engine MAZDA 232 1990 Suplement Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 63 of 677

82 OUTLINE

CAMSHAFT

IDENTlFlCA~lON MARK

/

EXHAUST

IDENTlFlCATlON MARK

INTAKE

IN

EX BP TURBO

BP26

8P26 BP NON-TURBO

BP05

BP06

TDC

EXHAUST OPEN

The camshaft valve timing specifications are different to improve engine power.

Page 64 of 677

D

D

SUPPLEMENTAL SERVICE iNFORMATION, COMPRESSION 82

SUPPLEMENTAL SERVICE INFORMATION

The following points in this section are changed in comparison with Workshop Manual [Europe (7 203~IO-899,

Australia (I 204-1 U-89F) 1.

Compression

l Inspection

Engine

l Removal

l Engine stand mounting

l Engine stand dismounting

l Ins:attaIion 93GQ32-77 I

COMPRESStON

If the engine exhibits low power, poor fuel economy, or poor idle, check the following:

1. Ignition system (Refer to Section G.)

2. Compression

3. Fuel system (Refer to Section F3.)

93G032-774 93GO32-712

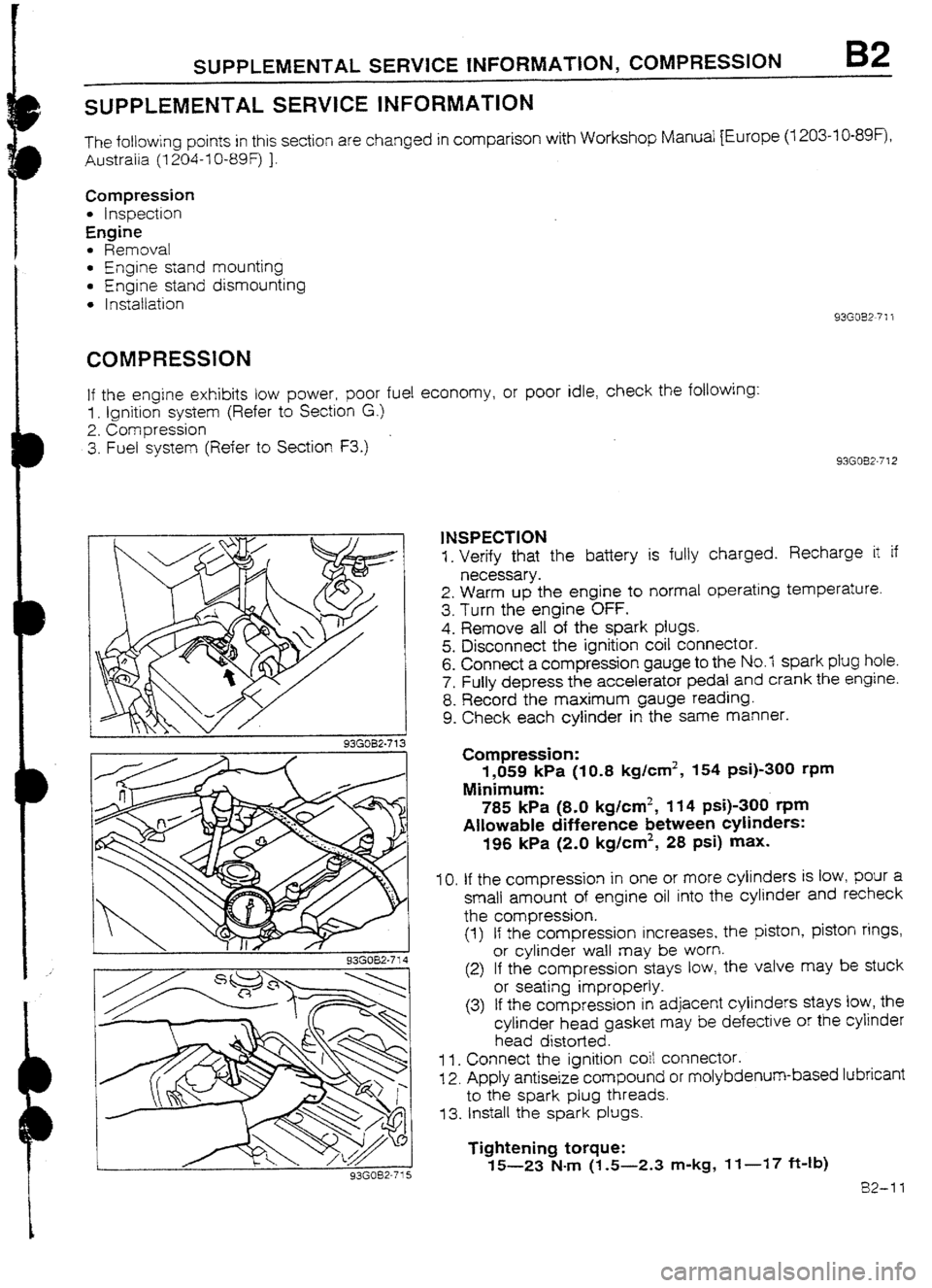

1NSPECTION

1. Verify that the battery is fully charged. Recharge it if

necessary.

2. Warm up the engine to normal operating temperature.

3. Turn the engine OFF.

4. Remove all of the spark plugs.

