ECU MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 12 of 279

MAlNTENANCE NOTE GI

.

FREE ROLLER

I t 3EGlX-304

MAlNTENANCE NOTE

SPEEDOMETER TESTER CHECK

Caution

l Do not clutch abruptly.

l Do not attempt rabbit starts or accelerate quickly. 13EGIX-302

[Front wheel free-roller method]

1. Set the free roller securely on the floor under the front wheels

by matching it to the wheel base and front tread.

2. Place the vehicle softly on the tester and free roller.

3. Start the engine, and engage the clutch softly at a low speed

in 2nd gear; then gradually increase the speed.

4. Upon completion of the test, stop the engine by gradually

decelerating with soft braking.

[Front wheel jack-up method1

1’. Place the rear wheels on the roller.

2. Jack up the front wheels and mount on a safety stand.

3. Start the engine, and engage the clutch softly at a low speed

in 2nd gear; then gradually increase the speed.

Caution

l When using either the front wheel free-roller meth-

od or front wheel jack-up method, secure the vehi-

cle to prevent forward and lateral movement by

attaching towing hardware (chain or wire) to the

front and rear tow hook or tie-down hook.

BRAKE TESTER CHECK

Caution

. To stabilize the drag force of the viscous coupling,

conduct the brake test after the speedometer test.

1. Place the wheels to be tested (front or rear) on the roller.

2. Shift itit0 NEUTRAL.

3. Drive the tester roller and check.

a-9

Page 15 of 279

GI IDENTIFICATION NUMBER tOCATlONS/UNlTS/ABBREVIATlONS

IDENTIFICATION NUMBER LOCATIONS

VEHICLE tDENTtRCATtUN NUM8ER (VIM) ENGINE MODEL AND NUMBER

I

UNITS

N.rn { kgf m or kgfcm,

f-t&f or tn.lbf 1 . . . . . . . . . . . . . . . . Torque

rpm ._ . . . Revolutions per minute

A.. ,_...___.... Ampere(s)

v I... Volt(s)

$2 . .._..__......_.....__... Ohm(s) (resls‘tance)

kPa { kgflcm*, psr] . . . . . . . Pressure

{usually positive)

mmHg I inl-lg ] . . . . . . . . . Pressure

(usually negatrve)

W . . . ._ .._.__ .._ . . . . . . ..,......... Watt

titers [US qt, Imp qt 1 . V&me

mm { rn 1 . . . . . . . . . . . . . . . . . . . . . . . Length

89UOGX-006

ABBREWATIONS

ABDC _. . . . . . . . . . . After bottom dead

center

A/C . . . . . . . ._.. _. . . . . . . . . Air conditioner

ACC .__ . . . . . . . Accessones

ATX .._ ._ . . . . . . . . . . . . . . Automate transaxle

ATDC _.. __ _. . . . . After top dead center

ATF ,... ._....__._.. Automatic transmission

fluid

BAC ._ . . . . . . . . . . . . . . ,. Bypass air control

BBDC _. . . . . . . . . . . . . .._. Before bottom dead

center

BTDC ., ._._... . . . Before top dead center

CPU . . . . . . . . . Central processrng unit EC-AT

........................... Electronrcally-controlled

automatic transmlsslon

ECU ._ ....................... Engine control unit

EG 1 ..................... Electronc gasoll ne

injectron

E/L. ............................ Electrrcal load

EX .............................. Exhaust

IC ................................ Integrated clrcult

IGN ........................... lgnrtlon

IN ..... ........................ Intake

INT

............................... Intermittent

ISC ............................ Idle speed control

U-l ................................

Left hand

M..

........................... Motor

MIL

........ ...................... MatfunctIon Indicator

iamp

MTX. ........................... Manual transaxle

00.. .............................. Overdnve

Of F .............................. Swrtch off

ON

............................... Switch

on

PCV .............................. Positive crankcase

ventilation

PRC .......................... Pressure regulator

control

P/S ............................. Power steerrng

P/W ............................

