engine MAZDA 323 1992 Suplement Service Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 70 of 279

F3 II TURBOCHARGER CONTROL SYSTEM ‘1

1’

:j

TURBOCHARGER CONTROL

SYSTEM

TURBOCHARGER

Re’inovaf / Installation

Caution

l Be careful of the following points after turbocharger removal.

l Do not carry the turbocharger by the actuator rod or actuator hose.

l Do not drop the turbocharger.

l Set the turbocharger down with the turbine shaft horizontat.

l Cover the intake, exhaust, and oil passages to prevent dirt or other material from entering

the turbocharger.

l Use the specified new studs when installing the turbocharger.

1, Disconnect the negative battery cable.

2. Raise the vehicle and support it on safety stands.

3. Remove the undercover.

4. Orain the engine coolant.

5. Remove in the order shown in the figure, referring to Removal Note.

6. Install in the reverse order of removal, referring to Installation Note.

I-- 7.8-1 1 N-m ~80-110 kgfcm. 69-96 idbf j

3946 13.94.7, 2% 3842 13.94.3, 28-

31--46 13.2-4.7, 23-341

T, REPLACE .

12-18 1 f-2-1.8, 8.7-13 I

GASKET, REPLACE

19-26 1 t .9-2.6, 14-19 1

7.6-11 Mm t80-?lO kgfcm, 69-95 hlbfl

~-t-n 1 kgf-m, Wlbt]

13EOF3 3.31

F3-3i

Page 71 of 279

F3 TURBOCHARGERCONTROLSYSTEM

1. Radiator

2. Insulator 3. Air hose, and air pipe

4. Oxygen sensor connector

5. Front exhaust pipe

13EOF534

F3-38 6. Water hose

7. Oil pipe

8. Exhaust manifold and turbocharger

Removal Note ,.........I.....f.~.~l....... II.I.... below

Installation Note . . . . , , l.. . . . . . . , ,.. ,..*, , . . . . . . . . . below

13EOF3-339

Removal Note Exhaust

manifold and turbocharger 1. Remove the exhaust manifold and the turbocharger as an

assembly.

2. Separate the turbocharger assembly from the exhaust

manifold.

Installation Note

Exhaust manifold and turbocharger’ I I Remove .all old gaskets and

sealant. 2. Install new gaskets.

3. Supply 25 cc ( 1.5 cu in ] of oil through the oil passage

of the turbocharger.

4. Mount the turbocharger assembly to the exhaust manifold.

5. Install the turbocharger and the exhaust manifold assem-

bly to the engine and loosely tighten the nuts.

6. Install the bracket and the front exhaust pipe, and tighten

the turbocharger mounting nut%

WASTEGATE SOLENOD VALVE

Caution

l The wastegate solenoid valve must be replaced with

the turbocharger, it cannot be replaced by itself.

Inspection 1. Disconnect the connector.

2. Measure the resistance of the solenoid valve.

Resistance: 35-45 !‘l (at 20°C f68OFj) 3. M not as specified, replace the wastegate solenoid valve and

turbocharger as an assembly, if necessary.

(Refer to page F3-37.)

3. Instc

Page 74 of 279

FUEL SYSTEM F3

13EOF3.34

c I 13EOF3-364 FUEL PUMP CONNECTOR

/

!NSTALL CLAMPS

I

l nspection

1, Disconnect the resistor/relay connector.

2. Ground the fuel pump resistor relay terminal D.

3. Apply battery voltage and check for continuity as shown.

Terminal C

Continuity between A and I3

Battery voltage applied NO

ov Yes

4. Measure the resistance between terminals E and F.

Resistance : 0.38--0.42Q (at 2O*C {6S°F 1)

PRESSURE REGULATOR

Inspection

Fuel line pressure

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page F3-21.)

1. Disconnect the negative battery terminal.

2. Connect a fuel pressure gauge between the fuel filter and

the fuel main hose. (install clamps as shown.) , .

I

3. Connect the negative battery terminal.

/t.

4, Start the engine and run it at idle.

