service MAZDA 232 1990 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 2 of 677

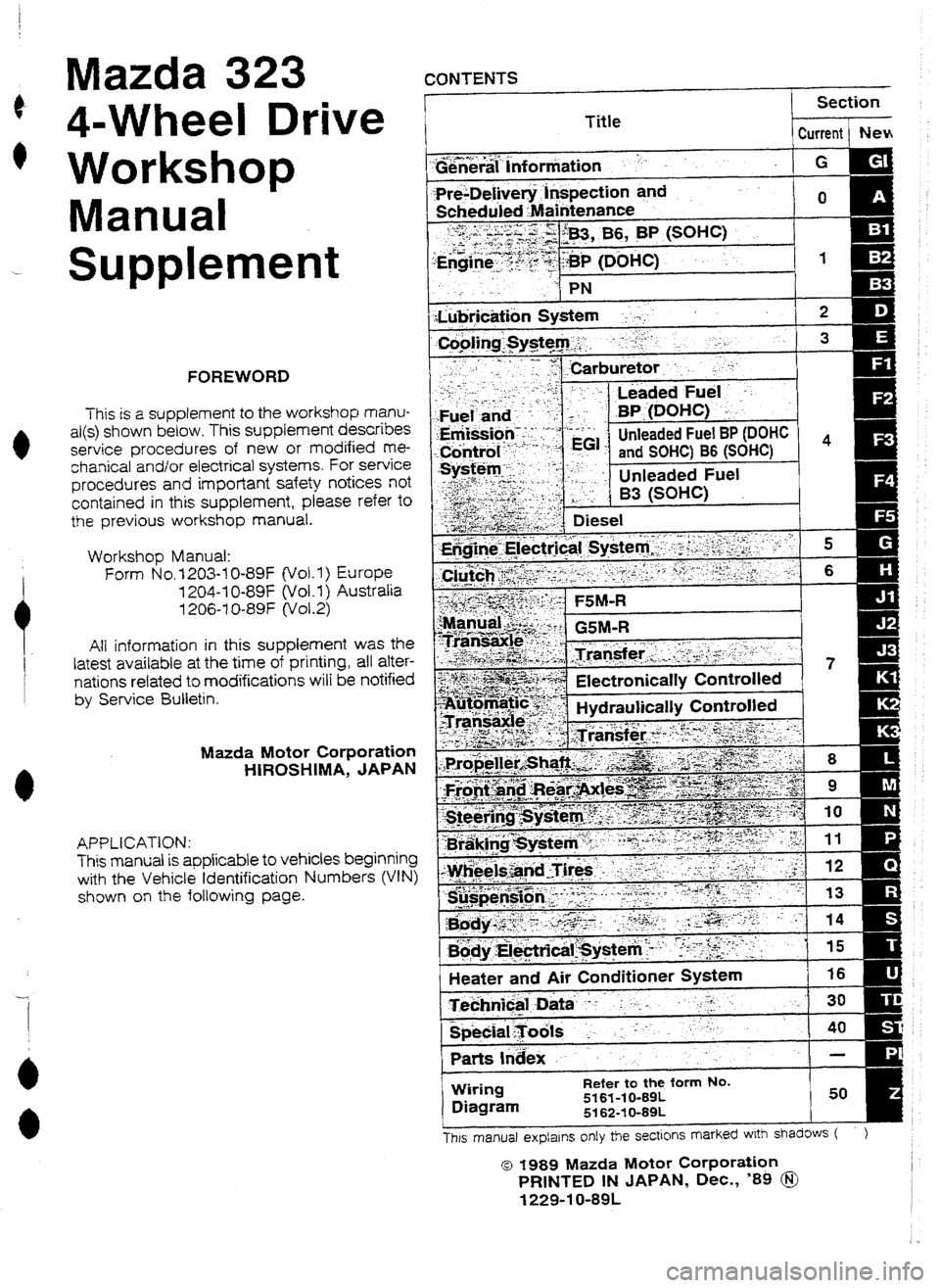

Mazda 323

4-Wheel Drive

Workshop

Manual CONTENTS

Title Section

Current ) NeH

Supplement

FOREWORD

This is a supplement to the workshop manu-

al(s) shown below. This supplement describes

service procedures of new or modified me-

chanical and/or electrical systems. For service

procedures and important safety notices not

contained in this supplement, please refer to

the previous workshop manual.

Workshop Manual:

Form No. 1203-I O-89F (Vol. I> Europe

1204-I O-89F (vol. I > Australia

I ZM-1 o-89F (vol.2)

Ali information in this supplement was the

latest available at the time of printing, all alter-

nations related to modifications wili be notified

by Service Bulletin.