Power window

RH ............................... Rlght hand

SST

............................. Special service tool

ST.. ............................... Starl

SW.. ............................. Switch

TDC. ............................ Top dead center

4WD .............................

4-wheel drive

03UGIX-802

INS7

If a t’

and

Whe

1, II-!

2. II-!

3. E-

4. Dr

W-1 2

Page 17 of 279

..,. .

a

._

GI CAUTKN

PRECAUTIONS TO TAKE WHEN SERVICING AN ELECTRICAL SYSTEM l Note the following items when servicing the electrical system.

l Do not alter the wiring or electrical equipment in any way; this may damage the vehicle or cause a fire

from short-circuiting a circuit or overloading it.

l The negatrve (-) battery cable must be removed first and

rnstalled last. l Do not reptace with fuses exceedrng specified capacity

Cautron

l 8e sure that the ignitton and other switches are off

before disconnectrng or connecting the battery cables.

Failure to do so may damage the semrconductor

components. Caution l Repfacing a fuse with one of a larger capacrty than

desrgnated may damage components or cause a frre.

l Secure harnesses with provrded clamps to take up slack. l Tape areas of the harness

that may rub or bump l When mounting

components, be sure the

against sharp edges to

protect rt from damage. harness IS not caught or

damaged.

Caution

l Clamp all harnesses near vibratrng components (for

example, the engine) to remove slack and to prevent

contact resultrng from vibration. i Drsconnect heatsensitive l Make sure that the

parts (for example, relays

and ECU) when performing connectors are securely

connected when installed.

l Do not handle electrical components roughly or drop

them. maintenance (such as

weldrng) where

temperatures may exceed

80°C [176OFj.

-*

HI

Page 18 of 279

CAUTION GI

HANDLING CONNECTORS

Caution

*‘Be sure to grasp the connectors, not the wires, when disconnecting them.

1. Raise the rear

2. Lift the tab with a

thin piece of metal

and remove the

poor termrnat contact.

Lift the tab with a thin

When using a matching Make sure the termmals

male terminal, make are

not pushed out of

sure there

IS no

c Round connectors >

1. Raise the cover.

2. Lift the termrnal to

3. Make sure the

terminal is securely

mounted in the

Pull lightty on individual

wires to check that they

are secured rn the 1. Raise the cover.

2. Remove A.

3. Lift the tab with a

thin piece of metal

and remove the

Page 32 of 279

82 INSTRUCTlUN FOR HANDLING METALUC SODIUM-FltLED EXHAUST VALVE

1NSTRUCTION FOR IiANDLlNG METALLIC SODIUM-FILLED EXHAUST VALVE

improper handling of metallic sodium can cause sever burns, loss of eye sight, and the production of

htghty ftammabie hydrogen gas. Therefore, handle and dispose of such valves carefully.

First aid

l If metallic sodium get into your eyes, quickly fiush it out with large amounts of water. See a

physician.

l If it gets on your skin, wash it off with plenty of water. See a physician.

l If it catches fire, use a dry powder fire extinguisher or dry sand to put it out. Never use water.

Note

l Do not use the valve as tool.

l Do not drain the metaltic sodium from the vatve.

l Neutralize the metallic sodium-filled valve before its disposal.

