ignition MAZDA 323 1992 Suplement Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 185 of 279

GI Reading Wiring Diagrams

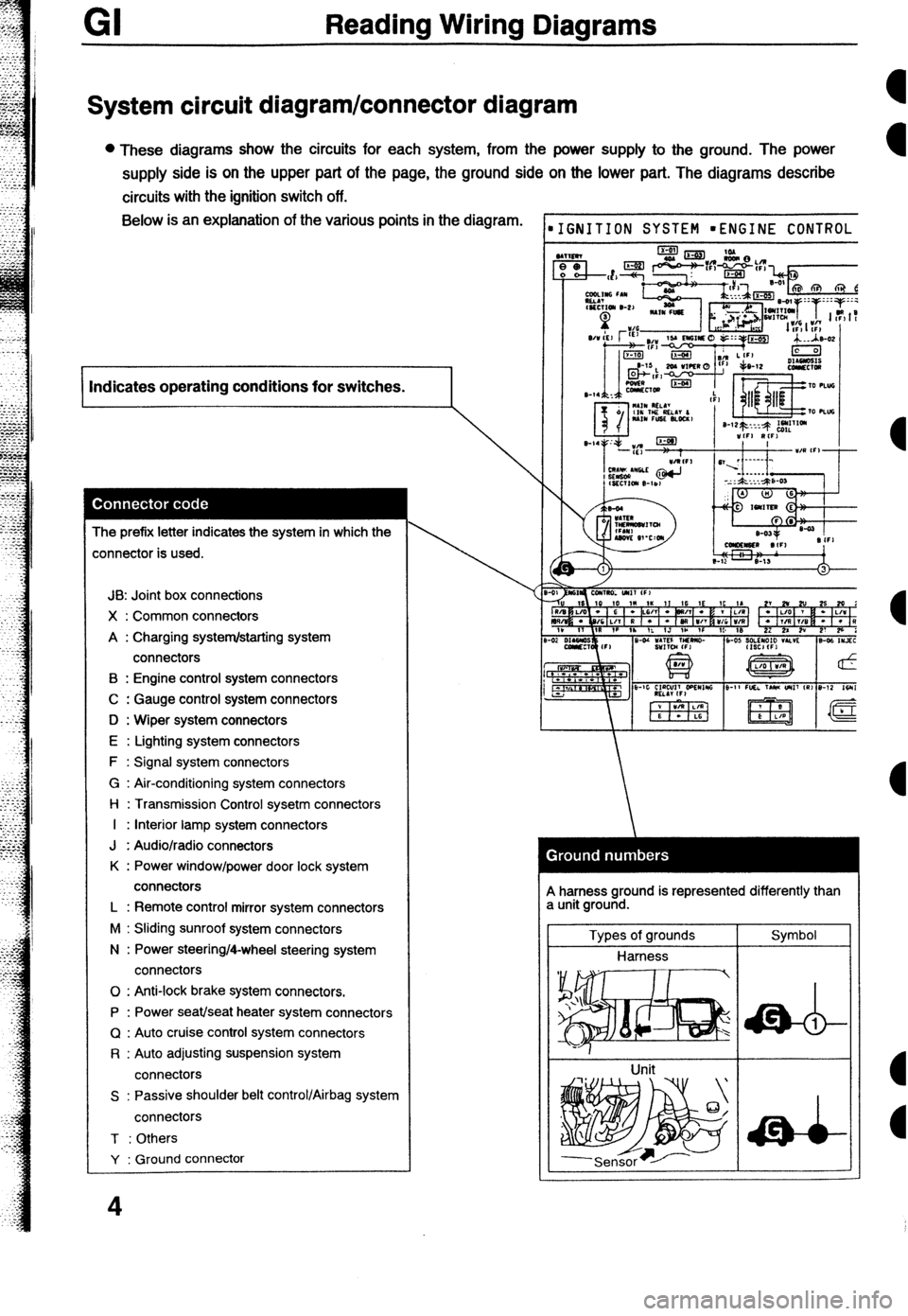

System circuit diagram/connector diagram

l These diagrams show the circuits for each system, from the power supply to the ground. The power

supply side is on the upper part of the page, the ground side on the lower part. The diagrams describe

circuits with the ignition switch off. Below is an explanation of the various points in the diagram.

