clutch MAZDA 232 1990 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 179 of 677

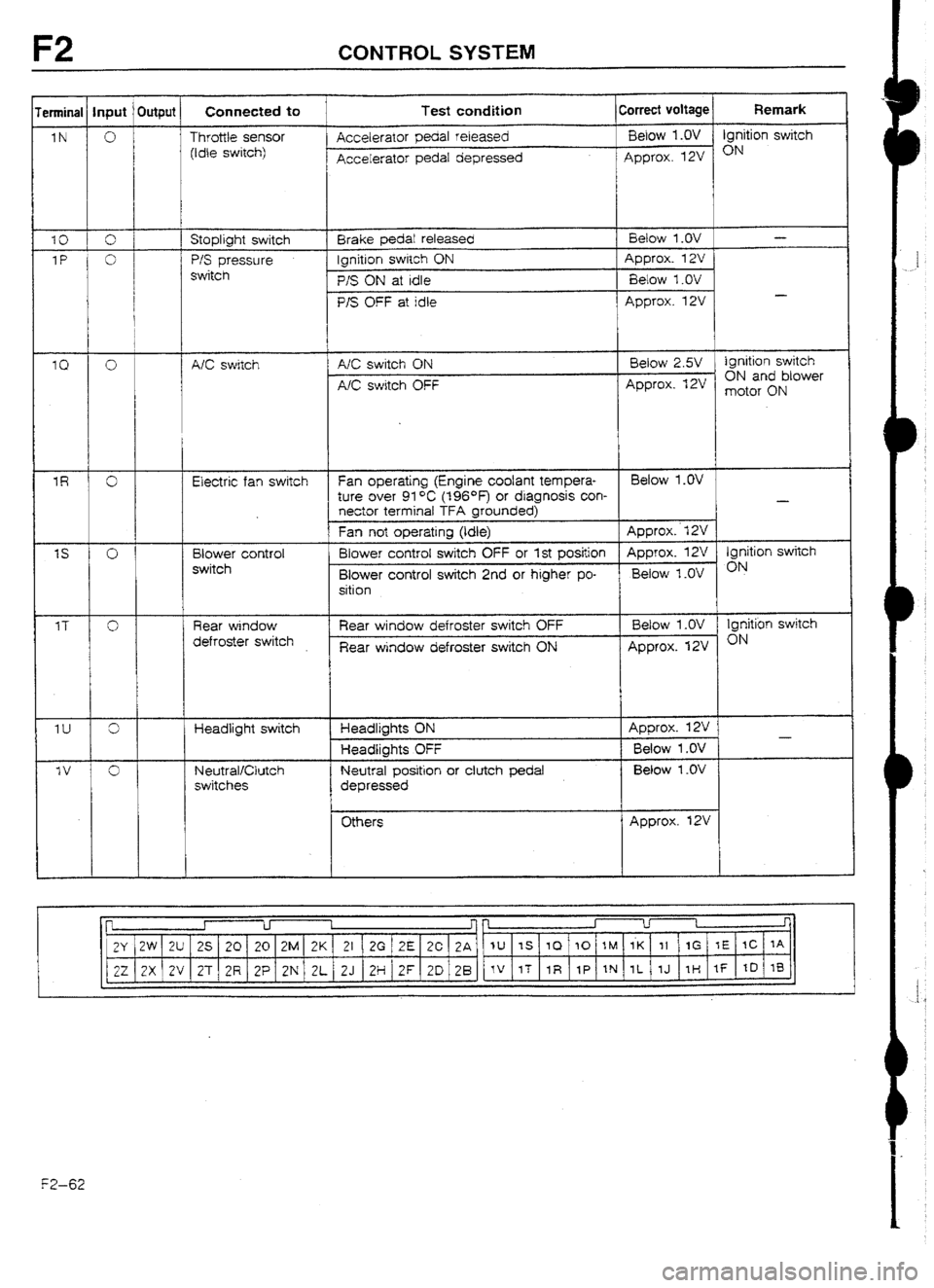

F2 CONTROLSYSTEM

erminat Input ’ Output Connected to Test condition Correct voltage Remark

1N 0 I Throttle sensor Accelerator pedal released &low l.OV j Ignition switch

(Idle switch)

