lock MAZDA 323 1992 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 156 of 279

![MAZDA 323 1992 Suplement Owners Manual TECHNICAL DATA TD

Hem

Camshafi

Engine

BP DOHC turbo

IN Standard

Cam height mm 1 in) Wear limrt

EX Standard

Wear llmrt

Standard

Journal diameter mm 1 In] (M.1 --NW

Out-of-round

Standard

Ca MAZDA 323 1992 Suplement Owners Manual TECHNICAL DATA TD

Hem

Camshafi

Engine

BP DOHC turbo

IN Standard

Cam height mm 1 in) Wear limrt

EX Standard

Wear llmrt

Standard

Journal diameter mm 1 In] (M.1 --NW

Out-of-round

Standard

Ca](/img/28/57055/w960_57055-155.png)

TECHNICAL DATA TD

Hem

Camshafi

Engine

BP DOHC turbo

IN Standard

Cam height mm 1 in) Wear limrt

EX Standard

Wear llmrt

Standard

Journal diameter mm 1 In] (M.1 --NW

Out-of-round

Standard

Camshaft bearing oil clearance mm { in ] (No. f-440.5)

Maximum

Camshaft runout mm {in)

Camshaft end play mm Iin] - Standard

Maximum

Winder block

Height mm {in)

Distortion mm {in]

Grinding mm (in)

Cylinder bore diameter Standard size

mm Iin) 0.25 [ 0.010) oversize .

0.50 [ 0.020 ] oversize

Cylinder bure taper and out-of-round mm [in]

Piston

44.094 { 1.7360 ]

43.894 f 1.7281 ]

44.603 [ 1.7560)

44.403 [ t .748t ;

X940-25.965 I 1.0213-l .0222 j

0.05 (0.002] max.

0.035-0.081 [ 0.0014-0.0032 )

0.15 (0.006)

0.03 (0.0012 1 max.

0.07-O. 19 [ 0.0028-0.0075 1

0.2 IO.008 1

221.5 (8.720)

0.15 [0.006) max.

0.20 [0.008] max.

83.006-83.013 13.2679-3.2682 ]

83.256-83.263

13.2778-3.2781 ]

83.506-83.513

( 3.2876-3.2879 )

0.019 [0.0007) max.

Piston diameter Standard size 82:954-82.974 13.2659-3.2667 1

Measured at 90° to pin

bore axis and 11 .Omm

oversize 83.21 I-83.217

10.433 in] below oil ring 0.25 j 0.010 ]

13.2760-3.2763 ]

groove mm {In)

0.50 { 0.020) oversize 83.461-83,467

{ 3.2859-3.2861 )

Piston to cybnder clearance

Piston ring

mm (in) Standard 0.039-0.052 [ 0.0015-0.0020 ]

Maximum

0.15 [0.006]

Thickness mm {in] Top

Second

, Top

End gap (Measured in the cylinder) Second

mm I in 1 Oil (rail)

Maximum

TOP

Ring groove width in piston

mm (in) Second

r

Oil

Piston ring-to-ring groove clearance TOP

mm (in] Second

Maximum

Piston pin

Diameter mm {in)

Piston-to-piston pin clearance mm iin]

Connecting rod bush-to-piston pin clearance mm Iin)

Connecting rod and connecting rod bearing

Length (Center to center) mm {in] 1

Bending mm [in]

Small end bore (Bush inner diameter) mm [in)

Big end bore mm {in)

Bfg end width mm [in) 1

Standard

Connecting rod side clearance mm I in 1 Maximum I

Crankshaft

Crankshaft iunout mm {ln) 1.470-l ,495 { 0.0579-0.0589 ]

1.47-l -49 [0.0579-0.0587 )

0.15-0.30 [ 0.006-0.012 1

0.35-0.50 { 0.014-0.019 1

0.20-0.70 (0.008-0.028 )

1.0 [0.039)

1.520-I .535 f0.0598~9.0604 f

1.52-l .54 ~0.0598-0.0606)

3.02-3.04 (0.1189-0.1197 1

0.025-0.065 { 0.001 O-0.0026 ]

0.03-OXI7 (O.O012--0.0028)

._

0.15 (0.006]

19.987-l 9.993 (.0.7869-0.7871 )

-0.005-0.013 { -0.0002-0.0005 1

O.Ql O-0.027 ~0.0004-0.0011 )

m D 132.85-132.95 (5.230-5.234 1

0.075 ( 0.0030 ] max./50 I1:97 ]

20.003-20.014 ( 0.7875-0.7880 1

48.000-48.016 [ 1.8898-l 48904 ]

21.838-21.890 (0.8598-0.86t81

0.11 O-O.262 f 0.0043-0.0103 1

0.30 [0.012)

0.04 (0.0016)

mdx.