I Indicates operating conditions for switches.

I

The prefix letter indicates the system in which the

:onnector is used.

JB: Joint box connections

X : Common connectors

A : Charging system/starting system

connectors

B : Engine control system connectors

C : Gauge control system connectors

D : Wiper system connectors

E : Lighting system connectors

F : Signal system connectors

G : Air-conditioning system connectors

l-l : Transmission Control sysetm connectors

I : Interior lamp system connectors

J : Audio/radio connectors

K : Power window/power door lock system

connectors

L : Remote control mirror system connectors

M : Sliding sunroof system connectors

N : Power steering/4-wheel steering system

connectors

0 : Anti-lock brake system connectors.

P : Power seat/seat heater system connectors

Q : Auto cruise control system connectors

R : Auto adjusting suspension system

connectors

S : Passive shoulder belt control/Airbag system

connectors

T : Others

Y : Ground connector

4

IGNITION SYSTEM mENGINE CONTROL

A harness ground is represented differently than

a unit ground.

Types of grounds

Harness

Unit Symbol

Page 190 of 279

-

Reading Wiring Diagrams GI

Symbol

Horn Meaning l Generates sound when current flows. Symbol Switch (1) Meaning l Allows or breaks current flow by

opening and closing circuits.

Speaker

ccl

Heater l Generates heat when current flows. Normally open (NO)

Switch (2)

I

Normally closed (NC)

Harness l Unconnected intersecting harness.

Speed sensor

+ Movement of magnet in speedometer

turns contact within sensor on and off. (Not connected)

w Connected intersecting harness.

Ignition switch

l Turning ignition key switches circuit to

operate various component.

(Connected)

Relay (1)

l Current flowing through coil produces electromagnetic force causing contact to open or close.

No current to coil Current to coil

Uormally open (NO)

Relay (2) Normally open relay (NO)

lormally closed (NC) [/I jr No flow @jj 1 Flow

Normally closed relay (NC)

Sensor (variable) a Resistance changes with other Diode l Known as a semiconductor rectifier,

components operation. the diode allows current flow in one

IA direction only.

R

CaIhode(K)--++- Anode(A)

- Flow 01 electric C”llO”,

KIIZT)-A K-A K-A

#ensor (thermistor) 0 Resistance changes with temperature. Light-emitting diode l A diode that lights when current flows.

V-ED) l Unlike ordinary bulbs, the diode does

not generate heat when it.

%u

I-

- Cathode(K) -$----- Anode(A)

Capacitor

l Component that temporarily stores

electrical charge.

----it----

Flow of current

Solenoid

l Current flowing through coil generates Reference diode l AIIOWS current to flow in one direction

electromagnetic force to operate (Zener diode) up to a certain voltage; allows current

to flow in the other direction once that

ti

n voltage is exceeded.