5. Disconnect the ignition coil connector.

6. Connect a compression gauge to the No.7 spark plug hole.

7. Fully depress the accelerator pedal and crank the engine.

8. Record the maximum gauge reading.

9. Check each cylinder in the same manner.

Compression:

1,059 kPa (IO.8 kg/cm2, 154 psi)-300 rpm

Minimum:

785 kPa (8-O kg/cm2, 114 psi)-300 t-pm

Allowable difference between cylinders:

196 kPa (2.0 kglcm2, 28 psi) max.

IO. If the compression in one or more cylinders is low, pour a

small amount of engine oil into the cylinder and recheck

the compression.

(1) If the compression increases, the piston, piston rings,

or cylinder waII may be worn.

(2) If the compression stays tow, the valve may be stuck

or seating improperly.

(3) If the compression in adjacent cylinders stays low, the

cylinder head gasket may be defective or the cylinder

head distorted.

1 I. Connect the ignition coit connector.

12. Apply antiseize compound or molybdenum-based lubricant

to the spark plug threads.

73. Install the spark plugs.

Tightening torque:

15-23 N-m (1.5-2.3 m-kg, If-17 ft-Ib)

82-11

Page 65 of 677

B2 REMOVAL

REMOVAL

Warning

l Release the fuel pressure. (Refer to Section FZ.)

