DOOR LOTUS ELISE 2005 Owner's Manual

[x] Cancel search | Manufacturer: LOTUS, Model Year: 2005, Model line: ELISE, Model: LOTUS ELISE 2005Pages: 205, PDF Size: 4.51 MB

Page 84 of 205

b332

FITTING ROOF STAYS

Soft Top Roof - Fitting

WARNING:Do not attempt to fit the soft top roof whilst the car is in

motion. This could cause a crash in which you or others

could be killed or seriously injured.

1. From its stowage bag in the rear luggage compartment, with-

draw the roof assembly and support stays. Lower both door

windows, or open both doors.

2. Insert the two, identical, roof support stays, with the arrows pointing forwards, into the slots above the rear window, and

in the windscreen header rail. Note that the slots are keyed

to allow fitment of the stays in only the correct orientation.

3. Lay the soft top roof across the centre of the roof space with

the arrows on the side rails pointing forwards.

External Operations

82

Arrows

point for ward

Rear end keyway

oh_croft_InD.indd 8220/05/2004 07:59:01ProCarManuals.com

Page 86 of 205

ohs149

RELEASING ROOF SIDE RAIL

Soft Top - Removal

WARNING:Do not attempt to remove the soft top roof whilst the

car is in motion. This could cause a crash in which you or

others could be killed or seriously injured.

1. With the car stationary, open both doors or lower both door windows.

2. On the inside face of the right hand roof side rail, locate the

two latch release levers: Pull the two lever handles towards each other to release the side rail latches (press down on the

side rail if necessary to relieve the load on the latch pins), and rotate the rail upwards to release the canopy tension.

3. Repeat step (2) for the

left hand side rail.

NOTICE: Releasing the right hand roof side rail first, will minimise

the possibility of the canopy tensioning cable adjusters causing damage to the roof seals.

4. Free the front and rear tensioning cables from the gutters be

-

fore carefully rolling up each side of the roof canopy towards the centre. Lift the roof assembly off the car, and pack in the

roof bag.

External Operations

84

oh_croft_InD.indd 8420/05/2004 07:59:01ProCarManuals.com

Page 88 of 205

b330

FRONT SPIGOT BRACKET

Hard Top - Fitting

1. Open both doors, and preferably with the aid of an assistant, lower the roof onto the car holding aside the loose tethered

fixings to avoid their entrapment or their causing paint damage. Position the rear edge of the roof first before locating the front

edge against the windscreen header rail.

2. Locate a front spigot bracket into its latch plate lower slot (lifting the roof slightly to allow this) and retain to the roof with the Torx bolt. Use only the special Torx tool supplied in the car tool kit (stowed in the battery cover pocket), and do not

fully tighten at this stage.

