sensor MAZDA 323 1992 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 98 of 279

M FRONT AXLE

WHEEL HUB, STEERING KNUCKLE

RemovaI / Inspection I Installation

1. Remove in the order shown in the figure, referring to Removal Note.

2. Inspect all parts and repair or replace as necessary.

3. InstaH in the reverse order of removal, referring to Installation Note.

Caution

l Loosely tighten the shock absorber bolts. Lower the vehicle and tighten the bolts to the specified

torque with the vehicle unladen.

4. Adjust the front wheel alianment.

16-22 ]1.6-2.3, 12-161 I

19.0-l 2.0, 65-86.7 I

1. Wheel hub nut

2. Wheel and tire

3. Locknut

Removal Note . . . . . . .._.. . . . . . . . . . . . . . . . . . . . page M-7

installation Note .I.........,..,............ page M-7

4. Brake caliper assembly

Service . _. . . . . . . . . ,__. . . , , . ._. _. , , . . . , . ._ ._. . . . . . Section P

5. Disc plate

lnspectioti .~~*.......*~...,......,,,.....*~...~. Section P

6. ABS wheel speed sensor (if equipped)

7. Tie rod end

Removal Note . . . . . . .._.......... I . .._.....= page M-7

lnstallatiofi Note . . .._... _.__......,....... page M-7

M-6

8. Lower ball joint

9. Steering knuckle, wheel hub, and dust cover

Inspect-wheel hub for cracks and damage

Inspect knuckle spindle for cracks and

damage

Inspect dust cuver for damage and dis-

tortion

Disassembly I Inspection I

Assembly . ..C1..............~...,.....,.....

page M-8

Page 104 of 279

REAR AXLE

WHEEL HUB, KNUCKLE

Removal I Inspection / installation

1. Remove in the order shown in the figure, referring to

Removal Note. 2. Inspect all parts and repair or replace as necessary.

3. Install in the reverse order of removal, referring to Installation Note.

Caution

l Loosely tighten the shock absorber bolts. Lower the vehicle and tighten the bolts to the specified

torque with the vehicle unladen.

4. Adiust the rear wheel alianment.

16-22 1?.6-2.3, 12-16 I

7

IO.o-13.0,

66-66.7 1 1. Wheel and tire

2. Locknut

Removal Note..; . . . . . . . . , . . . . ,.......- -.. page M-f 3

Installation Note .._...,.,...._.__........ page M-13

I$ Brake caliper assembly

Service . . . . . . . . . . . ..e......._......... ,.,...,....

Section P

4. Disc plate

‘Service ..I....................__....... . . . . . . . . . Section P 5. Af3S wheel speed sensor (if equipped)