9

Page 191 of 279

Reading Wiring Diagrams

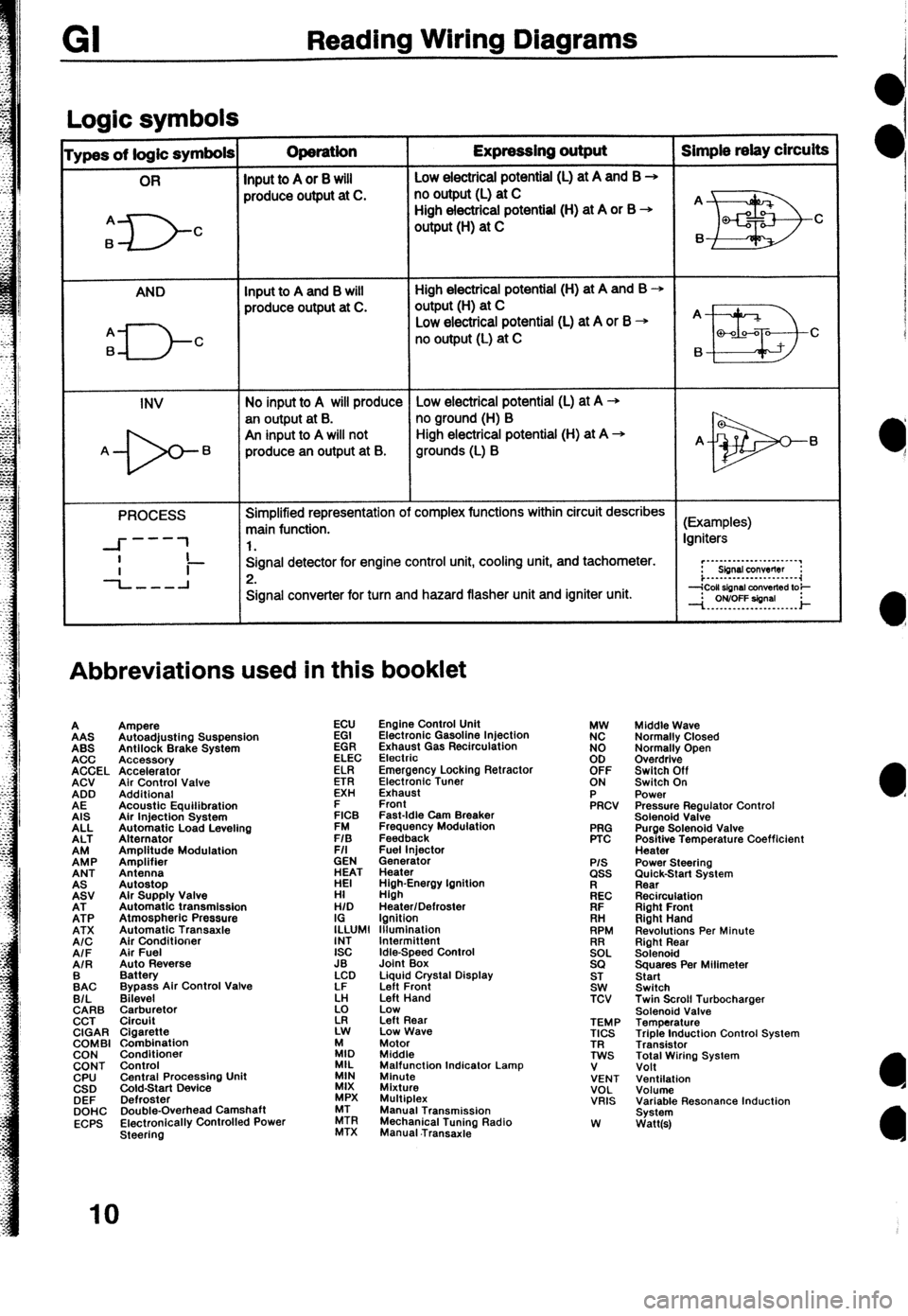

Loaic symbols I

ypes of logic symbols Operation Expressing output Simple relay circuits

OR

Input to A or 8 will Low electricai potential (L) at A and B +

produce output at C. no output (L) at C

A

6

D- High electrical potential (H) at A or B +

C output (H) at C

AND Input to A and B will High electrical potential (H) at A and B +

produce output at C. output(H) at C

q---J-c

Low electrical potential (L) at A or B + A

no output (L) at C

B a-00-a C

6

INV No input to A will produce Low electrical potential (L) at A -+

an output at B. no ground (H) B

An input to A will not High electrical potential (H) at A +

A- 6 produce an output at B. grounds (L) B A- 6

PROCESS Simplified representation of complex functions within circuit describes

main function. (Examples)

---

--I- 1 1. Igniters

I

-L-l Signal detector for engine control unit, cooling unit, and tachometer.