Mazda Motor Corporation

HIROSHlMA, JAPAN

APPLlCATlON:

This manual is applicable to vehicles beginning

with the Vehicle Identification Numbers (UN)

shown on the following page. Electronically Controlled

Wiring

Diagram

Refer to the form No. 5161-l O-89L

5162-t O-89L

Thrs manual explarns only the sectIons marked with shadows ( ) 0 1989 Mazda Motor

Corporation

PRlNTED IN JAPAN, Dec., ‘88 @$ 1229-l O-891

Page 5 of 677

GI IMPORTANT tNFORMATlUN

IMPORTANT INFORMATION

1

.ftl

1

BASIC ASSUMPTIONS

This workshop manual assumes that you have certain special tools that are necessary for the safe and effi-

cient performance of service operations on Mazda vehicles and that you know how to use

them properly.

It also assumes that you are familiar with automobile

systems and basic service and repair procedures. You

should

not attempt to use this manual unless these assumptions are correct and you understand the conse-

quences described below.

SAFETY RlSK

This manual contains certain notes, warnings, and other precautionary information that you should carefully

read and follow to reduce the risk of personal injury to yourself or others and the risk of improper service

that may damage the vehicle

or render it unsafe. If there is no such information in regard to any specific

service method, this does not mean there is no possibility that personal safety or vehicle safety will be

jeopardized by the use of incorrect methods or toots.

POSSIBLE LOSS OF WARRANTY

The manufacturer’s warranty on Mazda vehicles and engines can be voided if improper service or repairs

are performed by persons other than those at an Authorized Mazda Dealer.

WARNING ON LUBRICANTS AND GREASES ’

Avoid all prolonged and repeated contact with mineral oils, especially used oils. Used 08s contaminated

during service (e.g., engine sump oils) are more irritating and more likely to cause serious effects, including

skin cancer, in the event of gross and prolonged skin contact.

Wash skin thoroughly after work involving oil.

Protective hand cleaners may be of value provided they can be removed from the skin with water. Do not

use gasoline, paraffin, or other solvents to remove oil from the skin.

Lubricants and greases may be slightly irritating to the eyes.

Repeated or prolonged skin contact should be avoided by wearing protective clothing if necessary. Particu-

lar care should be taken with used oils and greases containing lead. Do not allow work clothing to be con-

taminated with oil. Dry clean or launder such clothing at regular intervafs.

