heater MAZDA 323 1989 Factory Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1989, Model line: 323, Model: MAZDA 323 1989Pages: 1164, PDF Size: 81.9 MB

Page 1 of 1164

1992

Mazda

CONTENTS

Protege

Workshop

Manual

FOREWORD

This workshop manual is intended for use

by service technicians of Authorized Mazda

Dealers to help them service Mazda vehicles.

For proper repair and maintenance, a

thorough familiarization with this manual is im-

portant, and it should always be kept in a han-

dy place for quick and easy reference.

All the contents of this manual, including

drawings and specifications, are the latest avail-

able at the time of printing. As modifications

affecting repair or maintenance occur, relevant

information supplementary to this volume will

be made available at Mazda dealers. This

manual should be kept up-to-date.

Mazda Motor Corporation reserves the right

to alter the specifications and contents of this

manual without obligation or advance notice.

All rights reserved. No part of this book may

be reproduced or used in any form or by any

means, electronic or mechanical-including

photocopying and recording and the use of

any kind of information storage and retrieval

system-without permission in writing.

Mazda Motor Corporation

HIROSHIMA, JAPAN

APPLICATION:

This manual is applicable to vehicles beginning

with the Vehicle Identification Numbers (VIN)

shown on the following page.

Title

General Information Section

Pre-Delivery Inspection and

Scheduled Maintenance Services

SOHC

Engine

DOHC

Lubrication System

Cooling System

Fuel and Emission Control System

Engine Electrical System

Clutch

FSM-R

Manual Transaxle

GSM-R

Automatic Transaxle

Front and Rear Axles

Steering System

Braking System

Wheels and Tires

Suspension

Body

--

Body Electrical System

Heater and Air Conditioner Systems

Technical Data

Special Tools

Parts Index

Wiring DNvam

I Part No. 5209-10-91 F)

9999~95-019(3-92)

o 1991 Mazda Motor Corporation

PRINTED IN USA, JUL. ‘91

1270-l O-91 G

(9999-95-0178-92)

Page 20 of 1164

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION

PRE-DELIVERY INSPECTION TABLE

Following items may be done at any time prior to delivery to your customer.

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Glass, exterior bright metal and paint for damage

Cl Wheel lug nuts, and locks (if equipped)

88-118 N.m (9-12 m-kg, 65-87 ft-lb)

q All weatherstrips for damage or detachment

0 Operation of hood release and lock

0 Operation of trunk lid, rear hatch, and fuel lid opener

Cl With trunk open, check for spare jack, tire, tools, and

fasteners securing these items in place.

Cl Door operation and alignment

Cl Headlight aim

INSTALL the following parts:

Cl Wheel caps or rings (if equipped)

q Outside rearview mirror(s)

1 UNDER HOOD-ENGINE OFF )

INSPECT and ADJUST, if necessary, the following items to

the specifications:

0 Fuel, coolant and hydraulic lines, fittings, connections and

components for leaks

Cl Engine oil level

0 Power steering fluid level

0 Brake and clutch master cylinder fluid level

El Windshield washer reservoir fluid level

Cl Radiator coolant level

Cl Tightness of battery terminals

Cl Manual transaxle oil level

riizmiq

INSTALL the following parts:

Cl Rubber stopper for inside rearview mirror

CHECK operation of the following items:

0 Seat controls (sliding and reclining) and head restraint

Cl Folding rear seat

0 Door locks, including childproof door locks (if equipped)

Seat belts and warning system

Cl Ignition switch and steering lock

0 Inhibitor switch (ATX only)

U Starter interlock switch (clutch pedal, MTX only)

Cl All lights, including warning and indicator lamps

Cl Sound warning system

Cl Horn, wipers and washers (front and rear, if equipped)

0 Audio system (if equipped) 0 Cigarette lighter and clock

0 Sunroof (if equipped)

II Remote control outside rearview mirrors (if equipped)

Cl Power windows (if equipped)

q Heater, defroster and air conditioner at various mode

selections (if equipped)

CHECK the following items:

Cl Presence of spare fuse

0 Upholstery and interior finish

CHECK and ADJUST, if necessary, the following items:

0 Pedal height and free play of brake and clutch pedal

Pedal height mm (in) Free play mm (in)

0 Parking brake

5-7 notches/98 N (10 kg, 22lb)

UNDER HOOD-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

q Automatic transaxle fluid level

[I

CHECK the following items:

Cl Underside fuel, coolant and hydraulic lines, fittings, con-

nections and components for leaks

0 Tires for cuts or bruises

0 Steering linkage, suspension, exhaust system and all un-

derside hardware for looseness or damage

[I

CHECK the following items:

0 Brake operation

0 Clutch operation

Cl Steering control

Cl Operation of gauges

q Squeaks, rattles or unusual noise

Cl Emergency locking retractors

0 Cruise control system (if equipped)

1 AFTER ROAD TEST (

CHECK for necessary owner information materials.

