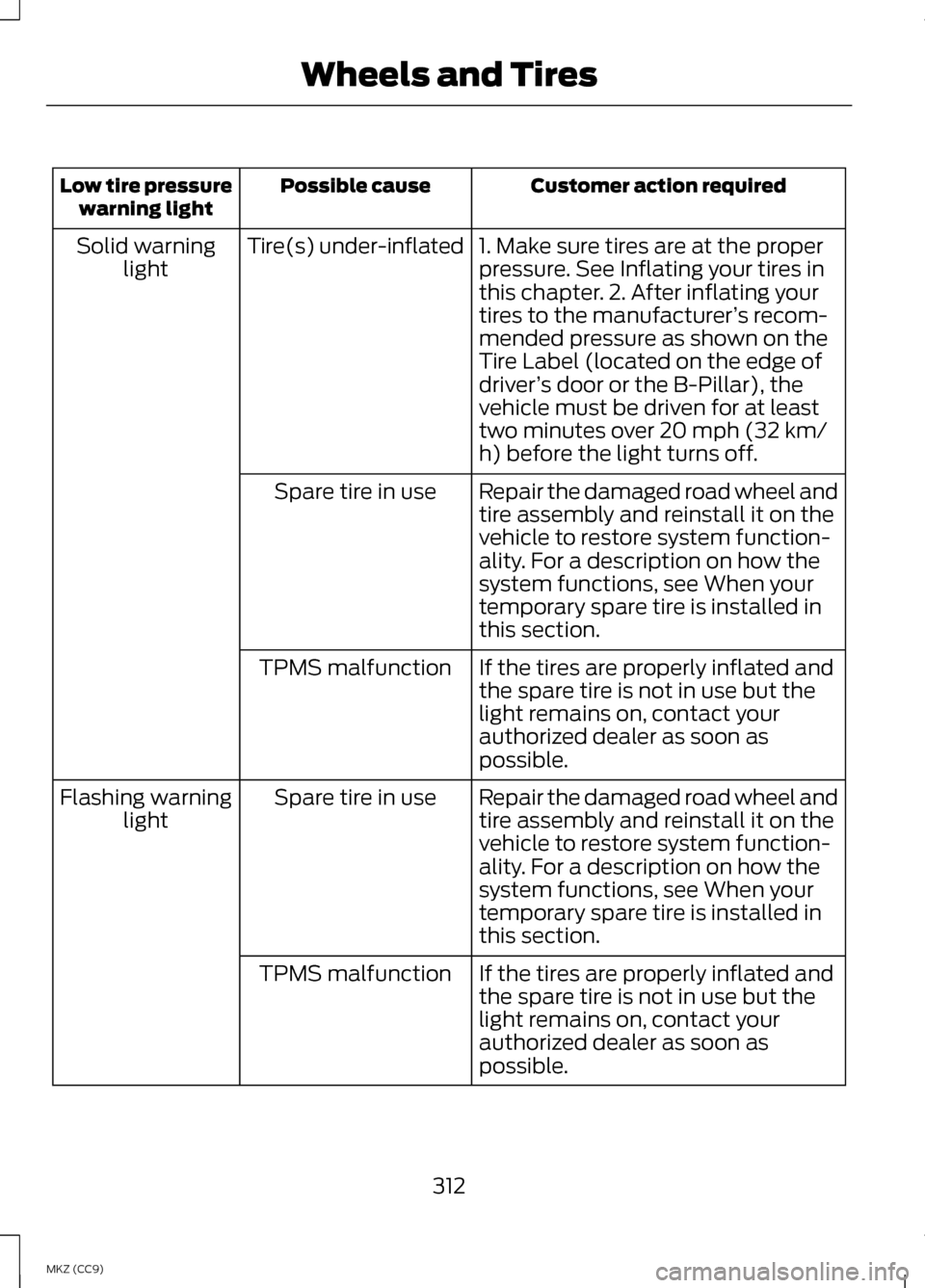

Customer action required

Possible cause

Low tire pressure

warning light

1. Make sure tires are at the proper

pressure. See Inflating your tires in

this chapter. 2. After inflating your

tires to the manufacturer’s recom-

mended pressure as shown on the

Tire Label (located on the edge of

driver ’s door or the B-Pillar), the

vehicle must be driven for at least

two minutes over 20 mph (32 km/

h) before the light turns off.