3. Repeat step (2) for the opposite front spigot bracket.

External Operations

86

oh_croft_InD.indd 8620/05/2004 07:59:02ProCarManuals.com

Page 92 of 205

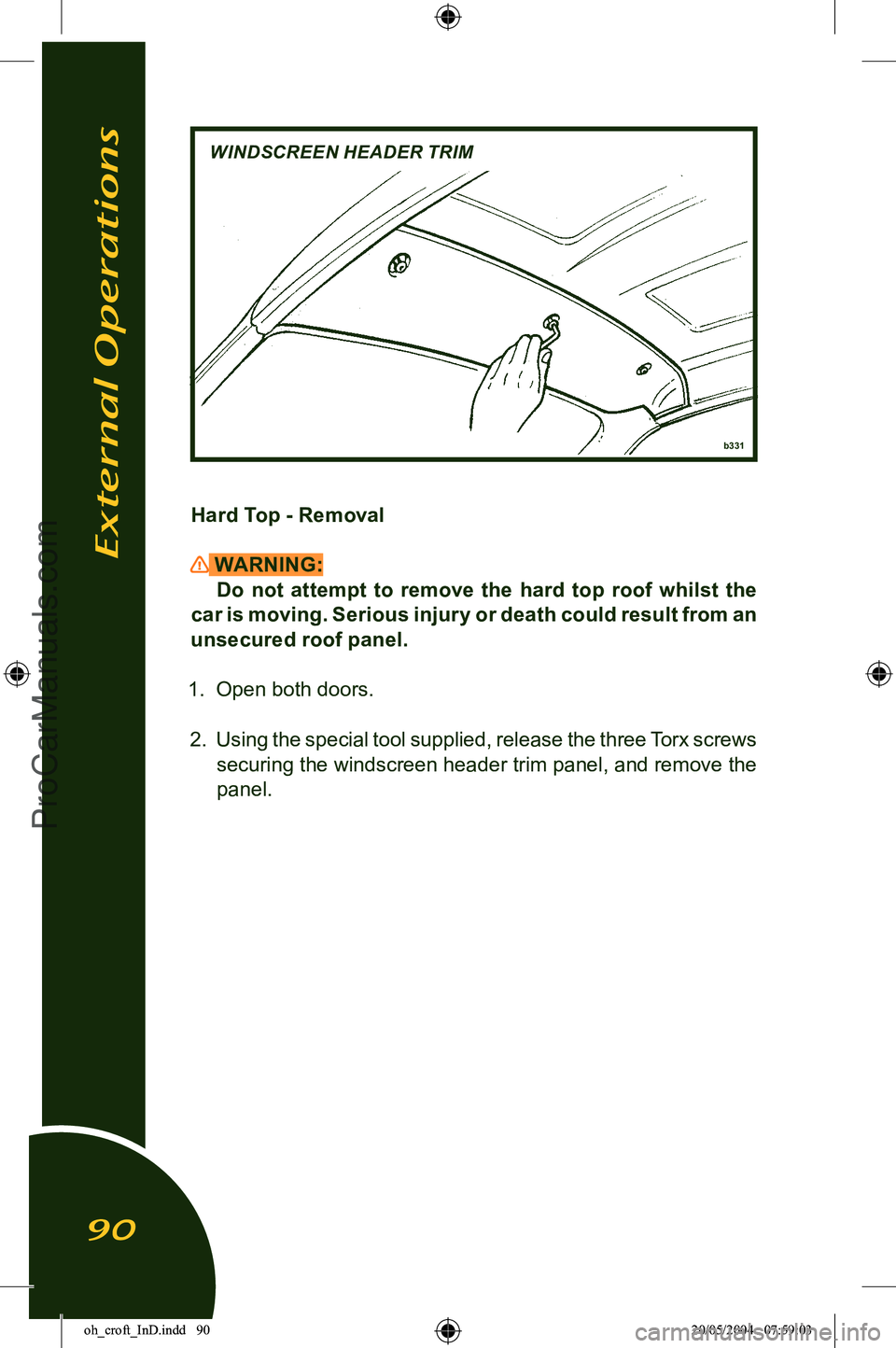

b331

WINDSCREEN HEADER TRIM

Hard Top - Removal

WARNING:Do not attempt to remove the hard top roof whilst the

car is moving. Serious injury or death could result from an

unsecured roof panel.

1. Open both doors.

2. Using the special tool supplied, release the three Torx screws securing the windscreen header trim panel, and remove the

panel.

External Operations

90

oh_croft_InD.indd 9020/05/2004 07:59:03ProCarManuals.com

Page 95 of 205

SERVICING AND MAINTENANCEBODYCARE

Body Features Lotus are among the world leaders in the field of automotive

composite moulding design and manufacturing techniques.

Composite materials have major advantages for specialist car bodies, and these brief notes introduce some features of the

construction and service properties of automotive composite bodies. The manufacturing process enables the thickness of com

-

posite mouldings to be varied in order to provide ef ficient structures of high strength and low weight. Composites will not

corrode, so the strength of composite components is retained regardless of age, unless physical damage is sustained. On

the Elise, the body construction utilises several mouldings to

form a single unit for the whole of the nose and front wings, and

a second unit for the whole of the rear body aft of the doors.

These two moulded assemblies are fixed using threaded fasten

-

ers to permit easy removal for access to chassis or powertrain

components, or to allow simple and economic accident repair.

