alternator MAZDA 232 1990 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 22 of 677

SCHEDULED MAINTENANCE SERVICES (Australia) A

SCHEDULED MAINTENANCE SERVICES (Australia)

Chart symbols:

I : Inspect: Visual examination or functiona! measurement of a system’s operation (Performance)

A: Adjust

R: Replace or change

T : Tighten

Note

l As the result of visual examination or functional measurement of a system’s operation (Per-

formance), correct, clean or replace as required.

REMARKS:

After 90,000 km or 72 months, continue to follow

the described maintenance items and intervals periodically.

As

“I

*2

*3

“4

l 5 for *

marked items in this maintenance chart please pay attention to the following points.

If the vehicfe is operated under the foltowing conditions, it is suggested that

the engine oil and oil f&r

be changed more often that at usual recommended intervals.

a> Driving in dusty condrt,ons.

b) Extended periods of idling

or low speed operation.

c) Driving for a prolonged period iti coid temperatures or driving only short distances regularly.

Replacement of the timing belt is required at every 105,000 km. failure to replace the timing belt may

result in damage to the engine.

If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, repface more often

than at usual recommended intervals.

Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

if equipped.

Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid shotlid be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emission control and related

system, as well as for efficient engine operation. It is strongly recommended that all servicing related to these

systems be done by your Authorised Mazda Dealer.

93GOAX-702

-

A-3 i

Page 24 of 677

!

i

i

I

i

t-

I

i

i

e

-1

SCHEDULED MAfNTENANCE SERVICES (Europe) A

MAINTENANCE TABLE (Leaded Fuel Model)

Chart symbols:

1 : Inspect: Visual examination and/or functional measurement of system’s operation or performance

A: Adjust: Examination resulting in adjustment or replacement

R: Replace or change

T: Tighten

REMARKS

After 80.000 km or 48 months, continue to foltow the described maintenance at the recommended intervals.

As

*I

*2

“3

*4

*5

*6

*7 for *’

marked items in this’ maintenance chart, note the following points.

Major service interval at 12 months!ZO,OOO km (I 2,000 miles).

Lubrication service based on distance only, 10,000 km (6,000 miles), not time.

Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

ii equipped.

Replacement of the timing belt is required every ICQOUO km (60,000 miles). Failure to replace the timing

belt may result in damage to the engine.

If the vehicle is operated under any of the following conditions, it is suggested that the engine

oil and

oil filter be changed more often than the recommended intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for prolonged periods in cold temperatures or regularly driving only short distances.

If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often

than the recommended intervals.

This is a full function check of all electrical systems, i.e, afl lights, washers (inctuding condition of blades)

electric windows sunroof, horn, etc.

Replace every two years.

tf there has been continuous hard driving, mountain driving, or it the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emission control and related

system, as well as for efficient engine operation. It is strongly recommended that all servicing related to these

systems be done by your Authorised Mazda Dealer.

93GOAX-704

A-5

Page 27 of 677

A SCHEDULED MAINTENANCE sERvw3 (Europe)

SCHEDULED MAfNTENANCE SERWCES (Europe)

MAWTENAN CE TABLE (Unlead Fuel Model)

Chati symbols:

I : Inspect: Visual examination and/or functional measurement of system’s operation or performance

A: Adjust: Examination resulting in adjustment or replacement

R: Replace or change

T: Tighten

REMARKS

After 80,000 km or 48 months, continue to follow the described maintenance at the recommended intervals.

As for * marked items in this maintenance chart, note the following points.

* 1 Major service interval at 12 months120,OOO km (12,000 miles).

Lubrication service based on distance only 10,000 km (6,000 miles) not time.

*2 Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

if equipped.

“3 Replacement of the timing belt is required at every 100,000 km (60,000 mile). failure to replace the tim-

ing belt may result in damage to the engine.

“4 If the vehicle is operated under any of the following conditions, it is suggested that the engine oil and

oil filter be changed more often than the &commended intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c> Driving for a prolonged periods in cold temperatures or regularly driving only short distances.

*5 If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more oten

than at usual recommended intervals.

*6 This is a full function check of all electrical systems, i.e, all lights, washers (including condition of blades)

electric windows, sunroof, horn etc.

“7 Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emission control and related

system, as well as for efficient engine operation. It is strongly recommended that all servicing related to these

systems be done by your Authorised Mazda Dealer.