Following items must be done just before the delivery to your customer.

q Load test battery and charge if necessary

1 Volts 1 0 Install fuses for accessories

i.. _

0 Adjust tire pressure to the specification

Load test result cl Remove seat and floor mat protective covers

(Refer to door label) 0 Vacuum and clean interior of vehicle

0 Clean outside of vehicle q Inspect installation of option parts with invoice

23UOAX-002

A-2

Page 47 of 1164

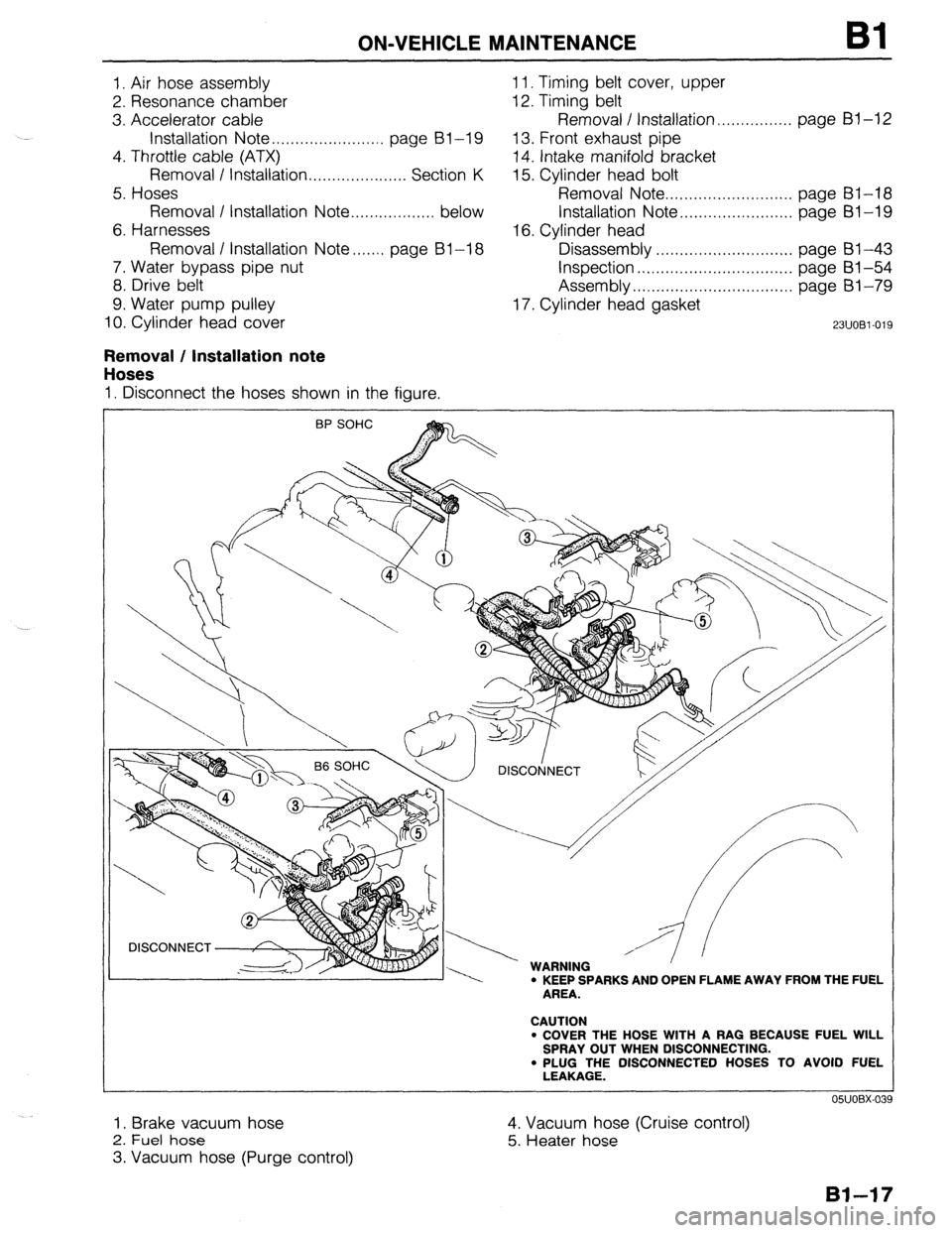

ON-VEHICLE MAINTENANCE Bl

I. Air hose assembly 1 I. Timing belt cover, upper

2. Resonance chamber 12. Timing belt

3. Accelerator cable Removal / Installation.. . . . . . . . . . . . . . . page Bl-12

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page BI-I9 13. Front exhaust pipe

4. Throttle cable (ATX)

14. Intake manifold bracket

Removal / Installation . . . . . . . . . . . . . . . . . . . . . Section K 15. Cylinder head bolt

5. Hoses Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page BI-18

Removal I Installation Note ..,............... below Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Bl-I9

6. Harnesses 16. Cylinder head

Removal I Installation Note....... page BI-I8 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 61-43

7. Water bypass pipe nut

Inspection . . , . . . . . . . . . . . . . . . . . . . . . . . . . ., . . page BI -54

8. Drive belt Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page BI-79

9. Water pump pulley 17. Cylinder head gasket

10. Cylinder head cover

23UOBl-019

Removal / Installation note

Hoses

I. Disconnect the hoses shown in the figure.

\ / DlSCOtjNECT

, w I.,,, -----. WARNING ’ ’ ’ l KEEP SPARKS AND OPEN FLAME AWAY FROM THE FUEL

AREA.

CAUTION

l COVER THE HOSE WITH A RAG BECAUSE FUEL WILL

SPRAY OUT WHEN DISCONNECTING.

. PLUG THE DISCONNECTED HOSES TO AVOID FUEL

LEAKAGE.

