engine MAZDA 232 1990 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 131 of 677

![MAZDA 232 1990 Suplement Repair Manual F2 TURBOCHARGER CONTROL [BP TURBO]

93GOF.Z721

!=2-14 LARGE

+ FULLY OPEN

BYPASS AIR

i 8EGlNNIp

AMOLIN OF OPEN

SMALIL

430 VACUUM

(5-l) mmt-lg

TURBOCHARGER OnW

INLET

lntercooler

The air-to-a MAZDA 232 1990 Suplement Repair Manual F2 TURBOCHARGER CONTROL [BP TURBO]

93GOF.Z721

!=2-14 LARGE

+ FULLY OPEN

BYPASS AIR

i 8EGlNNIp

AMOLIN OF OPEN

SMALIL

430 VACUUM

(5-l) mmt-lg

TURBOCHARGER OnW

INLET

lntercooler

The air-to-a](/img/28/57056/w960_57056-130.png)

F2 TURBOCHARGER CONTROL [BP TURBO]

93GOF.Z721

!=2-14 LARGE

+ FULLY OPEN

BYPASS AIR

i 8EGlNNIp

AMOLIN OF OPEN

SMALIL

430 VACUUM

(5-l) mmt-lg

TURBOCHARGER OnW

INLET

lntercooler

The air-to-air intercooler utilizes fresh air flow through the in-

tercooler core to reduce the intake air temperature.

If

the air compressed by the turbocharger was sent directly

into the combustion chamber without passing through the in-

tercooler, the charging air efficiency would be

reduced by the

high temperature of the intake aii-.

The intercooler, by cooling this high temperature air, substan-

tially increases the charging air efficiency

and engine output,

as well as supressing ignition knocking by reducing the com-

bustion gas temperature.

The intercooler is mounted at

the left front of the vehicle.

Air Bypass Valve

The air bypass valve bypasses intake air from the air funnel

to before the turbocharger in order to reduce air vibration noise

during deceleration.

When the throttle valve is closed suddenly during high-rpm

and heavy-load operation, air vibration occurs between the

throttle vatve and the turbocharger as a result of pressuriza-

tion

caused by inertia of the intake air. This system prevents

such noise.

Page 133 of 677

F2 FUEL SYSTEM

FUEL VAPOR VALVE

FUEL VAPOR VALVE

93GOF2-722

The fuel vapor valve is installed in the fuel tank to allow fuel vapors within the tank to escape to the charcoal

canister.

The fuel vapor valve contains a shut-off valve to prevent raw fuel from escaping during hard cornering

01

at other times when there is significant fuel slosh.

FUEL PUMP CONTROL SYSTEM [BP TURBO]

Outline

l The fuel pump control system supplies electric power to the fuel pump at ail times while the engine is

running. The fuel pump can thus operate even though the fuel pump switch in the airflow meter OFF.

rhe fuel pump switch may open (switch OFF) on deceleration due to back-flow of air from the turbocharger.]

l To improve fuel pump longevity, the fuel pump is controlled by the engine control unit (ECU). (Refer to

next page.)

MAIN RELAY (FUEL 1NJ RELAY)

I I FUEL PUMP

RESISTOR/RELAY ECU

I

ON

P CIRCUIT OPENING

I--

DIAGNOSIS

CONNECTOR

TERMINAL F/P CPU

F2-16

Page 134 of 677

FUEL SYSTEM F2

Two-stage WeI pump operation

Engine running (Except heavy load or cranking)

The ECU 1 I circuit is ON, opening the contact plate in the fuel pump resistor/relay. Current from the circuit

opening relay to the fuel pump flows through the resistor in the fuel pump resistor/relay, and the voltage

to the fuel pump is reduced to approx. WV, causing the fuel pump to operate at a reduced speed to im-

move fuel pump longevity.

MAIN RELAY

Engine under heavy load or cranking

The ECU 1 I circuit is OFF and the contact plate in the fuel pump resistor/relay is closed. Unreduced battery

current flows to the fuel pump through the contact plate, causing the fuel pump speed and output to be

increased to meet the demands of the engine.

I

L

:: _:

:.i

I,. I,

:: :

_:. :

. . :

:: :_

.:: 1.

pi ‘.

. . ::

:: :_ c

-. .>:

i :: . . . . . . . . .

:; .::..:.y ::.