Re!e;,nEe

l

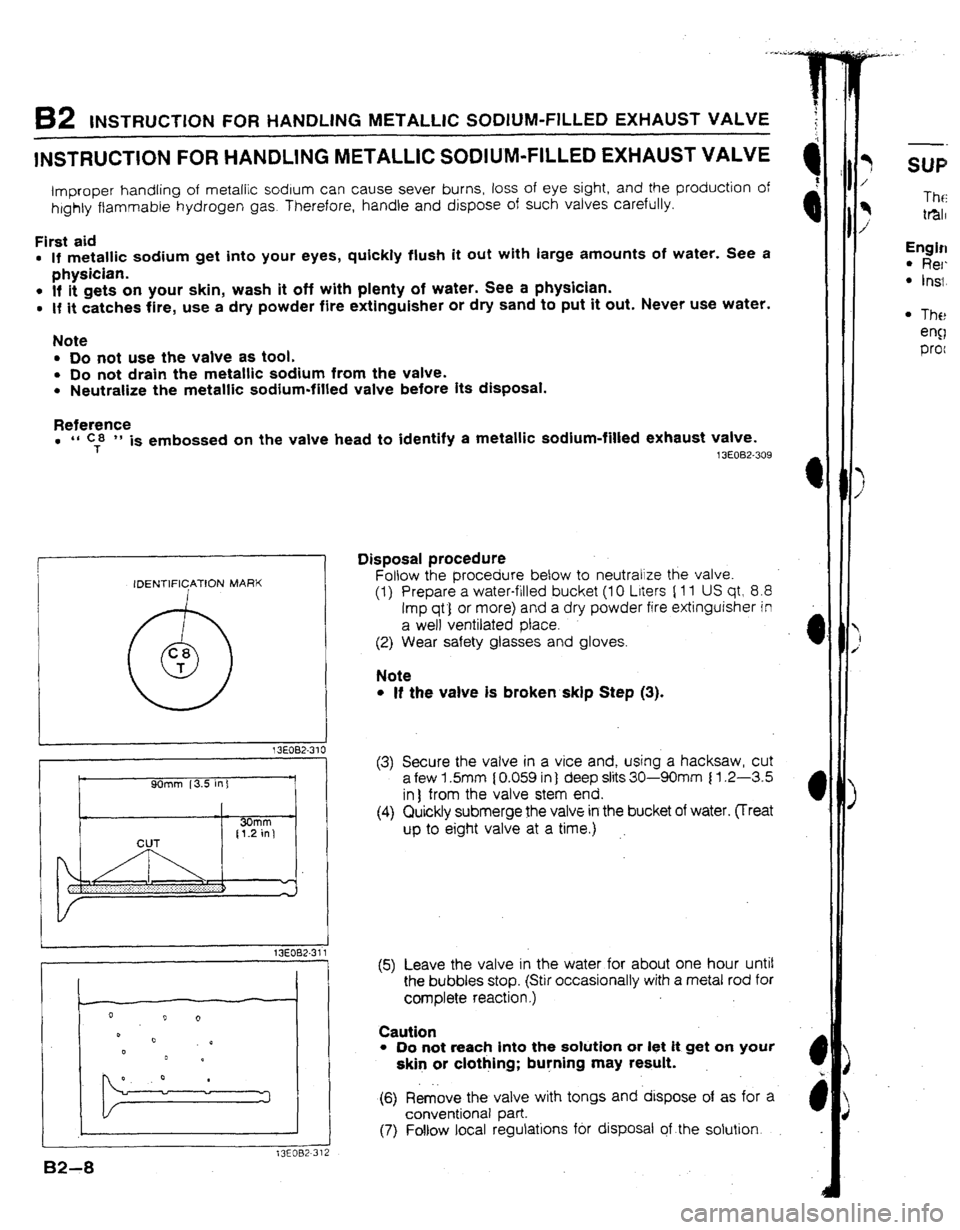

T is embossed on the valve head to identify a metallic sodium-filled exhaust valve. 13E082-309

IDENTIFICATION MARK

0 C8

T

9Omm 13.5 in] Disposal procedure

Follow the procedure below to neutralize the valve.

(1) Prepare a water-filled bucket (10 Liters [ 11 US qt? 8.8

Imp qtj or more> and a dry powder fire extinguisher in

a well ventilated place.

(2) Wear safety glasses and gloves.

Note

l If the valve is broken skip Step (3).

I

1 X002-31 1

, (3) Secure the valve in a vice and, using a hacksaw, cut

a few 1.5mm [ 0.059 in) deep slits 30-90mm 11.2-3.5

in) from the valve stem end.