I. Brake vacuum hose

2. Fuel hose

3. Vacuum hose (Purge control) 4. Vacuum hose (Cruise control)

5. Heater hose

Page 60 of 1164

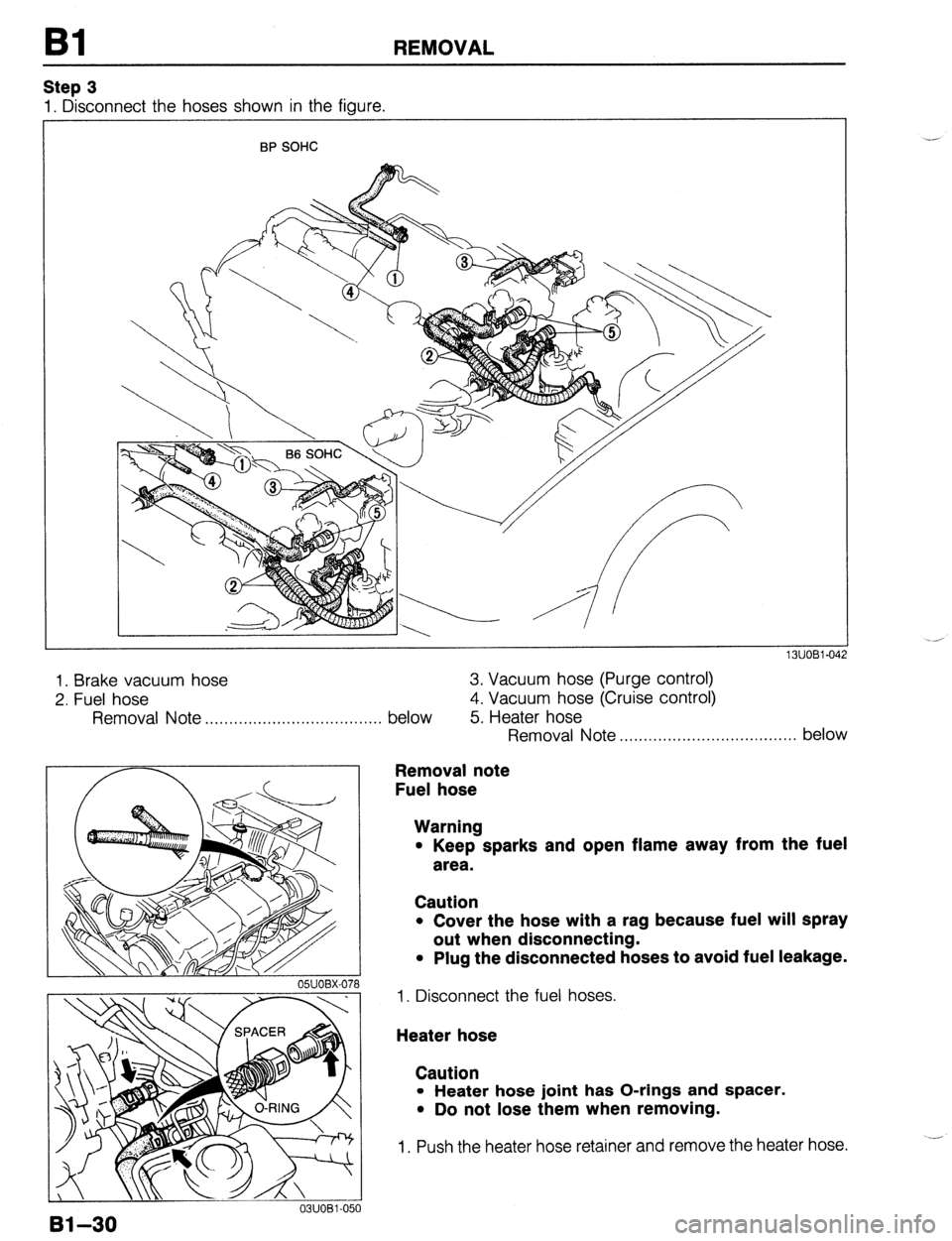

Bl REMOVAL

Step 3

1. Disconnect the hoses shown in the figure.

BP SOHC

1. Brake vacuum hose

2. Fuel hose

Removal

Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bl-30

05UOBX-078

03UOBi -050

below 3. Vacuum hose (Purge control)

4. Vacuum hose (Cruise control)

5. Heater hose

Removal Note ..,,,................................ below

Removal note

Fuel hose

Warning

l Keep sparks and open flame away from the fuel

area.

Caution

l Cover the hose with a rag because fuel will spray

out when disconnecting.

l Plug the disconnected hoses to avoid fuel leakage.

1. Disconnect the fuel hoses.

Heater hose

Caution

l Heater hose joint has O-rings and spacer.

l Do not lose them when removing.