9MUGiX-502

Page 6 of 677

HOW TO USE TtiIS MANUAL GI

HOW TO USE THIS MANUAL

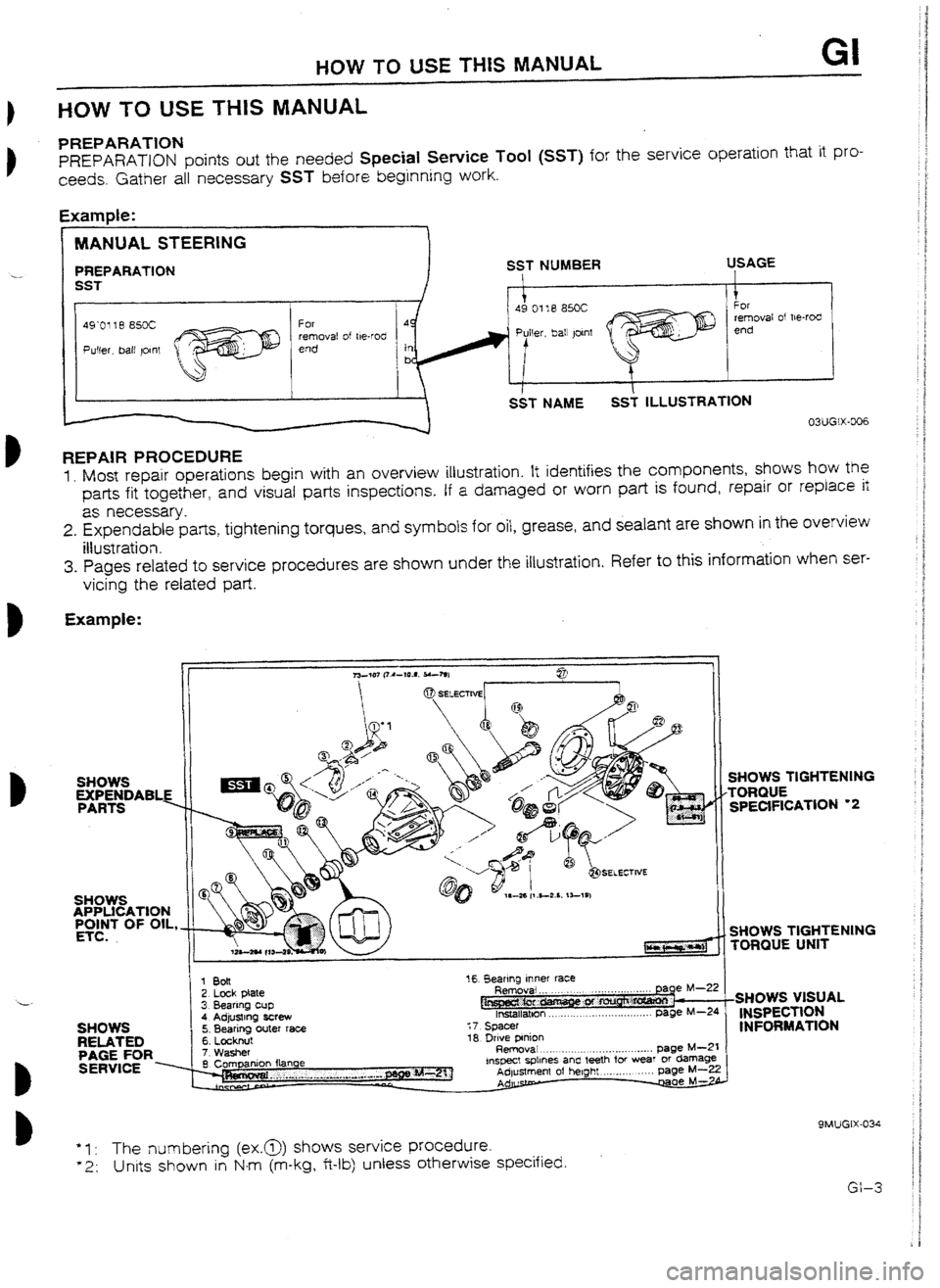

PREPARATION

PREPARATON points out the needed SpeciaI Service Tool (SST) for the service operation that it pro-

ceeds. Gather all necessary SST before beginning work.

Example:

MANUAL STEERING

PREPARATION

remova! of W-rod

REPAIR PROCEDURE I.

Most repair operations begin with an overview illustration. It identifies the components, shows how the

parts fit together, and visual parts inspections. If a

damaged or worn part is found, repair or replace it

as necessary.

2. Expendable parts, tightening torques, and symbols for oil, grease, and sealant are shown in the overview

iItustration.

3. Pages related to service procedures are shown under the illustration. Refer to this information when ser-

vicing the related part.

Example: --__ __-

EXPENDABLE iI

-

SHOWS TlGHTENlNG

TORQUE UNIT

-

SHOWS Zh REiAT&

PAGE FOR 1 8oit

16 Bearing lnne

2. Lock plate Removal . .

,.

3. Bearrng cup

I!.~ f%

fnstallatbon ._ . . . ._. . . . . .

I

A Adirtstma drew - _ ‘.v,--..s ----. 5. Bearing outer race :7 Spacer

G I h-tnllt 1R hriu* mninn

I V. LVYR*IY. .” I.~.1 7Washer Rerr&l'~ .._. . . . . ..__ . . . . . . . ..__......... page M---21

- -0mpanlon f&we inspect spllnes and teeth for wear or damage Adlustment of heloht ._._..... . . . . . DaPe k&Z?

I

r..r...~r.--~.~r....e.-..c~~...~.,~.-*

Q SERVICE x

9MUGlx-034 ‘I : The numbering (ex.@))

shows service procedure. ‘2: Units shown

in N-m (m-kg, Wb) unless otherwise specified.