(4) Quickly submerge the valve in the bucket of water. vreat

up to eight valve at a time.)

:

1

t3EOB2-312 (5) Leave the valve in the water for about one hour until

the bubbles stop. (Stir occasionally with a metat rod for

complete reaction.)

Caution

l Do not reach into the solution or let it get on your

skin or clothing; burning may result.

(6) Remove the valve with tongs and dtspose of as for a

conventional part.

(7) Follow local regulations fbr disposal of the solution. /

q Tht-i

i tmr

Engin

l Rer.

l Ins;

l The

eng

proc

Page 34 of 279

F3

c

FUEL AND EMISSION

CONTROL

SYSTEMS

i

INDEX . . . . . . . . l ..,.... *..,. . . . . . . m...*.*...*..... F3- 2

UUTLtNE

...................................... F3- 4

OUTLINE OF CONSTRUCTION.. ....

F3- 4

SYSTEM DIAGRAM ...................... F3- 5

VACUUM HOSE ROUTING

DIAGRAM

................................. F3- 6

WIRING DIAGRAM.. .....................

F3- 7

ECU RELATIONSHIP DIAGRAM ...... F3- 8

SPECIFICATIONS.. ....................... F3- 9

TURBOCHARGER CONTROL .......... F3-IO

OUTLINE

.................................... F3-10

SYSTEM DIAGRAM ...................... F3-10

WASTEGATE CONTROL ............... F3-11

FUEL SYSTEM

.............................. F3-12

OUTLINE ....................................

F3-12

CONTROL SYSTEM .......................

F3-13

STRUCTURAL VIEW .....................

F3-13

PRESSURE REGULATOR

CONTROL SYSTEM ....................

F3-14 SUPPLEMENTAL SERVICE

tNFOF?MATtON

............................. F3-I 5

SELF-DtAGNOStS FUNCTtON.. ........

F3-16

OUTLINE ....................................

F3-16

SERVICE CODE NUMBERS..

......... F3-16

TROU8LESHOOTtNG GUtDE

........... F3-19

RELATIONSHtP

CHART.. F3-19 ..............

DIAGNOSTIC JNDEX

.................... F3-20

PRECAUTIONS

............................

F3-21

SYMPTOM TROUBLESHOOTING .... F3-22

TURBOCHARGERCONTROL

SYSTEM ......................................

F3-37

TURBOCHARGER F3-37 ........................

WASTEGATE SOLENOID VALVE.. .. F3-38

INTERCOOLER ............................

F3-39

FUELSYSTEM ..............................

F3-40

FUEL PUMP ................................

F3-40

FUEL PUMP RESISTOR/RELAY ......

F3-40

PRESSURE

REGULATOR .............. F3-41

INJECTOR ..................................

F3-42

INJECTOR RESISTOR

................... F3-42

PRESSUR REGULATOR CONTROL

SYSTEM ......................................

F3-43

SOLENOID VALVE (PRESSURE

REGULATOR CONTROL)