TCI rl

Page 164 of 279

![MAZDA 323 1992 Suplement Owners Manual TECHNNlCAL DATA TD

STEERlNG SYSTEM

item

Steering wheel

Outer diameter

mm (in]

Free play

mm [in]

Operation force N [kgf, Ibf]

Lock-to-lock

Steering gear

TYF

Steerrng gear ratio

Backlash be MAZDA 323 1992 Suplement Owners Manual TECHNNlCAL DATA TD

STEERlNG SYSTEM

item

Steering wheel

Outer diameter

mm (in]

Free play

mm [in]

Operation force N [kgf, Ibf]

Lock-to-lock

Steering gear

TYF

Steerrng gear ratio

Backlash be](/img/28/57055/w960_57055-163.png)

TECHNNlCAL DATA TD

STEERlNG SYSTEM

item

Steering wheel

Outer diameter

mm (in]

Free play

mm [in]

Operation force N [kgf, Ibf]

Lock-to-lock

Steering gear

TYF

Steerrng gear ratio

Backlash between rack and pinion

mm Iin] 1

N-m { kgfcm, inlbf ]

PInion Reload measured by torque wrench

preload

kgf ( ibf )

Preload measured by pull scale with attachment

Distance between left and right brackets

mm Iin]

Rack stroke mm {ini

Lubricant type

Oil capacity L (US qt, imp qt]

Dfive belt

I

Deflection with force of 98 N { 10 kgf, 22 Ibf 1 mm [in) Specifications

370 { 14.57)

O-30 [O-l .16)

29 13.0, 6.6) or less

2.51

Rack and pinjon

Infinite too)

0 101

l.O--.I.3 (10-14, 8.?-12.1)

1.0-1.4 (2.2-3.08)

258 (10.16)

121 (4.76)

ATF Dexron@II or M-III

0.8 (0.85, 0.70)

New

belt: 8-9 [0.31-0.351

Used belt: Q---t0 [ 0.35-0.39 1

BRAKlNG SYSTEM

Brake type Item ‘WIthout A8S With ABS

. Front . . . . . djsc, Rear . . . . . dtsc

Brake pedal

Heiaht mm linl i 203-206 f 7.99-8.7 1 I

Free play mm {in]

Reserve travel

Clearance when pedal depressed at 5& N 160 kgf, G? I’dl;’ 4-7 !0.16--0.281 12-15 [0.47-0.591

70 (2.76) min 60 (2.36) min

l t Master cylinder t

Master cylinder

Front disc brake . Type

Bore diameter mm {inj 25.4 11 .UO ] Tandem

t 23.8 (0.94 ]

- .-~

Type Ventilated

Thickness of pad mm [in) Standard 10 10.39)

Minimum 2 fO.08)

Thickness of disc plate

mm [in] Standard 24 10.94)

Minimum - 22 to.791

Runout of disc plate mm fin] 0.1 ~0.004]

Cylinder bore mm (ini 57.2 (2.25 ]

Rear brake (disc) b

r Type I

Solid

Thickness of pad mm (In] Standard 8.0 (0.311

Minimum 1 10.04)

Thickness of disc plate mm [in] r Standard 10 [0.39]

Minimum 8 {0.31)

Runout of drsc ‘plate mm (iti)

0.1 (0.004]

Cylrnder bore mm {in]

34.9 II.371

Parking brake

_ Type Mechanicaj twerear-wheel control

Parking brake lever notches

When lever is pulted at 98N [‘lo kgf, 22 tbf I 5-7

Page 167 of 279

TD TECHNlCAt DATA -

BODY EtECTRtCAL SYSTEM

ttem

Headlight

Front fog light

Front turn signat light

Parking light

Front side turn light

StocYlailliaht Specifications (w)

ECE

I Swiss

60155

55

21

5

5

2115

Exterior tamps

Taillight &8) 5

Rear turn single tight 21

Back-up light

21

License plate light

5

Flash-to-pass light 55 (Austrra)

I -

Running Ilght

55 (Sweden, Norway, Iceland)

Rear fog light 21

Interior and spot lamp Interior 10

Spot 6

Interior Iamps

Interior lamp 10

Spot tamp (in overhead console) 8

Cargo compartment lamp

5

High beam

3.4

Turn light

3.4

Brake 3

Hold 3

Charge 3

011 pressure 3 -.

lndcator and n Washer 3

warning Iamps TUF~O 3

Fuel

1 3

Rear fog

I

! 3

1

ABS

Parktng brake

Illumination I 3

3 .