1. Push the heater hose retainer and remove the heater hose.

Page 165 of 1164

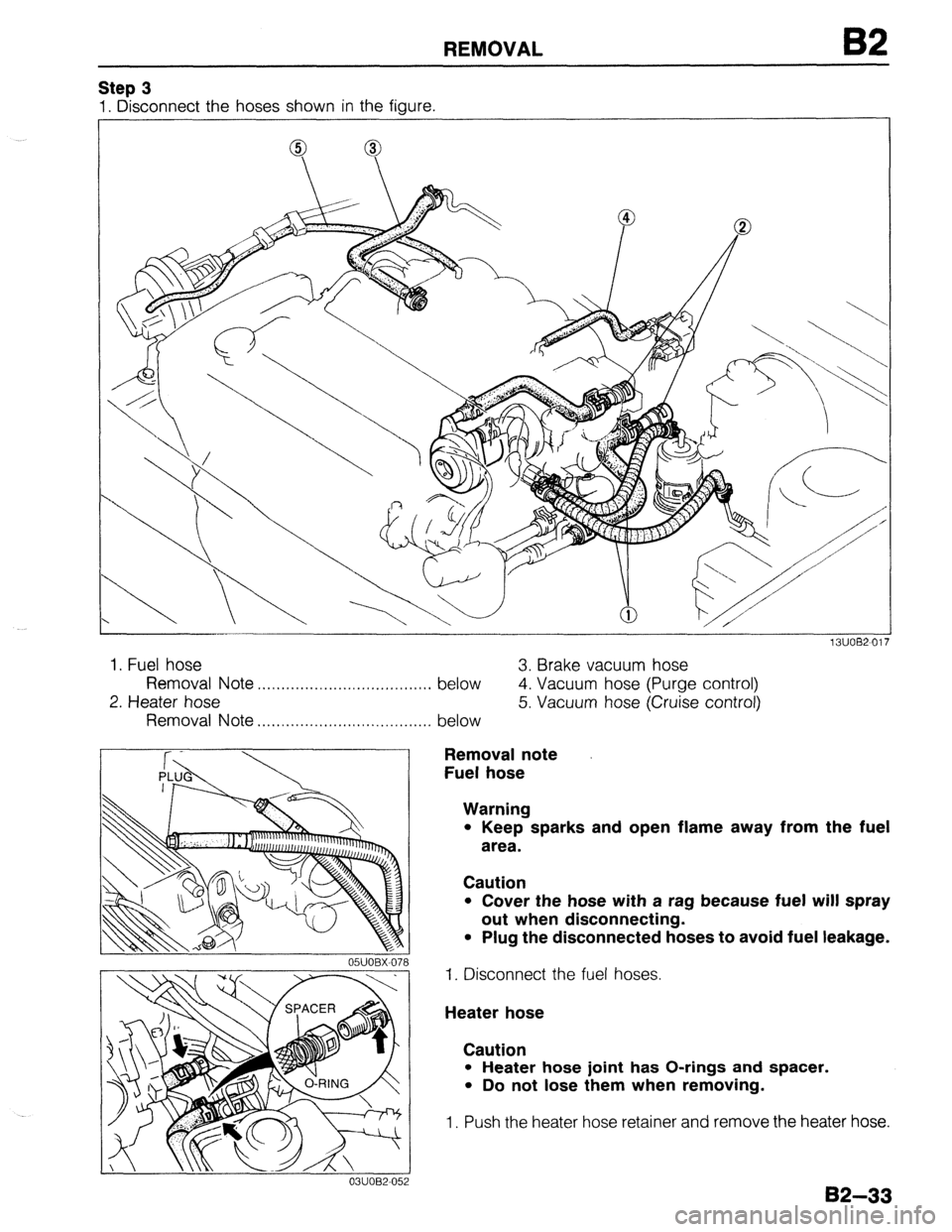

REMOVAL

Step 3

1. Disconnect the hoses shown in the figure.

J”“DC-” I I

1. Fuel hose

3. Brake vacuum hose

Removal

Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

below

4. Vacuum hose (Purge control)

2. Heater hose

Removal Note . . . . . . . . . . . . . , . . . . . . . . . . . .

05UOBX-078

0311082-052

. . . . .

below 5. Vacuum hose (Cruise control)

Removal note

Fuel hose

Warning

l Keep sparks and open flame away from the fuel

area.

Caution

l Cover the hose with a rag because fuel will spray

out when disconnecting.

l Plug the disconnected hoses to avoid fuel leakage.

1. Disconnect the fuel hoses.

Heater hose

Caution

l Heater hose joint has O-rings and spacer.

l Do not lose them when removing.