Page 7 of 677

GI HOW TO USE -MS lVlANUAL/FUNDAMENTAL PROCEDURES

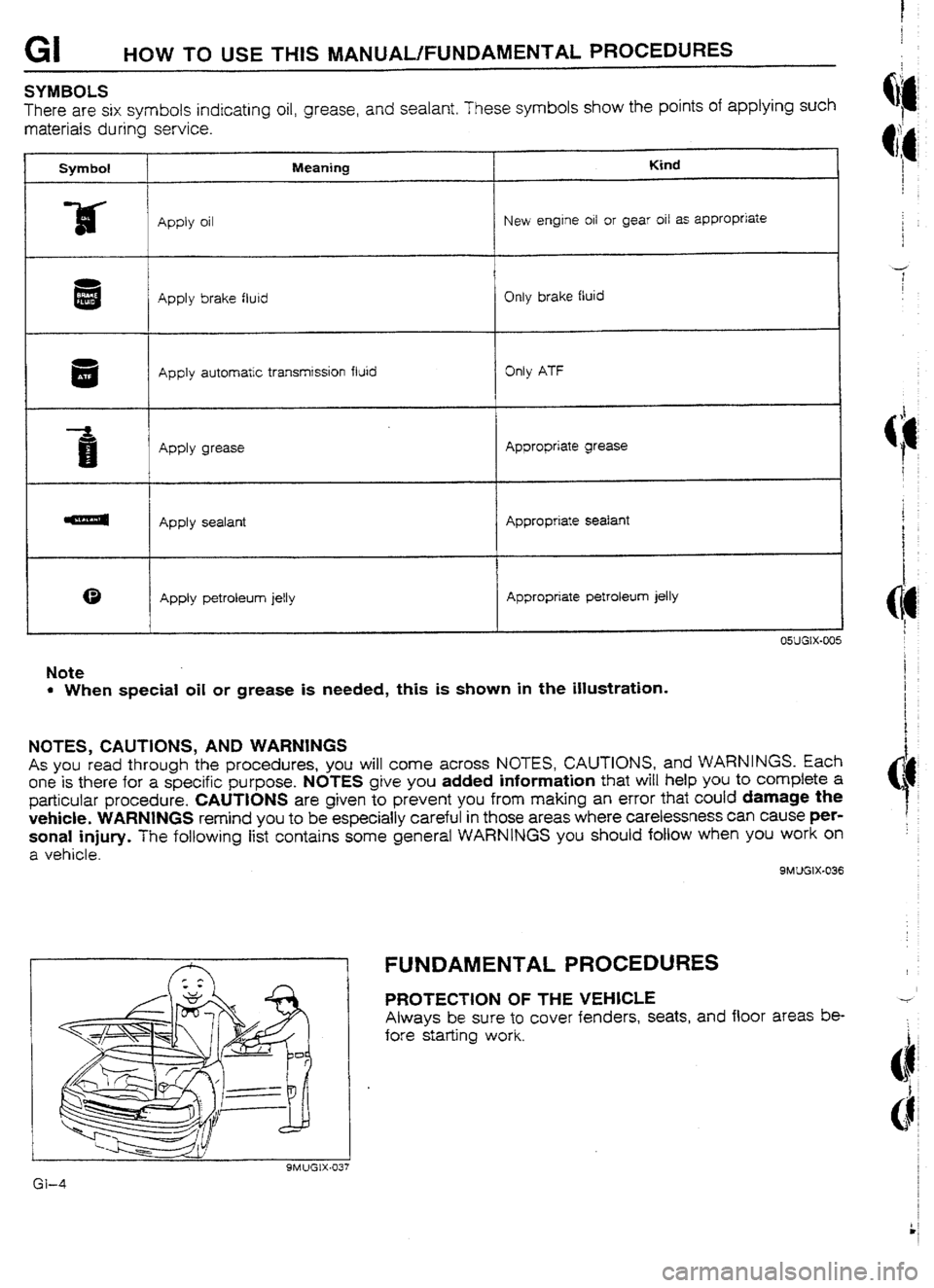

SYMBOLS

There are six symbols indicating oil, grease, and sealant.

These symbols show the points of applying such

materials during service.

Symbol

It Meaning Kind

I

Apply oil New engine

oil or gear oil as appropriate

Apply brake fluid Only brake fluid

Apply automatic

transmission fluid

Apply grease Only ATF

Appropriate grease

Appty sealant Appropriate sealant

m

0 Apply petroleum jelty Appropriate petroleum jelly

Note

l When special oil or grease is needed, this is shown in the illustration.

NOTES, CAUTIONS, AND WARNINGS

As you read through the procedures, you will come across NOTES, CAUTIONS, and WARNINGS. Each

one is there for a specific purpose. NOTES give you added information that will help you to complete a

particular procedure. CAUTlUNS are given to prevent you from making an error that could damage the

vehicle. WARNINGS remind you to be especially careful in those areas where carelessness can cause per-

sona! injury. The foliowing list contains some general WARNINGS you should follow when you work on

a vehicle.

9MUGlX-036

FUNDAMENTAL PROCEDURES

PROTECTON OF THE VEHICLE

Always be sure to cover fenders, seats, and floor areas be-

fore starting work.