3.4

Rear

Cliff. lock f 3

3 I STANDARD BOLT AND NUT TIGHTENING TORQUE

! Diameter Pkh I 41

8T f&lb N-m I 81 mm {tn] mm fin] N-m 1 m-kg

dsf Wtb 1 Nm

mkg ft4b 6 IO.2361 1 {0.039] 4.2-6.2 /0.43-O-63 3.1-4.6

6.9-9.8 0.7-1.0 5.0-7.2 7.8-11.8 O-8-1.2 5.8-8.8

8 IO.3151 1.25 (0.049) 9.8-14.7 1 1.0-1.5 7.2-10.8 16-23 1 1.6-2.3 12-17 18-26 1.8-2.7 13-20

10 IO.3941

It.25 10.04911 20-28 1 2.0-2.9 1 14-21 31-46 1 3.2-4.7

23-34 36-54 3.7-5.5 27-40

I r

12 IO.4721

1.5 lO.OSSj 34-50 3.5-5-l 25-37 1 55-80

5.6-8.2 41-59 63-93 6.4-9.5 46-69

14 {0.551] 1.5 IO.059) - - - 75-103 7.7-10.5 56-76 102-137 lo-14 75-101

16 #0.630] 1.5 {O.OSSl - -

- f16-157 12-16 85-116 156-211 16-22 115-156

t8 (0.709) 1.5 [0.059] - - - 167-225 17-23

123-166 221-299 23-31 163-221

20 IO.7871 I,5 {0.059]

- - - 231-314 24-32 171-231 308-417 31-43

227-307

22 (0.866) 1.5 IO.0591

- 1 - - 334-423 32-43 231-312 417-564 43-58

' 307-416

24 10.945) 1.5 10.059) - 1

- - 1475-5461 41-56 298-403 1536-7261 55-74

396-536

c)

c) I

-.

c’

c .