93GOAX-707

A-8

Page 31 of 677

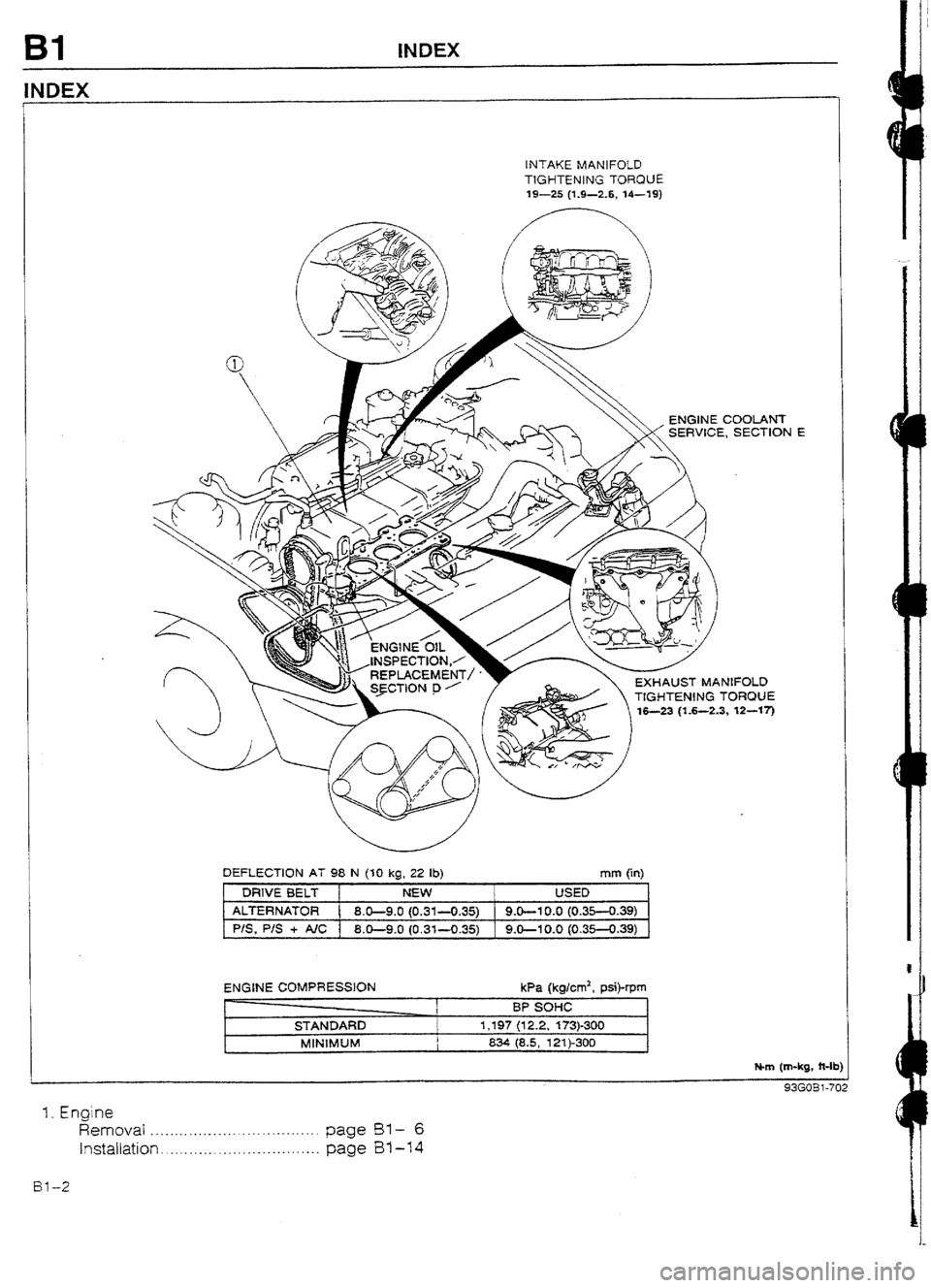

Bl INDEX

INDEX

INTAKE MANIFOLD

TIGHTENING TORQUE

19-25 (1.9-2.6, U-19)

EXHAUST MANIFOLD

TtGHTIEN!NG TORQUE

,3, 12-w-j

DEFLECTION AT 98 N (30 kg, 22 lb)

mm (in)

DRIVE BELT NEW USED

AlTERNATOR

8.0-9.0 (0.31-0.35) 9.0-l 0.0 (0.35-0.39)

PIS, P/S + AIC 1 8.0-9-O (0.31-O-35) 9.0-I 0.0 (0.35-0.39)

ENGINE COMPRESSION

STANDARD

MlNlMUM kPa (kglcm2, psi)-rpm

BP sol-lc

1,197 (12.2, 173)-300

834 (8.5, 121)-300

N-m (m-kg, ?t-It

cIz!f-mRl-71

1. Engine

Removal . . . . . . ..*..*-..............-....... page BY-- 6

Installation . . . . . . ..__. . . . . . . . .._...... . . . .

page B1-14

Bl-2

Page 55 of 677

B2 INDEX

INDEX

~IMIY~ULU

TIGHTENING TORQUE

19-25 (1.9-2.6, 14-19)

/5--l ENGINE COMPRESSION

STANDARD

MINIMUM kPa (kglcm2, psi)-rpm

BP Turbo

I

1,059 (10.8, 1543-300

1 i-85 (8.0, 114)-300

EXHAUST MANlFOt

TIGHTENING TORQUE

DEFLECTION AT 98 N (IO kg, 22 Ib)

mm (in)