Accelerator pedal depressed Approx. 12V *N

IO I 0 j [ Stoplight switch Brake pedal released Betow 1 .OV -

1P j 0 1 i P/S pressure lgnitlon switch ON Approx. 12V

I

switch

f/S ON at idle Below 1 .UV

I

P/S OFF at idle Approx. 12V -

I

to 0 A/C switch A/C switch ON

NC switch OFF Beiow 2.W ignition switch

ON and blower

Approx* t2V motor ON

i

1R 0 Electric fan switch Fan operating (Engine coolant tempera- Betow l.OV

ture over 91 *C (t96*F) or diagnosis con-

-

nector terminal TFA grounded)

Fan not operating (Idle) Approx.. f 2V

IS 0 Blower control Blower controf switch OFF or 1st position Approx. 13 Ignition switch

switch

Blower control switch 2nd or higher po- Below 7 .OV ON

sition

IT

Cl Rear window

defroster switch Rear window defroster switch OFF

Rear window defroster switch ON Below 1 .OV Ignition switch

Approx. 12V ON

1u 3 Headlight switch Headlights ON Approx. 12V

-

Headlights OFF Below 1 .OV

-Iv Cl ’ Neutral/Clutch

Neutral position or clutch pedal Below I .OV

switches

depressed

Others Approx. 12V

l-7 I r

f

2V 2W 2U 25 20 20 2M 2K 21 2G IZE 2C 2A IU IS 10 10 IM 1K 11 1G rE tC IA

22 2X (2V 2T 2R 2P 2N 2L 2J 2H’ZF 20 2B fV 1T 1R IP IN 1L 7J III If ItI 1B l F2-62

Page 180 of 677

CONTROL SYSTEM F2

Incorrect voltage

Always below 1 .OV Possible cause

l Throttle sensor misadjustment l Short circuit in wiring from throttle sensor to ECU terminal IN l ECU malfunction

Always approx. f 2V

Atways below 1 .OV (Stopfights OK)

Always below 1 .OV

l Throttle sensor misadjustment l Open circuit in wiring from throttle sensor to ECU terminal IN l Open ctrcuit in wiring from throttle sensor to ECU terminal 20

l Open crrcurt in wiring from stoplight switch to ECU terminal 10

l P/S pressure switch malfunction l Short circuit in wirrng from P/S pressure switch to ECU termrnai 1 P

l ECU malfunction

Always approx. 12V

Atways below 2.5V (Btower fan OK) . P/S pressure switch malfunction

l Open circuit in wiring from P/S pressure switch to ECU terminal I P l Open circuit in wiring from P/S pressure switch to ground

l A/C switch malfunction l Short circuit in wiring from A/C switch to ECU terminal 1 Q l Poor connection at ECU connector l ECU malfunction

Always approx. 12V (Blower fan OK)

l ’ A/C switch malfunction l Open c~rcurt in wiring from NC switch to ECU terminal 1Q l ken circuit H-I winnu from A/C switch to blower control switch

Always below 1.W

l Open or short circuit in wiring from fan relay to ECU terminal IR

(Electrkal cooling fan UK} l ECU malfunctron

Always below 1 .OV (Blower fan OK)

l Short crrcutt in wiring from blower control swrfch to ECU terminal IS l Poor connection at ECU connector l ECU malfunction

Always approx. 12V (Blower fan OK)

Always below Illumination lamp

1.w ON when rear

window defroster

switch ON 1

l Open circurt in wrring from blower control switch to ECU terminat IS

I

l Open or short circuit rn wiring from rear window defroster switch to ECU

terminal 1 T

ftlumination lamp

never ON

l Open circuit in wiring from ignition switch to rear window defroster switch

l Rear window defroster switch malfunction I

Always below 1 .OV (Headlights OK)

l Open or short circurt in wiring from headlight relay to ECU termtnal 1 U

Always below 1 .OV

Always approx. l2V

l Neutral switch malfunction l Clutch switch malfunction l Short circuit in wiring from ECU terminal IV to neutral or clutch switch

l Neutral switch maifunctton l Clutch switch malfunction l Open circuit in wiring from ECU terminal IV to neutral or clutch swttch

l Poor connection at ECU connector

93GOFZ789

F2-63

Page 194 of 677

H

CLUTCH

iNDEX ..*..*.............*..*..............................* l-l- 2

OUTLINE .................................................. l-b- 4

OUTLtNE OF CONSTRUCTION

................. H- 4

SPECtFlCATtUNS ....................................

