engine MAZDA 232 1990 Suplement Manual PDF

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 153 of 677

![MAZDA 232 1990 Suplement Manual PDF F2 TROUBLESHOOTING GUIDE

20 POOR ACCELERATION [BP TURBO]

IESCRIP- . Performance poor while accelerating

rm

l Idle condition normal

[TROUBLESHOOTING HINTS]

3 Wastegate always open or opens early MAZDA 232 1990 Suplement Manual PDF F2 TROUBLESHOOTING GUIDE

20 POOR ACCELERATION [BP TURBO]

IESCRIP- . Performance poor while accelerating

rm

l Idle condition normal

[TROUBLESHOOTING HINTS]

3 Wastegate always open or opens early](/img/28/57056/w960_57056-152.png)

F2 TROUBLESHOOTING GUIDE

20 POOR ACCELERATION [BP TURBO]

IESCRIP- . Performance poor while accelerating

rm

l Idle condition normal

[TROUBLESHOOTING HINTS]

3 Wastegate always open or opens early @ Low intake air amount

3 Turbocharger damage

l Throttle valve not open fully

3 Factors other than engine malfunction *Clogged intake air system l

Ciutch slIpping @ Air/Fuel mixture Iean l Brake draggrng l fuel line pressure decreases

l low tire pressure l Fuel Injection malfunction

l Incorrect tire size @ Poor Ignition

. Overloaded vehicle @ Low engine compression

@ Atcohol blended fuel used

TEP INSPECTION ACTION

-l Install pressure gauge

in intake air pipe and I Yes

1 Go to Step 3

check boost pressure at engine speed of 4,000

rpm

w page F2-45

Boost pressure:

More than 2.0 kPa (0.02 kglcm2, 0.3 psi)

No Check for air leakage and exhaust gas

leakage

4 If OK, go to next step

4 If not OK, repair

2 Check wastegate w page F2-45

Yes Remove Intake air pipe from turbo-

charger and check if compressor wheel

rotates smoothly w page F2-46

c3 If OK, check air cleaner element

and throttle valve

4 If not ok, replace turbocharger

3 Check factors

other than engine

Yes Go to next step l Clutch stipprng l 5rake dragging l Low tire pressure

No l Incorrect ttre size Repair or adjust

FZ-36

Page 156 of 677

TROUBLESl-lOOTING GUIDE F2

;TEP 1 INSPECT1ON

ACTION

13 Check if resistance of ignition coil 1s OK*

Yes Go to next step

Resistance (at 20°C iSS*FJ):

Primary coil winding . . . . . . . .

0.81~-0.99Q

Secondary coil winding,,.. 1 O--16 kR

PRIMARY COIL

WINDING SECONDARY COIL

WlNDlNG

NO Replace

14 Check for correct engine compression”

Yes Gc to next step

1 Engine compression (Minimum):

785 kPa (8.0 kg/cm , It4 psi)-300 ipm

NO Check engine condition” l Worn piston, piston rings or cylinder

wall

l Defective cylinder head gasket l Distorted cylinder head l Improper valve seating

*Valve sthing in guide

15 Change fuel and check if acceleration improves

Yes Change fuel to another brand

NO

Go to next step

16 Check if NC cut-off control system is OK’

Yes Go to next step

No Repair or replace

17

I Try known good ECU and check if condition

improves

* Refer to 323 Workshop Manual [1203-IO-89F (Europe) or i204-IO-89F (Australia)].