Ii- 2. r”~“-‘-‘-““‘~~‘.“’

Sbnsl conwflw :

i...-..--.---......-.~~

Signal converter for turn and hazard flasher unit and igniter unit.

Abbreviations used in this booklet

A

AAS

ABS

ACC

ACCEL

ACV

ADD

AE

AIS

ALL

ALT

EP

ANT

EV

EP

ATX

A/C

AIF

AIR

:AC

B/L

CARB

CCT

CIGAR

COMBI

CON

CONT

CPU

CSD

DEF

DOHC

ECPS Ampere

Autoadjusting Suspension

Antilock Brake System

Accessory

Accelerator

Air Control Valve

Additional

Acoustic Equilibration

Air Injection System

Automatic Load Leveling

Alternator

Amplitude Modulation

Amplifier

Antenna

Autostop

Alr Supply Valve

Automatic transmission

Atmospheric Pressure

Automatic Transaxle

Air Conditioner

Air Fuel

Auto Reverse

Battery

Bypass Air Control Valve

Bilevel

$rr$:,tor

Cigarette

Combination

Conditioner

Control

Central Procassino Unit

&Id-Start Device -

Defroster

Double-Overhead Camshaft

Electronically Controlled Power

Steering ECU

EGI

EGR

ELEC

ELR

ETR

EXH

E

FICB

FM

F/S

F/I

GEN

ET

HI

H/D

I;LUMl

INT

ISC

JB

LCD

LF

k!

z Engine Control Unit

Electronic Gasoline Injection

Exhaust Gas Recirculation

Electrio

Emergency Locking Retractor

Electronic Tuner

Exhaust

Front

Fast-Idle Cam Breaker

Frequency Modulation

Feedback

Fuel lniector

Generator

Heater

High-Energy Ignition

High

Heater/Defroster

Ignition

lllumlnation

Idle-Speed Control

Joint Box

Liquid Crystal Display

Left Front

Left Hand

Low

Left Rear

Low Wave

:I, Motor

Middle

MIL

MIN Malfunction Indicator Lamp

Minute

MIX

Mixture

MPX Multiplex

ZR Manual Transmission

MTX Mechanical Tuning Radio

Manual .Transaxie PRG

PTC

P/S ass

kc

FIF

. . .

RH

RPM

!2EL

SQ

ST

SW

TCV

TEMP

TICS

TR

TWS

V

VENT

VOL

VRIS

W Middle Wave

Normally Closed

Normally Open

Overdrive

Switch Off

Switch On

Power

Pressure Regulator Control

Solenoid Valve

Purge Solenoid Valve

Positive Temperature Coefficient

Heater

Power Steering

;im&k-Start System

Recirculation

Right Front

Right Hand

Revolutions Per Minute

Right Rear

Solenoid

Squares Per Milimeter

Start

Switch

Twin Scroll Turbocharger

Solenoid Valve

Temperature

Triple Induction Control System

Transistor

Total Wiring System

Volt

Ventilation

Volume

Variable Resonance Induction

System

Watt(s)

IO

Page 192 of 279

Troubleshooting GI

Precautions to take when servicing an electrical system

l Note the following items when servicing the electrical system.

l Do not alter the wiring or electrical equipment in any way; this may damage the vehicle or cause a fire from

short-circuiting a circuit or overloading it. l

The negative (-) battery cable must be removed first and

installed last. l Do not replace with fuses exceeding specified capacity.

1OA

f5A

Zaution

o Be sure that the ignition and other switches are off

Caution

before disconnecting or connecting the battery

l Replacing a fuse with one of a larger capacity than

cables.

designated may damage components or cause a fire.

Failure to do so may damage the semiconductor

components.

0 Tape areas of the

l When mounting l Secure harnesses with provided clamps to take up slack.

harness that may rub or

components, be sure the

bump against sharp

harness is not caught or

edges to protect it from

damaged.

damage.

