lock MAZDA 323 1992 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 98 of 279

M FRONT AXLE

WHEEL HUB, STEERING KNUCKLE

RemovaI / Inspection I Installation

1. Remove in the order shown in the figure, referring to Removal Note.

2. Inspect all parts and repair or replace as necessary.

3. InstaH in the reverse order of removal, referring to Installation Note.

Caution

l Loosely tighten the shock absorber bolts. Lower the vehicle and tighten the bolts to the specified

torque with the vehicle unladen.

4. Adjust the front wheel alianment.

16-22 ]1.6-2.3, 12-161 I

19.0-l 2.0, 65-86.7 I

1. Wheel hub nut

2. Wheel and tire

3. Locknut

Removal Note . . . . . . .._.. . . . . . . . . . . . . . . . . . . . page M-7

installation Note .I.........,..,............ page M-7

4. Brake caliper assembly

Service . _. . . . . . . . . ,__. . . , , . ._. _. , , . . . , . ._ ._. . . . . . Section P

5. Disc plate

lnspectioti .~~*.......*~...,......,,,.....*~...~. Section P

6. ABS wheel speed sensor (if equipped)

7. Tie rod end

Removal Note . . . . . . .._.......... I . .._.....= page M-7

lnstallatiofi Note . . .._... _.__......,....... page M-7

M-6

8. Lower ball joint

9. Steering knuckle, wheel hub, and dust cover

Inspect-wheel hub for cracks and damage

Inspect knuckle spindle for cracks and

damage

Inspect dust cuver for damage and dis-

tortion

Disassembly I Inspection I

Assembly . ..C1..............~...,.....,.....

page M-8

Page 99 of 279

FRONT AXLE M

13EOMX308

13EOMX-310

1

13EOMX-311

Removal note

Locknut

Caution

l Do not damage the drive shaft.

l Do not reuse the locknut.

1.

Raise the staked portion of the locknut using a chisel.

2. Lock the

hub by applying the brakes.

3. Remove the locknut.

Tie rod end

Caution i

l Do not damage the dust boot.

t

Losen the nut and disconnect the tie rod end bv using the

I

SST.

P

Installation note

Tie rod end

Caution

l Do not damage the dust boot.

tnstall the nut and secure it with the new cotter

Tightening torque:

43-56 N-m (4.3-5.8 kgf,m, 31-41 ft-lbf

Locknut

lnstail a new

locknut and stake it, as shown. pin.

Tightening torque: 236-318 N-m

f 24.0-32.5 kgfm, 174-235 ftelbf ]

M-7.

Page 104 of 279

REAR AXLE

WHEEL HUB, KNUCKLE

Removal I Inspection / installation

1. Remove in the order shown in the figure, referring to

Removal Note. 2. Inspect all parts and repair or replace as necessary.

3. Install in the reverse order of removal, referring to Installation Note.

Caution

l Loosely tighten the shock absorber bolts. Lower the vehicle and tighten the bolts to the specified

torque with the vehicle unladen.

4. Adiust the rear wheel alianment.

16-22 1?.6-2.3, 12-16 I

7

IO.o-13.0,

66-66.7 1 1. Wheel and tire

2. Locknut

Removal Note..; . . . . . . . . , . . . . ,.......- -.. page M-f 3

Installation Note .._...,.,...._.__........ page M-13

I$ Brake caliper assembly

Service . . . . . . . . . . . ..e......._......... ,.,...,....

Section P

4. Disc plate

‘Service ..I....................__....... . . . . . . . . . Section P 5. Af3S wheel speed sensor (if equipped)

6. Wheel hub, knuckle

Disassembly I Inspect& /

Assem bty . . . . . . . ..I..........*..*.*...-... page M-14

Inspect wheel hub and knuckle for damage

or cracks

Inspect dust cover for damage or defor-

mation

M-12

Page 105 of 279

REAR AXLE M

Removal note

Locknut

Caution

l Do not damage the drive shaft.

l Do not reuse the locknut.

I. Raise the staked portion of the tocknut using a chisel.

2. Lock the hub by applying the brakes.

3. Remove the locknut.

1 13EOMX-308

13EOMX-327 installation note

Locknut

Install a new locknut and stake it, as shown.

Tightening torque: 236-318 N-m

[ 24.0-32.5 kgfm, f 74-235 ftelbf

‘I

Page 107 of 279

REAR AXLE

13EOMX-330

13EOMX-331

I

t3EOMX.318

. _.

-.

3. Press out the bearing race by using the SST.

Wheel bearing

Remove the wheel bearing by using the SST.

Dust cover

Caution

l Do not remove the dust cover if not necessary.

l Do not reuse-the dust cover if removed.

1. Mark the dust cover and steering knuckle for proper reas- *

sembly.