............. F3-43

CONTROL SYSTEM

....................... F3-44

PREPARATION ............................ F3-44

ENGINE CONTROL UNIT (ECU) ..... F3-45

7 3EOF3-301

Page 35 of 279

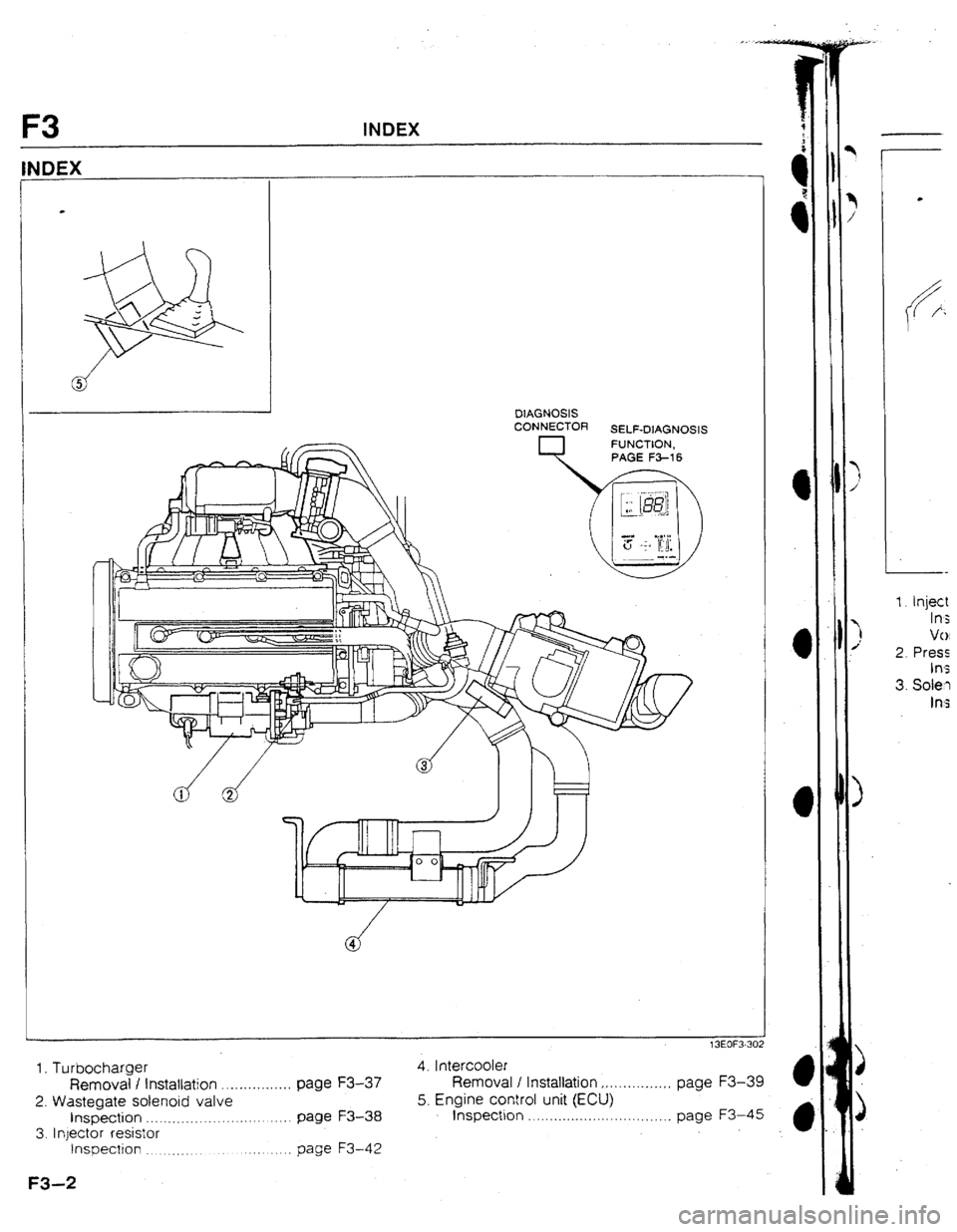

F3 INDEX

INDEX

I

J

D1AGNOSIS

CONNECTOR

SELF-DlAGNOSIS

1. Turbocharger

Removal I installation . . . . . . . . . . . . . . . . page F3-37

2. Wastegate solenoid valve

inspection . .__._. ._. . . . . . . . . . page W-38

3. Injector resistor

Inspection __ __,., __ . page F3-42 4, I ntercooler

Removal / Installation . . . . . . . .._...... page F3-39

5. Engine control unit (ECU)

lnspect~on . . . . . .._........... . . . . . . . . . . . page F3-45

F3-2

--

I. Inject

IfI;