. . . . . . . ..__. I

93GW2-725

FZ-17

Page 138 of 677

![MAZDA 232 1990 Suplement Repair Manual CONTROL SYSTEM

WE~DOST WARNlNG BUZZER [BP TURBO]

To improve engine reliability, the overboost warning buzzer installed in the instrument cluster sounds during

overboost conditions as detected by en MAZDA 232 1990 Suplement Repair Manual CONTROL SYSTEM

WE~DOST WARNlNG BUZZER [BP TURBO]

To improve engine reliability, the overboost warning buzzer installed in the instrument cluster sounds during

overboost conditions as detected by en](/img/28/57056/w960_57056-137.png)

CONTROL SYSTEM

WE~DOST WARNlNG BUZZER [BP TURBO]

To improve engine reliability, the overboost warning buzzer installed in the instrument cluster sounds during

overboost conditions as detected by engine

speed and intake air amount caiculations within the ECU. The

driver is thus warned to reduce engine

speed.

DETECTtON

OVERBOOST

BUZZER

TURBOCHARGE INDICATOR [BP TURBO]

When the turbocharger boost pressure calcul’ated by intake air amount and engine speed reaches the predeter-

mined level and the transaxle is in gear, the turbocharge indicator illuminates to inform the driver of turbocharge

operation.

1

AIRFLOW METER

DISTRI BUTUR

rd” i

4 NEUTRAUCLUTCH

SWITCH ECU

* CALCULATION

-, OF

BOOST

PRESSURE

TURBOCHARGE

INDICATOR

Page 139 of 677

![MAZDA 232 1990 Suplement Repair Manual F2 CONTROL SYSTEM

KNOCK CONTROL SYSTEM [BP TURBO]

This svstem retards the ignition timina when enaine knocking occurs because of usage of low octane fuel, etc.

1NTAKE

MANIFO

KNOCK SENSOR

(INSTAL MAZDA 232 1990 Suplement Repair Manual F2 CONTROL SYSTEM

KNOCK CONTROL SYSTEM [BP TURBO]

This svstem retards the ignition timina when enaine knocking occurs because of usage of low octane fuel, etc.

1NTAKE

MANIFO

KNOCK SENSOR

(INSTAL](/img/28/57056/w960_57056-138.png)

F2 CONTROL SYSTEM

KNOCK CONTROL SYSTEM [BP TURBO]

This svstem retards the ignition timina when enaine knocking occurs because of usage of low octane fuel, etc.

1NTAKE

MANIFO

KNOCK SENSOR

(INSTALLED BETWEEN No.2 AND

No.3 CYLINDER)

IGNITER

KNOCK iX?NTROL

UNIT

Operation

When the engine vibrates, the knock sensor generates a slight voltage signal that is the sent to the knock

control unit. The knock control unit determines whether the signal is a knocking signal. If it is a knocking

signal, the ignition spark is retarded according to the intensity of the knock to a maximum of 4O.

Inhibition of spark retardation

In order to improve drivability and fuel economy, the ECU inhibits the above spark retardation when the

‘engine load Ls light, the coolant temperature is below O°C (32OF), the engine is cranking during engine test

conditions.

Note

l The knock ~ensur and knock control unit cannot be inspected individually.

When a matfunction code number 05 is indicated, replace the knock controt unit or sensor

only after inspecting the related wiring and connectors.

F2-22

Page 140 of 677

![MAZDA 232 1990 Suplement Repair Manual CONTROL SYSTEM F2

t OXYGEN SENSOR [BP TURBO]

I

CERAMlC HEATER

93GOF2-733

Because the temperature of the exhaust gas is inherently low in turbocharged engines, the BP Turbo model

uses a rapid hea MAZDA 232 1990 Suplement Repair Manual CONTROL SYSTEM F2

t OXYGEN SENSOR [BP TURBO]

I

CERAMlC HEATER

93GOF2-733

Because the temperature of the exhaust gas is inherently low in turbocharged engines, the BP Turbo model

uses a rapid hea](/img/28/57056/w960_57056-139.png)

CONTROL SYSTEM F2

t OXYGEN SENSOR [BP TURBO]

I

CERAMlC HEATER

93GOF2-733

Because the temperature of the exhaust gas is inherently low in turbocharged engines, the BP Turbo model

uses a rapid heating ceramic heater to detect the air/fuel ratio,

PRESSURE REGULATOR CONTROL SYSTEM [BP TURBO]

PRESSURE

REGULATOR

I SOLENOID VALVE

(PRESSURE REGULATOR CONTROL)

FUEL

+ (FROM

DELIVERY PIPE1

II

FUEL INJ I

RELAY

(MAIN REU\Y)

I

II Ir

-__. _ - -’ VACUUM

CT0 DYNAMIC

Ill

CHAMBER)

BATTERY -

c

FUEL

(TO FUEL TANK)

nme*rn -.-a

To prevent percolation of the fuel during hot restart idle, vacuum to the pressure regulator k cut for 180

sec., and the fuel injection pressure is increased to slightly more than 284 kPa (2.90 kg/cm’, 41.2 psi).