4

Page 170 of 279

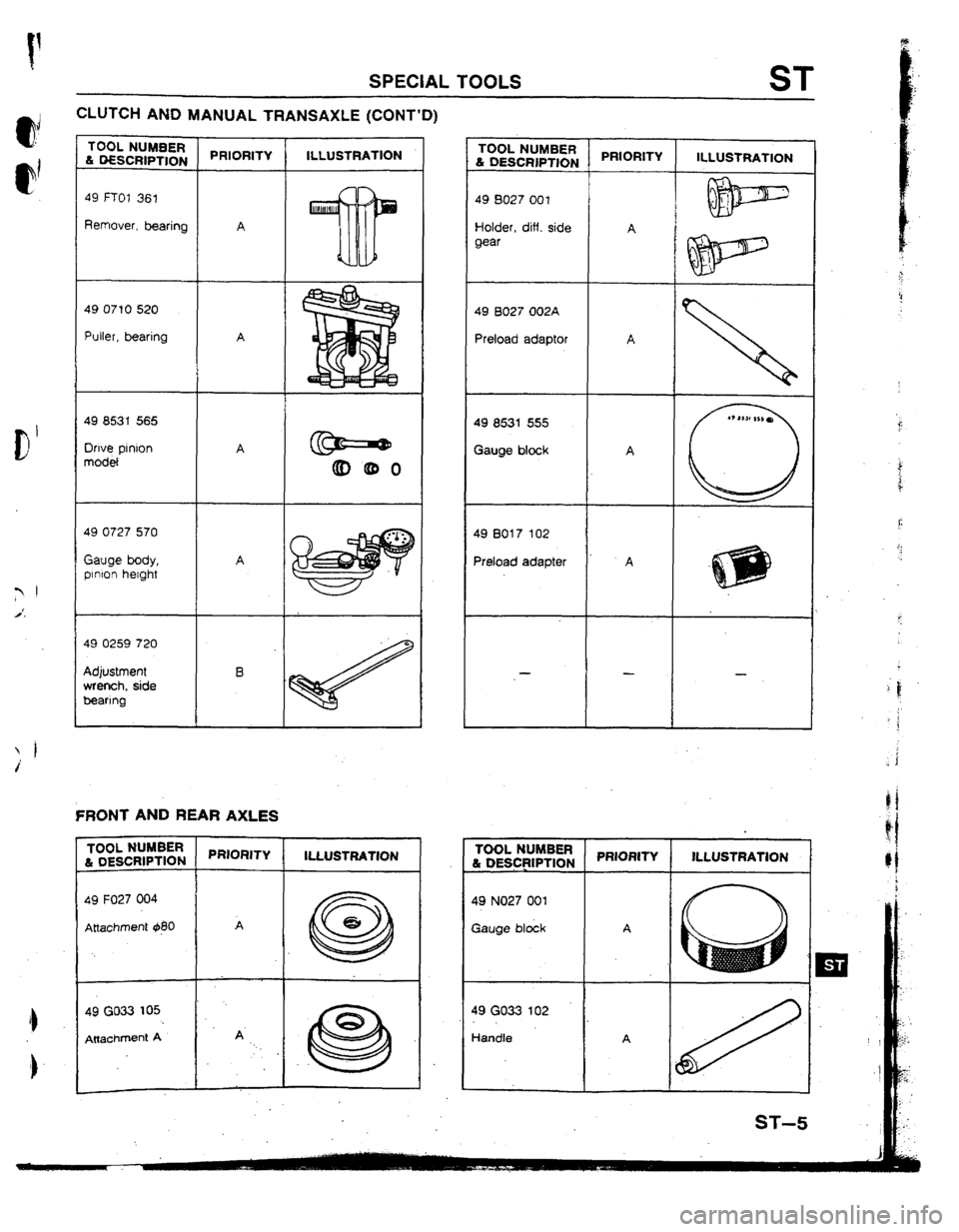

SPECIAL TOOLS ST

ENGlNE

TOOL NUMBER

b DESCRIPTION PRlORlTY ILLUSTRATlON

49 0107 680A

Engine stand A

49 LO10 IA0

Hanger set,

engine stand

49 0636 IOOA

Arm, valve spring

lifter

49 8012 OA2

Prvot

A

49 5120 170

1 I

Remover, valve

seal

A ff==cB

49 E011 IA0

Brake, ring gear A Installer set, valve

seal & valve

Remover &

installer, valve

49 0221

061A

49 DO11

102

Lock tool,

crankshaft

- 49 GO14

001

Wrench, tit filter

49 9200 145

Adapter, radiator

Page 172 of 279

SPECIAL TOOLS ST

CLUTCH AND MANUAL TRANSAXLE (CONT’D)

PRIORITY ILLUSTRATION TOOL NUMBER

& DESCRIPTION TOOL NUMBER

& DESCRIPTION PRIORITY IttUSTRATlON

49 8027 001

Holder, diff. side A

gear 49 FTO? 361

Remover, bearing

49 B027 002A

P reload adaptor A 49 0710 520

Puller, bearing

49 8531 555

Gauge block A 49 8531 565

Drwe pinton

model A

49 0727 570 49 8017 102

Preload adapter A

Gauge body,

plnron herght

49 0259 720

Adjustment

wrench, side

bearing

-

FRONT AND REAR AXLES

C

i TOOL NUMBER

8, DESCRIPTION PRIORITY / ILLUSTRATION TOOL NUMBER

& DESCRIPTION

49 F027 004 49 NO27 001

Attachment

tf~?O Gauge Mock

49 GO33 102

Attachment A

Page 174 of 279

SPECIAL TOOLS ST

STEERING (CONT’D)

PRIORITY TOOL NUMBER

et QESCRlPTlUN ILLUSTRATION

19 HO02 671

4dapter

Power steering) A

(Power steering)

(Power steering)

49 6032 3t2

(Power steering)

49 6032 323

Remover body,

rod seal

49 8032 316

Support block,

PM

(Power steering)

49 B032..327

Wrench,

outer box

49 9032 315

Installer, oil seal A

(Power steering)

0

19 8032 317

qemover ,

Dearing & oil seal

:Power steermg) B

49 8032 324

Protector body,

rod seal A

49 8032 305

Holder, power

steering pump

(Power steermg) A

49 8032 326

Protector,

outer box A

49 8032 306

Wrench, plug

(Power steermg) A

49 8032 321

Adapter

(Power steering) A

A

n

49 GO32 317

House (Power steering)

ST-7

Page 175 of 279

ST SPECIAL TOOLS --

BRAKIN

STEERING (CONT’D)

--

TOOL fi

h DESC

--

19 1285

Wer,

Qeedle :

--

49 8065

Harness;

--

49 cw:

Setting

retainer

--

49 804

Socke: PRIORITY / ILLUSTRATJUN TOOL NUMBER

& DEScCRIPTION TOOL NUMBER

& DESCRIPTION PRlORITY

ILLUSTRATION

A

(IlIP

A

0

A

c!iz9 49 B032 310

49 8032 320

0

Wrench

A

(Power steermg)

jq

49 F032 303

Handle

(Power steering)

Protector, pmon seal

(Power steermg)

49 B032 311

Protector,

Jipper seat

(Power steering)