Vr,

2. Press

In3

3. Sole-l

Ins

Page 41 of 279

F3 OIJTUNE

SPE

* TEN

The @

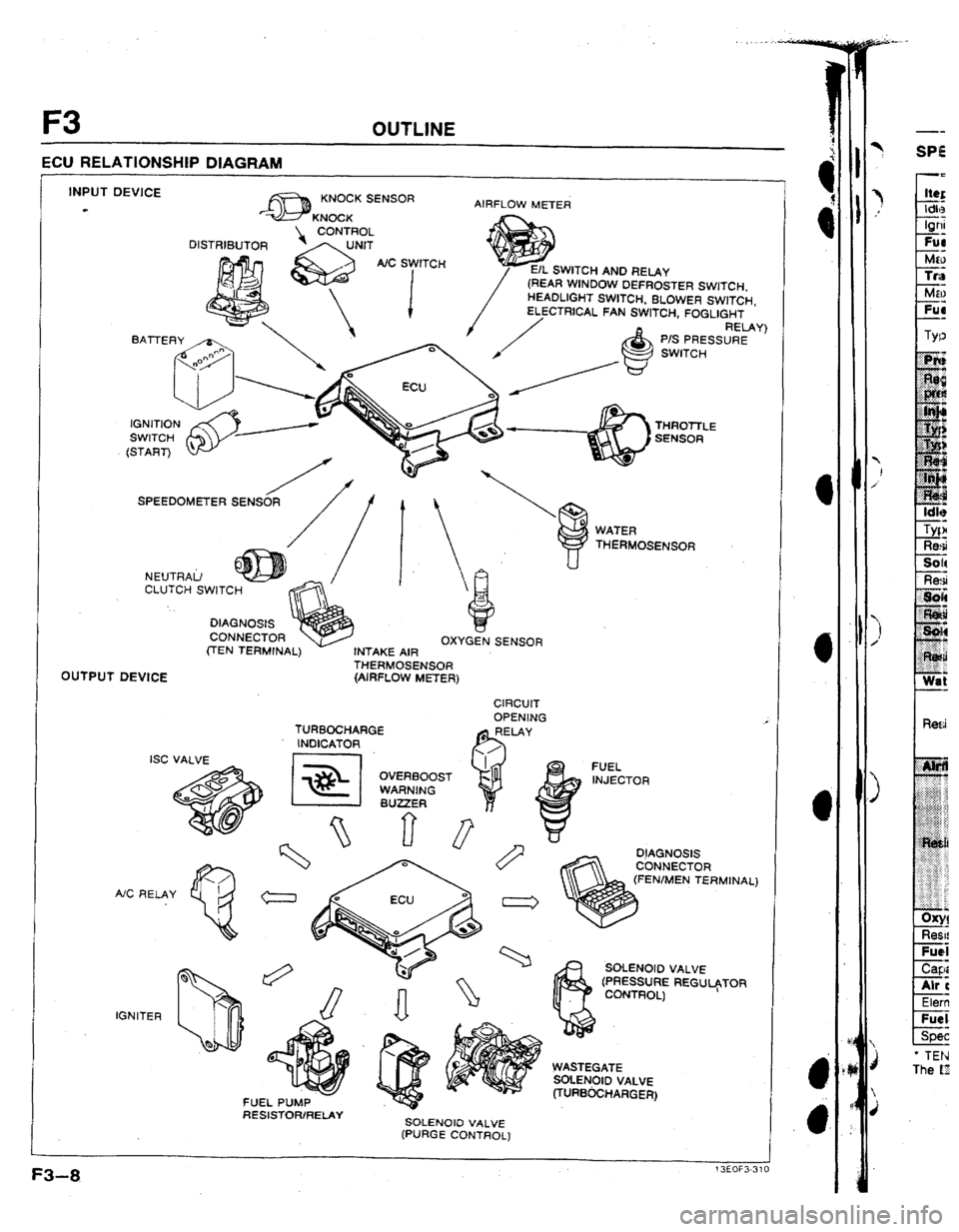

ECU RELATtONSHtP DtAGRAM

1NPUT DEVICE

KNOCK SENSOR

c AIRFLOW METER

KNOCK

DlSTRlBUTOR

91c YfTC”