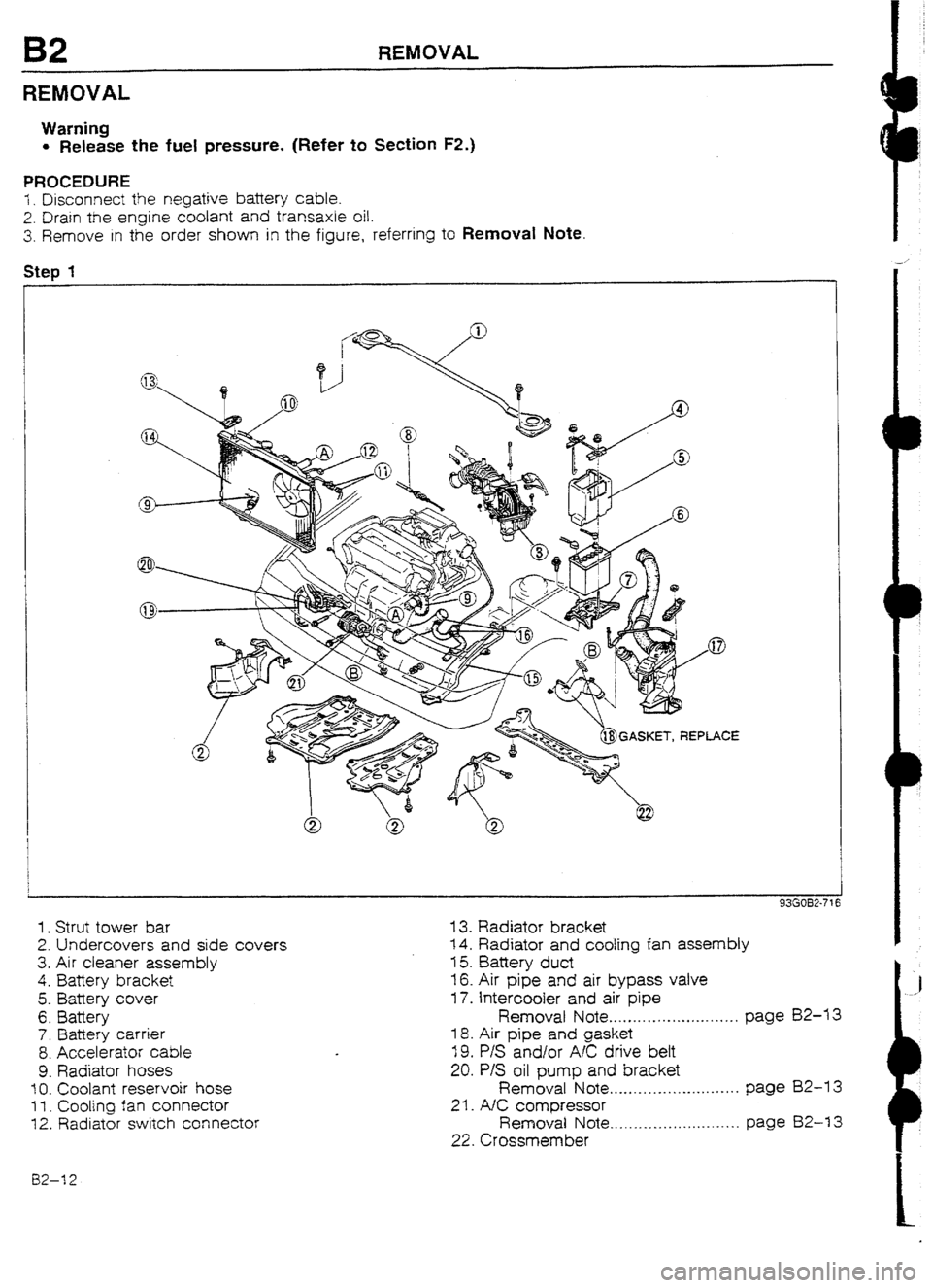

PROCEDURE

i. Disconnect the negative battery cable.

2. Drain the engine coolant and transaxle oil.

3. Remove in the order shown in the figure, referring to Removaf Note

Step 1

1. Strut tower bar

2. Undercovers and side covers

3. Air cleaner assembly

4.