5. Measure the fuel line pressure.

Fuel line pressure:

206-255 kPa [ 2.1-2.6 kgflcml, 30-37 psi )

6. Disconnect the upper vacuum hose from the pressure regu-

lator and measure the fuel line pressure.

Fuel line pressure:

304-392 kPa (3.1-4.0 kgf/cm2, 44-57 psi )

F3-41

Page 76 of 279

. !I11

PRESSURE REGULATOR CONTROL SYSTEM F3

13EOF3353

(PRC HIGH TEMP.)

13EOF3-35:

BAl-fERY VOLTA

PRESSURE REGULATOR CONTROL

SYSTEM

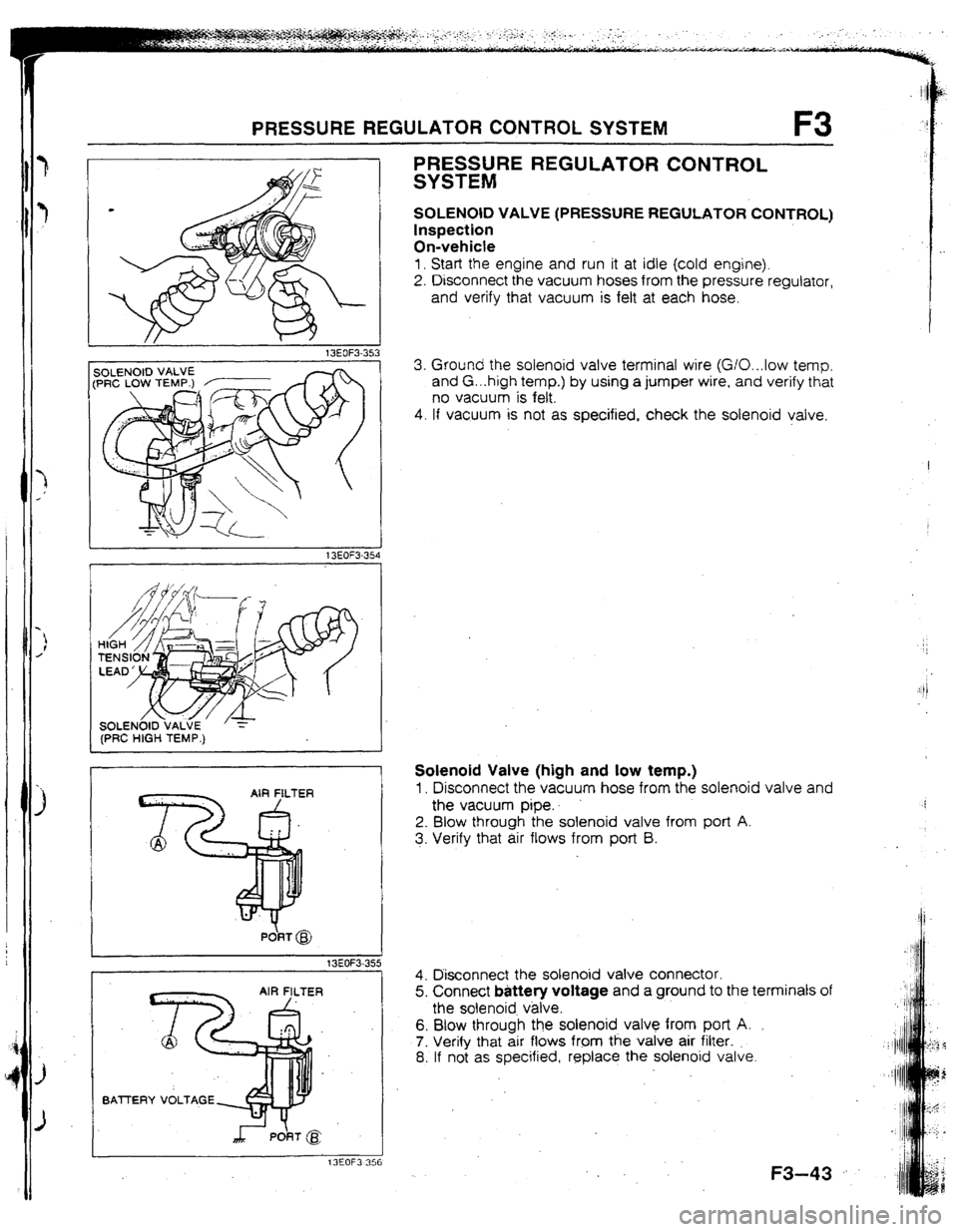

SOLENOID VALVE (PRESSURE REGULATOR CONTROL)

