Rear LINCOLN NAVIGATOR 2017 Owners Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2017, Model line: NAVIGATOR, Model: LINCOLN NAVIGATOR 2017Pages: 532, PDF Size: 3.9 MB

Page 321 of 532

If the low tire pressure warning light is on,

visually check each tire to verify that no tire

is flat. If one or more tires are flat, repair as

necessary. Check the air pressure in the road

tires. If any tire is under-inflated, carefully

drive the vehicle to the nearest location

where air can be added to the tires. Inflate

all the tires to the recommended inflation

pressure.

Tire Pressure Monitoring System Reset

Procedure

WARNING

To determine the required pressure(s)

for your vehicle, see the Safety

Compliance Certification Label (on the door

hinge pillar, door-latch post or the door edge

that meets the door-latch post, next to the

driver seat) or the Tire Label on the B-Pillar

or the edge of the driver door. Note:

You need to perform the tire pressure

monitoring system reset procedure after

each tire rotation on vehicles that require

different recommended tire pressures in the

front tires as compared to the rear tires. Overview

To provide the vehicle's load carrying

capability, some vehicles require different

recommended tire pressures in the front tires

as compared to the rear tires. The tire

pressure monitoring system equipped on

these vehicles is designed to illuminate the

low tire pressure warning light at two

different pressures; one for the front tires

and one for the rear tires.

Since tires need to be rotated to provide

consistent performance and maximum tire

life, the tire pressure monitoring system

needs to know when the tires are rotated to

determine which set of tires are on the front

and which are on the rear. With this

information, the system can detect and

properly warn of low tire pressures.

System reset tips:

•

To reduce the chances of interference

from another vehicle, perform the system

reset procedure at least three feet (one

meter) away from another Ford Motor

Company vehicle undergoing the system

reset procedure at the same time.

• Do not wait more than two minutes

between resetting each tire sensor or the

system will time-out and the entire

procedure will have to be repeated on

all four wheels.

• A double horn will sound indicating the

need to repeat the procedure.

Performing the System Reset Procedure

Read the entire procedure before attempting.

1. Drive the vehicle above 20 mph (32 km/h) for at least two minutes, then park

in a safe location where you can easily

get to all four tires and have access to

an air pump.

2. Place the ignition in the off position and keep the key in the ignition.

3. Cycle the ignition to the on position with

the engine off.

318

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 322 of 532

4.

Turn the hazard flashers on then off three

times. You must accomplish this within

10 seconds. If the reset mode has been

entered successfully, the horn will sound

once, the system indicator will flash and

a message is shown in the information

display. If this does not occur, please try

again starting at Step 2. If after repeated

attempts to enter the reset mode, the

horn does not sound, the system

indicator does not flash and no message

is shown in the information display, seek

service from your authorized dealer.

5. Train the tire pressure monitoring system

sensors in the tires using the following

system reset sequence starting with the

left front tire in the following clockwise

order: Left front (driver's side front tire),

Right front (passenger's side front tire),

Right rear (passenger's side rear tire), Left

rear (driver's side rear tire).

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds. Note:

The single horn chirp confirms that the

sensor identification code has been learned

by the module for this position. If a double

horn is heard, the reset procedure was

unsuccessful, and you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease the

air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained (driver's

side rear tire), the system indicator stops

flashing, and a message is shown in the

information display.

10. Turn the ignition off. If two short horn beeps are heard, the reset procedure

was unsuccessful and you must repeat

it. If after repeating the procedure and

two short beeps are heard when the

ignition is turned to off, seek assistance

from your authorized dealer. 11. Set all four tires to the recommended

air pressure as indicated on the Safety

Compliance Certification Label (affixed

to either the door hinge pillar,

door-latch post, or the door edge that

meets the door-latch post, next to the

driver's seating position) or Tire Label

located on the B-Pillar or the edge of

the driver's door.

CHANGING A ROAD WHEEL WARNINGS

The use of tire sealant may damage

your tire pressure monitoring system

and should only be used in roadside

emergencies. If you must use a sealant, the

Ford Tire Mobility Kit sealant should be used.