2. Remove the dust cover by using a chisel.

Ice scraper

Caution

l Do not remove the ice scraper if not necessary.

. If it is removed, use a new bolt applied specified

thread locking compound.

Hub bolt

caution

l Do not remove the hub bolts if not necessary.

i Do not reuse the hub bolts if removed.

Remove the hub bolts by using a press.

.

M-q.5

Page 111 of 279

N OUTLJNE

UUTLJNE

OUTLINE Of CONSTRUCTION

l EncJine speed sensing power steering (ESPS) is standard equipment for all models. The construction and

operation are basically the same as for previous models.

l The lock-to-lock specification of the steering wheel is reduced from 2.76 to 2.51.

13EONX-302

SPECIFICATIONS

hem Specifications

Steermg wheel Outer diameter mm {in] 370 { 14.57)

Lock-to-lock turns :i-‘~~:~.~~~~~~:~~;~~~~ :;‘:.. .‘:I .:::::.::~::::,:.:::.i: ,,,,.,:, :‘,:,,.:,: .,: I. . ..- :.~6:.n.:::;,:~~:~~~~~~~.~::~,:~:.: :: :

” .: ‘-.: .:.:::~:‘::.‘.::‘:‘:.I;:.‘,.: >.. .: :” 3 :. ,;:.+..i<.I. ‘_ : ; t:

. . ..: :: ::.:. .:::. ::r .;

. . . . . . . . . .y : :.: ,. .: ,_ : ., :

Me Collapsible

Steering shaft and joint Joint type

Tilt stroke

J 2-cross joint

mm {in] 30 11.18)

Type Rack-and-pinion

I

Steering gear Gear ratio

Rack stroke mm [in] 00 (infinite)