93GOF2-747

F2-39

Page 159 of 677

![MAZDA 232 1990 Suplement Manual PDF F2 TROUBLESHOOT1NG GUIDE

25 HIGH OIL CONSUMPTION [BP TURBO]

DESCRIP- 1

l Oil consumption excessive

TION l Exhaust gas white

TROUBLESHOOTING HINTS1

a PCV system malfunctton *

@ Englne malfunctio MAZDA 232 1990 Suplement Manual PDF F2 TROUBLESHOOT1NG GUIDE

25 HIGH OIL CONSUMPTION [BP TURBO]

DESCRIP- 1

l Oil consumption excessive

TION l Exhaust gas white

TROUBLESHOOTING HINTS1

a PCV system malfunctton *

@ Englne malfunctio](/img/28/57056/w960_57056-158.png)

F2 TROUBLESHOOT1NG GUIDE

25 HIGH OIL CONSUMPTION [BP TURBO]

DESCRIP- 1

l Oil consumption excessive

TION l Exhaust gas white

TROUBLESHOOTING HINTS1

a PCV system malfunctton *

@ Englne malfunction (Oil

working up, working down, or leakage)

3 Oil leakage from turbocharger

ZEP [ INSPECTION Repair or

replace 1 Check if PCV hose, ventilation hose or their at-

taching nipples are separated, damaged,

ciogged, or restricted 2

Check insrde of air hose, air pipe, and intercool-

er for excesstve oil

3 1 Check white exhaust gas visible when ventilation

1 hose or PCV hose removed

1

4 Remove turbocharger and check at oil seals of

compressor and turbine shafi for oil leakage Yes

NO Yes

NO Yes

No Check hoses for clogged

Yes Replace turbocharger

NO

ACTION

Go to next step

Possibly oil working up

Check PCV valve and PCV hose for

clogged

+ If OK, go to next step

e If not UK, repalr or replace

Go to next step

Go to next step

Engine malfunction (Oil working up,

working down, or leakage)

Check foltowing

. Worn piston or cyiinder

l Worn piston ring groove’ l Stuck piston rings* l Worn vatve seal* l Worn valve stem * l Worn vatve guide’

* Refer to 323 Workshop Manual [1203-IO-89F (Europe) or 1204-IO-89F (Australra)].

93GOF2-74:

FZ-42

Page 162 of 677

TURBOCHARGER CONTROL SYSTEM F2

TURBOCHARGER CONTROL SYSTEM

PREPARATION

SST

49 HO80 740

Gauge. pressure

I 93GOF2-754

93GOF2-755

L I 93GOF2-756

93GOF2-757 93GOF2-753

SYSTEM OPERATION

1. Install a pressure gauge 149 kPa (0.5 kg/cm2, 7.1 psi)

min.1.

2. Connect a tachometer to the diagnosis connector lG-

terminal.

3. Start the engine.

4. Verify that the boost pressure when the engine speed is

4,000 rpm is within specification.

Specification: More than 2.0 kPa ( 0.02 kg/cm2, 0.3 psi)

5. If not within the specification, check for air Ieakage, exhaust

gas leakage, and for the wastegate stuck open.

6. if OK, replace the turbocharger.

WASTEGATE

Inspection

1. Remove the air hose from the wastegate actuator.

2 Connect the SST to the actuator.

3. Raise the front of the vehicle and support it on safety stands.

4. Remove the undercover.

F2-45

Page 163 of 677

F2 TURBOCHARGER CONTROL SYSTEM

I 93GOF2-756

93GOF2-75!

93GOF2-761

5. Mark the actuator rod.

Caution

l Do not apply compressed air over 98 kPa (1.0

kg/cm2, 14 psi).

6. Adjust the compressed air pressure to 83 kPa (0.85

kg/cm”, 12 psi).

7. Verify that the rod moves when applying and releasing air

pressure.

WASTEGATE SOLENOID VALVE

Inspection

1, Remove the ,solenoid valve.

2. Verify that air does nut flow from @ through @

3. Apply IN to the solenoid valve and verify that air flows from

@ through @

TURBUCHARGEFI

Inspection

1. Be sure tf7e engine is cool.

2. Remove the air hose.

3. Check that the compressor wheel assembly turns smoothly.

4. If there is excessive drag or noise, replace the turbocharger.

93GOF2-761

FZ-46

Page 164 of 677

TURSUCHARGER CONTROL SYSTEM F2

Removal I InstaIlation

Caution

l Be carefui of following points after turbocharger removal.

l Do not carry the turbocharger by the actuator rod or actuator hose.

l Do not drop the turbocharger.

l Set the turbocharger down with the turbine shaft horizontal.