Operating condition

l Coolant temperature: Above 90°C (194OF)

l Intake air temperature: Above 58OC (136OF)

g No-load condition

FZ-23

Page 141 of 677

F2 CONTROLSYSTEM

AK CUT-OFF SYSTEM (AI-X)

To improve the retiability of the engine at high temperature condition, the water thermoswitch on the radiator

is switched OFF above approx. II I “C (232OF) and stops the A/C operation.

ECU

NC OPERATION BLOWER FAN

WATER

THERMOSWITCH

IABOVE

111 OC (232OF): OFF]

NC SWITCH

IGNITION

T

l 1

BLOWER SWITCH

MAGNET

CLUTCH

93GOF2-73

F2-24

Page 142 of 677

SUPPLEMENTAL SERVICE INFORMATION F2

SUPPLEMENTAL SERVICE INFORMATION

The following points in this section are changed in comparison to the Mazda 323 Workshop Manual

[I 203-I U-89F (Europe) or 120410-89F {Australia)].

intake air system components [BP Turbo]

l Removalllnspectionll nstaltation

WASTEGATE [BP Turbo]

l Inspection

WASTEGATE SULENOlD VALVE [BP Turbo]

l Inspection

Turbocharger [BP Turbo]

l Inspection

l Removalllnstaltation

Air bypass valve [BP Turbo]

l Removal/hstallation

l 1 nspection

lntetcoolet [BP Turbo]

l RemovaMnspection/tnstaltation

Fuel tank

l Removal ! Inspection I Installation

Fuel pump control unit [BP Tubto]/4x4 control unit [BP SOHC]

l 1 nspection

l Replacement

Transfer pump switch

l Inspection

l Replacement

Transfer pump

l Inspection

l Replacement

Fuel pump resistor/relay

l System operation

l Inspection

injector [8P Turbo]

l Volume test

Exhaust system components

l Removal / 1 nspection / Installation

Engine control unit (ECU) [BP Turbo]

l Terminal voftage

Oxygen sensor [BP Turbo]

l Inspection

l Replacement

Knock sensor [BP Turbo]