H- 4

CLUTCH CONTROL

.................................... t-i- 5

CLUTCH PEDAL ..................................... H- 5

CLUTCH MASTER CYLINDER ................... H-

7

RELEASE 5EARlNG ................................ H- 8

1 SERVICE /

SUPPLEMENTAL SERVICE INFORMATION.. H- 9

TROUBLESHOOTlNG

GUIDE.. .................... Ii- 9

CLUTCH FLUID (WITH ABS) ......................

H-l 0

PREPARATION ....................................... u-IO

REPLACEMENT ......................................

H-10

CLUTCH PEDAL (BP DOHC TURBO) ........... H-1 1

REMOVAL I INSPECTION / INSTALLATtON . . H-11

CLUTCH MASTER CYLINDER

(BP DOHC TURBO OR WITH ABS)

............ H-f 3

PREPARATION .......................................

u-1 3

REMOVAL I INSPECTION I INSTALLATION

(BP DOHC TURBO) ............................... H-13

AIR BLEEDlNG (-WtTH ABS) ...................... ti-14

OVERHAUL

(BP DOHC TURBO). ............... H-15

CLUTCH RELEASE CYLINDER (WITH ABS). H-l 7

PREPARATION .......................................

H-l 7

AtR

BLEEDING (WITH ABS). ..................... H-17