49 8032 325

Guide. rod seal

BRAKING

PRIORITY

ILLUSTRATION TOOL NUMBER

b DESCRlPTlON TOOL NUMSER

& DESCRIPTION PRIORITY

ILLUSTRATION

49 8043 001

Adjust gauge

I A 49 0259 770B

Wrench, flare nut

A

49 0221 60X

Expand tool,

disc brake 49 8043 002

Installer, bearing A

TOOL

& DES

--

49 BC:

Replac

rubber

InstallE

dust 3 49 0208 701A

Atr out tool, boot 49 8043 003

Turning, lock tool A

49 FAt8 602

49 U043 OAO

I

Gauge set,

I A

oil pressure Wrench ,disc

brake piston

Page 179 of 279

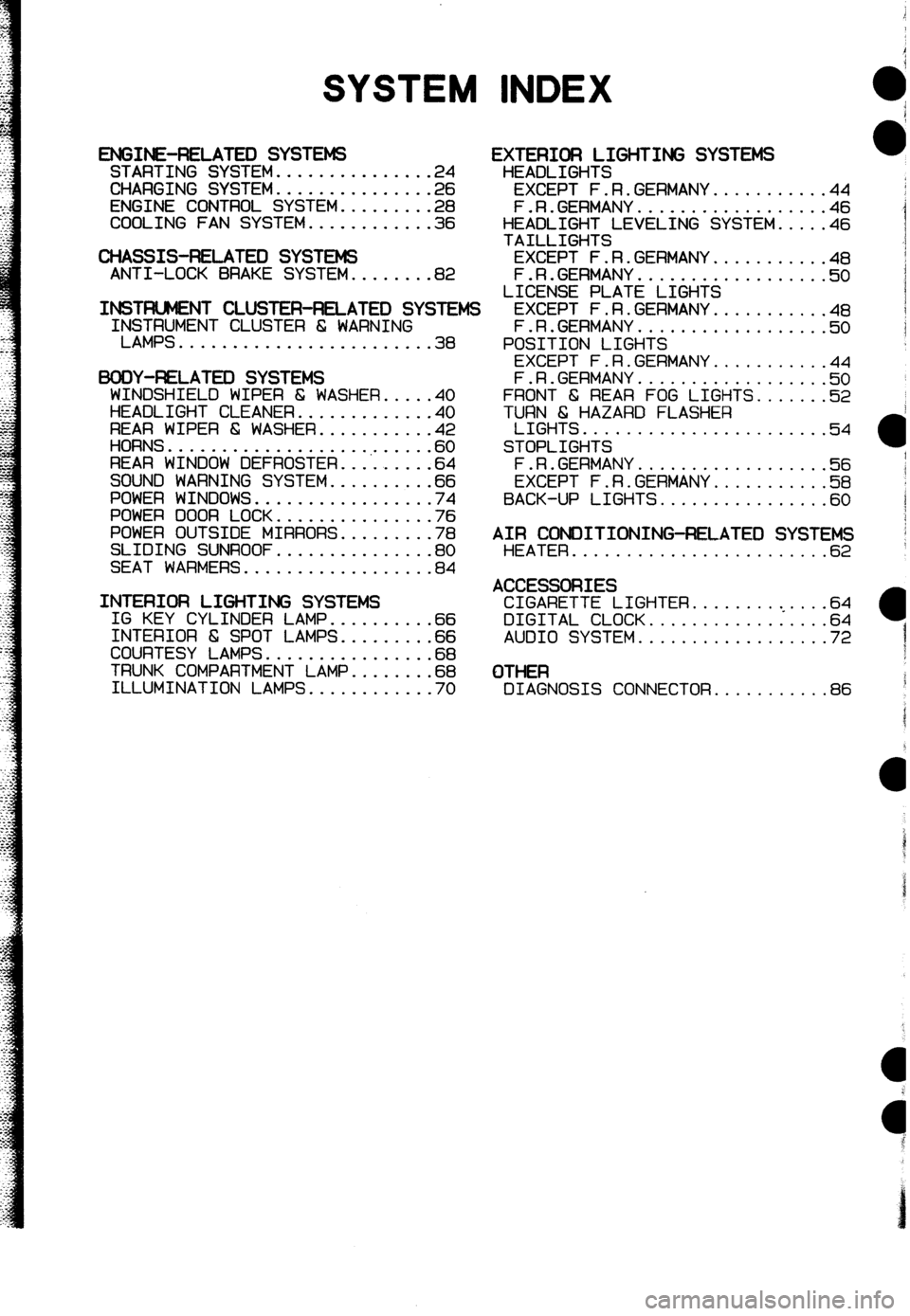

SYSTEM INDEX

ENGINE-RELATED SYSTEMS STARTING SYSTEM...............2 4

CHARGING SYSTEM...............2 6

ENGINE CONTROL SYSTEM.........2 8

COOLING FAN SYSTEM............3 6

CHASSIS-RELATED SYSTEMS ANTI-LOCK BRAKE SYSTEM........82

INSTFUJMENT CLUSTER-RELATED SYSIEMS IrS$;MENT CLUSTER 6 WARNING

........................ 38

BODY-F&LATEX) SYSTEMS

WINDSHIELD WIPER 6 WASHER.....4 0

HEADLIGHT CLEANER.............4 0

REAR WIPER & WASHER...........4 2

HORNS...................,......6 0

REAR WINDOW DEFROSTER.........6 4

SOUND WARNING SYSTEM..........6 6

POWER WINDOWS.................7 4

POWER DOOR LOCK...............7 6

POWER OUTSIDE MIRRORS.........7 8

SLIDING SUNROOF...............8 0