l Replacement 93GOFZ736

F2-25

Page 149 of 677

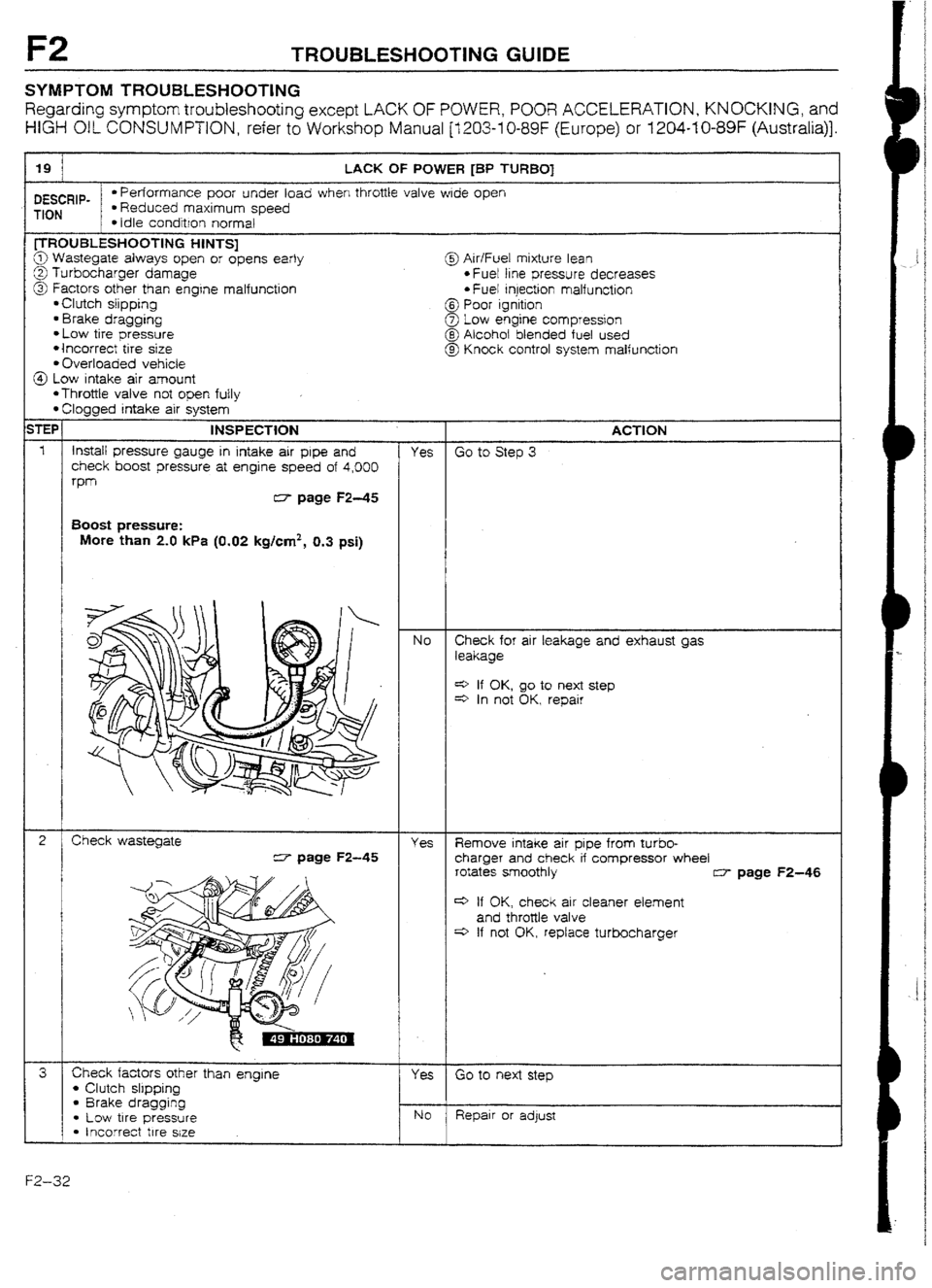

F2 TROUBLESt=iUUTlNG GUIDE

SYMPTOM TROUBLESHOOTING

Regarding symptom troubleshooting except LACK OF POWER, POOR XCELERATION, KNOCKING, and

HIGH UIL CONSUMPTION, refer to Workshop Manual [I 203-l O-89F (Europe) or 1204-l O-89F (Australia)].

19 LACK OF POWER [BP TIJR801

DESCRIP- *Performance poor under load when throttle valve wide open

TION *Reduced maximum speed

l Idle condition normal

[TROUBLESHOOTING HINTS1

3 Wastegate always open or opens early

3 Turbocharger damage

@ Factors other than engine malfunction

*Clutch sllpping

l Brake dragging

*Low tire pressure

l Incorrect tire size l Overloaded vehicle

@ Low intake air amount

*Throttle valve not open fully

*Clogged intake air system

TEP INSPECTlON

1

Install pressure gauge in intake air pipe and

check boost pressure at engine speed of

4,000

wm

CT page F2-45

Boost pressure:

More than 2.0 kPa (0.02 kglcm2, 0.3

psi)

@ Air/Fuel mixture lean

l Fuel iine pressure decreases l Fuel injection malfunction

@ Poor ignrtjon

@ Low engine compression

@ Alcohol blended fuel used

@ Knock control system malfunction

ACTION

Yes Go to Step 3

NO Check for air leakage and exhaust gas

leakage

4 If OK, go to next step

4 In not OK, repair

2 Check wastegate

Yes Remove intake air pipe from turbo-

f7 page F2-45 charger and check if compressor wheel

rotates smoothly t7 page F2-46

4 If OK, check air cleaner element

and throttle valve

+ If not OK, replace turbocharger

3 Check factors other than engrne Yes

l Clutch slipping Go to next step

1 8rake dragging

’

l Low tire pressure NO Repair or adjust

l Incorrect tire srze

FZ-32

Page 152 of 677

TROUBLESHUOT1NG GUIDE F2

;TEP

14

15

16 Change fuel and check if condjtjon improves INSPECTION

Check if resistance of rgnrtm

coil IS OK’

Resistance (at 20°C [SS*Fj):

Primary coil winding _....-.. Cl.81 -0.99Q

Secondary coil winding.,.. IO-16 kQ ACTION

Yes Go to next step

PRIMARY COIL

WINDING SECONDARY COIL

WIND tNG

Check fur correct engine compressron”

Yes Go to next step

Engine compression:

785 kPa (8.0 kg/cm2, 1 I4 psi)-300’ rpm L 1

No Check engine condition *

l Worn p&ton, piston rings or cylinder

wall

l Defective cylinder head gasket l Distorted cylinder head l Improper valve seating

l Valve sticking in guide

Yes Change fuel to another brand

No

I I Try known good ECU and check if con-

dition imDroves

* Refer to 323 Workshop Manual [ 1203-lo-89F (Europe) or 1204-l O-89F (Australia)l.

93GOF2-74 6

F2-35