CLUTCH UNIT

.......................................... u-1 8

PREPARATION

....................................... H-f 8

REMOVAL I INSTALLATION ...................... H-19

93GOHX-701

Page 195 of 677

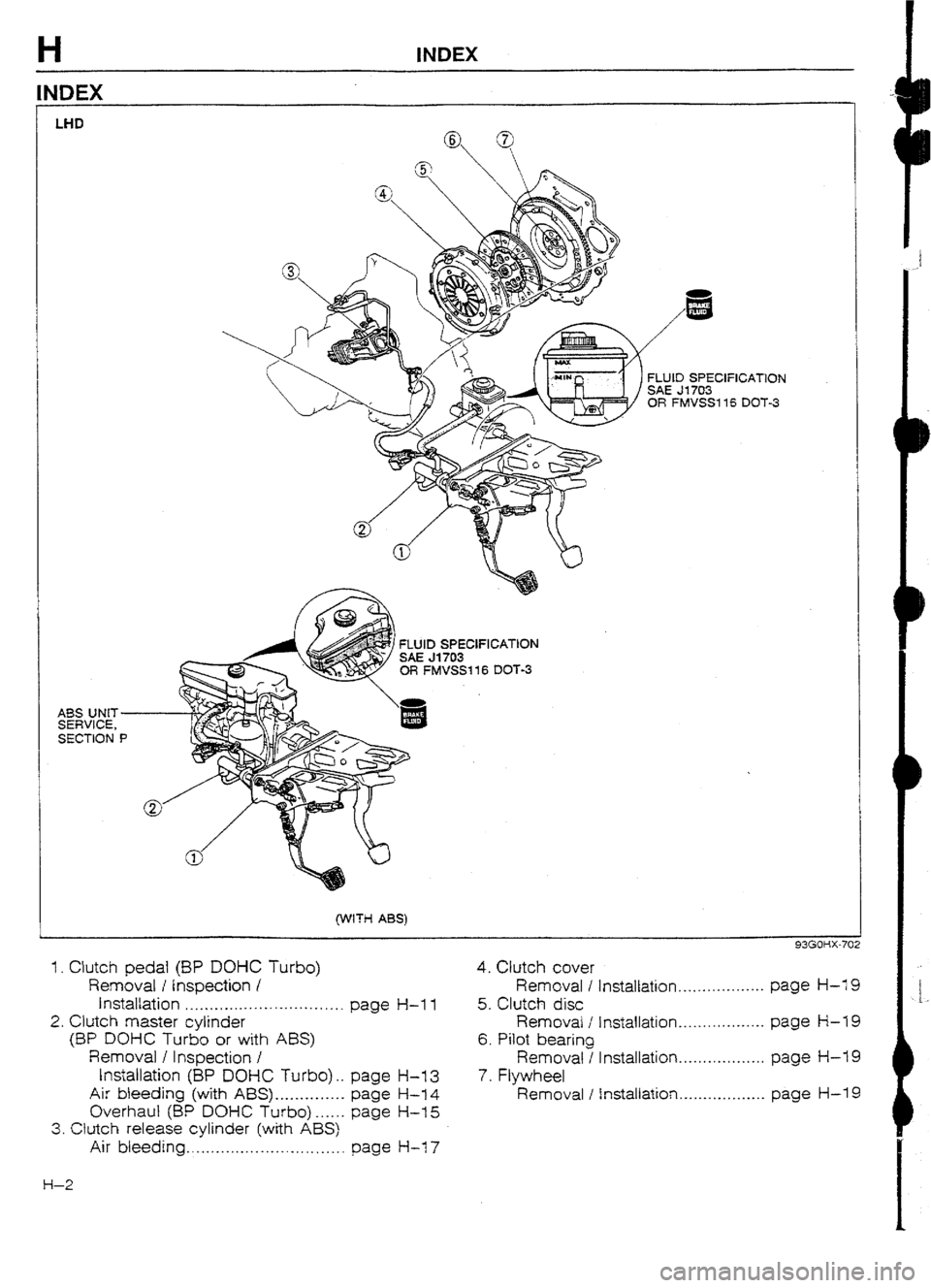

H INDEX

INDEX

I

LHD

@ ,a

1,

FLUID SPEClFlCATlON

OR FMVSS116 DOT-3

(WITH ABS) f . Clutch pedal (8P DOHC Turbo)

Removal I Inspection I

93GOHX-7C 4. Clutch cover

Removal I Installation . . . . . . . . . . . . . . . . . . page H-1 9

Installation . . . . . ..+., ._. . . . . . . -. . . . . . . . . _. . page H-l 1

2. Clutch master cylinder

(BP DOHC Turbo or with ABS)

Removal I Inspection I

Installation (BP DOHC Turbo). . page H-l 3

Air Ueeding (with ABS) . . .._........_ page H-14

Overhaul (BP DOHC Turbo) _...._ page H-15

3. Ctutch release cylinder (with ABS)

Air bleeding .._.,._.......,............._... page H-l 7 5. Clutch disc

Removal I f

6. Pilot bearing

Removal I I

7. Flywheel

Removal /

H-2 nstallation .................. page H-l 9

nstallation. .................