6. Wheel hub, knuckle

Disassembly I Inspect& /

Assem bty . . . . . . . ..I..........*..*.*...-... page M-14

Inspect wheel hub and knuckle for damage

or cracks

Inspect dust cover for damage or defor-

mation

M-12

Page 159 of 279

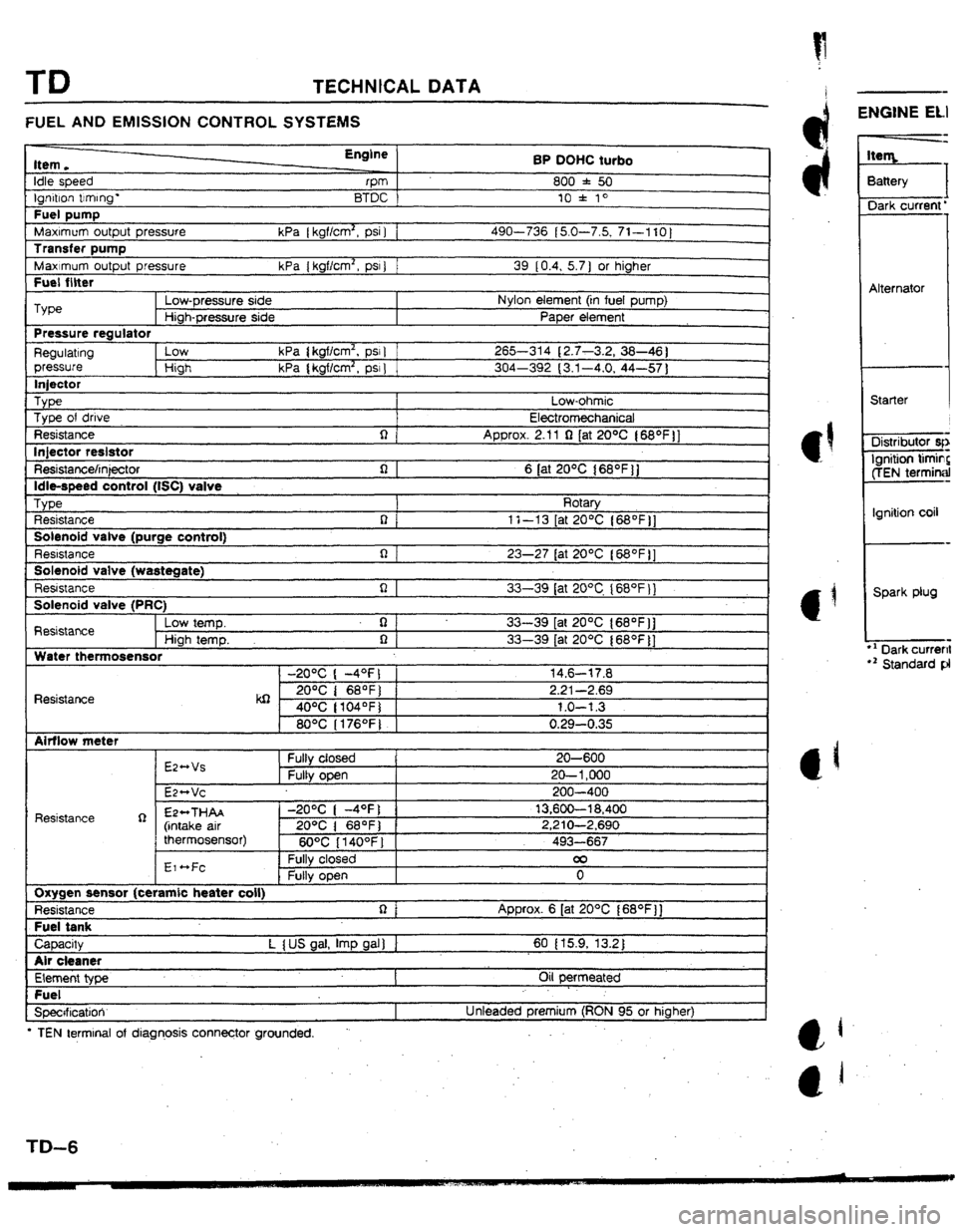

TO TECHNICAL DATA

FUEL AND EMISSION CONTROL SYSTEMS

Item.

Idle speed

tgf-don trrmng-

Fuel pump

MaxImum output pressure

Transfer pump

Maximum output pressure

Fuel filter Engine

rPm

BTDC

kPa [ kgf/cm2, psi 1 1

kPa { kgflcm2, PSI ) 1 BP OUHC turbo

800 f 50

10 l 10

490-736 (5.0-7.5, 71-1 IO]

39 10.4, 5.7 ) or higher

I Type

Low-pressure side Nylon element (in fuel pump)

Hiah-Dressure side PaDer element

Pressure regulator

Regulating low kPa ( kgflcm2, psr 1 265-314 (2.7-3.2, 38-46 1

pressure High kPa { kgflcm2, psr 1 304-392 (3.1-4.0, 44-57 1

lniector

_ Type Low-ohmic

Type of drive

Electromechanical

Resistance q

Approx. 2.11 Q (at 20% ( 68*f )]

lniector reslstor

L - Resistance/injector

Idle-speed control (tSC) valve

TvDe n 1 6 [at 20°C 168OFjj

I Rotarv

Resistance

Solenoid valve (purge control)

Resbstance

Solenoid valve {wastegate)

Resistance n(

R I

i-l I 1 t-13 [at ZO*C {68OF j]

23-27 tat 20°C l68OFll

. r.