Page 13 of 677

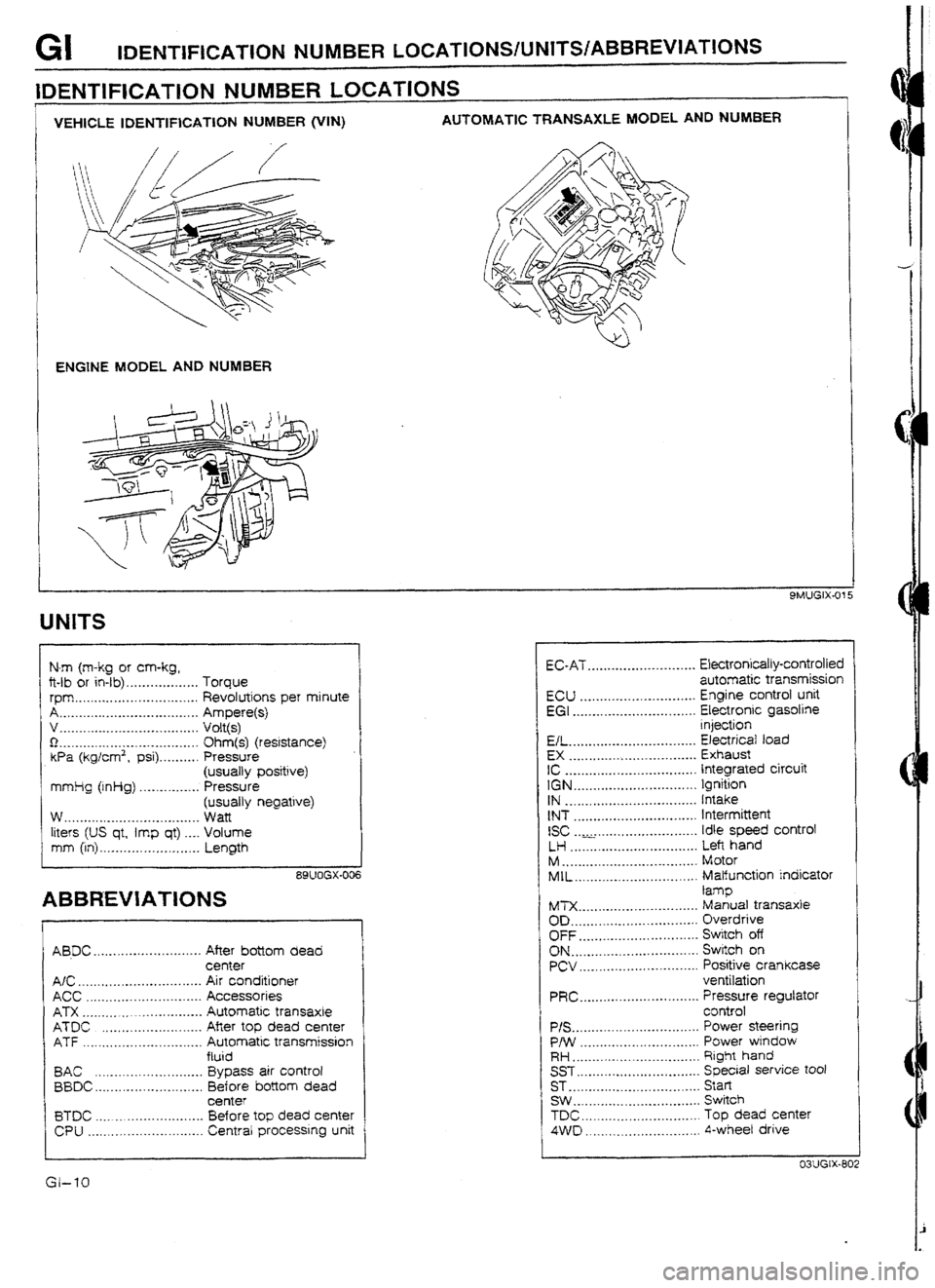

GI IDENTIFICATION NUMBER LOCATIONSIUNITSIABBREVlATlONS

IDENTIFICATCON NUMBER LOCATIONS

I

VEHKZLE IDENTIFICATION NUMBER @‘IN) AUTOMATIC TRANSAXLE MODEL AND NUM8ER

ENGINE MODEL AND NUMBER

UNlTS

N-m (m-kg or cm-kg,

ft-lb or in-lb) . . . . . .._.......... Torque

rpm ._._..._.. . . . . . . .._.._.._. . .._. Revolutions per minute

A . . .._._._...__.._.._.._. .__...._. . . Ampere(s)

v .._.... .* .*... ..__.._...*. ..*. .*. ,. Volt(s)

0 I.._._............**..-.-*..-....... Ohm(s) (resistance)

Wa (kg/cm2, psi) . . . . . . . . . . Pressure

(usually positive)

mmlig (inHg) . . . . . . .._.._... Pressure

(usually negative)

w . . . ..*.....e*.-..-..-.....*.e..... Watt

liters (US qt, imp qt) .._. Volume

mm (in) ,_._.._._..._.,_. .~. . ..__ Length

89UOGX-006

ABBREVIATIONS

AB.DC ........................... After bottom dead

center

A/C _ .............................. Air conditioner

ACC ............................. Accessories

ATX ............................. Automatic transaxte

ATDC ......................... Afier top dead center

ATF .............................. Automatic transmission

ftuid

BAC ........................... Bypass air control

BBDC.. ......................... Before bottom dead

center

BTDC ........................... Before top dead center

CPU ............................. Central processing unit t EC-AT ........................... Ekctronically-controlled

automatic transmission

ECU ............................. Engine control unit

EGI ............................... Electronic gasotine

injection

EL ................................ Electricaf toad

EX ................................ Exhaust

IC ................................. Integrated circuit

IGN ............................... Ignition

IN ................................. Intake

tNT ............................... Intermittent

ISC ............................. Idle speed control

LH ................................ Left hand

M .................................. Motor

MIL ............................... Malfunction indicator

lamp

tb4TX. ............................. Manual transaxle

OD. ............................... Overdrive

OFF .............................. Switch off

ON ................................ Switch on PCV .............................. Positive crankcase

ventilation

PRC.. ............................ Pressure regulator

control

P/S ................................ Power steering

P/W .............................. Power wtndow

RH.. .............................. Right hand

SST ............................... Special service tool

ST .................................