The tire pressure monitoring system sensor

and valve stem on the wheel must be

replaced by an authorized dealer after use

of the sealant. If the tire pressure monitor sensor

becomes damaged, it will no longer

function. See Tire Pressure Monitoring

System (page 313). 319

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 324 of 532

3. Full-size dissimilar spare without label

on wheel

When driving with the full-size dissimilar

spare wheel and tire assembly, do not:

• Exceed

70 mph (113 km/h).

• Use more than one dissimilar spare

wheel and tire assembly at a time.

• Use commercial car washing equipment.

• Use snow chains on the end of the

vehicle with the dissimilar spare wheel

and tire assembly. The usage of a full-size dissimilar spare

wheel and tire assembly can lead to

impairment of the following:

•

Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability.

• Wet weather driving capability.

• All-wheel driving capability. When driving with the full-size dissimilar

spare wheel and tire assembly additional

caution should be given to:

•

Towing a trailer.

• Driving vehicles equipped with a camper

body.

• Driving vehicles with a load on the cargo

rack.

Drive cautiously when using a full-size

dissimilar spare wheel and tire assembly and

seek service as soon as possible.

Location of the Spare Tire and Tools

The spare tire is located under the vehicle,

just forward of the rear bumper. The jack,

jack handle and lug wrench are located in

the following locations: Location

Item

Under the vehicle, just forward of the rear bumper

Spare tire

Under the access panel located in the floor compartment behind therear seat

Jack tools

321

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 327 of 532

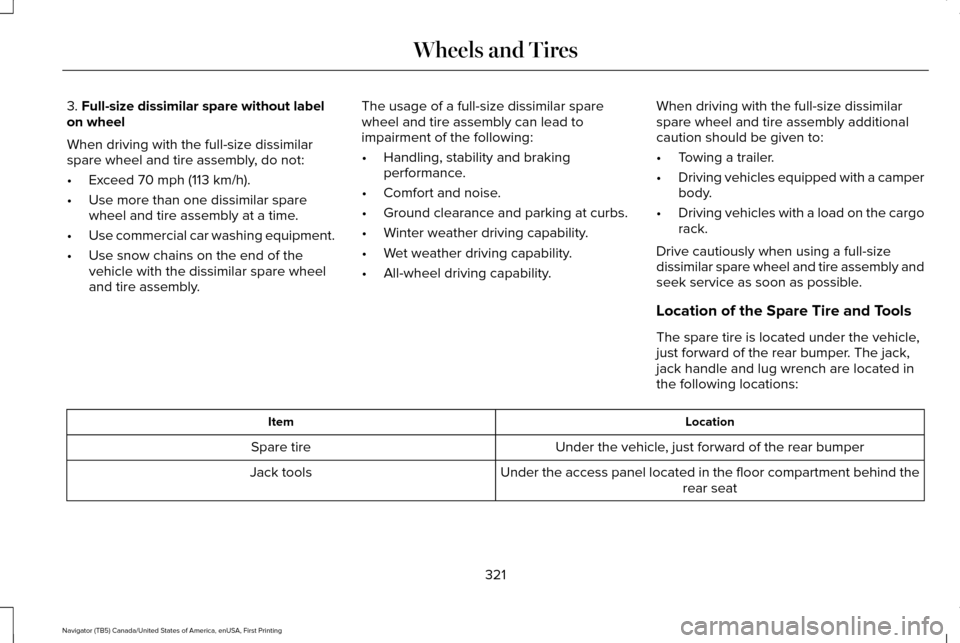

Rear jacking point 1. With the vehicle on level ground, block

both sides of the wheel diagonally

opposite (other side and end of the

vehicle) to the wheel being changed. Do

not jack the vehicle on a hill or incline.

2. Obtain the spare tire and jack tools from

their storage locations.

3. Use the tip of the jack handle to remove

any wheel trim.

4. Loosen each wheel lug nut one-half turn

counterclockwise but do not remove

them until the wheel is raised off the

ground.

5. Position the jack according to the jack locator arrows found on the frame and

turn the jack handle and extension tool

assembly clockwise.

6. Raise the vehicle to provide sufficient ground clearance when installing the

spare tire, about 1/4 inch (6 millimeters).