Tire(s) under-inflated

Solid warning

light

Repair the damaged road wheel and

tire assembly and reinstall it on the

vehicle to restore system function-

ality. For a description on how the

system functions, see When your

temporary spare tire is installed in

this section.

Spare tire in use

If the tires are properly inflated and

the spare tire is not in use but the

light remains on, contact your

authorized dealer as soon as

possible.

TPMS malfunction

Repair the damaged road wheel and

tire assembly and reinstall it on the

vehicle to restore system function-

ality. For a description on how the

system functions, see When your

temporary spare tire is installed in

this section.

Spare tire in use

Flashing warning

light

If the tires are properly inflated and

the spare tire is not in use but the

light remains on, contact your

authorized dealer as soon as

possible.

TPMS malfunction

312

MKZ (CC9) Wheels and Tires

Page 315 of 475

When Inflating your Tires

When putting air into your tires (such

as at a gas station or in your garage),

the tire pressure monitoring system

may not respond immediately to the

air added to your tires.

It may take up to two minutes of

driving over 20 mph (32 km/h) for the

light to turn off after you have filled

your tires to the recommended

inflation pressure

How Temperature Affects your

Tire Pressure

The tire pressure monitoring system

monitors tire pressure in each

pneumatic tire. While driving in a

normal manner, a typical passenger

tire inflation pressure may increase

approximately 2 to 4 psi (14 to 28

kPa) from a cold start situation. If the

vehicle is stationary overnight with the

outside temperature significantly

lower than the daytime temperature,

the tire pressure may decrease

approximately 3 psi (21 kPa) for a drop

of 30°F (17°C) in ambient

temperature. This lower pressure

value may be detected by the TPMS

as being significantly lower than the

recommended inflation pressure and

activate the TPMS warning light for

low tire pressure. If the low tire

pressure warning light is on, visually

check each tire to verify that no tire is

flat. (If one or more tires are flat, repair

as necessary.) Check air pressure in

the road tires. If any tire is

under-inflated, carefully drive the

vehicle to the nearest location where

air can be added to the tires. Inflate

all the tires to the recommended

inflation pressure.

TIRE CARE

Information About Uniform

Tire Quality Grading

Tire Quality Grades apply to new

pneumatic passenger car tires.

The Quality grades can be found

where applicable on the tire

sidewall between tread shoulder

and maximum section width. For

example: Treadwear 200

Traction AA Temperature A.

These Tire Quality Grades are

determined by standards that the

United States Department of

Transportation has set.

313

MKZ (CC9) Wheels and TiresE142542

Page 316 of 475

Tire Quality Grades apply to new

pneumatic passenger car tires.

They do not apply to deep tread,

winter-type snow tires,

space-saver or temporary use

spare tires, light truck or LT type

tires, tires with nominal rim

diameters of 10 to 12 inches or

limited production tires as defined

in Title 49 Code of Federal

Regulations Part 575.104 (c)(2).

U.S. Department of

Transportation Tire quality

grades: The U.S. Department of

Transportation requires Ford

Motor Company to give you the

following information about tire

grades exactly as the government

has written it.

Treadwear

The treadwear grade is a

comparative rating based on the

wear rate of the tire when tested

under controlled conditions on a

specified government test course.

For example, a tire graded 150

would wear one and one-half (1

½) times as well on the

government course as a tire

graded 100. The relative

performance of tires depends

upon the actual conditions of their

use, however, and may depart

significantly from the norm due to

variations in driving habits, service

practices, and differences in road

characteristics and climate. Traction AA A B C WARNING

The traction grade assigned

to this tire is based on

straight-ahead braking traction

tests, and does not include

acceleration, cornering,

hydroplaning or peak traction

characteristics. The traction grades, from highest

to lowest are AA, A, B, and C. The

grades represent the tire

’s ability

to stop on wet pavement as

measured under controlled

conditions on specified

government test surfaces of

asphalt and concrete. A tire

marked C may have poor traction

performance.