Inspection

On-vehicte

1. Start the engine and run it at idle (cold engine).

2. Disconnect the vacuum hoses from the pressure regulator,

and verify that vacuum is felt at each hose.

3. Ground the solenoid valve terminal wire (G/O...low temp.

and G. ..high temp.) by using a jumper wire, and verify that

no vacuum is felt.

4. If vacuum is not as specified, check the solenoid valve.

Solenoid Valve (high and low temp.)

1, Disconnect the vacuum hose from the solenoid valve and

the vacuum pipe..

2. Blow through the solenoid valve from port A.

3. Verify that air flows from port B.

4. Disconnect the solenoid valve connector.

5. Connect battery voltage and a ground to the terminals of

the solenoid v&e.

6. Blow through the solenoid valve from port A.

7. Verify that air flows from the valve air filter.

8. If not as specified, replace the solenoid valve.

.

F3-43

Page 78 of 279

CONTROL SYSTEM F3

hT==TdI ,

USE CONNECTOR A 1

L

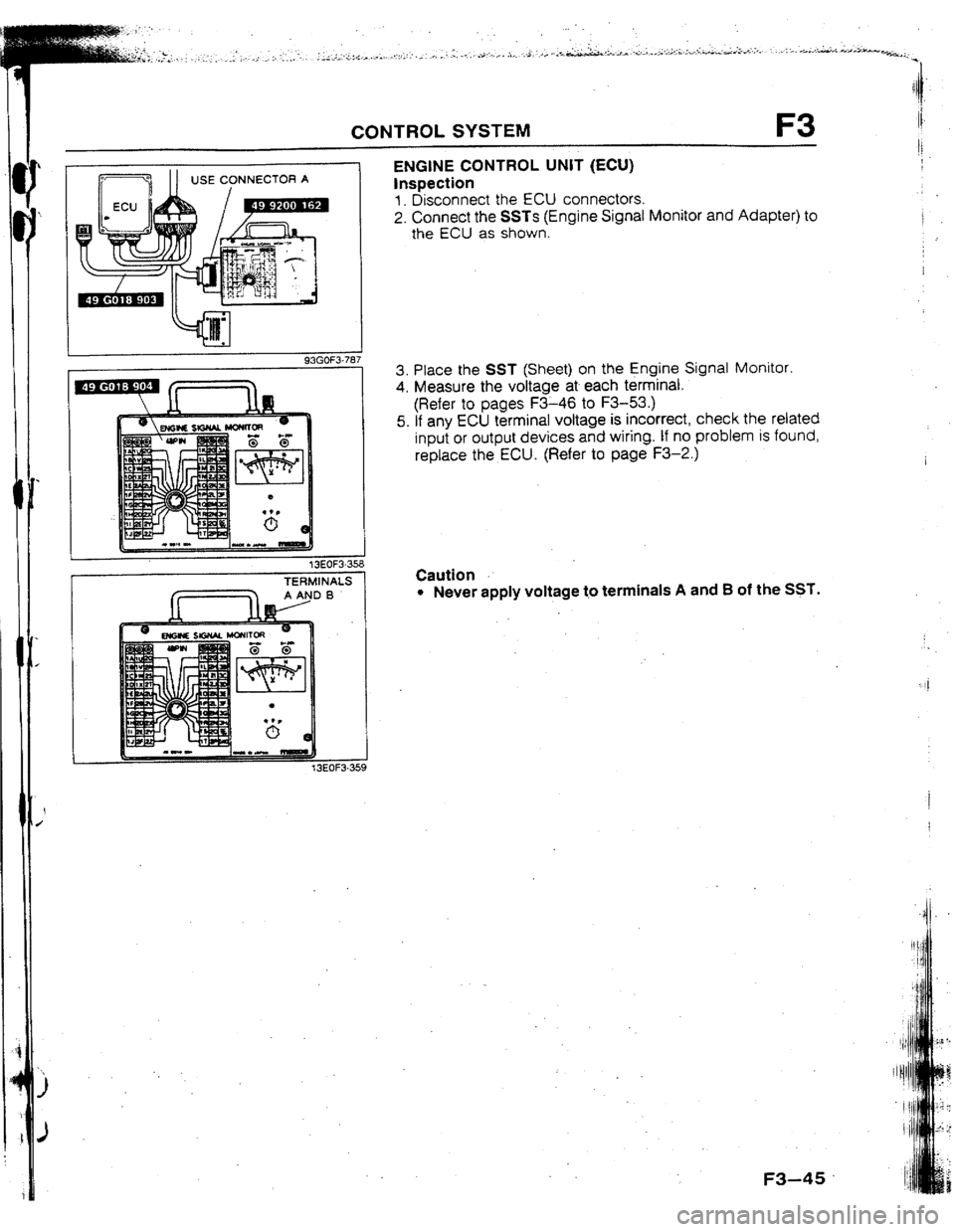

93GOF3-787 ENGINE CONTROL UNIT (ECU)

Inspection

1. Disconnect the ECU connectors.

2. Connect the SSTs {Engine Signat Monitor and Adapter) to

the ECU as shown.

3. Place the SST (Sheet) on the Engine Signal Monitor.

4. Measure the voltage at each terminal.

(Refer to pages F3-46 to F3-53.)

5. If any ECU terminal voltage is incorrect, check the related

input or output devices and wiring. If no problem is found,

replace the ECU. (Refer to page F3-2.)

t

1 13EOF3-358

r

TERMINALS

f. -I AANDB . Caution l Never apply voltage t.o terminals A and 8 of the SST.