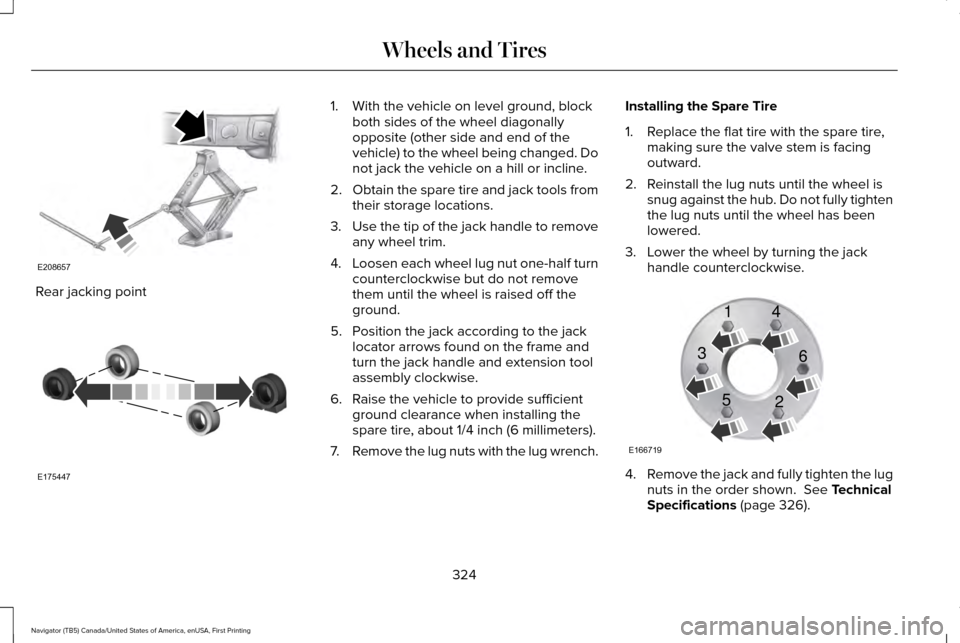

7. Remove the lug nuts with the lug wrench. Installing the Spare Tire

1. Replace the flat tire with the spare tire,

making sure the valve stem is facing

outward.

2. Reinstall the lug nuts until the wheel is snug against the hub. Do not fully tighten

the lug nuts until the wheel has been

lowered.

3. Lower the wheel by turning the jack handle counterclockwise. 4.

Remove the jack and fully tighten the lug

nuts in the order shown. See Technical

Specifications (page 326).

324

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and TiresE208657 E175447 E166719

1

3

5 4

6

2

Page 328 of 532

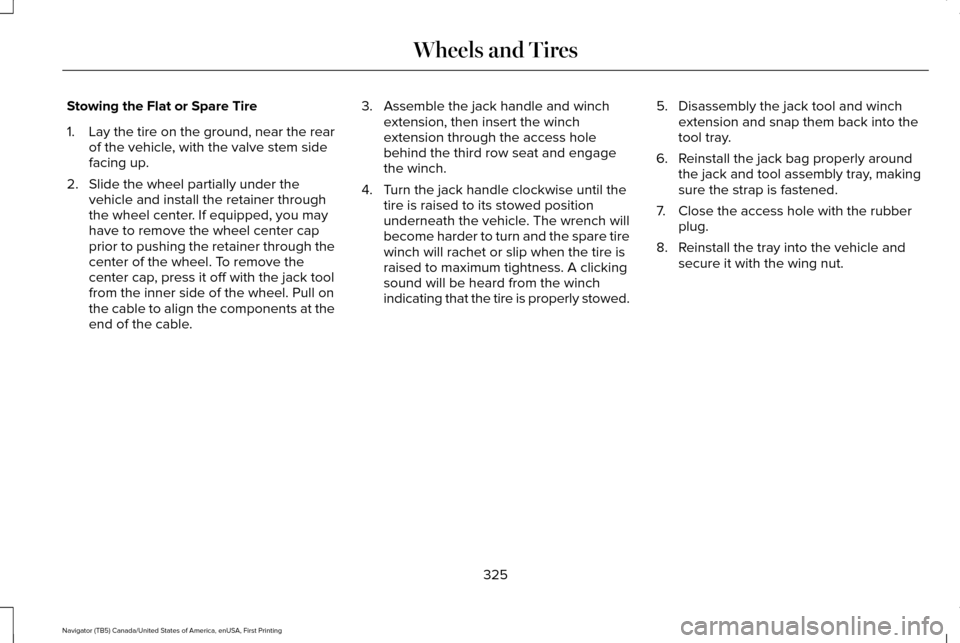

Stowing the Flat or Spare Tire

1.