Zaution

B Clamp all harnesses near vibrating components

(for example, the engine) to remove slack and to

prevent contact resulting from vibration.

D Do not handle electrical components roughly or drop

them.

l Disconnect heat-

sensitive parts (for

example, relays and

ECU) when performing

maintenance (such as

welding) where

temperatures may exceed

80°C (176°F). l Make sure that the

connectors are securely

connected when

installed.

11

Page 194 of 279

Troubleshooting

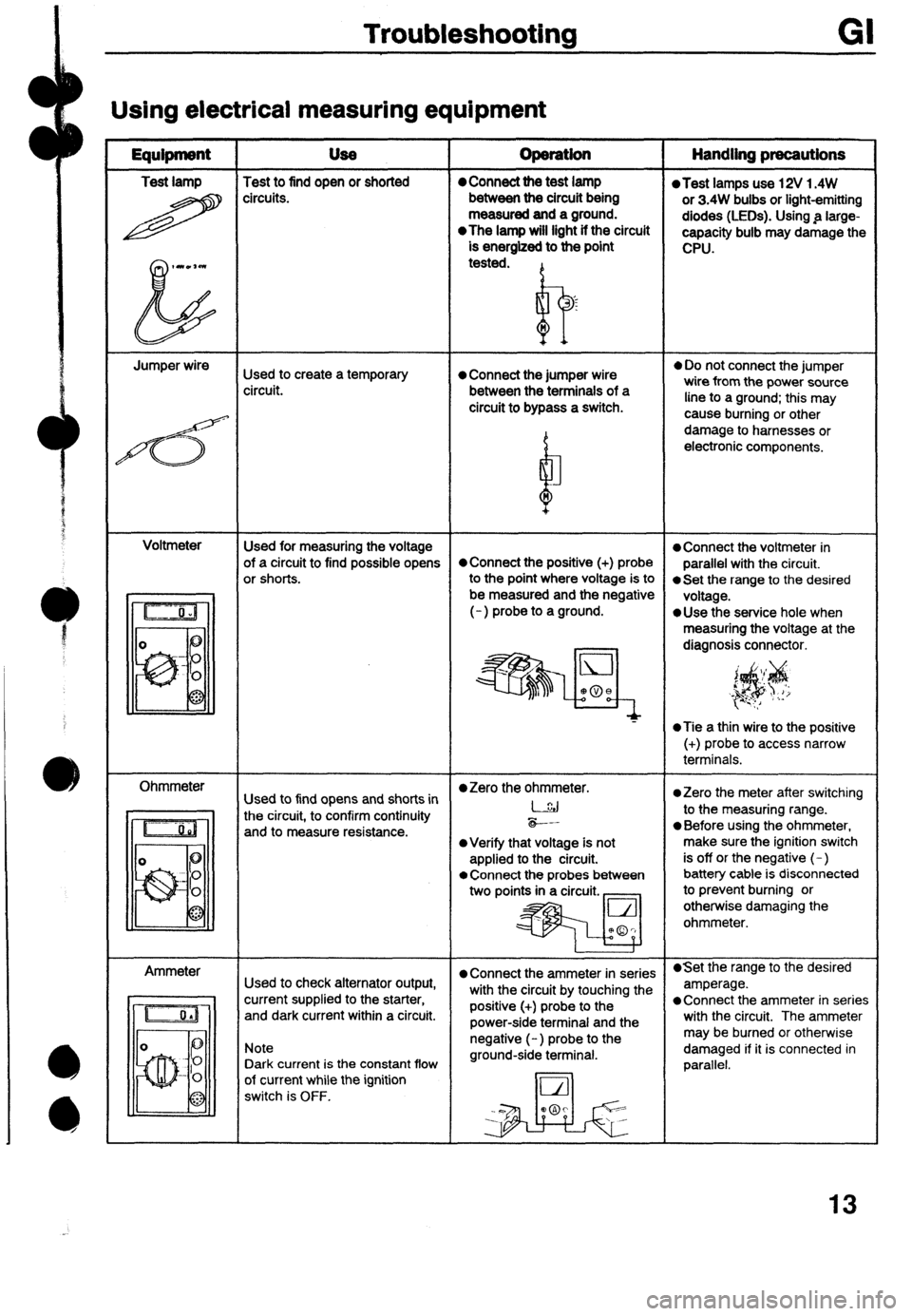

Using electrical measuring equipment

Equipment USe

Test lamp Test to find open or shorted

H circ”its. operation Handling precautions 0 Connect the test lamp l Test lamps use 12V 1.4W

between the circuit being

or 3.4W bulbs or light-emitting

measured and a ground.

diodes (LEDs). Using .a large-

l The lamp will light if the circuit

capacity bulb may damage the

is energized to the point

CPU.

tested.

I? ‘s

n

Jumper wire

Used to create a temporary 0 Connect the jumper wire

l Do not connect the jumper

circuit. between the terminals of a wire from the power source

circuit to bypass a switch. line to a ground; this may

4 cause burning or other

b damage to harnesses or

electronic components.

M

Voltmeter

Used for measuring the voltage

l Connect the voltmeter in

of a circuit to find possible opens *Connect the positive (+) probe

parallel with the circuit.

or shorts.

to the Point where Voltage is to 0 Set the range to the desired

be measured and the negative

voltage.

(-) probe to a ground.

*Use the service hole when

measuring the voltage at the

diagnosis connector.

‘$$

‘, i_ I/

*Tie a thin wire to the positive

(+) probe to access narrow

terminals.

Ohmmeter

l Zero the ohmmeter.

Used to find opens and shorts in *Zero the meter after switching

the circuit, to confirm continuity l-.&j

to the measuring range.

and to measure resistance. -*-.

0 Before using the ohmmeter,

l Verify that voltage is not make sure the ignition switch

applied to the circuit. is off or the negative (-)