page H-f 9

nstallation .................. page H-l 9

Page 196 of 677

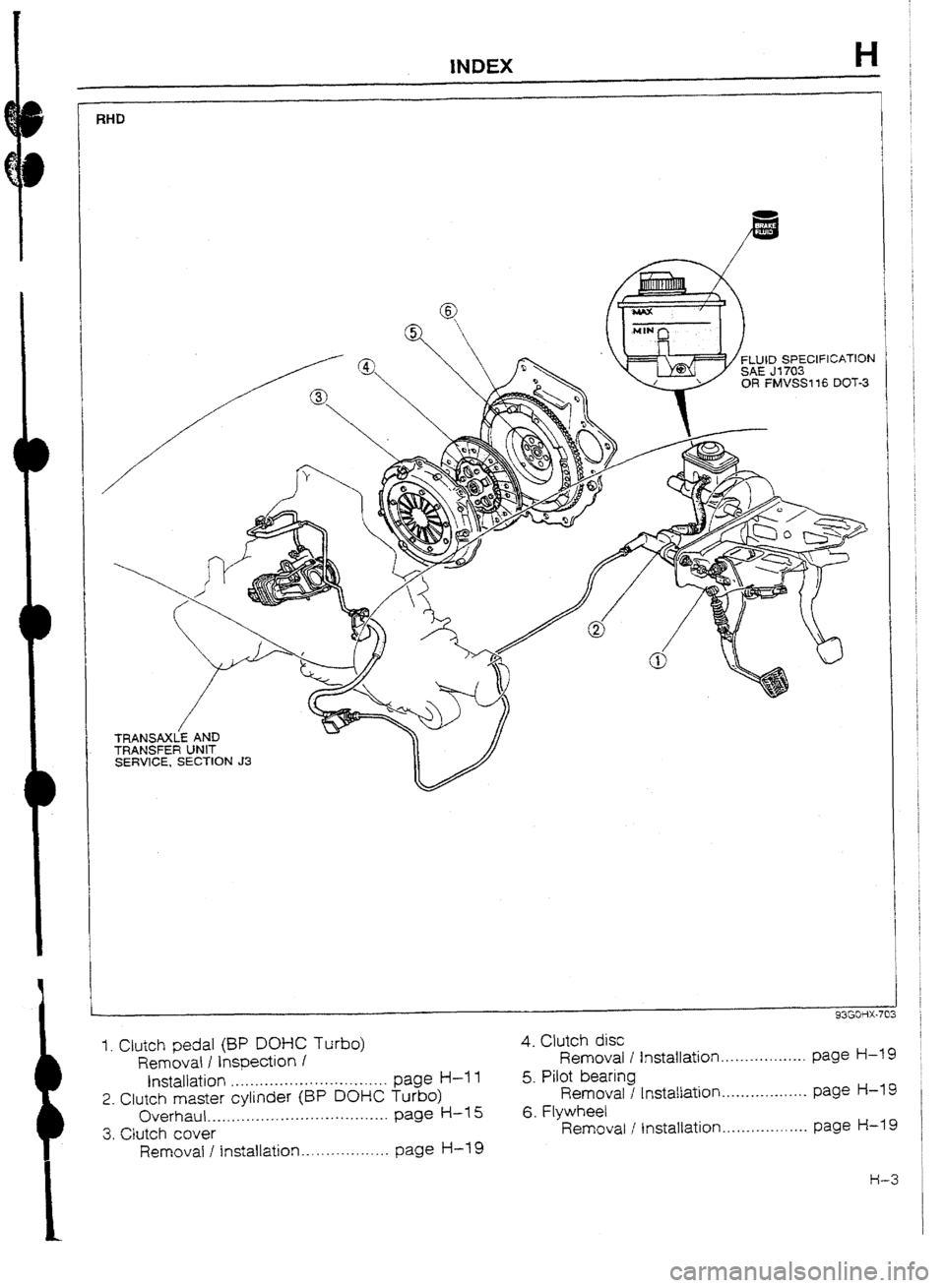

i

1

INDEX H

I. Clutch pedal (BP DOHC Turbo)

Removal I inspection /

Installation ................................ page H-l 1

2. Crutch master cylinder (BP DUHC Turbo)

Overhaul .....................................

page H-l 5

3. Clutch cover

Removal I Installation.. ................

page H-t 9 4. Clutch disc

Removal I Installation..

................ page H-19

5. Pilot bearing

Removal J Installation ..................

page H-l 9

6. Flywheel

Removal I installation.. ................ page H-l 9

H-3

Page 197 of 677

H OUTLINE

OUTLINE

OUTLINE OF CONSTRUCTION

A hydraulic clutch control mechanism is used.

The basic construction is the same as that of 323 2WD model, but there is no interchangeability of parts

except for the release cylinder.

1. An assist/return spring is used on the BP DOHC Turbo model to reduce the required clutch pedal effort..

2. The hydraulic clutch master cylinder for the 8P DOl-lC Turbo model has a built-in check valve.

3. To improve clutch operation feeling and increased parts life, a friction plate and needle roller bearings

are used between the release fork and the release bearing.