Lay the tire on the ground, near the rear

of the vehicle, with the valve stem side

facing up.

2. Slide the wheel partially under the vehicle and install the retainer through

the wheel center. If equipped, you may

have to remove the wheel center cap

prior to pushing the retainer through the

center of the wheel. To remove the

center cap, press it off with the jack tool

from the inner side of the wheel. Pull on

the cable to align the components at the

end of the cable. 3. Assemble the jack handle and winch

extension, then insert the winch

extension through the access hole

behind the third row seat and engage

the winch.

4. Turn the jack handle clockwise until the tire is raised to its stowed position

underneath the vehicle. The wrench will

become harder to turn and the spare tire

winch will rachet or slip when the tire is

raised to maximum tightness. A clicking

sound will be heard from the winch

indicating that the tire is properly stowed. 5. Disassembly the jack tool and winch

extension and snap them back into the

tool tray.

6. Reinstall the jack bag properly around the jack and tool assembly tray, making

sure the strap is fastened.

7. Close the access hole with the rubber plug.

8. Reinstall the tray into the vehicle and secure it with the wing nut.

325

Navigator (TB5) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 332 of 532

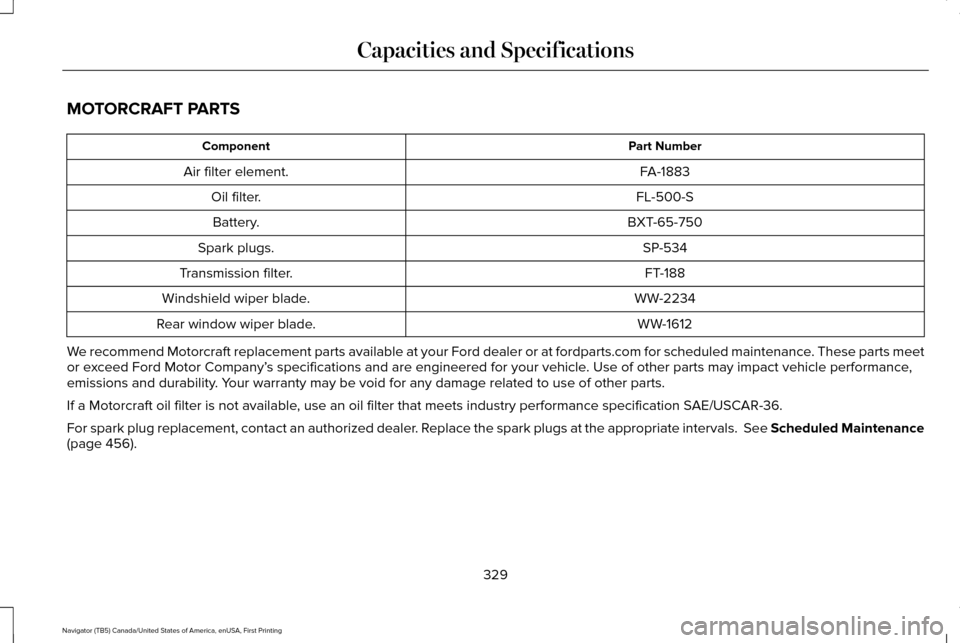

MOTORCRAFT PARTS

Part Number

Component

FA-1883

Air filter element.

FL-500-S

Oil filter.

BXT-65-750

Battery.

SP-534

Spark plugs.

FT-188

Transmission filter.

WW-2234

Windshield wiper blade.

WW-1612

Rear window wiper blade.

We recommend Motorcraft replacement parts available at your Ford dealer o\

r at fordparts.com for scheduled maintenance. These parts meet

or exceed Ford Motor Company’ s specifications and are engineered for your vehicle. Use of other parts may impact vehicle performance,

emissions and durability. Your warranty may be void for any damage related to use of other parts.