l Connect the probes between battery cable is disconnected

two points in a circuit. _ to prevent burning or

otherwise damaging the

ohmmeter.

Ammeter

l Connect the ammeter in series l Set the range to the desired

Used to check alternator output,

with the circuit by touching the amperage.

current supplied to the starter,

and dark current within a circuit. positive (+) probe to the l Connect the ammeter in series

power-side terminal and the with the circuit. The ammeter

Note

Dark current is the constant flow negative (-) probe to the

ground-side terminal. may be burned or otherwise

damaged if it is connected in

parallel.

of current while the ignition

switch is OFF.

13

Page 197 of 279

GI Troubleshooting

FindIng short circuits

Shorts occur between the power (positive) and ground (negative) sides of a circuit.

Therefore, finding a short circuit requires determining how the circuit is routed.

Circuits

not connected to control unit

I

Examples

ihort location 1 SvmWom

I Battery

,pOSlhl

terminal) lgnitbn switch

I Finding short circuit

4

1. Remove the fuse and

main fuse of the circuit.

2. Disconnect ail connecton

Of electrical components in the circuit.

3. Attach a voltmeter or test

Motor

M

Qi!

Short (A)

Short (8)

Short (C)

Short (0) l The motor operates

regardless of whether the

thermoswitch is ON or OFF

when the ignition switch is ..-..

ON. -

@The fuse is not melted.

0 The main fuse melts when the

ignition switch and thermo-

switch are ON and the relay is

operating.

lgnitlon switch

Switch short locatior

Short (A)

Short (B)

Short (C) Test lamp lamp to the fuse box and

reconnect each connector, beginning

nearest the power

, source. Circuits connected to control unit

1 Examples

Symptom

l Fuse melts.

Short (D)

Short (E) 14. Check the voltmeter

reading or test lamp as

the connectors are

connected.

l solenoid A operates when the

ignition switch is ON.

l The CPU transistor burns out

when the ignition switch is

turned ON.

l The CPU thinks the switch is

ON because the same

conditions exist as when the

switch is ON.