Other composite mouldings include the door shells, sills, front access panels, windscreen frame and rear bulkhead, some panels being bonded to the aluminium alloy chassis with an

elastomeric adhesive.

Several different processes are used to manufacture the

various panels depending on the functional requirements, with the main outer panels using an injection compression mould

-

ing technique which eliminates the ‘gelcoat’ used on the outer

surface of conventionally manufactured composite panels. This

process provides considerably increased resistance to surface

damage from minor knocks, where a conventional composite panel would suffer cracking of the gel coat, or a steel panel be

-

come dented. If severe damage is caused to a composite panel

where the underlying structure is broken, repairs may take the

form of panel replacement, or of panel repair using techniques

where new composite material is integrated with the old to result in undiminished panel strength.

Servicing & Maintenance

93

oh_croft_InD.indd 9320/05/2004 07:59:03ProCarManuals.com

Page 120 of 205

Use a good quality proprietary tire pressure gauge and always replace the tire valve dust cap to prevent the

ingress of dirt and moisture into the valve, which could cause leakage. Many fuel filling stations provide tire inflation facilities,

which specific usage instructions should be carefully fol

-

lowed. For tire pressure information, refer to ‘Technical

Data’ or the Certification Label on the driver’s door jamb

(see page 121).

Replacement Tires When replacing tires, refer to the ‘Technical Data’ sec

-

tion in this handbook, or consult your dealer to check the current Lotus specification and recommendations. Do not

use tires which differ from these specifications.

WARNING: Note that some tread patterns are directional, so

that the tire must be fitted onto the wheel with regard

to which side of the car the wheel is to be used. In

these cases, a direction of rotation arrow is included in the tire sidewall markings.

When balancing the wheel and tire assemblies, the

wheels should be located by the centre spigot hole - NOT by the wheel bolt holes. In order to maintain the correct

ohs115b

Direction of rotation arrow

Tires & Wheels

118

oh_croft_InD.indd 11820/05/2004 07:59:10ProCarManuals.com

Page 123 of 205

characteristics and climates.

Traction - AA, A, B, C: The traction grades, from highest to lowest are: A A, A, B, and C. They represent the tires ability to stop on wet pavement as measured under con

-

trolled conditions on specified government test surfaces of asphalt and concrete. A tire marked ‘C’ may have poor

traction performance.

WARNING: The traction grade assigned to this tire is based

on braking (straight ahead) traction tests and does

not include acceleration, cornering, hydroplaning, or

peak traction characteristics.

Temperature - A, B, C: The temperature grades are A (the highest), B, and C, representing the tire’s resistance to the generation of heat and its ability to dissipate heat when

tested under controlled conditions on a specified indoor laboratory test wheel. Sustained high temperature can cause the material of the tire to degenerate and reduce tire

life, and excessive temperature can lead to sudden tire fail

-

ure. The grade ‘C’ corresponds to a level of performance

which all passenger car Tires must meet under Federal Motor Car Safety Standard No. 109. Grades ‘B’ and ‘A’ represent higher levels of performance on the laboratory

test wheel than the minimum required by law.

WARNING: The temperature grade for this tire is established

for a tire that is properly inflated and not overloaded. Excessive speed, underinflation, or excessive load

-

ing, either separately or in combination, can cause

heat buildup and possible tire failure.

These grades are moulded onto the sidewalls of pas

-

senger car tires. All passenger car tires must conform to Federal safety requirements in addition to these grades.

Tire Placard/Label The tire and loading Information label stuck on the

driver’s door jamb specifies the correct size and pres

-

Tires & Wheels

121

oh_croft_InD.indd 12120/05/2004 07:59:11ProCarManuals.com

Page 124 of 205

sure of tires to be used on the Elise. It also specifies the total weight the car can carry, called the car capacity

weight. This includes the weight of driver, passenger and luggage. Also to be found on the driver’s door jamb is the Cer

-

tification label (‘Manufactured by Lotus Cars Ltd.’) which stipulates the Gross Car Weight Rating (GV WR). The

GVWR includes the weight of the car, occupants, fuel and luggage. Never exceed the GVWR or the Gross Axle

Weight Rating (GAWR) for either the front or rear axle. The maximum load which may be carried in the rear luggage compartment is 110 lb (50 kg). Note that the Elise is not designed to tow a trailer, and no such attempt should be

made.