Battery bracket

5. Battery cover

6. Battery

7. Battery carrier

8. Accelerator cable

9. Radiator hoses

10. Coolant reservoir hose

f I. Cooling fan connector

12. Radiator switch connector

13. Radiator bracket

14. Radiator and coofing fan assembly

15. Battery duct

16. Air pipe and air bypass valve

17. Intercooler and air pipe

Removat Note . . . . . . . . . . . . .._.. m _._._..., page 82-U

18. Air pipe and gasket

19. P/S and/or AK drive bett

20. P/S oil pump and bracket

Removal Note . . . . .._.__.....~..~........ page BZ-13

21. A/C compressor

Removal Note . . . . . .._................... page 82-I 3

22. Crossmember

02-12

Page 66 of 677

REMOVAL B2

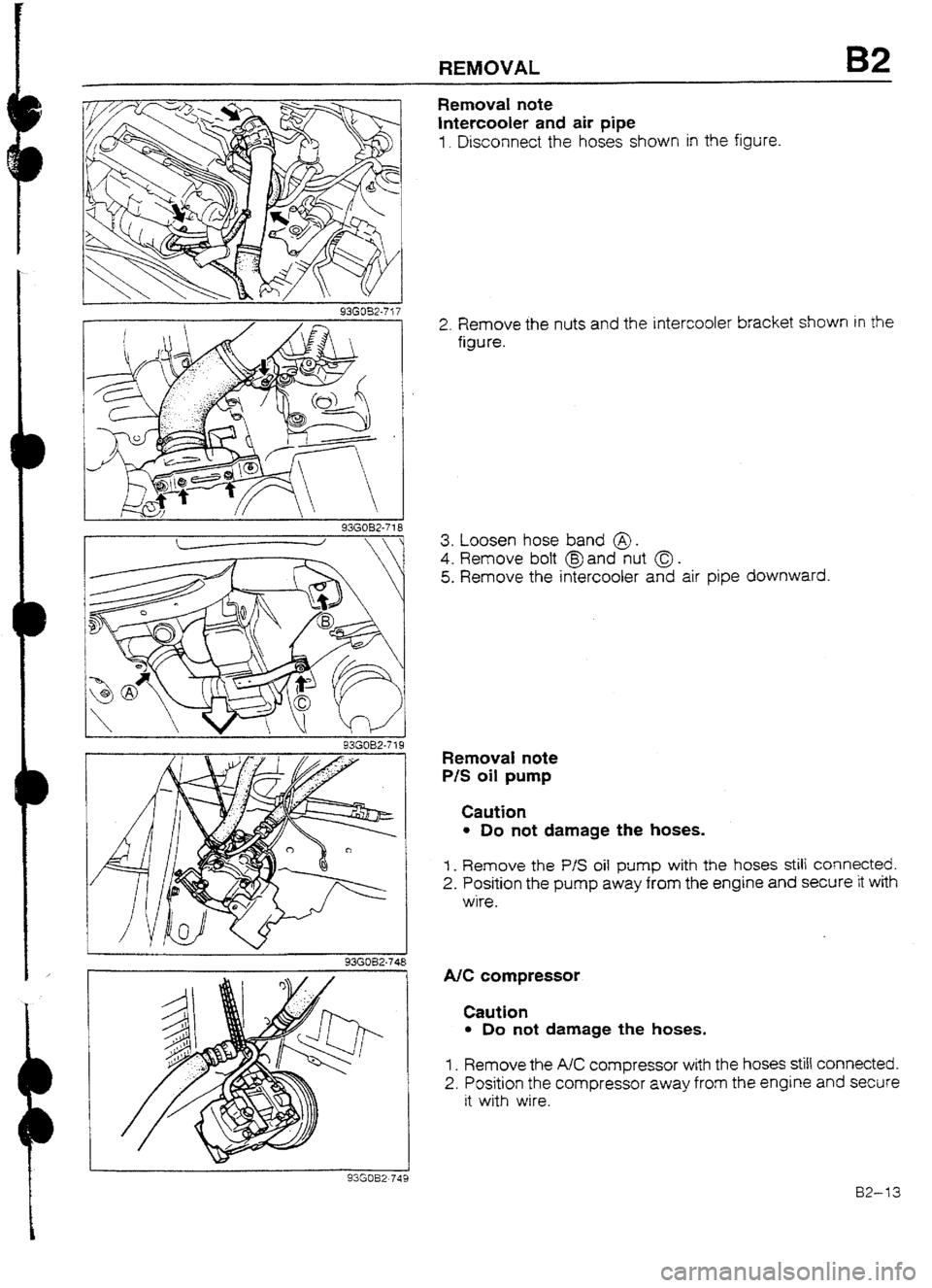

Removal note

intercooler and air pipe

I. Disconnect the hoses shown in the figure.

936032-718

2. Remove the nuts and the intercooler bracket shown in the

figure.

3. Loosen hose band @.

4. Remove bolt @and nut 0.

5. Remove the intercooler and air pipe downward.

RemovaI note

P/S oil pump

Caution

l Do not damage the hoses.

I _ Remove the P/S oil

pump with the hoses still connected.

2. Position the pump away from the engine and secure it with

wire.

93GO52-748

1 93GOB2~749

NC compressor

Caution

l Do not damage the hoses.

1. Remove the AC compressor with the hoses still connected.

2. Position the compressor away from the engine and secure

it with wire.