@The CPU senses the sensor

to be 0 Q because the same

conditions exist as when the

resistance value is 0 Q.

l The CPU equipped with the

self-diagnosis function outputs

the code. l-

Finding short circuit

1. Remove the fuse and main

fuse of the circuit.

2. Disconnect ail connectors oi

electrical components in the

circuit.

rest lamp 3. Attach a voltmeter or test

lamp to the fuse box and

reconnect each connector,

beginning nearest to the

power source.

Check the voltmeter reading

or test lamp as the

connectors are connected.

Sensor/switch

1. Attach the test lamp or

voltmeter to the CPU

connector.

2. Connect to the switch/

sensor connector.

3. Check the voltmeter reading

voltmeter reads OV or the test lamp

16

Page 209 of 279

I-la1 = ENGINE CONTROL SYSTEM (l/3)

MAIN W/R (F) 0 ocrg\

m BOA JEJJS ROOM “27

rnn L’H(F-=-l ^T.^..^^-^

GNITION

I w

I I C (Fl

JB-04

I W/Y LG/Y W/B

0 (EM) (EM) (EM) (EM)

IA ID 1K lF

(SECTION n-1)

ENGINE CONTROL UNIT

7:: 81-03

IA

64) L .L (EM)

I I

I ’ W/R (EM)

B/W (RI

(EM1

I I B/R EM)

ThiCT”, l.lCIlT

II”.J / ““l~lL,Y I Ii

CLUSTER

(SECTEN cl -G/R +z::

t I I - ,- I

CONTROL SYSTEM

(SECTION B-lb)

I FUEL

B PUMP

(R)

I PUMP RELAY

~-_-, _-.. -, l-01 ENGINE CONTROL UNITtEM)

1” IS 10 10 1M 1K II IG 1E IC i&

R/B O/L G/B G * Xi/ L G/W x V L/R

BR/Y B/L B/G L/Y R/W * L/B O/B W/B W/y W/R

IV lT ,R !P fN IL 1J fH 1F 10 113

L-04 FUEL PUMP(R)

181-05 IGNITER (EM) 2H 2F 2D 28

91-06 CONDENSER (EM)

181-07 IGNITION COIL (EM)

I 8

I

-27 TRANSFER PUMP (Rl 161-28 FUEL PUMP RELAY (EM)

I

Y/L L/Y

B XL I i1-02 MAIN RELAY(E)

81-03 CIRCUIT OPENING

(FUEL INJ) RELAY (EM)

28

Page 215 of 279

1B 0 Main relay

(FUEL INJ r&y)

Ignition switch

(STARI)

1D 0 Self-Diagnosis

Checker

(monitor lamp)

I IJ 0 A/C relay

Ignition switch ON

vs

NC switch ON at idle

6&w 2 54

NC swtch OFF at Idle VB

-

‘“‘~~

System Selector test switch at

I I I

I I I 1L - - - -

- -

IM 1 - 1 - -

I - -

- 1T ThrorUe SW&X

(ii switch)

Foghghl relay

P/S pressure

switch

A/C switch

Electric coding fan

swlch

Blower control

swtch

Rear wlndow

defroster swtch

Neutral/Clutch

switches Tesl condnton

Accelerator pedal released

Accderator pedal depressed -*

B&low l.OV

Vi3

Togllghtsmtcll

Foglight switch OFF

lanitton switch ON V0

OY

VR .-

P/S pressure switch ON at tdle

P/S pressure swtch OFF at I& 6&w 1 .ov

Ye

Fan operatbng (coolant temperature over

97OC I207OF ) or diagnosis connector

Blower control switch OFF or 1st posttion

E~iower conlroi svntch 2nd or higher po-

Rear wndow defroster OFF

Rear wndow defroster ON ~~

Neutral pcsitw or clutch pedal

rlr-n -

Ignition swrlch

ON and biowtr

motor ON -

Ignition switch

ON

Ignition switch

ON

34

Page 216 of 279

Ve:BenyVdhfp

Test condttton

-roliqc lblwk

lgnhn switch ON

VI3

- bmtm

2A

28

x

2D

2E

2F

26

2H

21

2J

2K

21

2M

2N

20

2P

20

2R Test condtthw

ranabla

2s

2T

2u

2v

2W

2x

2Y

arm-up)