SEAT WARMERS..................8 4

INTERIOR LIGHTING SYSTEMS IG KEY CYLINDER LAMP..........6 6

INTERIOR 6 SPOT LAMPS.........6 6

COURTESY LAMPS................6 8

TRUNK COMPARTMENT LAMP........6 8

ILLUMINATION LAMPS............7 0

EXTERIOR LIGHTING SYSTEMS

HEADLIGHTS

EXCEPT F.R.GERMANY...........44

F.R.GERMANY..................46

HEADLIGHT LEVELING SYSTEM.....46

TAILLIGHTS

EXCEPT F.R.GERMANY...........48

F.R.GERMANY..................5 0

LICENSE PLATE LIGHTS

EXCEPT F.R.GERMANY...........4 8

F.R.GERMANY..................5 0

POSITION LIGHTS

EXCEPT F.R.GERMANY...........4 4

F.R.GERMANY..................!i? 0

FRONT 6 REAR FOG LIGHTS.......52

TURN 6 HAZARD FLASHER

LIGHTS.......................54

STOPLIGHTS

F.R.GERMANY.a................5 6

EXCEPT F.R.GERMANY...........5 8

BACK-UP LIGHTS................6 0

AIR CONDITIONING-RELATED SYSTEMS HEATER........................6 2

ACCESSORIES CIGARETTE LIGHTER.........<....64

DIGITAL CLOCK.................64

AUDIO SYSTEM..................72

OTHER DIAGNOSIS CONNECTOR...........86

Page 185 of 279

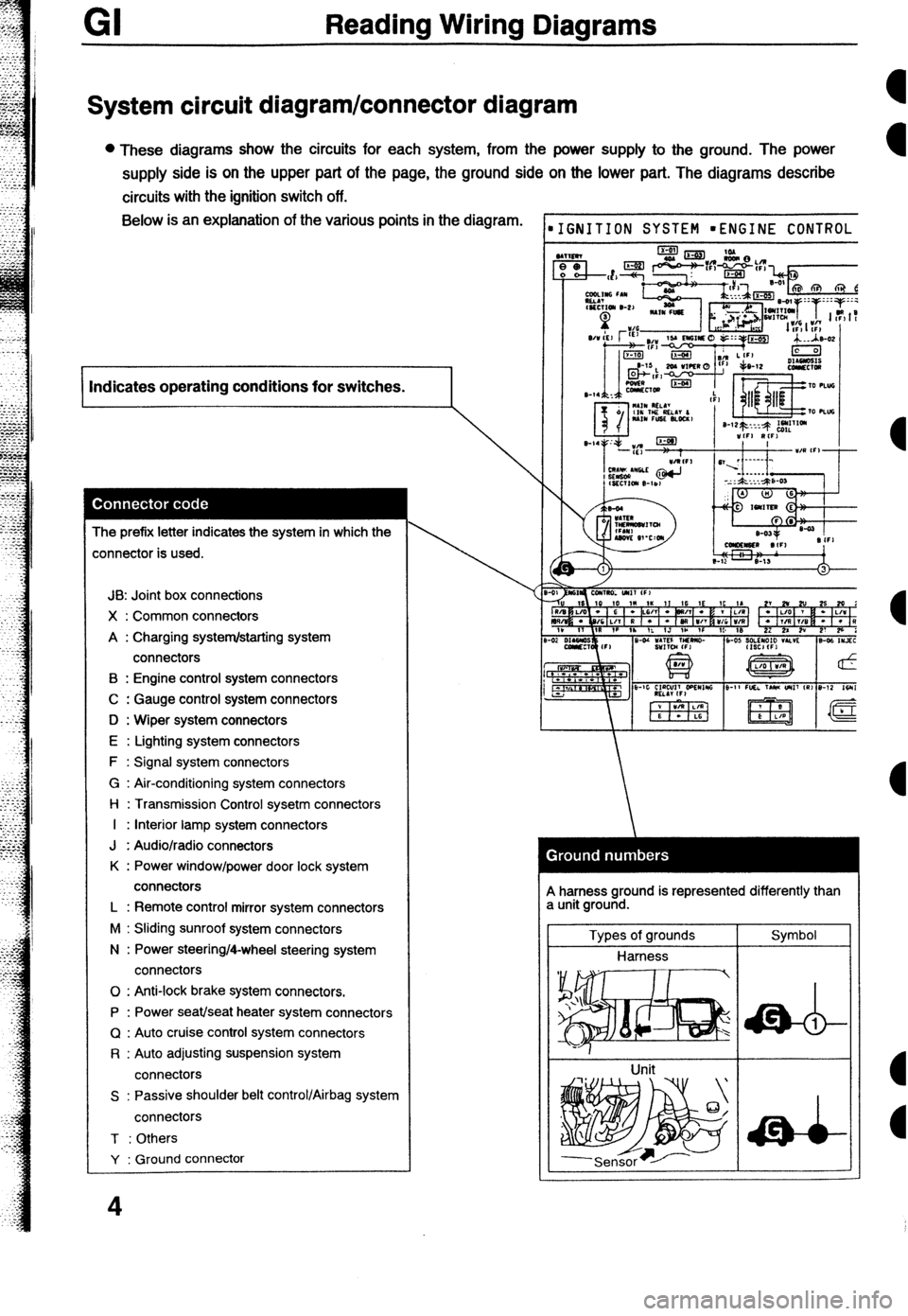

GI Reading Wiring Diagrams

System circuit diagram/connector diagram

l These diagrams show the circuits for each system, from the power supply to the ground. The power