Start

SW . . .............................. Switch

TDC. ............................. Top dead center

4VVD ............................. 4-wheel drive

Page 15 of 677

GI CAUTKN

SMUGIX-a21

I VOLTMETER

1 9MUGlX-021

POWER SOURC

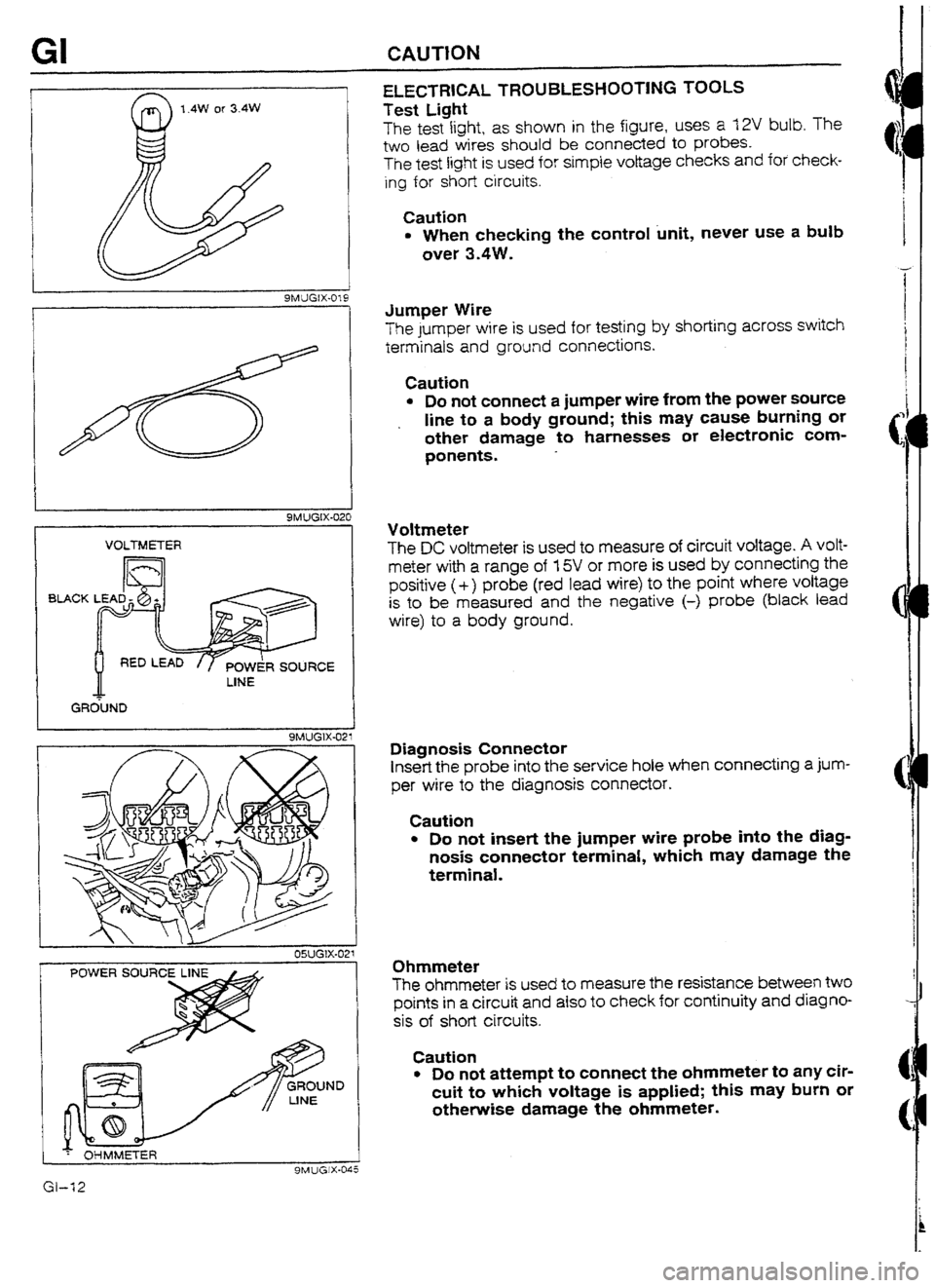

ELECTRICAL TROUBLESHOOTING TOOLS

Test Light

The test light, as shown in the figure, uses a f2V bulb. The

two lead wires should be connected to

probes.

The test light is used for simple voltage checks and for check-

ing for short circuits.

Caution

l When checking the control unit, never use a butt,

over 3.4w.

Jumper Wire

The jumper wire is used for testing by shorting across switch

terminals and ground connections.

Caution

l Do not connect a jumper wire from the power source

, line to a body ground; this may cause burning or

other damage to harnesses or electronic com-

ponents. -

Voltmeter

The DC voltmeter is used to measure of circuit

voltage. A volt-

meter with a range of 15V or more is used by connecting the

positive ( + ) probe (red lead wire) to the point where voltage

is to be measured and the negative (-1 probe (black lead

wire) to a body ground.

Diagnosis Connector

Insert the probe into the service hole when connecting a jum-

per wire to the diagnosis connector.

Caution

l Do not insert the jumper wire probe into the diag-

nosis connector terminal, which may damage the

terminal.

Ohmmeter

The ohmmeter is used to measure the resistance between two

points in a circuit and atso to check for continuity and diagno-

sis of short circuits.

Caution

l Do not attempt to connect the ohmmeter to any cir-

cuit to which voltage is applied; this may burn or

otherwise damage the ohmmeter.