THERMOSENSOR

OXYGENSENSOR N EUTRAti

CLUTCH SWITCH

CONNECTOR

(TEN TERMINAL,)

INTAKE AIR

OUTPUT

DEVtCE THERMOSENSOR

{AIRFLOW METER)

CIRCUIT

OPENING

TURBOCHARGE

jAGNOSE

ONNECTOR

EN/MEN TERMINA

h SOLENOID VALVE

(PRESSURE REGUL+TOR

CONTROL)

WASTEGATE

SOLENOID VALVE IGNITER

- - (TURBtiHARGER)

FUEL PUMP

RESlSTORlRELAY

SOLENOID VALVE

(PURGE CONTROL)

F3-8 13EOF3-311

Page 47 of 279

F3 CONTROL SYSTEM

PRESSURE REGULATOR CONTROL SYSTEM

SOLENOID VALVE TO MAIN RELAY

(PRC HIGH TEYP.)

t ECU

I

PRESSURE REGULATOR

// VACUUM

IJ WATER

THERMOSENSOR

F----------- lNTAKE AIR

THERMOSENSOR

SWITCH SOLEltolD VALVE

(PRC LOW TEMP.)

TO FUEL TANK

13EOF3-31 To prevent vaporlock in the fuel system during hot restart idle, a two-stage pressure regulator is adoped

to the new 323 4WD.

Low temperature operation: The vacuum to the pressure regulator (A and B ports) is cut (solenoid valve

[low temp.] UN), and the fuel injection pressure is increased to 284 kPa (2.90 kgf/cm2, 41 psi ) ,

High temperature operation: The vacuum to the pressure regulator (A port) is cut (solenoid valve [high

temp.] ON), and the fuel injection pressure is increased to 343 kPa [ 3.5 kgf/cm2, 49 psi 1.

Condition and operation

Condition Operation

1

coolant Intake alt Solenoid vrlve Solenoid vatve Opemtlon

I temperature temperature Engine (Idw temp.)

(high temp.) time Operation 40% [fU40f)-

Above 90°C 5U°C (t22OFI ON OFF 180s Low temp.

f f940Fj No load

Above 5O*C

I122OF) OFF ON 210s t-ltgh temp.

3

t3EOF3-319

F3-14 Wast

l Ins fuel

l In:; InJeci

l In:;

l Vol Injecl

l In:;

Presr

l SCI Engir

l InsI

Page 48 of 279

![MAZDA 323 1992 Workshop Manual Suplement SUPPLEMENTAL SERVICE INFORMATION .

I

The following points in this section are changed in comparison to the Mazda 323 4-Wheel Drive Work-

shop Manual [I 229-l O-89t].

Turbocharger

l Removal / Inst MAZDA 323 1992 Workshop Manual Suplement SUPPLEMENTAL SERVICE INFORMATION .

I

The following points in this section are changed in comparison to the Mazda 323 4-Wheel Drive Work-

shop Manual [I 229-l O-89t].

Turbocharger

l Removal / Inst](/img/28/57055/w960_57055-47.png)

SUPPLEMENTAL SERVICE INFORMATION .

I

The following points in this section are changed in comparison to the Mazda 323 4-Wheel Drive Work-

shop Manual [I 229-l O-89t].

Turbocharger

l Removal / Installation

Wastegate solenoid valve

l Inspection

htercooter

l Removal I Installation

Fuel pump (main)

l Inspection

Fuel pump resistor/relay

l System operation

l Inspection

Injector

l Inspection

l Volume test

Injector resistor

l Inspection

Pressure regulator control system

l Solenoid valve (pressure regulator control}

Engine control unit (ECU)

l Inspection 13EOF3.320

F3-I 5