33-39 lat 20°C I68OF 11

Solenoid valve (PRC)

Resistance Low temp. q

33-39 [at 2O*C {SS*F]]

High temp. 0 1 33-39 [at 20°C (68OF]]

Water thermosensor

-20°C ( -4OFJ 1 14.6-17.8

Resistance kQ 2o”c I 68OF) 2.21-2.69

40°C ( tO4OF) 1.0-l 3

80°C I176OFJ 0.29-0.35

Airflow meter

Resistance R E244Vs

E2*Vc Fuity closed

Fully open I 20-600

20- 1,000

200-400

EP++THAA

(intake air

thermosensor) -2O*C ( -4OFj 1 13,600-l 8,400

20% 1 68OF) 1 2,210-2,690

6O*C 114OOFl i 493-667

EI ~Fc

I Fully closed 00

0 1

Oxygen sensor (ceramic beater coil)

Resistance

Fuel tank Approx. 6 [at 20°C f68OF)]

I CaDacW L I US oal. ImD aal I I 60 I 15.9, 13.2 I

I

Air cleaner

Element type

Fuel

Specrficatioir Oil permeated

Unteaded premium (RON 95 or higher)

l TEN terminal of diagnosis connector grounded. .

-

ENGINE ELI

3attery

I

Dark current’

Alternator

Starter

Distributor qr

Ignition timin?

ffEN terminal

Ignition coil

Spark plug

l ’ Dark current

r2 Standard pl

Page 176 of 279

SPECIAL TOOLS ST

BRAKING (CONT’D)

TOOL NUMBER

81 DESCRIPTION PRIORITY tLLUSTRATION

49 1285 071

Puller, A

needle bearing

49 B066 001

Harness (ABS) A

49 BO66 OAO

retainer

49 B043 004

Socket wrench A

FRONT AN5 REAR SUSPENSION

c TOOL NUMBER

& DESCRIPTION PRIORITY ILLUSTRATION

1

49 8034 2AOA

Replacer set,

rubber bush A

49 8038 785

:

Installer, A

dust boot TOOL NUMBER

& DESCRIPTION PRIORITY

ILLUSTRATION

49 GO25 001

Installer, P ’

sensor rotor

49 LO43 002

retainer

49 LO43 003

Setting tool,

retainer A

49 LO43 004

Protector

q@

:

- - -

TOOL NUMBER

& DESCRIPTION

49 GO34 1AO

Compressor,

coil spring

support Mock

PRIORITY

A ILLUSTRATION

Page 190 of 279

-

Reading Wiring Diagrams GI

Symbol

Horn Meaning l Generates sound when current flows. Symbol Switch (1) Meaning l Allows or breaks current flow by

opening and closing circuits.

Speaker

ccl

Heater l Generates heat when current flows. Normally open (NO)

Switch (2)

I

Normally closed (NC)

Harness l Unconnected intersecting harness.

Speed sensor

+ Movement of magnet in speedometer

turns contact within sensor on and off. (Not connected)

w Connected intersecting harness.

Ignition switch

l Turning ignition key switches circuit to

operate various component.

(Connected)

Relay (1)

l Current flowing through coil produces electromagnetic force causing contact to open or close.

No current to coil Current to coil

Uormally open (NO)

Relay (2) Normally open relay (NO)

lormally closed (NC) [/I jr No flow @jj 1 Flow

Normally closed relay (NC)

Sensor (variable) a Resistance changes with other Diode l Known as a semiconductor rectifier,

components operation. the diode allows current flow in one

IA direction only.

R

CaIhode(K)--++- Anode(A)

- Flow 01 electric C”llO”,

KIIZT)-A K-A K-A

#ensor (thermistor) 0 Resistance changes with temperature. Light-emitting diode l A diode that lights when current flows.

V-ED) l Unlike ordinary bulbs, the diode does

not generate heat when it.

%u

I-

- Cathode(K) -$----- Anode(A)

Capacitor

l Component that temporarily stores

electrical charge.

----it----

Flow of current

Solenoid

l Current flowing through coil generates Reference diode l AIIOWS current to flow in one direction

electromagnetic force to operate (Zener diode) up to a certain voltage; allows current

to flow in the other direction once that

ti

n voltage is exceeded.

9

Page 196 of 279

Troubleshooting GI

Measuring continuity/resistance

Touch the ohmmeter probes to the switch terminals to check

Verify the operating state of the switch before checking

continuity because readings vary accordingly.

Note Continuity is checked according to the direction of the positive

(+) and negative (-) probes ofihe ohmmeter in the circuit

containing the diode.

Connection

I Continuity

Yes

The negative (- ) probe of the ohmmeter is

connected to the positive terminal of the internal

ohmmeter battery, the positive (+) probe to the

negative terminal of the battery. No

Connect the ohmmeter probes to the sensor or solenoid valve

terminals to check resistance.