supply side is on the upper part of the page, the ground side on the lower part. The diagrams describe

circuits with the ignition switch off. Below is an explanation of the various points in the diagram.

I Indicates operating conditions for switches.

I

The prefix letter indicates the system in which the

:onnector is used.

JB: Joint box connections

X : Common connectors

A : Charging system/starting system

connectors

B : Engine control system connectors

C : Gauge control system connectors

D : Wiper system connectors

E : Lighting system connectors

F : Signal system connectors

G : Air-conditioning system connectors

l-l : Transmission Control sysetm connectors

I : Interior lamp system connectors

J : Audio/radio connectors

K : Power window/power door lock system

connectors

L : Remote control mirror system connectors

M : Sliding sunroof system connectors

N : Power steering/4-wheel steering system

connectors

0 : Anti-lock brake system connectors.

P : Power seat/seat heater system connectors

Q : Auto cruise control system connectors

R : Auto adjusting suspension system

connectors

S : Passive shoulder belt control/Airbag system

connectors

T : Others

Y : Ground connector

4

IGNITION SYSTEM mENGINE CONTROL

A harness ground is represented differently than

a unit ground.

Types of grounds

Harness

Unit Symbol

Page 191 of 279

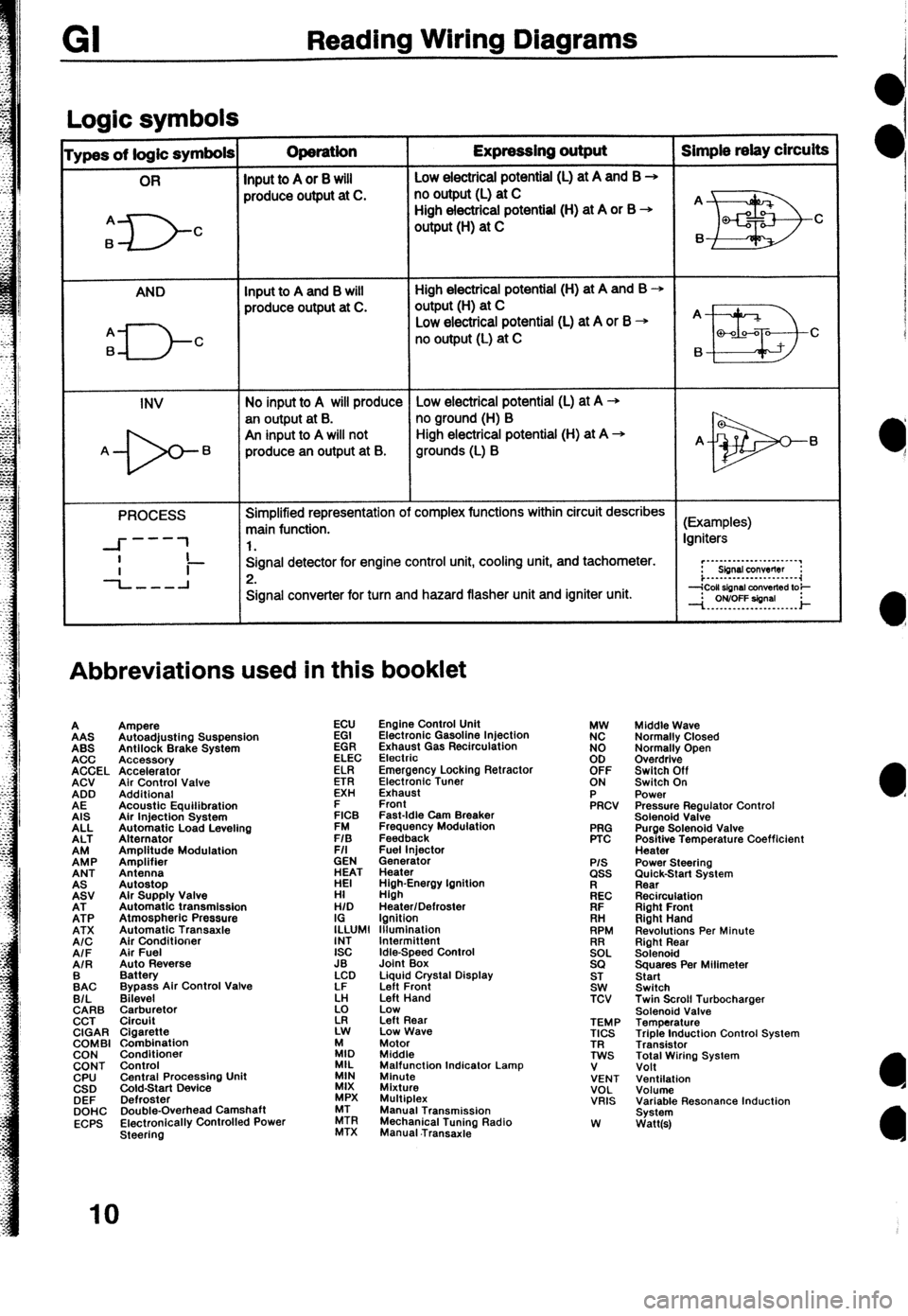

Reading Wiring Diagrams

Loaic symbols I

ypes of logic symbols Operation Expressing output Simple relay circuits

OR

Input to A or 8 will Low electricai potential (L) at A and B +

produce output at C. no output (L) at C

A

6

D- High electrical potential (H) at A or B +

C output (H) at C

AND Input to A and B will High electrical potential (H) at A and B +

produce output at C. output(H) at C

q---J-c

Low electrical potential (L) at A or B + A

no output (L) at C

B a-00-a C

6

INV No input to A will produce Low electrical potential (L) at A -+

an output at B. no ground (H) B

An input to A will not High electrical potential (H) at A +

A- 6 produce an output at B. grounds (L) B A- 6

PROCESS Simplified representation of complex functions within circuit describes

main function. (Examples)

---

--I- 1 1. Igniters

I

-L-l Signal detector for engine control unit, cooling unit, and tachometer.