If a Motorcraft oil filter is not available, use an oil filter that meets industry performance specification SAE/USCAR-36.

For spark plug replacement, contact an authorized dealer. Replace the spark plugs at the appropriate intervals. See Scheduled Maintenance

(page 456).

329

Navigator (TB5) Canada/United States of America, enUSA, First Printing Capacities and Specifications

Page 335 of 532

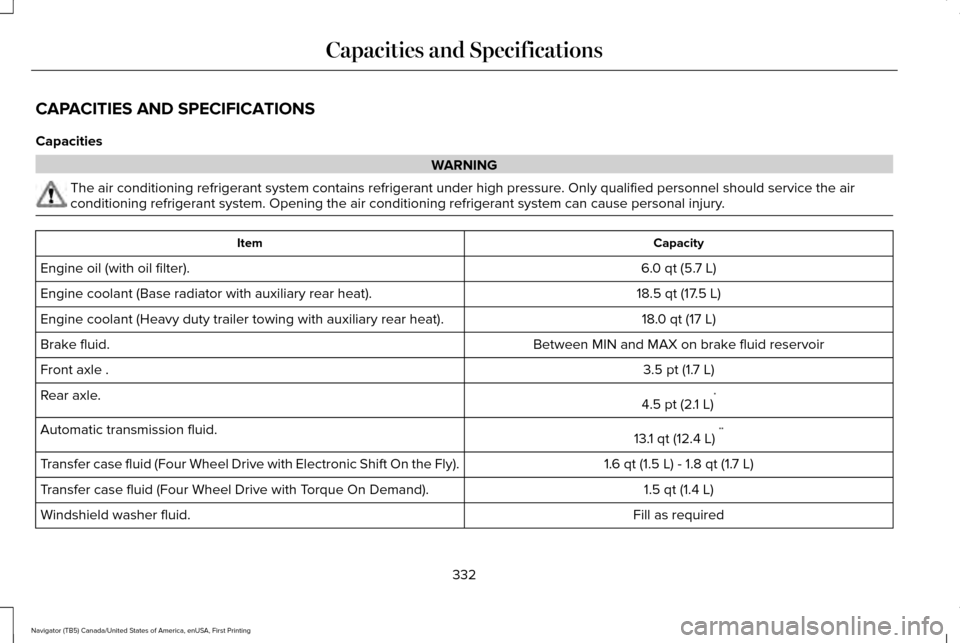

CAPACITIES AND SPECIFICATIONS

Capacities

WARNING

The air conditioning refrigerant system contains refrigerant under high \

pressure. Only qualified personnel should service the air

conditioning refrigerant system. Opening the air conditioning refrigeran\

t system can cause personal injury.

Capacity

Item

6.0 qt (5.7 L)

Engine oil (with oil filter).

18.5 qt (17.5 L)

Engine coolant (Base radiator with auxiliary rear heat).

18.0 qt (17 L)

Engine coolant (Heavy duty trailer towing with auxiliary rear heat).

Between MIN and MAX on brake fluid reservoir

Brake fluid.

3.5 pt (1.7 L)

Front axle .

4.5 pt (2.1 L)*

Rear axle.

13.1 qt (12.4 L)**

Automatic transmission fluid.

1.6 qt (1.5 L) - 1.8 qt (1.7 L)

Transfer case fluid (Four Wheel Drive with Electronic Shift On the Fly)\

.

1.5 qt (1.4 L)

Transfer case fluid (Four Wheel Drive with Torque On Demand).

Fill as required

Windshield washer fluid.

332

Navigator (TB5) Canada/United States of America, enUSA, First Printing Capacities and Specifications