Page 20 of 677

1

I PRE-DELIVERY INSPECTION

AND

SCHEDULED MAINTENANCE

SERVICES

PRE-DELIVERY INSPECTION TA8LE ..-*...a.. A- 2

SCflEDULED MAiNTENANCE SERVICES

(Australia)

. ..* . . . . . . . l . . . . . . . . . . . . . . . . l .*..* . . . . l . . . . . . . A- 3

SCHEDULED MAINTENANCE SERVICES

(Europe)

. . . . . . . . . . . . . . . . . l . . . . . . . . . . . . . . . . . . .*..* . . . . . . . . A- 5

93GOAX-701

Page 22 of 677

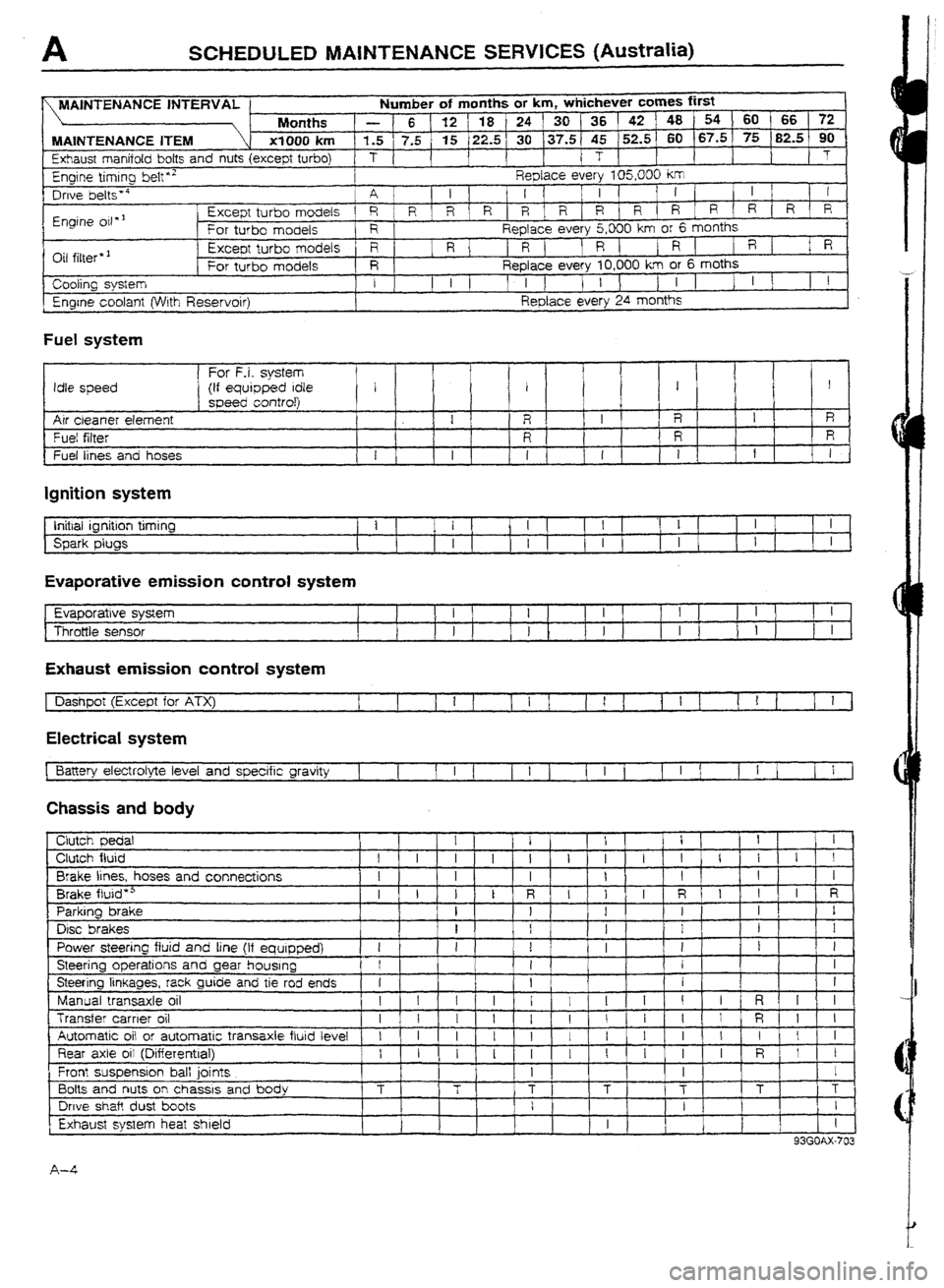

SCHEDULED MAINTENANCE SERVICES (Australia) A

SCHEDULED MAINTENANCE SERVICES (Australia)

Chart symbols:

I : Inspect: Visual examination or functiona! measurement of a system’s operation (Performance)

A: Adjust

R: Replace or change

T : Tighten

Note

l As the result of visual examination or functional measurement of a system’s operation (Per-

formance), correct, clean or replace as required.

REMARKS:

After 90,000 km or 72 months, continue to follow

the described maintenance items and intervals periodically.

As

“I

*2

*3

“4

l 5 for *

marked items in this maintenance chart please pay attention to the following points.

If the vehicfe is operated under the foltowing conditions, it is suggested that

the engine oil and oil f&r

be changed more often that at usual recommended intervals.

a> Driving in dusty condrt,ons.

b) Extended periods of idling

or low speed operation.

c) Driving for a prolonged period iti coid temperatures or driving only short distances regularly.