121 f4.761

Capacity

Power steertng fluid 1 (US qt Imp qt) 018 (0.85, 0.701

We ATF DexrorPlI or M-ID

,

Shaded area rndicates new specrfcatlon. t3EONX-303

N-2

Page 125 of 279

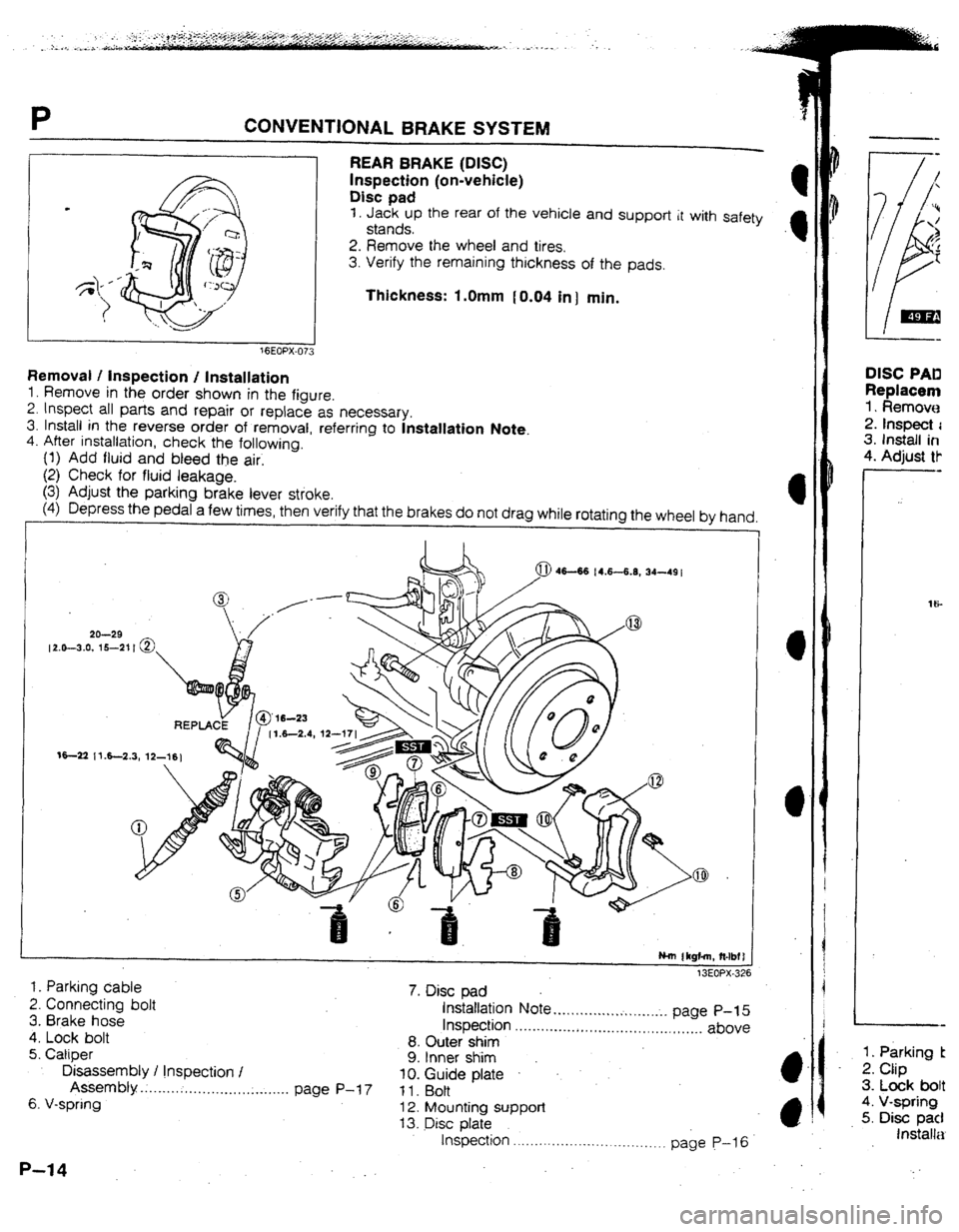

P CONVENTIONAL BRAKE SYSTEM

f 6EOPX-073

REAR BRAKE (DISC)

inspection (on-vehicle)

Disc pad

1, Jack up the rear of the vehicle and support it with safety

stands.

2, Remove the wheel and tires.

3. Verify the remaining thickness of the pads.

Thickness: f .Omm fU.04 in) min.

Removal I Inspection / Installation

1. Remove in the order shown in the figure.

2. Inspect all parts and repair or replace as necessary.

3. Install in the reverse order of removal, referring to Installation Note.

4. After instaHation, check the following.

(1) Add fluid and bteed the air.

(2) Check for fluid leakage.

(3) Adjust the parking brake lever stioke.

(4) Depress the pedal a few times, then verify that the brakes do not drag while rotating the wheel bv hand,

1. Parking cable

7. Disc pad

13EOPX-32f page P-15 ,..

. . ..I...... above 2. Connecting bolt installation

3. Brake hose Note . ..*. 1 ,...... I.r. . . . . .

4. Lock bolt Inspection . ..-f...........III.I.......,,.

8. Outer shim

5. Caliper 9. Inner shim

Disassembly I Inspection I

Assem bty IO. Guide plate .

-. . . _. . . . . . . . . . . . . . . . . , . . . . . . . . . . . page P-l 7

Il. Bolt

6, V-spring 12. Mounting support

I 3. Disc plate

Inspection . . . . . . . . . . . . . . . . . . . .._...._.~

P-1 4 . . . page p-16 DISC PAD

Replacem

1 s Remove

2. Inspect

i 3. Install in

4. Adjust tF

1. Parking t

2. Ciip

3. Lock bolt

4. V-spring

5. Disc pad

Installa

Page 126 of 279

CONVENTIONAL BF?AKE SYSTEM P

InstaHation note

Disc pad

Install the piston with the SST by turning it clockwise until

it stops.

13EOPX-327

DISC PAD Replacement

1. Remove in the order shown in the figure.

2. Inspect all parts and repair or replace as necessary.

3, Install in the reverse order of removal, referring to hstallation Note.

4. Adjust the parking brake lever stroke.

f . Parking

brake cable 2. Clip

3. Lock bolt

4. V-spring

5. Disc pad 6. Outer shim

7, lhner shim -

8. Guide plate

lnstaflation note . . . , . .._. . .I . . . . . . . . . . . . . . _. . . . . . . above . _’

.

P-1 5

Page 129 of 279

CONVENTfONAt BRAKE SYSTEM

13EOPX-33C

16EOPX-7 16

1

3

J

13EOPX 331

Disassembly note

Piston

Remove the piston with the SST.

Note

l The piston is removed by turning the SST counter-

clockwise.

Piston seal

Remove the piston seal with the SST.

Needle bearing

1. Secure the catiper in a vise.

Caution

l Do not remove the needle bearing if not necessary.

l Insert a soft, protective material (such as copper

ptates) in the jaws of the vise.

2. Remove the needle bearing from the caliper with the SST.

Bleeder screw

Loosen the bleeder screw by using the SST.

Assembly note

Bleeder screw

Tighten the bleed screw by using the SST.

Tightening torque:

5.9-8.8 Narn f 60-90 kgfcm, 53.-78 in4bf )

.

c

P-1 8

Page 130 of 279

I- CONVENTIONAL BRAKE SYSTEM

P

I f3EOFX-33,

Needle bearing

1. Set the new needle bearing in the caliper with the needle

bearing hole facing the caliper cylinder.

2. Press the needle bearing into the caliper with the SST until

the SST bottoms against the caliper.

Piston

Assemble the piston with the SST.

Note

l The piston is assembled by turning the SST

clockwise.

16EOPX-718

P--t9 . .