93GOHX-704

SPECIFICATIONS

Hem

Clutch control Engine/Transaxle

BP SUHC BP DOHC Turbo

GSMX-R

Hydrautic

Clutch cover

Type

Set load

N (kg, lb) Diaphragm spring

3,846 (392, 862) 5,494 (560, I ,232)

Outer diameter 1

mm (in) 225 (8.858) 230 (9.055)

I 1 nner diameter mm (in)

I 150 (5.906)

I 155 (6.102) I

CI utch disc

Pressure plate side

mm {in) 4.1 (0.161) 3.2 (0.126)

Thickness f

Flywheel side

mm (in) 3.5 (0.138) 3.2 (0. f 26)

I Type I Suspended

I

Clutch pedal LHD 6.55 Pedal

ratio

RHD 6.7

Full stroke mm (in)

I 135 (5.32)

I

Height (With carpet) mm [in)

I I 96-204 (7.72-8.03)

I

Master cylinder Inner diameter

mm {in)

I 15.87 (0.625)

Release cylinder inner diameter

mm (in)

I - 19.05 (0.750)

I

Clutch fluid SAE J1703 or FMVSSI 16 DOT-3

93GOHX-705

H-4

Page 198 of 677

CLUTCH CONTROL H,

CXUTCH CONTROL

CLUTCH PEDAL

l An assistireturn spring is used on BP DO-K Turbo engine-equipped models to reduce the required pedal

effort.

l The assist/return spring is mounted vertical to the pedal for a compact arrangement.

wiNGi B G”3 * RANGE A

RANGE B + + RANGE A

Operation With the clutch pedal fully

released, the assist/return spring is compressed, causing force F to act upon ful-

crum 0,

As a result, force Fy is created, and acts upon fulcrum @ to hold the pedal outward.

1 1 When clutch pedal depressed.

(1) Fukrum @ within range A

When the pedal is depressed, it moves inward, centered upon fulcrum @.

Fy, which is the force opposing pedal movement, acts upon futcrum @ until fulcrum @ crosses the

imaginary line connecting fulcrums

@ and @

As a result, there is a slight feeling of resistance when the clutch pedal is first depressed.

(2) With fulcrum @ within range 8

When fulcrum @ crosses the imaginary line between fulcrums @ and @, Fy now acts in the same

direction as pedal

movement, thus reducing the force required to depress the pedat.

H-5

Page 199 of 677

![MAZDA 232 1990 Suplement Owners Manual H CLUTCH CONTROL

RANGE B CT] e RANGE A

RANGE B ++I + RANGE A

93GOHX-70

2. When clutch pedal released.

(1) With fulcrum @ within range B

When the clutch pedal is released, reaction force f (from MAZDA 232 1990 Suplement Owners Manual H CLUTCH CONTROL

RANGE B CT] e RANGE A

RANGE B ++I + RANGE A

93GOHX-70

2. When clutch pedal released.

(1) With fulcrum @ within range B

When the clutch pedal is released, reaction force f (from](/img/28/57056/w960_57056-198.png)

H CLUTCH CONTROL

RANGE B CT] e RANGE A

RANGE B ++I + RANGE A

93GOHX-70

2. When clutch pedal released.

(1) With fulcrum @ within range B

When the clutch pedal is released, reaction force f (from clutch master cylinder push rod) is applied,

and fy force pushing outward overcomes Fy force, with the result that the clutch pedal moves out-

ward, centered upon fulcrum @.

(2) With fulcrum @ within range A

When futcrum @ crosses the imaginary iine 4etween fulcrums @ and a, force Fy, which is a result

of force F trying to expand the spring, is added to fy and pushes the pedal fully outward.