9 Cover the intake, exhaust, and oil passages to prevent dirt or other materia1 from entering.

l Use the specified new studs when installing the turbocharger.

1. Disconnect the negative battery cable.

2. Lift up the vehicle.

3.

Remove the undercover.

4. Drain

the engine coolant.

5. Remove in

the order shown in the figure.

6. fnstall in the reverse order of removat, referring to Installation Note.

7.8-l 1 N-m (80-l 10 cm-kg, 69-95 in-lb)

G I’

/

43-61 (4.4-6.2, 3245)

36-42 (3.94.3, 28-

7.8-1 1 N-m (80-110 cm-kg, 6

cm-kg, 69-95

indb)

26-31

12.7~g-2. 20-231

w

19-26 (l-9-2.6, 14-19)

7.6-17 N-m (80-7 t d cm-kg, 69-95 in-lb)

N-m (m-kg, Mb]

I 93GOF2-762

F2-47

Page 165 of 677

F2 TURBOCHARGERCONTROLSYSTEM

1. Radiator

2. Insulators

3.

Air hose, and air pipe

4. Oxygen

sensur connector

5. Front exhaust pipe

6. Bracket

1 I 93GOF2-765

93GOF2-761

7. Water hoses

8. Oil pipe

9. Oil return pipe

10. Exhaust

manifold and turbocharger

Removal Note . . . . . . . . . . . . . . . . . . . . . . .._.-........_ below

Installation Note . . . . ..__-.............._...___.._. below

93GOF2-763

Removal Note

Exhaust manifold and turbocharger

1. Remove the exhaust manifold and the turbocharger as an

assembly .

2. Remove the turbocharger from the exhaust

manifold.

InstaIlation Note

Exhaust manifold and turbocharger

1. Remove all gaskets and sealant.

2. Install new gaskets.

3. Supply 25 cc (1.5 cu in) of oil through the oil passage of

the turbocharger.

4. Install the turbocharger to the exhaust manifold.

5. Install the turbocharger and the exhaust manifold assem-

bly to the engine and loosely tighten the nuts.

6. install the bracket and the front exhaust pipe, and tighten

the turbocharger mounting nuts.

AIR BYPASS VALVE

Removal I Installation

1. Remove the vacuum hose and the air hoses from the air

bypass valve.

2. Remove the air bypass valve.

3. Install in the reverse order of removal.

Inspection

1. C_onnect a vacuum pump to air bypass valve port @-

2. Verify that air flows from port @through port @ when 250

f 35 mmHg (9.8 * 1.4 inHg) vacuum

is applied to port

0 a .