DRIVE BELT 1 NEW USED

ALTERNATOR 1 8.0-9.0 (0.31-U.35) 9.0-I 0.0 (0.35-U.39)

P/S, P/S + AIC ( 8.U-9.0 [O-31--0.35) 9.0-10.0 (0.35-0.39) 3826 3.9-A.?, -28134)

1. Engine

Removal -*-...-..I-*.* . ..wm._..... * e-e... -. page B2--I 2

Engine stand mounting ._.....__... page B2-20

Engine stand dismounting . . . . . . . page B2-21

Installation _ . . . . . . . . . . . . , . . _. . . . . . _. . . . . . . . , page EQ-23

BZ-2

Page 67 of 677

B2 REMOVAL

Step 2

1. Disconnect the harness connectors shown in the fiuure.

ALTERNATOR OIL PRESSURE SWITCH

\. PRESSURE REGULATOR

STARTER

CObjTROL VAVLE

E-SPEED CONTROL

CTOR

KNOCK SENSOR

SWITCH

03 w 08X-80’

Step 3

I. Disconnect the hoses shown in the figure.

-

------a-

93GOB2-720

82-14

Page 70 of 677

REMOVAL B2

Step 5

1. Engine mount member 5, No.3 engine mount

rubber

Removal Note . . . . . . .._.._...._....-.__._.._-_..-.* below 6. No.4 engine mount rubber and bracket

2. No.2 engine mount rubber and bracket 7. Alternator and drive belt

3. Clutch release cylinder 8. I ntercooler brat kets

Removal Note _._...._.._.._.....,,....__ page B2-18 9. Engine and transaxle assembly

4. Dynamic damper Removal Note . .._.................--.-..

page 62-f 8

Removal note

Engine mount member

1. Suspend the engine with a chain hoist.

Page 78 of 677

INSTAlLATION B2

93X82-72!

93G0BZ757

-

J 93GO32-730

Alternator and drive belt

1. Monut the alternator to the engine.

Tightening torque

@: 19-25 N-m (1.9-2.6

m-kg, 14-19 ft-lb)

@J: 37-52 N-m (3.8-5.3 m-kg, 27-38 ft-lb)

2. Install the drive belt. (Refer to page 82-Z)

Engine mount, clutch release cylinder

and engine mount

member

1. Install the No.3 engine mount rubber, and loosely tighten

the bott and nuts.

2. Install the No.4 engine mount rubber and bracket assem-

bly, and loosely tighten the bolts and nuts.

3. lnstalt the clutch release cylinder and pipe bracket assembly.

Tightening torque

@: 16-23 Nm [I .6-2.3 m-kg, 12-17 ft-lb)

0: 6.9-9.8 N-m (70-100 cm-kg, 61-87 in-lb)

4. Install the No.2 engine mount rubber and bracket assembly.

Tightening torque:

37-52 Nrn (3.8-5.3 m-kg, 27-38 R-lb)

B2-25

Page 83 of 677

B2 INSTALLATION

Step 5

1. Connect the harness connectors shown in the figure.

ALTERNATOR OIL PF;IESSURE SWITCH PRESSURE REGULATOR

STARTER CONTROL VAVLE

GRoYD O-i-l-tE SENSOR

IDLE-SPEED CONTROL

KNOCK SENSOR

OXYGEhENSO$

Step 6

Torque Specifications

03UO8X-33’

7.8-11 N-m

(80-110 cm-kg, 69- .

11 N-m (80--f ’IO cm-kg, 69-95 in-lb)

N-m

cm-kg, 69-95 in-Ib)

37-52 (3.8-5.3, 27

7.8--fl N-m (80 107 (9.6-T 1.9, 69-79)

N-m (m-kg, ft-lb)

03U03X-83

Page 188 of 677

G

ENGINE ELECTRICAL SYSTEM

INDEX . ..I 1.. . . . . . . . . . . . . . . . . . . . . . . ..*. . . ..I..... . . . . . ..I...

G- 2

j FEATURES 1

OUTLINE . . . . . . . . . ...*....* .I.............. .I . . . . . . . . . . . . . .

G- 3

OUTLINE. OF CONSTRUCTION ..I... . . . . . . . . . . . G-

3

SPECtFICATiONS . . . . . . . . . . . . ..I............... . . . . . .

G- 3

1 SERVICE 1

SUPPLEMENTAL SERVICE INFORMATION . . G- 4

STARTING SYSTEM

. ..I. . . . . . . . . a.. . . . . . . . . . . . . . . . . . . G- 4

STARTER

l ..I.... . . . . . . . . . . . . . . . . . . l .*.....* .I....... . . . G- 4

CHARGlNG SYSTEM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G- 5

PREPARATION

. . . . . . . . . . . . ..I..-... . . . . l . . . . . . . . 1. . . . . G- 5

ALTERNATOR (RHD)

. . . . . . . . . . . . . . . . . . . . . . . . . . ...*. G- 5

93GOGX-701