t-l-6

Page 200 of 677

C1UTCl-i CONTROL H

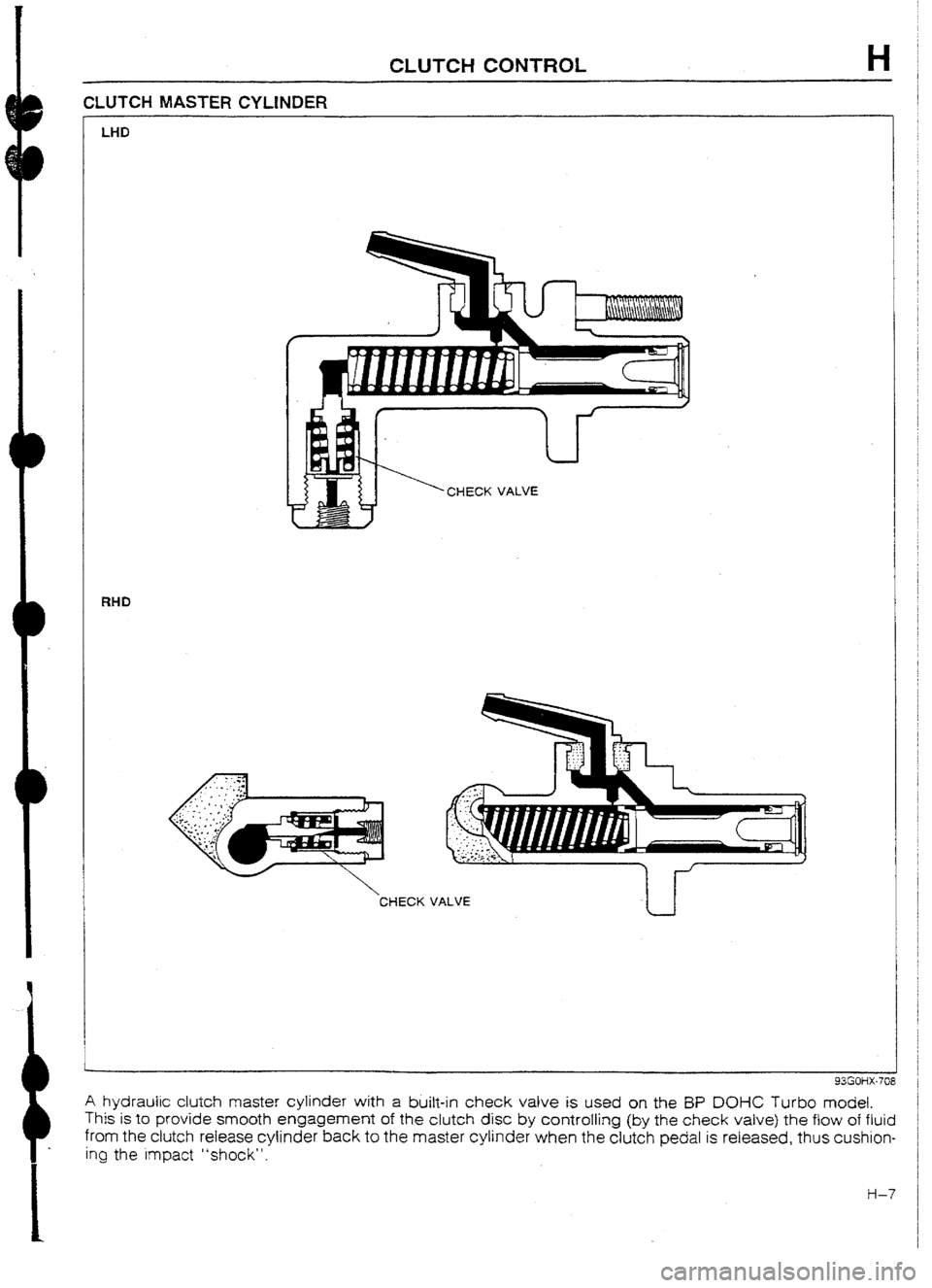

CLUTCH MASTER CYLINDER

‘CHECK VALVE

RHD

CHECK VALVE

93GOHX-708 A hydraulic clutch master cylinder with a built-in check valve is used on the BP DOHC Turbo model.