Caution

Verify the operating state of the sensor before checking

resistance because readings vary accordingly.

1. Short between the terminals with a jumper wire to discharQe

the capacitor.

2. Set the ohmmeter range to xl Ok R and connect it to the

capacitor terminals.

3. The capacitor is good if the needle of the ohmmeter swings

once and returns to its original position.

15

Page 197 of 279

GI Troubleshooting

FindIng short circuits

Shorts occur between the power (positive) and ground (negative) sides of a circuit.

Therefore, finding a short circuit requires determining how the circuit is routed.

Circuits

not connected to control unit

I

Examples

ihort location 1 SvmWom

I Battery

,pOSlhl

terminal) lgnitbn switch

I Finding short circuit

4

1. Remove the fuse and

main fuse of the circuit.

2. Disconnect ail connecton

Of electrical components in the circuit.

3. Attach a voltmeter or test

Motor

M

Qi!

Short (A)

Short (8)

Short (C)

Short (0) l The motor operates

regardless of whether the

thermoswitch is ON or OFF

when the ignition switch is ..-..

ON. -

@The fuse is not melted.

0 The main fuse melts when the

ignition switch and thermo-

switch are ON and the relay is

operating.

lgnitlon switch

Switch short locatior

Short (A)

Short (B)

Short (C) Test lamp lamp to the fuse box and

reconnect each connector, beginning

nearest the power

, source. Circuits connected to control unit

1 Examples

Symptom

l Fuse melts.

Short (D)

Short (E) 14. Check the voltmeter

reading or test lamp as

the connectors are

connected.

l solenoid A operates when the

ignition switch is ON.

l The CPU transistor burns out

when the ignition switch is

turned ON.

l The CPU thinks the switch is

ON because the same

conditions exist as when the

switch is ON.

@The CPU senses the sensor

to be 0 Q because the same

conditions exist as when the

resistance value is 0 Q.

l The CPU equipped with the

self-diagnosis function outputs

the code. l-

Finding short circuit

1. Remove the fuse and main

fuse of the circuit.

2. Disconnect ail connectors oi

electrical components in the

circuit.

rest lamp 3. Attach a voltmeter or test

lamp to the fuse box and

reconnect each connector,

beginning nearest to the

power source.

Check the voltmeter reading

or test lamp as the

connectors are connected.

Sensor/switch

1. Attach the test lamp or

voltmeter to the CPU

connector.

2. Connect to the switch/

sensor connector.

3. Check the voltmeter reading

voltmeter reads OV or the test lamp

16

Page 211 of 279

3-lb l ENGINE CONTROL SYSTEM (z/3)

KNOCK CONTROL UNIT

INJECTOR RESISTOR

DISTRIBUTOR

~I-01 ENGINE CONTROL UNIT (EM)

El-09 DISTRIBUTOR IEM) B l-l 1 ISC VALVE (EM)

2Y 2w 2u 2s 20 20 2M 2K 21 26 2E 2C 2A

R/B O/L G/B G f -G/Y L G/W * R/Y L/W R -G/h-G/R * Y/L Q/B 3/LGB/O

G W/L Y/B G/O W R/B R/L G/R R/Y Y x 3/BRB/#

22 2X 2V 2T 2R 2P 2N 2L 2J 2H 2F 20 28

I-12 SOLENOID VALVE

(PURGE CONTROL) (EM) 81-14 SOLENOID VALVECPRC LOW TEMP) (EM) 81-15 INJECTOR NO.1 (INJ) 81-16 INJECTOR ~0.3 (INJ) 81-17 INJECTOR N~.~(INJ) El-18 INJECTOR No.4 (IN,

1-19 WATER THERMOSENSOEBl-24 KNOCK CONTROL LJNIfBl-25 KNOCK SENSOR00 81-29 SOLENOID VALVE

Bl-30 INJECTOR RESISTOR 81-31 SOLENOID VALVE

30

Page 216 of 279

Ve:BenyVdhfp

Test condttton

-roliqc lblwk

lgnhn switch ON

VI3

- bmtm

2A

28

x

2D

2E

2F

26

2H

21

2J

2K

21

2M

2N

20

2P

20

2R Test condtthw

ranabla

2s

2T

2u

2v

2W

2x

2Y

arm-up)