Temperature A B C WARNING

The temperature grade for

this tire is established for a

tire that is properly inflated and

not overloaded. Excessive speed,

underinflation, or excessive

loading, either separately or in

combination, can cause heat

buildup and possible tire failure. The temperature grades are A

(the highest), B and C,

representing the tire

’s resistance

to the generation of heat and its

ability to dissipate heat when

tested under controlled conditions

on a specified indoor laboratory

314

MKZ (CC9) Wheels and Tires

Page 321 of 475

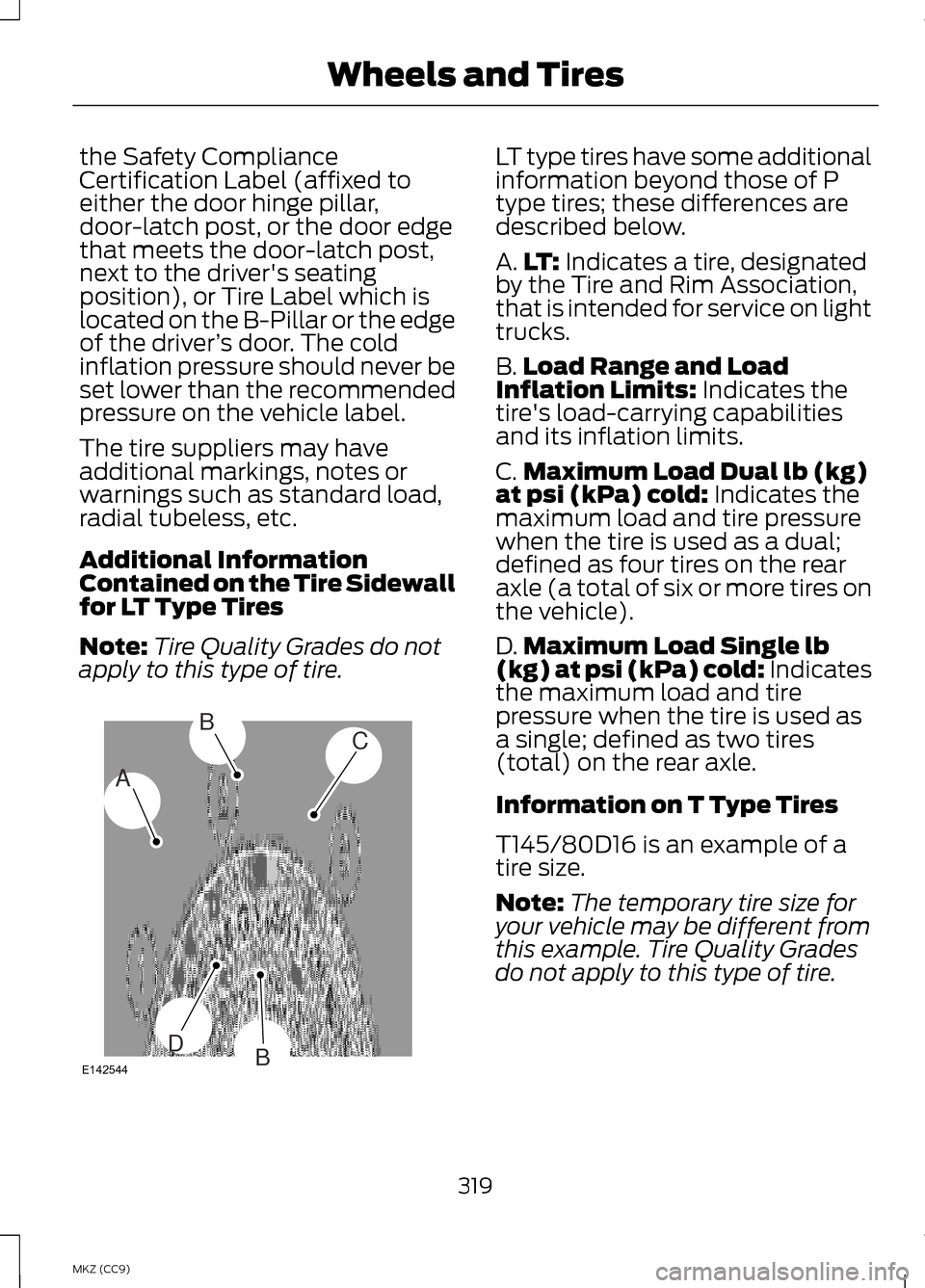

the Safety Compliance

Certification Label (affixed to

either the door hinge pillar,

door-latch post, or the door edge

that meets the door-latch post,

next to the driver's seating

position), or Tire Label which is

located on the B-Pillar or the edge

of the driver

’s door. The cold

inflation pressure should never be

set lower than the recommended

pressure on the vehicle label.

The tire suppliers may have

additional markings, notes or

warnings such as standard load,

radial tubeless, etc.

Additional Information

Contained on the Tire Sidewall

for LT Type Tires

Note: Tire Quality Grades do not

apply to this type of tire. LT type tires have some additional

information beyond those of P

type tires; these differences are

described below.

A.

LT: Indicates a tire, designated

by the Tire and Rim Association,

that is intended for service on light

trucks.

B. Load Range and Load

Inflation Limits:

Indicates the

tire's load-carrying capabilities

and its inflation limits.

C. Maximum Load Dual lb (kg)

at psi (kPa) cold:

Indicates the

maximum load and tire pressure

when the tire is used as a dual;

defined as four tires on the rear

axle (a total of six or more tires on

the vehicle).

D. Maximum Load Single lb

(kg) at psi (kPa) cold:

Indicates

the maximum load and tire

pressure when the tire is used as

a single; defined as two tires

(total) on the rear axle.

Information on T Type Tires

T145/80D16 is an example of a

tire size.

Note: The temporary tire size for

your vehicle may be different from

this example. Tire Quality Grades

do not apply to this type of tire.

319

MKZ (CC9) Wheels and TiresA

BC

BDE142544

Page 323 of 475