1. Push the heater hose retainer and remove the heater hose.

82-33

Page 231 of 1164

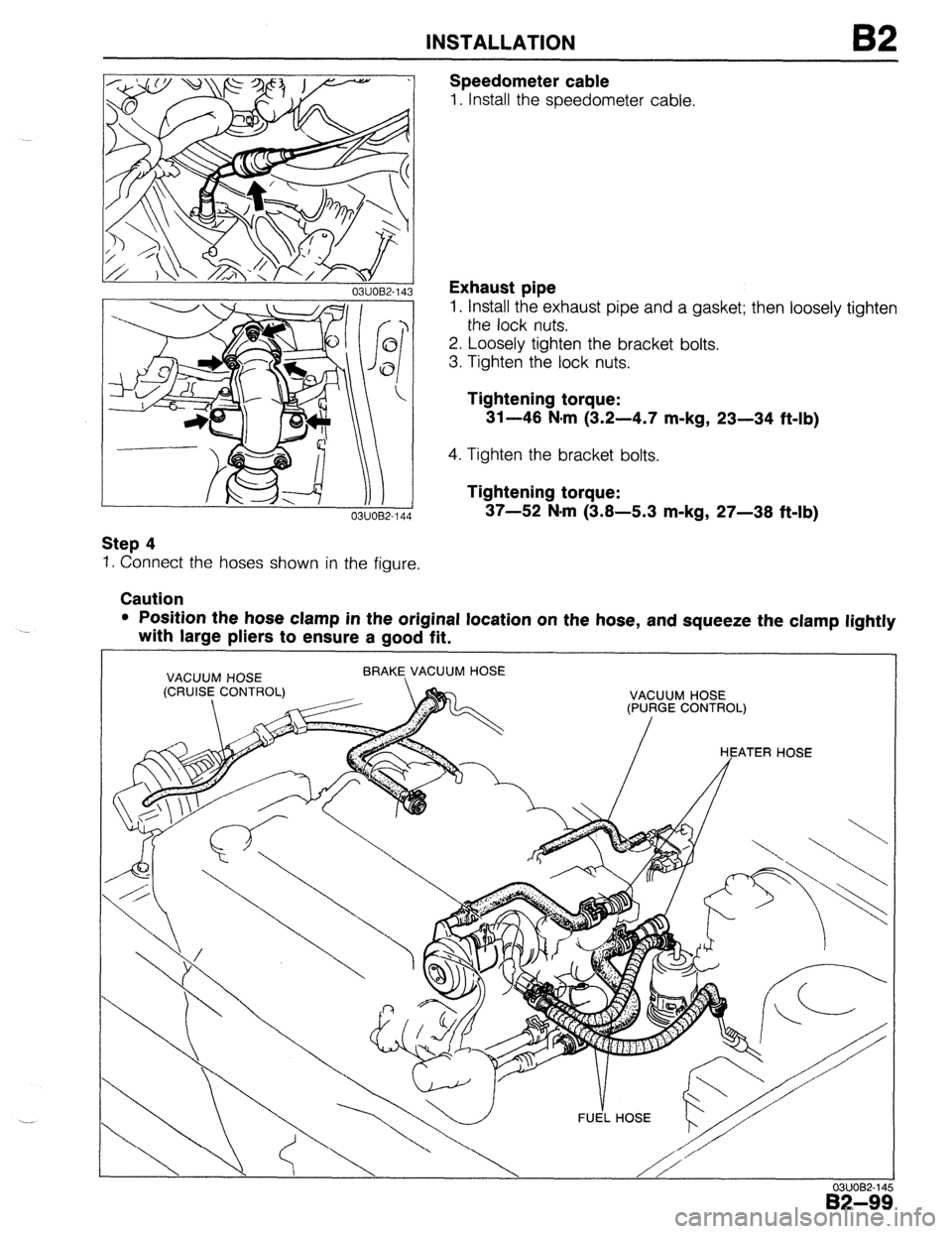

INSTALLATION

Step 4

I. Connect the hoses shown in the figure.

Caution Speedometer cable

1. Install the speedometer cable.

Exhaust pipe

1. Install the exhaust pipe and a gasket; then loosely tighten

the lock nuts.

2. Loosely tighten the bracket bolts.

3. Tighten the lock nuts.

Tightening torque:

31-46 N-m (3.2-4.7 m-kg, 23-34 ft-lb)

4. Tighten the bracket bolts.

Tightening torque:

37-52 N.m (3.8-5.3 m-kg, 27-38 ft-lb)

l Position the hose clamp in the original location on the hose, and squeeze the clamp lightly

with large pliers to ensure a good fit.

VACUUM HOSE

(CRUISE CONTROL) BRAKE, VACUUM HOSE 1 VACUUM HOSE

(PURGE CONTROL)

HEATER HOSE

FUE’L HOSE

03UOB2-14

B2-9:

Page 251 of 1164

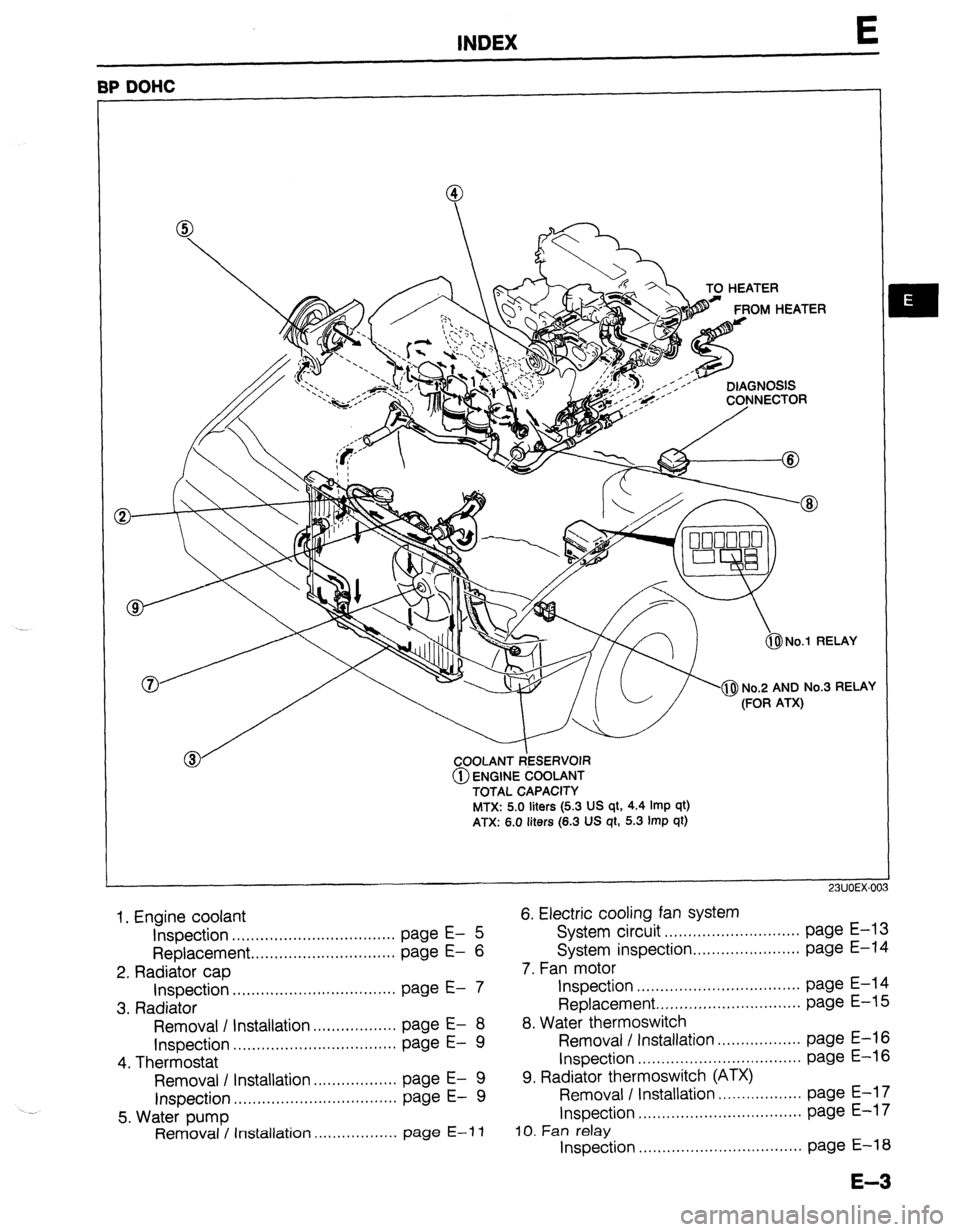

E

BP DOHC

-a TO HEATER

&$ No.1 RELAY

COOLANT ~~ESERVOI~~

@ ENGINE COOLANT

TOTAL CAPACITY

MTX: 5.0

liters (5.3 US qt, 4.4 Imp qt)

ATX: 6.0 liters (6.3 US qt, 5.3 Imp qt)

23UOEX-00

1. Engine coolant

6. Electric cooling fan system

Inspection ...................................

page E- 5 System circuit

.............................

page E-l 3

Replacement ...............................

page E-

6 System inspection

....................... page E-14

2. Radiator cap

7. Fan motor

Inspection ................................... page E- 7

Inspection ...................................

page E-14

3. Radiator

Replacement..

............................. page E-i 5

Removal / Installation..

................

page E-

8 8. Water thermoswitch

Inspection

.................. ................................... page E- 9 Removal / Installation

page E-16

4. Thermostat

Inspection ...................................

page E-l 6

Removal I Installation

.................. page E- 9 9. Radiator thermoswitch (ATX)

Inspection

.................. ...................................

page E- 9 Removal I Installation

page E-l 7

5. Water pump

Inspection

...................................

page E-l 7

Removal / Installation ..................

page E-i 1 10. Fan relay

Inspection ...................................

page E-l 8

E-3

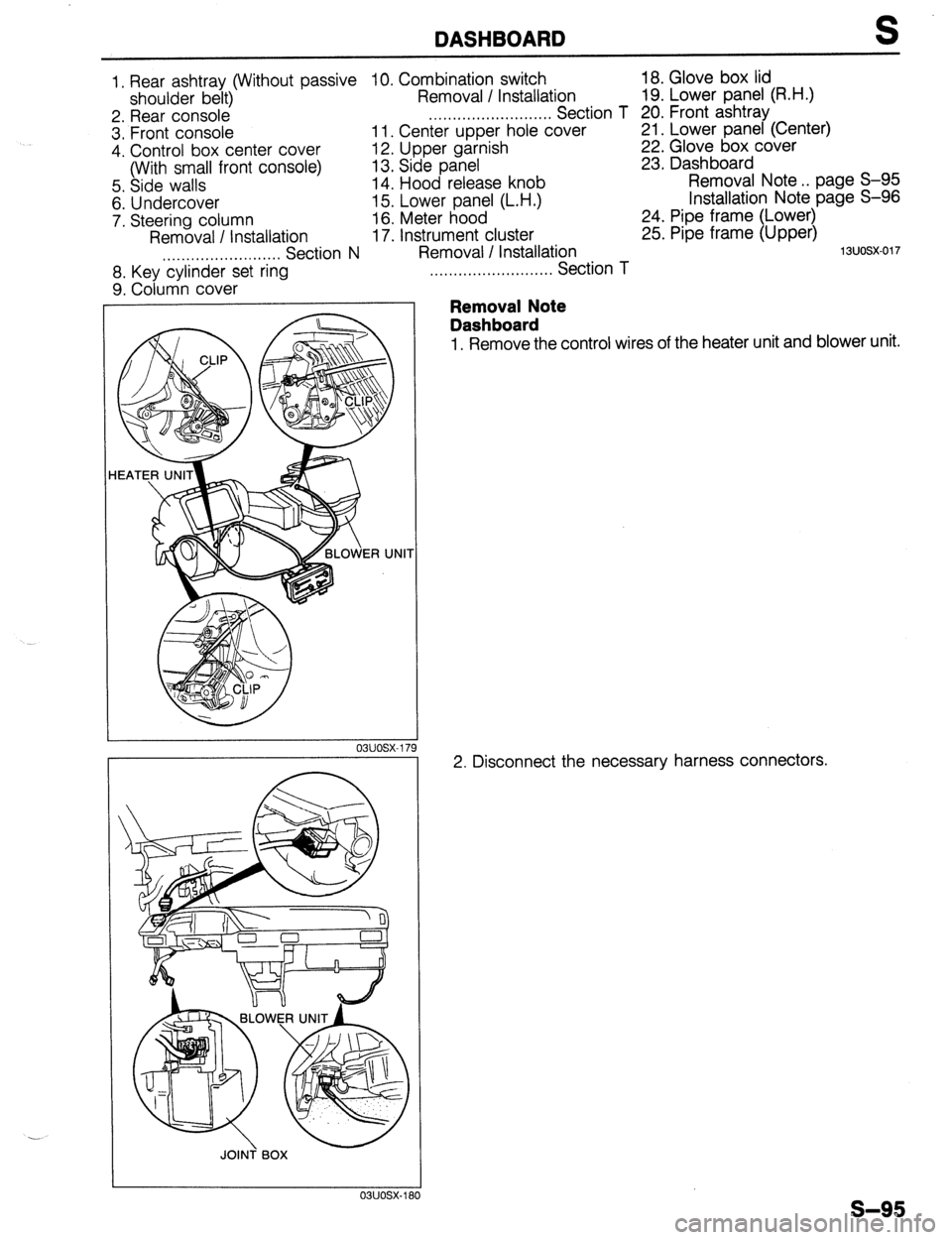

Page 831 of 1164

DASHBOARD S

1, Rear ashtray (Without passive IO. Combination switch 18. Glove box lid

shoulder belt) Removal / Installation 19. Lower panel (R.H.)