This is to provide smooth engagement of the clutch disc by controlling (by the check valve) the flow of fluid

from the clutch release cylinder back to the master cylinder when the clutch pedal is released, thus cushion- ing the impact “shock”.

l-l-7

Page 201 of 677

H CLUTCH CONTROL

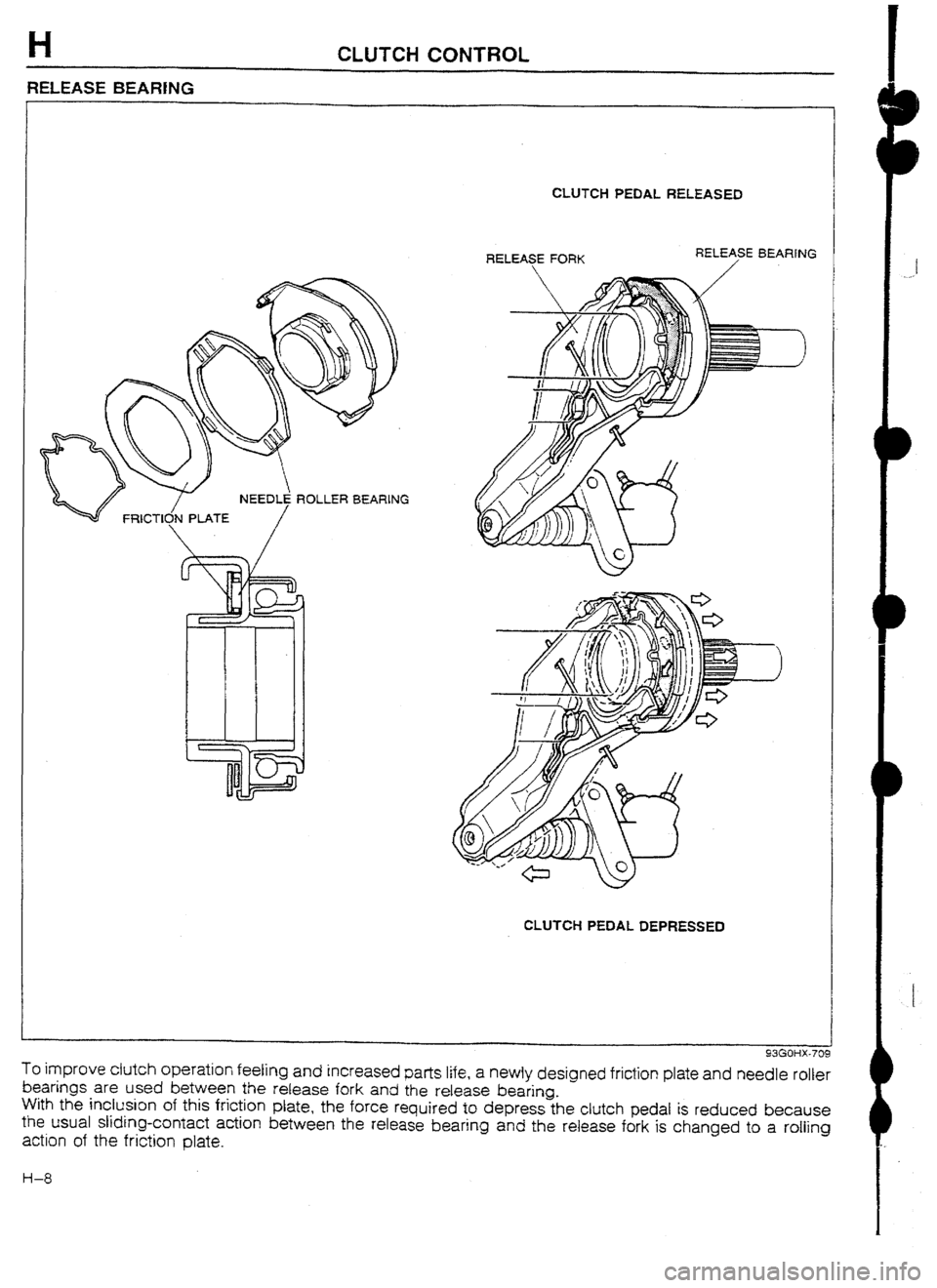

RELEASE BEARING

ROLLER BEARING

CLUTCH PEDAL RELEASED

RELEASE FORK RELEASE E?EARfNG

CLUTCH PEDAL DEPRESSED To improve clutch operation feeling and increased parts life, a newly designed friction plate and needle roller

bearings are used between the release fork and the release bearing.

With

the kdusion of this friction plate, the force required to depress the clutch pedal is reduced because

the usual sliding-contact action between the release bearing and the release fork is changed to a rolling

action of the friction plate,

H-8