You are strongly urged to buy a

reliable tire pressure gauge, as

automatic service station gauges

may be inaccurate. Ford

recommends the use of a digital

or dial-type tire pressure gauge

rather than a stick-type tire

pressure gauge.

Use the recommended cold

inflation pressure for optimum tire

performance and wear.

Under-inflation or over-inflation

may cause uneven treadwear

patterns

WARNING

Under-inflation is the most

common cause of tire failures

and may result in severe tire

cracking, tread separation or

blowout, with unexpected loss of

vehicle control and increased risk

of injury. Under-inflation increases

sidewall flexing and rolling

resistance, resulting in heat

buildup and internal damage to

the tire. It also may result in

unnecessary tire stress, irregular

wear, loss of vehicle control and

accidents. A tire can lose up to

half of its air pressure and not

appear to be flat! Always inflate your tires to the

Ford recommended inflation

pressure even if it is less than the

maximum inflation pressure

information found on the tire. The

Ford recommended tire inflation

pressure is found on the Safety

Compliance Certification Label (affixed to either the door hinge

pillar, door-latch post, or the door

edge that meets the door-latch

post, next to the driver's seating

position), or Tire Label which is

located on the B-Pillar or the edge

of the driver

’s door. Failure to

follow the tire pressure

recommendations can cause

uneven treadwear patterns and

adversely affect the way your

vehicle handles

Maximum Permissible Inflation

Pressure is the tire

manufacturer's maximum

permissible pressure and the

pressure at which the maximum

load can be carried by the tire. This

pressure is normally higher than

the manufacturer ’s recommended

cold inflation pressure which can

be found on the Safety

Compliance Certification Label

(affixed to either the door hinge

pillar, door-latch post, or the door

edge that meets the door-latch

post, next to the driver's seating

position), or Tire Label which is

located on the B-Pillar or the edge

of the driver ’s door. The cold

inflation pressure should never be

set lower than the recommended

pressure on the Safety

Compliance Certification Label or

Tire Label.

321

MKZ (CC9) Wheels and Tires