P

P

8°F) P

ov

ov

ov

ov

ov of sv

Approx. 2v

-

ov or 5v

tpplox. 1.5

- connected to

oveftmost warning

tluzz.af

I

I

i”e started wilh cootanl 1 Below 1.5V 1 No&ad engine 1Bo sec. alter eng

temperature is above 90% 1194°F ) and

CondilkJn

iniake air temperature is between 40%

I l@i°F) and So% (122OFj

Other condition at idle

VB

lgrition switch ON

L VE ‘Engine Signd

Idle

VFJ’ Monitor: Green

Engine speed above 2.ooO rpm during

VE and red lamps

Nash Sde”&d valve

m kw tap.)

deceteralion (alter warm-up) -

-

0 -

lanition switch ON -

-

-

-

0 lnjedor (Nos. 1. 3) -

Ignition switch ON

Idle

injector (Nos 2. 4) IgrMon switch ON

I -3 Va

I

ISC valve -

-

0

0

-

0

0

0

0

-

0

0

-

- Idle -

Lpprox. 4.01

4.!--5sv

0 of 5v Knock control unit

Engine speed above 2,GOD rf

Thio#e sensor/

Airllow mder Constant -

0 Solenoid valve

(purge conlro4) Ignition switch ON

II

-

I* I “la I

lgnitlon switch ON .-.- ._

lgnitiin swilch ON VB

-

Idle Below 1.w

210 sec. alter engine started with coolant Below 1.5V No&d engine

temperature above 90% ( 194OF) and

cofditlon

intake air temperature above 50°C

/122OF)

Other condition al idle Va - 0

0 Qrcuit-oparing

relay

sdenoid valve

(PRC high temp.) Accelerator pedal released

Accelerator pedal lully depfesw ,pprox. 0.5L

.pprox. 4.oi 22 -

1 J

Is- r,

L-7 r

2Y Zw 2U 2s 20 20 ZM 2K 21 2G 2E 2C ZA 1U IS 10 10 1M tK I, tG 1E ,C ,A

22 2X ZV 2T ZR 2P 2N 2L 2J 2H ZF 20 28 1V IT IF! ,P IN 1L 1J t” 1F 10 19 lamlion switch ON

Idle (cold engine)

Idle (alter warm-up) ov

o-l.OV

0.5-l.OV

o-0.4v

xpprox. 3.8

tipprox. 3.0

tpprox 2.5

bpprox. 2.5

Bdow 0.5v

V8 -

lncreasmg engine speed (after w

Deceleralion

lgnltro” switch ON Airllow meter -

n airflow meter intake aa

Ambient air temperalure 20°C (6

ErlQl”l? codant temperature 200(

Alter warm-up

Ignition switch ON Water

thermosensor

To&charge

rndlcator

1 I

UI “I

u-1 r

-

2Y ZW ZU ZS 20 20 2M ZK 21 2G 2E 2C ZA lU IS 10 10 1f.I 1K 11 1G 1E tC 1A

22 2X 2V 27 2P 2P 2N 2L 2J 2H ZF 2D 28 IV IT IA 1P IN IL 1.1 1H 1F ID It3

35

Page 238 of 279

NARNESS SYMBOL : z (FJ m (E) a (I) m (R) *(OFI)- (IN) ‘*t (FFi)* (EM)= (INJ)

F-2 1

/ E-12

FUSE BOX

MA,N FUSE IGNITION

SWITCH

CONNECTOR

/ / F-07 STOWGHT

LH

JOINT BOX