Page 167 of 677

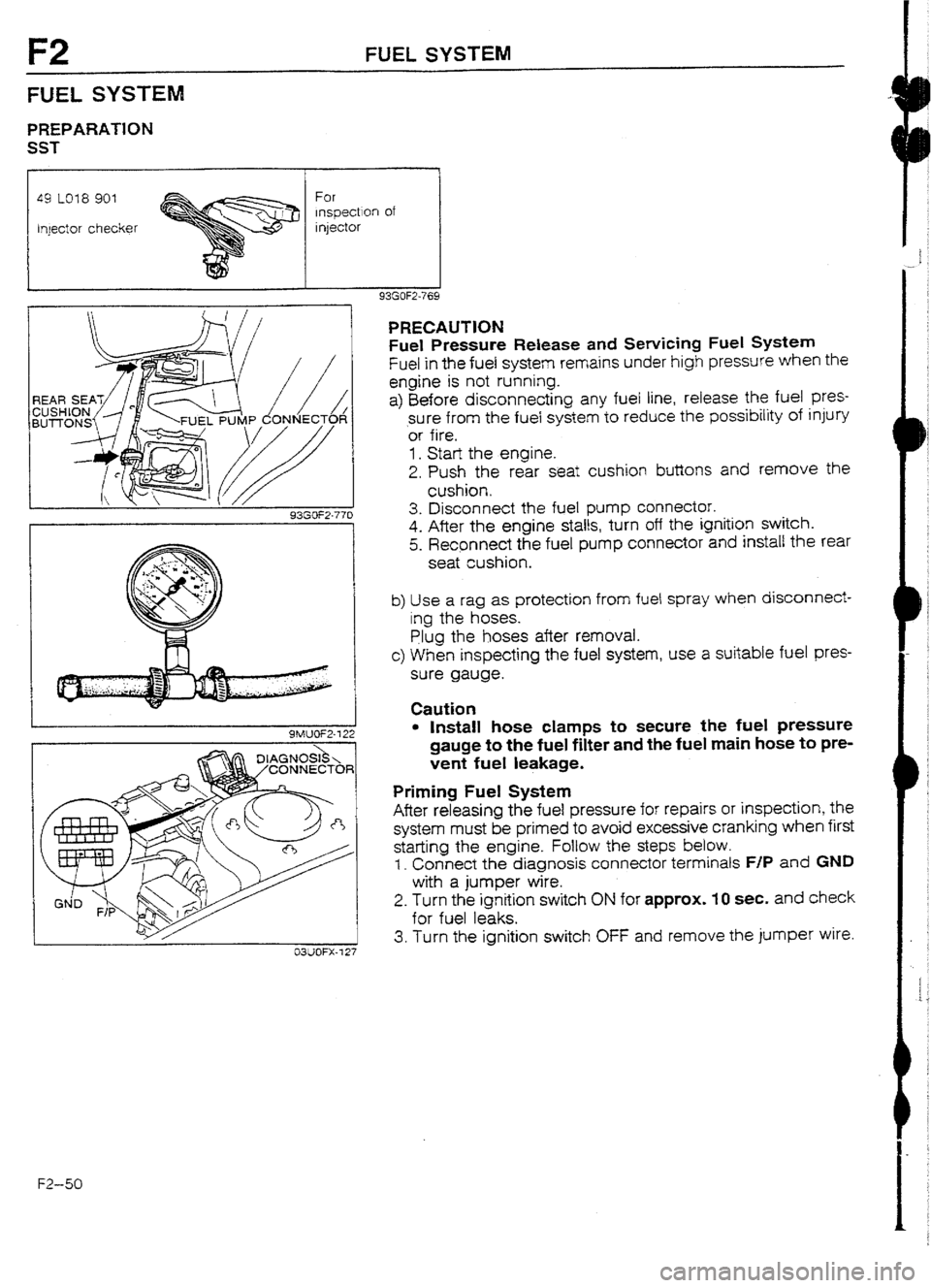

F2 FUEL SYSTEM

FUEL

SYSTEM

PREPARATlON

SST

49 LO18 901

Injector checker For

lnsgectlon of

injector

93GOF2.770

9MUOF2-722

03UOFX-7 27

F2-50

PRECAUTION

Fuel Pressure

Release and Servicing Fuel System

Fuel in the fuel system remains under high pressure when the

engine is not running.

a) Before disconnecting any fuel line, release the fuel pres-

sure from the fuel system to reduce the possibility of injury

‘or fife,

1. Start the engine.

2. Push the rear seat cushion buttons and remove the

cushion,

3. Disconnect the fuel pump connector.

4. After the engine stalts, turn off the ignition switch.

5. Recpnnect the fuel pump connector and install the rear

seat cushion.

b) Use a rag as protection from fuel spray when disconnect-

ing the hoses.

Plug the hoses after

removal.

c) When inspecting the fuel system, use a suitable fuel pres-

sure gauge.

Caution

l Install hose clamps to secure the fuel pressure

gauge to the fuel filter and the fuel main hose to pre-

vent fuet leakage.

Priming Fuel System

After releasing the fuel pressure for repairs or inspection, the

system must be primed to avoid excessive cranking when first

starting the engine. Follow the steps

below.

1. Connect the diagnosis connector terminals F/P and GND

with a jumper wire.