WARNING: Do not exceed the GVWR, or front or rear GAWR.

Exceeding these limits may cause unstable handling or car or tire damage which could cause a crash

in which you or others could be seriously injured or killed.

The Elise should never be used to tow a

trailer.

Federal Motor Car Safety Standards require Lotus to in

-

clude the following verbatim statement in this handbook:

Steps for Determining Correct Load Limit:

1) Locate the statement “The combined weight of occupants and cargo should never exceed XXX pounds”

on your car’s placard.

2) Determine the combined weight of the driver and pas

-

senger that will be riding in your car.

3) Subtract the combined weight of the driver and pas

-

senger from XXX kilograms, or XXX pounds.

4) The resulting figure equals the available amount of cargo and luggage load capacity. For example, if the

“XXX” amount equals 1400 lbs. and there will be five 150 lb. passengers in your car, the amount of available cargo and luggage load capacity is 650 lbs. (1400 - 750

(5 x 150) = 650 lbs.)

Note: Maximum load to be carried in the Elise rear lug-

gage compartment is 110 lb (50 kg).

Tires & Wheels

122

oh_croft_InD.indd 12220/05/2004 07:59:11ProCarManuals.com

Page 137 of 205

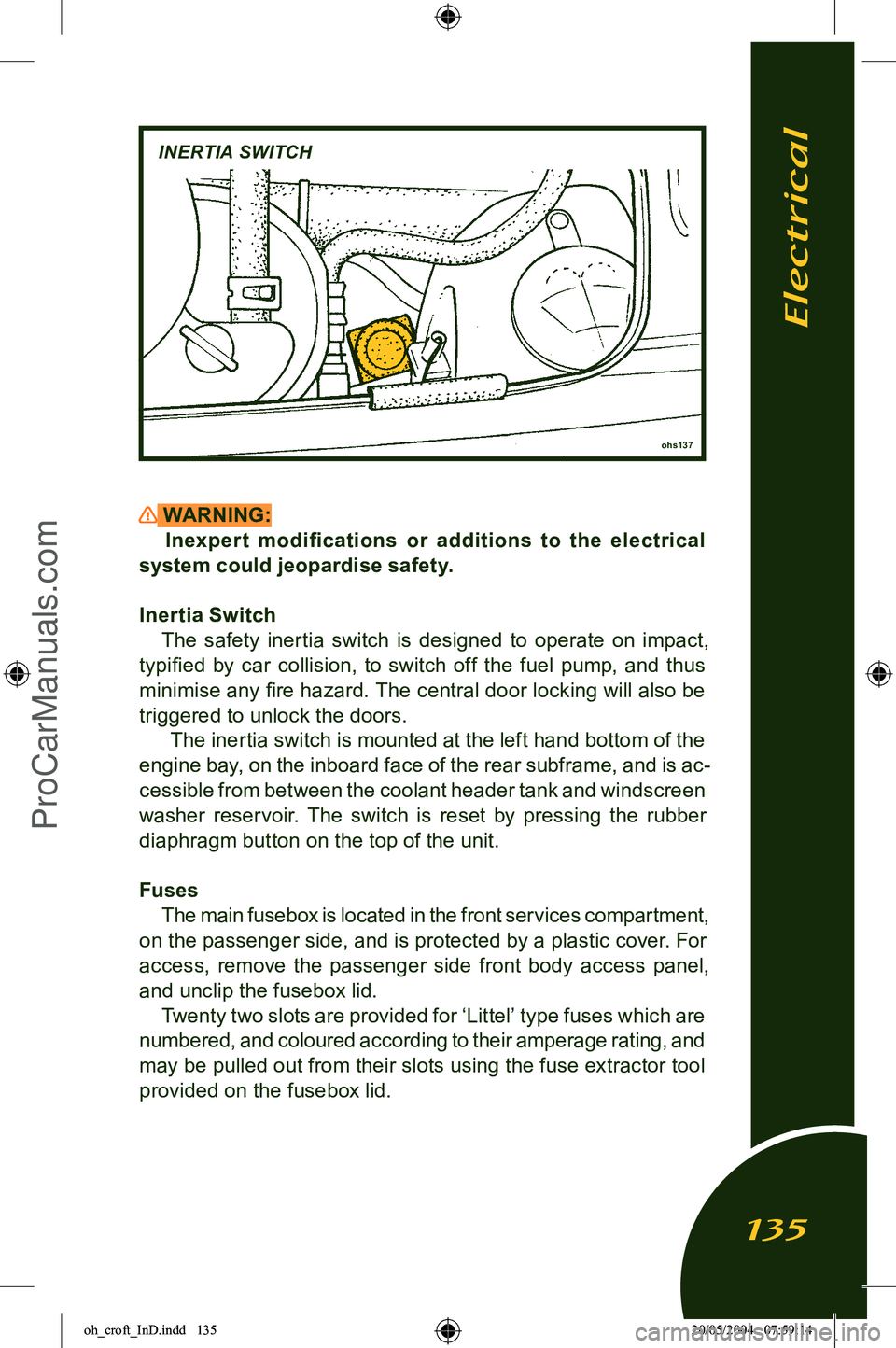

WARNING:Inexper t modifications or additions to the electrical

system could jeopardise safety.

Inertia Switch The safety inertia switch is designed to operate on impact,

typified by car collision, to switch off the fuel pump, and thus

minimise any fire hazard. The central door locking will also be

triggered to unlock the doors. The inertia switch is mounted at the left hand bottom of the

engine bay, on the inboard face of the rear subframe, and is ac

-

cessible from between the coolant header tank and windscreen

washer reservoir. The switch is reset by pressing the rubber

diaphragm button on the top of the unit.

Fuses The main fusebox is located in the front services compartment,

on the passenger side, and is protected by a plastic cover. For

access, remove the passenger side front body access panel,

and unclip the fusebox lid. Twenty two slots are provided for ‘Littel’ type fuses which are

numbered, and coloured according to their amperage rating, and

may be pulled out from their slots using the fuse extractor tool provided on the fusebox lid.