P

P

8°F) P

ov

ov

ov

ov

ov of sv

Approx. 2v

-

ov or 5v

tpplox. 1.5

- connected to

oveftmost warning

tluzz.af

I

I

i”e started wilh cootanl 1 Below 1.5V 1 No&ad engine 1Bo sec. alter eng

temperature is above 90% 1194°F ) and

CondilkJn

iniake air temperature is between 40%

I l@i°F) and So% (122OFj

Other condition at idle

VB

lgrition switch ON

L VE ‘Engine Signd

Idle

VFJ’ Monitor: Green

Engine speed above 2.ooO rpm during

VE and red lamps

Nash Sde”&d valve

m kw tap.)

deceteralion (alter warm-up) -

-

0 -

lanition switch ON -

-

-

-

0 lnjedor (Nos. 1. 3) -

Ignition switch ON

Idle

injector (Nos 2. 4) IgrMon switch ON

I -3 Va

I

ISC valve -

-

0

0

-

0

0

0

0

-

0

0

-

- Idle -

Lpprox. 4.01

4.!--5sv

0 of 5v Knock control unit

Engine speed above 2,GOD rf

Thio#e sensor/

Airllow mder Constant -

0 Solenoid valve

(purge conlro4) Ignition switch ON

II

-

I* I “la I

lgnitlon switch ON .-.- ._

lgnitiin swilch ON VB

-

Idle Below 1.w

210 sec. alter engine started with coolant Below 1.5V No&d engine

temperature above 90% ( 194OF) and

cofditlon

intake air temperature above 50°C

/122OF)

Other condition al idle Va - 0

0 Qrcuit-oparing

relay

sdenoid valve

(PRC high temp.) Accelerator pedal released

Accelerator pedal lully depfesw ,pprox. 0.5L

.pprox. 4.oi 22 -

1 J

Is- r,

L-7 r

2Y Zw 2U 2s 20 20 ZM 2K 21 2G 2E 2C ZA 1U IS 10 10 1M tK I, tG 1E ,C ,A

22 2X ZV 2T ZR 2P 2N 2L 2J 2H ZF 20 28 1V IT IF! ,P IN 1L 1J t” 1F 10 19 lamlion switch ON

Idle (cold engine)

Idle (alter warm-up) ov

o-l.OV

0.5-l.OV

o-0.4v

xpprox. 3.8

tipprox. 3.0

tpprox 2.5

bpprox. 2.5

Bdow 0.5v

V8 -

lncreasmg engine speed (after w

Deceleralion

lgnltro” switch ON Airllow meter -

n airflow meter intake aa

Ambient air temperalure 20°C (6

ErlQl”l? codant temperature 200(

Alter warm-up

Ignition switch ON Water

thermosensor

To&charge

rndlcator

1 I

UI “I

u-1 r

-

2Y ZW ZU ZS 20 20 2M ZK 21 2G 2E 2C ZA lU IS 10 10 1f.I 1K 11 1G 1E tC 1A

22 2X 2V 27 2P 2P 2N 2L 2J 2H ZF 2D 28 IV IT IA 1P IN IL 1.1 1H 1F ID It3

35

Page 219 of 279

INSTRUMENT CLUSTER

ILLUMINATION LAMP

;REFER TO SECTION I-4

c l INSTRUMENT CLUSTER &i WARNING LAMPS 0 .F.R.GERMAI

*....ABS

COMBINATION SWITCH

(SECTION E-l. 21

ENGINE CONTROL UNIT

(SECTIIXJ

B-ICI

SECTION F-2. 3)

l-l rr

II l-l

* * w

,,“,, W/R G/ G/Y Y l-l II

II rl

WY & * 2% l-l II II l-l

R R/B

* Y/L B B/G G/W 6/B 767 G/R

B/O * * L/W V * L

1.J II iH 1G *r- fk io IC pJ ipi * Y/R * W/E R/Y

a 2% 2.3 21 w 28 n- a a x ZB 2A

K 3 34 31 3 Lx+ 3 * a x 33 3*

-02 OIL PRESSURE

SWITCH(E) C-03 BRAKE FLUID SWITCH C-04 PARKING BRAKE

(0 SWITCH(R) C-05 WASHER LEVEL SENSO C-07 WATER THERMOSENSOR

(Fg

(INJ)

pjlfzJ

ma

f

38