2. Rear console ,..,,.,......,,.,.,....... Section T 20. Front ashtray

3. Front console 11. Center upper hole cover 21. Lower panel (Center)

4. Control box center cover 12. Upper garnish

22. Glove box cover

(With small front console) 13. Side panel 23. Dash board

5. Side walls 14. Hood release knob Removal Note . . page S-95

6. Undercover 15. Lower panel (L.H.) Installation Note page S-96

7. Steering column 16. Meter hood 24. Pipe frame (Lower)

Removal / Installation 17. Instrument cluster 25. Pipe frame (Upper)

. . . . . . . . ...*. . . . . ..n..... Section N Removal I Installation

1 suosx-017

8. Key cylinder set ring

9. Column cover

JOINT BOX

. . . . . . . . . . . . . . . . . . . . . . . . . . Section T

Removal Note

Dashboard

1, Remove the control wires of the heater unit and blower unit.

2. Disconnect the necessary harness connectors.

s-95

Page 832 of 1164

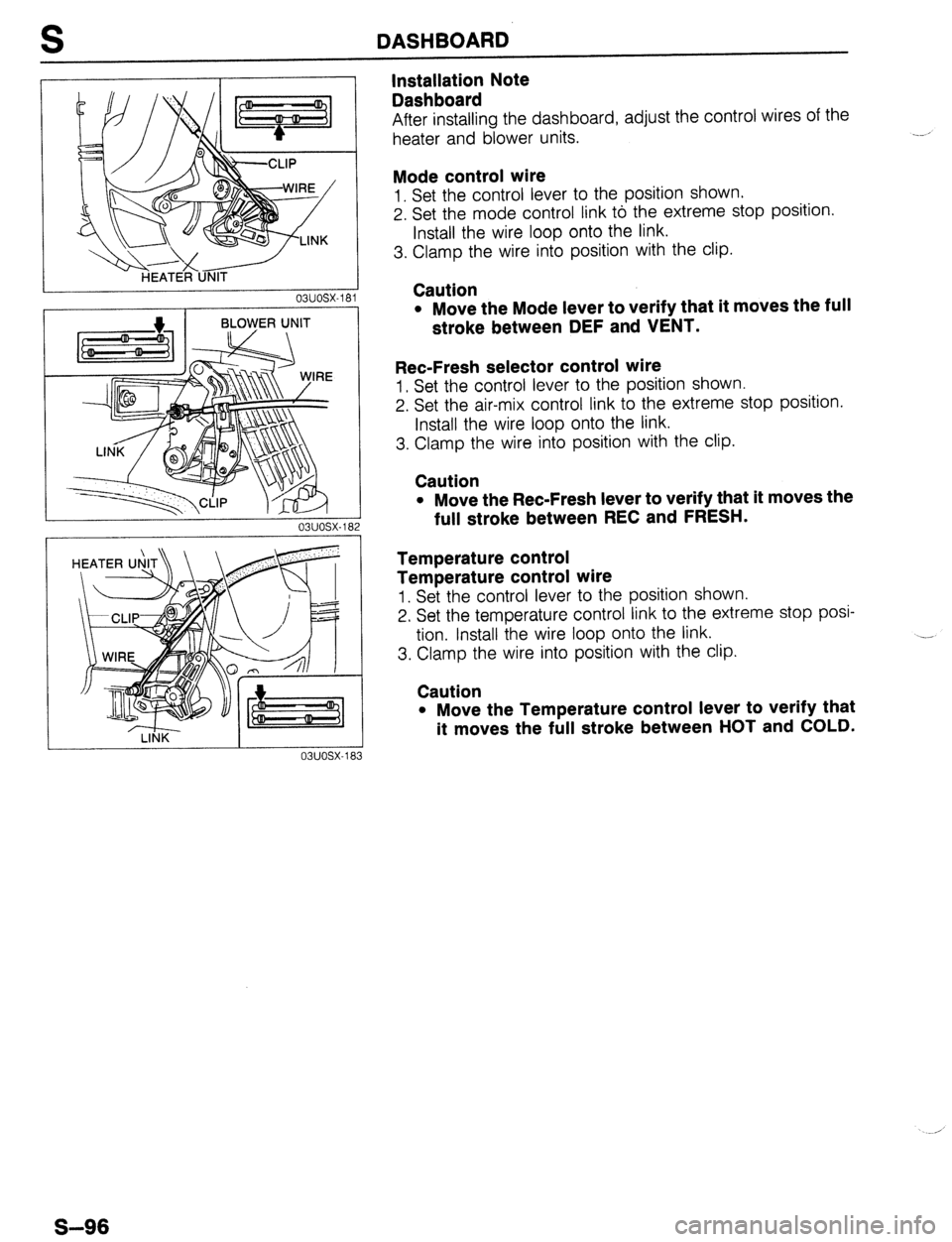

S DASHBOARD

03UOSX-182

03uosx-18 '3

Installation Note

Dashboard

After installing the dashboard, adjust the control wires of the

heater and blower units.