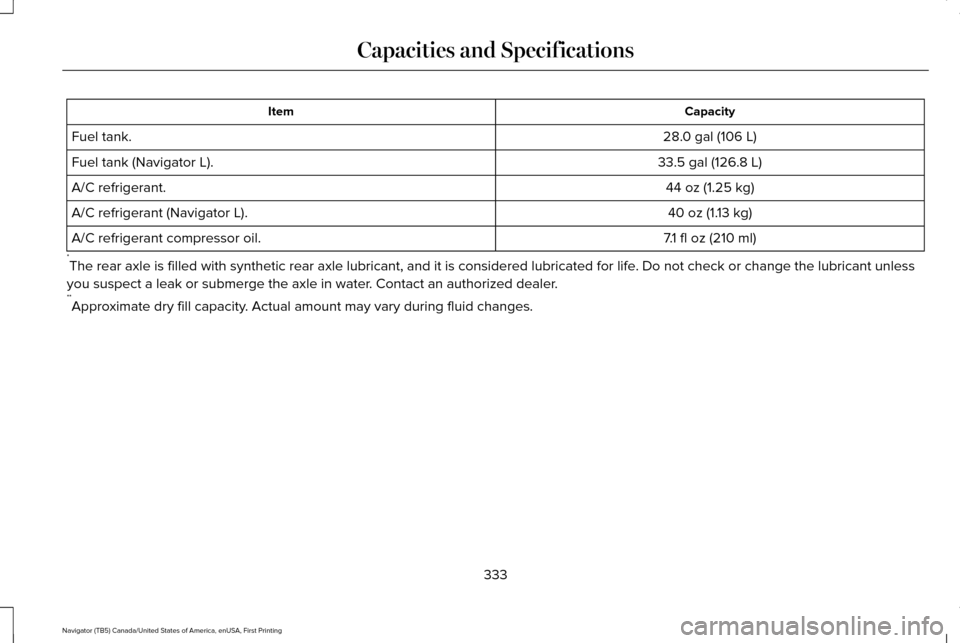

Page 336 of 532

Capacity

Item

28.0 gal (106 L)

Fuel tank.

33.5 gal (126.8 L)

Fuel tank (Navigator L).

44 oz (1.25 kg)

A/C refrigerant.

40 oz (1.13 kg)

A/C refrigerant (Navigator L).

7.1 fl oz (210 ml)

A/C refrigerant compressor oil.

* The rear axle is filled with synthetic rear axle lubricant, and it is co\

nsidered lubricated for life. Do not check or change the lubricant unless

you suspect a leak or submerge the axle in water. Contact an authorized dealer.

** Approximate dry fill capacity. Actual amount may vary during fluid changes.

333

Navigator (TB5) Canada/United States of America, enUSA, First Printing Capacities and Specifications

Page 338 of 532

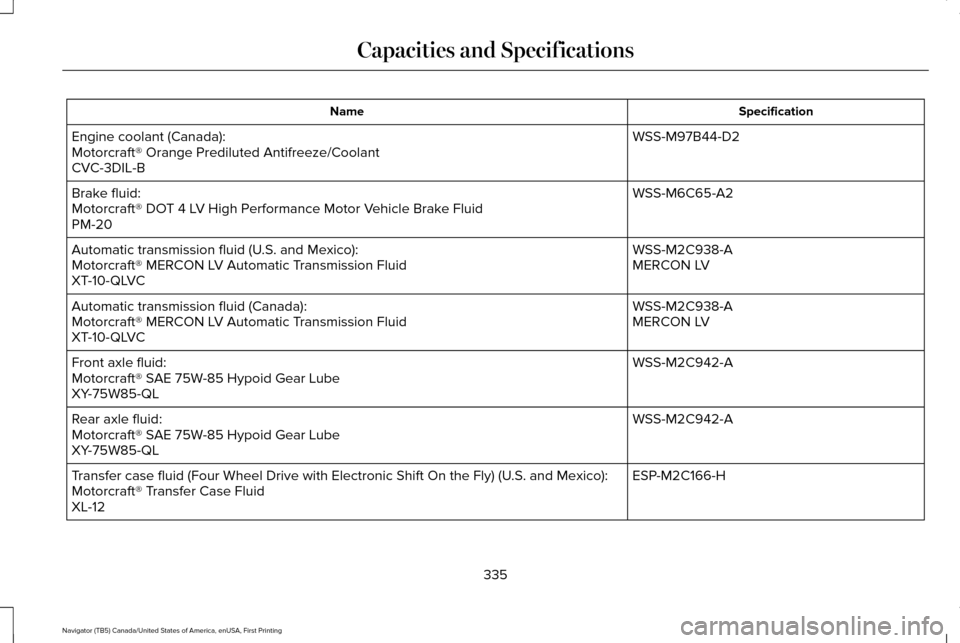

Specification

Name

WSS-M97B44-D2

Engine coolant (Canada):