Replacement of the timing belt is required at every 105,000 km. failure to replace the timing belt may

result in damage to the engine.

If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, repface more often

than at usual recommended intervals.

Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

if equipped.

Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid shotlid be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emission control and related

system, as well as for efficient engine operation. It is strongly recommended that all servicing related to these

systems be done by your Authorised Mazda Dealer.

93GOAX-702

-

A-3 i

Page 23 of 677

A SCHEDULED MAINTENANCE SERVICES (Australia)

lumber of months or km, whichever cumes first

P

_ 48 54 60 1 66 72

5

60 67.5 75 90 .--- .-- -

.-m-w --v-w _ _ -_-- - - _ _ - -

_ -- - - --- __-

_-

-- -- (82.5

Exhaust manifold bolts and nuts (except turbo) T 1

I i T 1

1 T

Engine timlrtg belt”’ Replace every 105,000 km

Drwe belts * a

A I 1 I 1 1 I 1

! ’ I I 1 1

Engine oil * ’ Except turbo models 1 RIR\R/RIRIRIR R R,R R R/R

For turbo models R

Replace every 5,000 km or 6 months

r-k:1 c:t+*-* 1 Except turbo models

R 1 R 1 1 R ( ) R ( 1 R ( 1

R 1 f R

-

1 VII IIIIc;I 1 For turbo models I R 1 ReDlace everv IO.000 km or E

Engine coolant (Wrth Reservoir)

Fuel

system

Replace e&y 24 months

For F-i. system

Idle speed (if equipped Idle 1 1 1 I

I speed controf)

Air cleaner element 1

R , I R I R

Fuet filter

I I? R R

~ Fuel lines and hoses

1 I 1 I I 1 I I 1 1

Ignition system

t Initial ignition timing

Spark plugs i I I I -1 I I

I I I I I

f

Evaporative emission control system

Evaporative system

Throttle sensor

Exhaust emission contra! system

[ Dashpot

(Except for ATX) I 1 I

1 1 I 1 1 t 1 1 1 1 1 ! 1 1 I 1

Electrical system

Battery electrolyte level and specific gravity ]

I 1 1 I 1 t I ’ 1 1 I 1 f I ( 1

I 1

Chassis and body

Brake lines, hoses and connections

Brake fluid * a

Parking brake

Disc brakes

1 Power steering fluid and line Ilf &uiDDedl

I 1 1 I I I

I 1 1 III II

I ’

I I

Steering operations and gear housing

I

1 1 I --r--j- 1 I

I

Steerino linkanes. rack auide and tie rod pnds .-- --

----.“.a ..‘-~--, J- -.-- _.- .-- -..-- I I I t I 1 1 I I I I I I I 1

Manual transaxle oil I \\!‘I rl\jl I 1 I R III

1 Transfer Automatic carrier oil or 09 automatic transaxle fluid level

1 1 I 1 111 I 1 I l 1 I 1 I 1[11i t I 1 I 1 I I 1 I

R 1 Iii 1 I

1 Rear axle oil (Differential) 1 t I I I I I I I I

t ’ I r . ’ 1 . I I I I I R I 1

I

I I

i T

1 T T T 1 T [ T I 1 T

Front suspension ball joints

Bolts and nuts on chassis and body

I I I . I ! ,

I 1 I . I 1 ’ I I ’

Drive shaft dust boots

I

I 1 I 1

I 1 1 I

~~

- - ’ C1utcl-1 pedat

Clutch fluid

1

A-4

Page 24 of 677

!

i

i

I

i

t-

I

i

i

e

-1

SCHEDULED MAfNTENANCE SERVICES (Europe) A

MAINTENANCE TABLE (Leaded Fuel Model)

Chart symbols:

1 : Inspect: Visual examination and/or functional measurement of system’s operation or performance

A: Adjust: Examination resulting in adjustment or replacement

R: Replace or change

T: Tighten

REMARKS

After 80.000 km or 48 months, continue to foltow the described maintenance at the recommended intervals.

As

*I

*2

“3

*4

*5

*6

*7 for *’

marked items in this’ maintenance chart, note the following points.

Major service interval at 12 months!ZO,OOO km (I 2,000 miles).

Lubrication service based on distance only, 10,000 km (6,000 miles), not time.

Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

ii equipped.

Replacement of the timing belt is required every ICQOUO km (60,000 miles). Failure to replace the timing

belt may result in damage to the engine.

If the vehicle is operated under any of the following conditions, it is suggested that the engine

oil and

oil filter be changed more often than the recommended intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for prolonged periods in cold temperatures or regularly driving only short distances.

If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often

than the recommended intervals.

This is a full function check of all electrical systems, i.e, afl lights, washers (inctuding condition of blades)

electric windows sunroof, horn, etc.

Replace every two years.

tf there has been continuous hard driving, mountain driving, or it the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emission control and related

system, as well as for efficient engine operation. It is strongly recommended that all servicing related to these

systems be done by your Authorised Mazda Dealer.

93GOAX-704

A-5