Ii- 2. r”~“-‘-‘-““‘~~‘.“’

Sbnsl conwflw :

i...-..--.---......-.~~

Signal converter for turn and hazard flasher unit and igniter unit.

Abbreviations used in this booklet

A

AAS

ABS

ACC

ACCEL

ACV

ADD

AE

AIS

ALL

ALT

EP

ANT

EV

EP

ATX

A/C

AIF

AIR

:AC

B/L

CARB

CCT

CIGAR

COMBI

CON

CONT

CPU

CSD

DEF

DOHC

ECPS Ampere

Autoadjusting Suspension

Antilock Brake System

Accessory

Accelerator

Air Control Valve

Additional

Acoustic Equilibration

Air Injection System

Automatic Load Leveling

Alternator

Amplitude Modulation

Amplifier

Antenna

Autostop

Alr Supply Valve

Automatic transmission

Atmospheric Pressure

Automatic Transaxle

Air Conditioner

Air Fuel

Auto Reverse

Battery

Bypass Air Control Valve

Bilevel

$rr$:,tor

Cigarette

Combination

Conditioner

Control

Central Procassino Unit

&Id-Start Device -

Defroster

Double-Overhead Camshaft

Electronically Controlled Power

Steering ECU

EGI

EGR

ELEC

ELR

ETR

EXH

E

FICB

FM

F/S

F/I

GEN

ET

HI

H/D

I;LUMl

INT

ISC

JB

LCD

LF

k!

z Engine Control Unit

Electronic Gasoline Injection

Exhaust Gas Recirculation

Electrio

Emergency Locking Retractor

Electronic Tuner

Exhaust

Front

Fast-Idle Cam Breaker

Frequency Modulation

Feedback

Fuel lniector

Generator

Heater

High-Energy Ignition

High

Heater/Defroster

Ignition

lllumlnation

Idle-Speed Control

Joint Box

Liquid Crystal Display

Left Front

Left Hand

Low

Left Rear

Low Wave

:I, Motor

Middle

MIL

MIN Malfunction Indicator Lamp

Minute

MIX

Mixture

MPX Multiplex

ZR Manual Transmission

MTX Mechanical Tuning Radio

Manual .Transaxie PRG

PTC

P/S ass

kc

FIF

. . .

RH

RPM

!2EL

SQ

ST

SW

TCV

TEMP

TICS

TR

TWS

V

VENT

VOL

VRIS

W Middle Wave

Normally Closed

Normally Open

Overdrive

Switch Off

Switch On

Power

Pressure Regulator Control

Solenoid Valve

Purge Solenoid Valve

Positive Temperature Coefficient

Heater

Power Steering

;im&k-Start System

Recirculation

Right Front

Right Hand

Revolutions Per Minute

Right Rear

Solenoid

Squares Per Milimeter

Start

Switch

Twin Scroll Turbocharger

Solenoid Valve

Temperature

Triple Induction Control System

Transistor

Total Wiring System

Volt

Ventilation

Volume

Variable Resonance Induction

System

Watt(s)

IO