Motorcraft® Orange Prediluted Antifreeze/Coolant

CVC-3DIL-B

WSS-M6C65-A2

Brake fluid:

Motorcraft® DOT 4 LV High Performance Motor Vehicle Brake Fluid

PM-20

WSS-M2C938-A

Automatic transmission fluid (U.S. and Mexico):

MERCON LV

Motorcraft® MERCON LV Automatic Transmission Fluid

XT-10-QLVC

WSS-M2C938-A

Automatic transmission fluid (Canada):

MERCON LV

Motorcraft® MERCON LV Automatic Transmission Fluid

XT-10-QLVC

WSS-M2C942-A

Front axle fluid:

Motorcraft® SAE 75W-85 Hypoid Gear Lube

XY-75W85-QL

WSS-M2C942-A

Rear axle fluid:

Motorcraft® SAE 75W-85 Hypoid Gear Lube

XY-75W85-QL

ESP-M2C166-H

Transfer case fluid (Four Wheel Drive with Electronic Shift On the Fly)\

(U.S. and Mexico):

Motorcraft® Transfer Case Fluid

XL-12

335

Navigator (TB5) Canada/United States of America, enUSA, First Printing Capacities and Specifications

Page 345 of 532

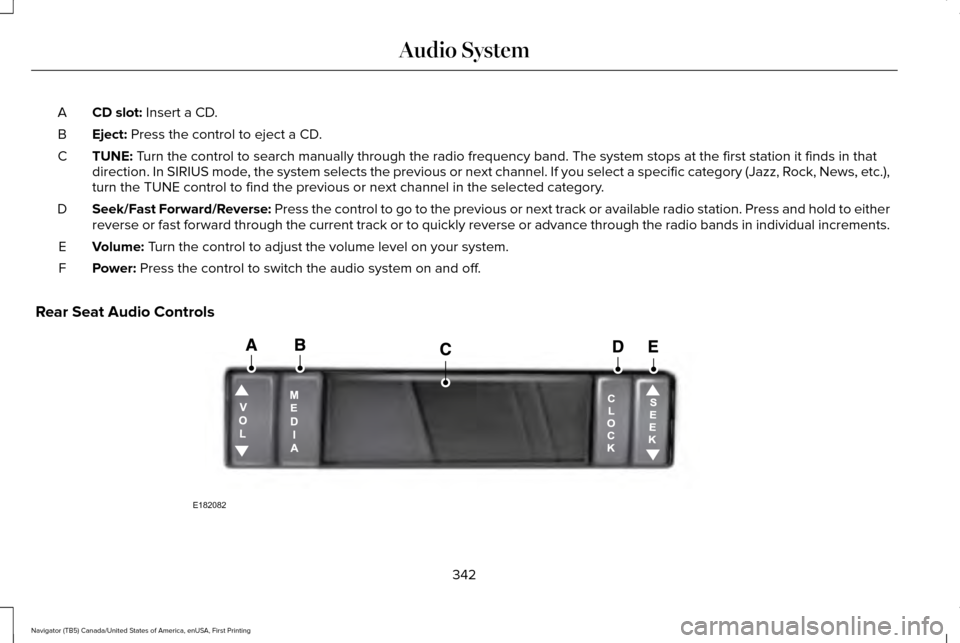

CD slot: Insert a CD.

A

Eject:

Press the control to eject a CD.

B

TUNE:

Turn the control to search manually through the radio frequency band. The\

system stops at the first station it finds in that

direction. In SIRIUS mode, the system selects the previous or next channel. If you select a speci\

fic category (Jazz, Rock, News, etc.),

turn the TUNE control to find the previous or next channel in the select\

ed category.

C

Seek/Fast Forward/Reverse:

Press the control to go to the previous or next track or available radi\

o station. Press and hold to either

reverse or fast forward through the current track or to quickly reverse \

or advance through the radio bands in individual increments.

D

Volume:

Turn the control to adjust the volume level on your system.

E

Power:

Press the control to switch the audio system on and off.

F

Rear Seat Audio Controls 342

Navigator (TB5) Canada/United States of America, enUSA, First Printing Audio SystemE182082