ohs137

INERTIA SWITCH

Electrical

135

oh_croft_InD.indd 13520/05/2004 07:59:14ProCarManuals.com

Page 190 of 205

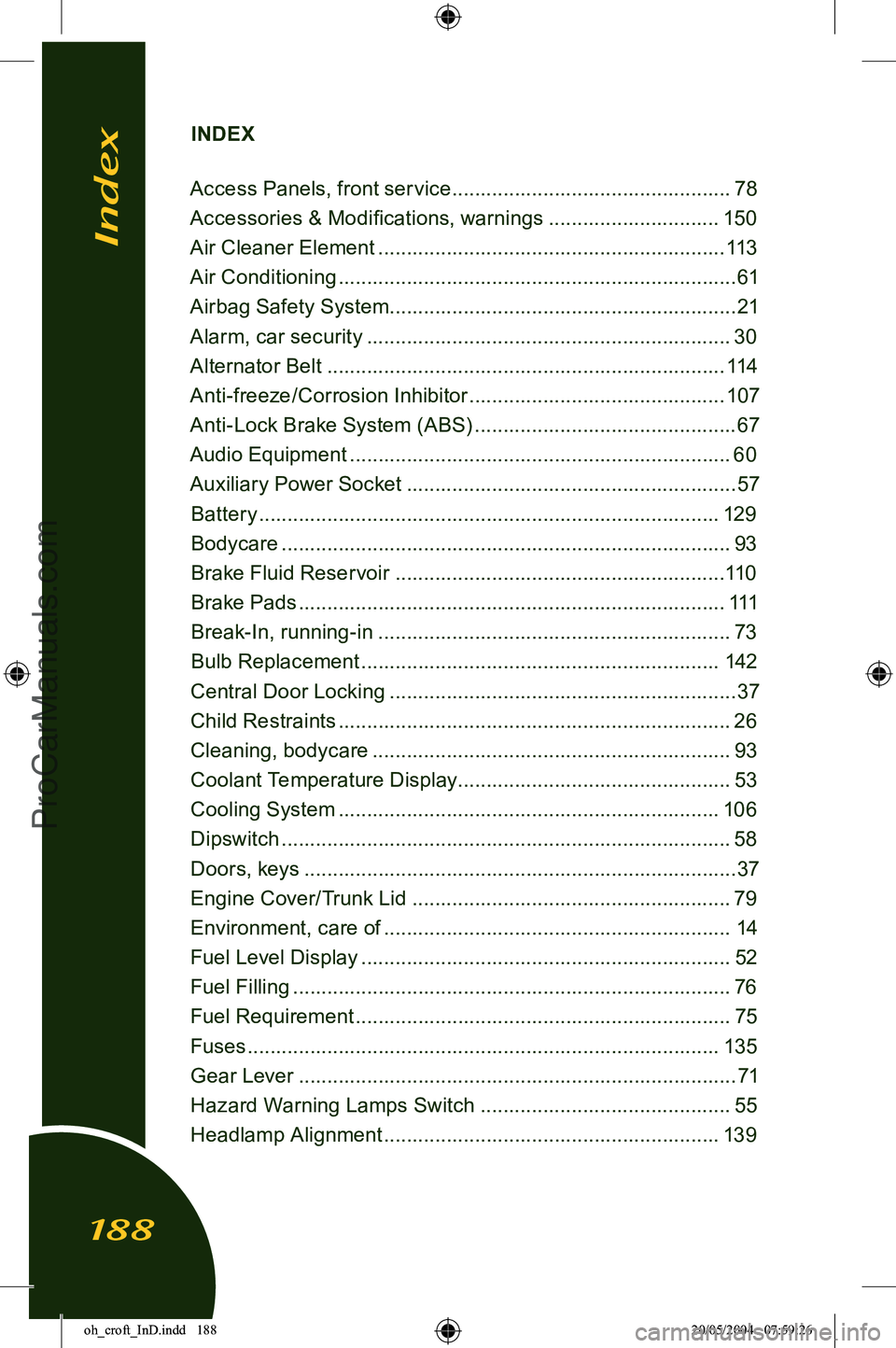

INDEX

Access Panels, front service ................................................. 78

Accessories & Modifications, warnings .............................. 150

Air Cleaner Element ............................................................. 113

Air Conditioning ...................................................................... 61

Airbag Safety System ............................................................. 21

Alarm, car security ................................................................ 30

Alternator Belt ...................................................................... 114

Anti-freeze/Corrosion Inhibitor ............................................. 107

Anti-Lock Brake System (ABS) .............................................. 67

Audio Equipment ................................................................... 60

Auxiliary Power Socket .......................................................... 57

Battery ................................................................................. 129

Bodycare ............................................................................... 93

Brake Fluid Reservoir .......................................................... 110

Brake Pads ........................................................................... 111

Break-In, running-in .............................................................. 73

Bulb Replacement ............................................................... 142

Central Door Locking ............................................................. 37

Child Restraints ..................................................................... 26

Cleaning, bodycare ............................................................... 93

Coolant Temperature Display ................................................ 53

Cooling System ................................................................... 106

Dipswitch ............................................................................... 58

Doors, keys ............................................................................ 37

Engine Cover/Trunk Lid ........................................................ 79

Environment, care of ............................................................. 14

Fuel Level Display ................................................................. 52

Fuel Filling ............................................................................. 76

Fuel Requirement .................................................................. 75

Fuses ................................................................................... 135

Gear Lever ............................................................................. 71

Hazard Warning Lamps Switch ............................................ 55

Headlamp Alignment ........................................................... 139

Index

188

oh_croft_InD.indd 18820/05/2004 07:59:26ProCarManuals.com