2. Turn the ignition switch

ON for approx. 10 set, and check

for fuel leaks.

3. Turn the ignition switch OFF and remove the jumper wire.

Page 176 of 677

CONTROL SYSTEM F2

CONTROLSYSTEM

PREPARATION

SST

49 HOt8 9A3

Self-dragnosls

checker

Engrne signal

IT-iOFlllO~ 49 GO18 904

Sheet System selector

I 93GUF2-786

For inspection of ECU

93GOF2-787

93GOF2-801

TERMNALS 1

--I”- -

03UOFX

ENGINE CONTROL UNIT (ECU)

Inspection

1. Disconnect the ECU connectors.

2. Connect the SSTs (Engine Signal Monitor and Adapt-

er) to the ECU as shown.

3. Place

the SST (Sheet) 011 the Engine Signal Monitor.

4. Measure the voltage at each terminal.

(Refer to pages FZ-60 to F2-67.)

5. If any ECU terminal voltage is incorrect, check the related

input or output devices and wiring. If no problem is found,

reptace the ECU. (Refer to above.)

Caution l

Never apply voltage to SST terminals A and B.

F2-59

Page 177 of 677

![MAZDA 232 1990 Suplement Manual PDF F2 CONTROL SYSTEM

Terminal voltage [BP TURBO]

eminal input Output , 1 Connected to Test condition Correct voltage Remark

IA - - Battery Constant Approx. 12V for backup

15 0 Main relay OFF Approx. MAZDA 232 1990 Suplement Manual PDF F2 CONTROL SYSTEM

Terminal voltage [BP TURBO]

eminal input Output , 1 Connected to Test condition Correct voltage Remark

IA - - Battery Constant Approx. 12V for backup

15 0 Main relay OFF Approx.](/img/28/57056/w960_57056-176.png)

F2 CONTROL SYSTEM

Terminal voltage [BP TURBO]

eminal input Output , 1 Connected to Test condition Correct voltage Remark

IA - - Battery Constant Approx. 12V for backup

15 0 Main relay OFF Approx. OV

(FUEL INJ relay) tgnltlon switch

-

ON Approx. 12V

1c 0 1 Ignition switch Wniie cranking Approx. 1 OV

-

(START)

lgnrtron switch ON Approx. OV

ID 0 Self -Diagnosis Test switch at “SELF-TEST” With Self-

Checker Lamp illuminated ior 3 sec. after ignition Approx. 5V Diagnosis Check-

(Monitor lamp) switch OFF* ON er and System

Lamp not illuminated after 3 sec. Approx. 12V Se’ector

Test switch at

“02 MONITOR” at idle

Monitor lamp illuminated Approx. 5V

Test switch at

“02 MONITOR” at idle

Monitor lamp not illumrnated Approx. 12’4

-lE - - - -

- -

1F 0 Self-Diagnosis Buzzer sounded for 3 sec. after ignition

Below 2.5V l With Self-

Checker switch OFF -+ ON Diagnosis

(Code Number)

Buzzer not sounded after 3 sec. Approx. 12V Checker and

Buzzer sounded Below 2.9 System Selector

l With System

Buzzer not sounded Approx. 12V Selector test

switch at

“SELF-TEST’ ’

I I 1G

0 Igniter

7H

0 Solenoid vahe

(Wastegate)

l!

0 Fuel pump

resistor/relay

I

lJ I r-Tcreiay Ignition switch ON

ld!e

Engine speed below 5,300 rpm

Engine speed above 5,300 rpm

While cranking

Idle

Ignition switch ON

AK switch ON at idle 1 Approx. OV

-

Approx. 0.2V

Approx. 12V

-

Below 1.5V

Approx. 1 OV

-

I3elow 15V

Approx. 12V

Below 2.5V

AIC switch OFF at idle Approx. 12V

-

IK 0 Diagnosis System Selector test switch at

connector

(TEN terminal)

1L - - -

- -

-

IM

t 0

1 Ground (Australia) Constant Below 1 .OV Not used

(Except Australia)

F2-60