Mode control wire

1. Set the control lever to the position shown.

2. Set the mode control link to the extreme stop position.

Install the wire loop onto the link.

3. Clamp the wire into position with the clip.

Caution

l Move the Mode lever to verify that it moves the full

stroke between DEF and VENT.

Ret-Fresh selector control wire

1. Set the control lever to the position shown.

2. Set the air-mix control link to the extreme stop position.

Install the wire loop onto the link.

3. Clamp the wire into position with the clip.

Caution

l Move the Ret-Fresh lever to verify that it moves the

full stroke between REC and FRESH.

Temperature control

Temperature control wire

1. Set the control lever to the position shown.

2. Set the temperature control link to the extreme stop posi-

tion. Install the wire loop onto the link.

3. Clamp the wire into position with the clip.

Caution

l Move the Temperature control lever to verify that

it moves the full stroke between HOT and COLD.

S-96

Page 866 of 1164

T

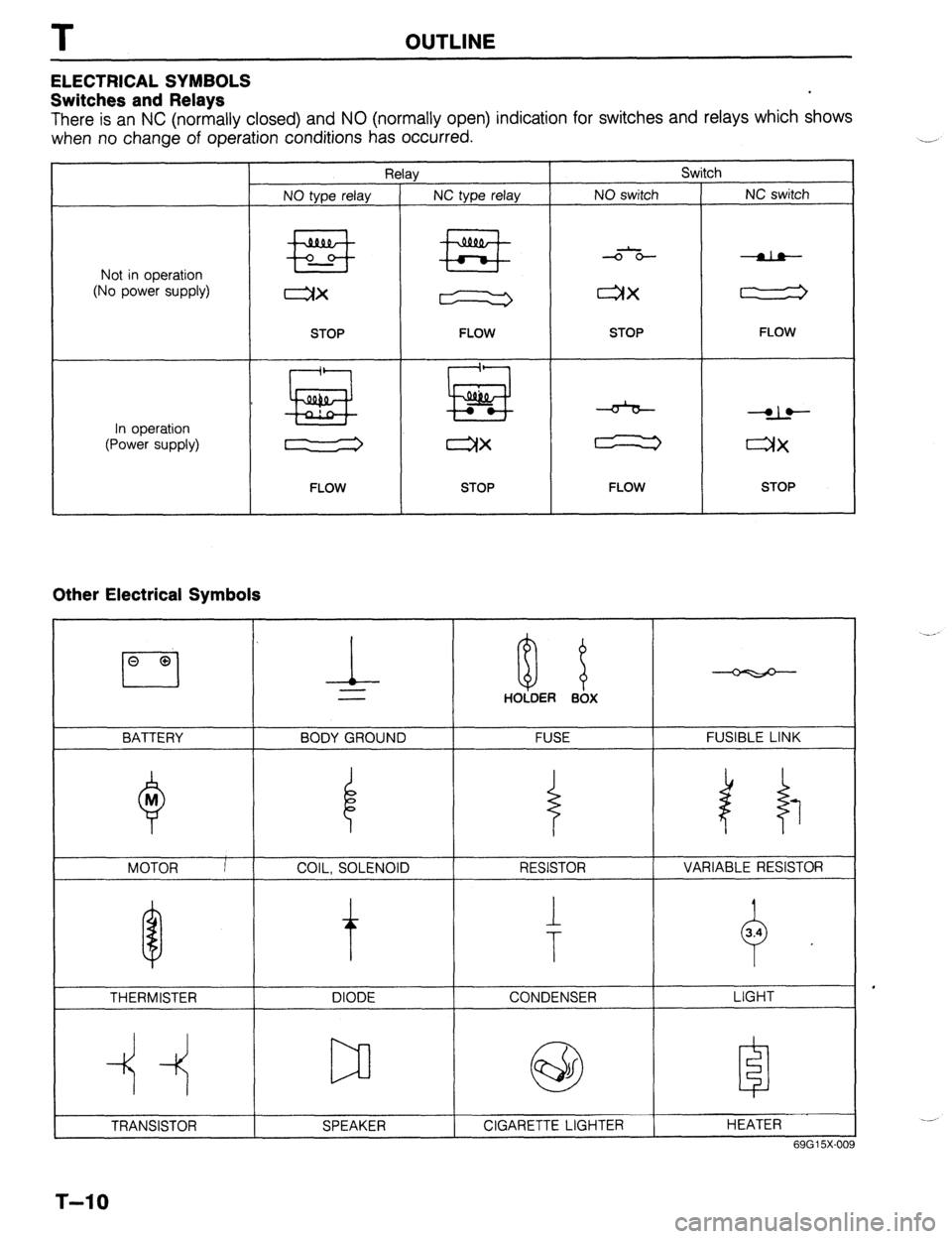

ELECTRICAL SYMBOLS

Switches and Relays OUTLINE

There is an NC (normally closed) and NO (normally open) indication for switches and relays which shows

when no change of operation conditions has occurred.

Relay Switch

NO type relay NC type relay NO switch NC switch

Not in operation

(No power supply) +E+ #Fig -o-- -da--

ax ax

STOP

FLOW STOP FLOW

In operation

(Power supply) * !jiij! kiig 6 dLe

cw r”X

FLOW STOP FLOW STOP

Other Electrical Symbols

BATTERY

THERMISTER DIODE CONDENSER

Q

M

MOTOR I

T-10

l-

BODY GROUND

COIL, SOLENOID i

0 8 HOLDER BOX

FUSE

RESISTOR

1

T

FUSIBLE LINK

1 i 1

VARIABLE RESISTOR

LIGHT

HEATER

69G15X-O(