B2-13

Page 70 of 677

REMOVAL B2

Step 5

1. Engine mount member 5, No.3 engine mount

rubber

Removal Note . . . . . . .._.._...._....-.__._.._-_..-.* below 6. No.4 engine mount rubber and bracket

2. No.2 engine mount rubber and bracket 7. Alternator and drive belt

3. Clutch release cylinder 8. I ntercooler brat kets

Removal Note _._...._.._.._.....,,....__ page B2-18 9. Engine and transaxle assembly

4. Dynamic damper Removal Note . .._.................--.-..

page 62-f 8

Removal note

Engine mount member

1. Suspend the engine with a chain hoist.

Page 71 of 677

82 REMOVAL

03UOSX-81 t

93GOB2-723

82-l 8

2. Remove the No.1 and No.2 engine mount nuts. caution

l Be careful that the engine does not fall when remov-

ing the member.

3. Remove the engine mount member bolts and nuts and the

engine mount mem her.

Clutch release cylinder

I. Remove the release cylinder pipe bracket from the transaxle.

2. Position the release cylinder with the hose connected away

from the transaxle for

easier removal.

Caution

l Do not damage the pipe and hose.

Engine and transaxle assembly

Caution

l Do not damage any components in the engine com-

partment.

1, Remove the engine and transaxle assembly.

Page 72 of 677

REMOVAL B2

Step 6

SeDarate the engine and transaxle in the order shown in the figure.

1. Intake manifold bracket 3. Transaxie mounting bolts

2. Starter and bracket 4. Transaxle

93GOB2-7;

B2-19

Page 73 of 677

B2 ENGINE STAND MOUNTING

ENGINE

STAND MOUNTING

PROCEDURE

1. Remove in the order shown ir! the figure.

1. Exhaust manifold insulator

2. Exhaust manifold and turbocharger assembly 4. Water bypass pipe

5. A/C compressor bracket

3. Exhaust manifold gasket

6. Water inlet pipe

93GOB2-725

82-20

Page 74 of 677

ENGlNE STAND DISMOUNTING B2

ENGiNE STAND DISMOUNTING

PROCEDURE

1. Remove the engine from the SST (engine stand).

2. Remove the SST (engine hanger) from the engine.

3. Install the parts shown in the figure.

4. Tighten the parts to the specified torques.

Torque Specifications

f&n (m-kg, ft-lb)

93GOB2-75

Water Inlet Pipe

1. Remove ail foreign material from the water inlet pipe mount-

ing surfaces.

2. Install a new gasket and the water inlet pipe.

Tightening torque:

f9-25 Nm (1.9-2.6 m-kg, 14-19 ft-lb)

93GOB2-753

82-21

Page 75 of 677

B2 ENGINE STAND DISMOUNTING

93GOB2-7%

93AOB2-077

05WOBX-25

82-22 Water Bypass Pipe

1. Apply a small amount of engine coolant to the new O-ring.

2. install the O-ring on the pipe.

3. InstaIi the water bypass pipe.

A/C Compressor Bracket (if equipped)

1. Install the A/C compressor bracket.

Tightening torque

@: 19-25 N&m (1.9-2.6 m-kg, 14-19 ft-lb)

@: 37-52 Nom (3.8-5.3 m-kg, 27-38 ft-fb)

Exhaust Manifold and Turbocharger Assembly

I= Remove all foreign material from the exhaust manifold con-

tact surfaces.

2. Install a new gasket.

3. Instatl the exhaust manifold and turbocharger assembly.

Tightening torque:

38-46 N-m (3.9-4.7 m-kg, 28-34 ft-lb)

4. Connect the water hose to the water bypass pipe.

5. Connect the water hose and the oil pipe to the cylinder

block.

Tightening torque

@: 12-18 N-m (I -2-l .8 m-kg,

6. Connect the oil return hose to the oi 8.7-13 ft-lb)

I pan.

Exhaust Manifold Insulator

1. Install the exhaust manifold insulator.

Tightening torque:

7.8-I 1 Mm (80-I IO cm-kg, 69-95 in-lb)