! :OF3-359

F3-45

Page 79 of 279

F3 CONTROL SYSTEM

Terminal voltage

Reference date

Vs: Battery voltage

‘em&al Input Output Connected to Test condition Correct voltage Remark

1A - - Battery Constant VB

For backup

18 0 Main relay

Ignition switch OFF ov

(FUEL INJ relay) -

ON

V8

1C 0 lgnitlon switch While cranking Approx. 1 OV

(START) -

Ignition switch ON ov

10 0 Self-Diagnosis Test switch at SELF TEST

Wtth Self-

Checker Lamp illuminated for 3 sec. after ignition Approx. 5V

(monitor lamp) switch OFFdON Diagnosis Check-

er and System

lamp not iltuminated after 3 sec. V8 Selector

Test switch at 02 MONITOR with engine

idling Approx. 5V

Monitor lamp illuminated

Test switch at 02 MONITOR with engine

idling Vi3

Monitor lamp not illuminated

IE - - - - - -

IF

0 Self-Diagnosis Buzzer sounded for 3 sec. after ignition

Below 2SV

l With Seif-

Checker switch OFF-+ON

Diagnosis

(service code)

Buzzer not sounded after 3 set V0 ’ Checker and

Buzzer sounded Below 2.5V System Selector

l With System

Buzzer not sounded VB Selector test

switch at SELF

TEST

1G 0 igniter tgnition switch ON

ov

-

Idte

Approx. 0.2V

It-l 0

Solenoid valve Ignition switch ON

VB

(wastegate)

Idle

Approx. 2V ’ -

II

0 Fuel pump While cranking

Approx. 1 OV

resistor/relay -

Idle

8etow 1.5V

IJ 0 NC relay Ignition switch ON

VB

A/C switch UN at idle

Below 2.5V

. NC switch OFF at idle V3

-

IK 0 Diagnosis

connector

(TEN terminal) System Selector test switch at

02 MONITOR

System Selector test switch at

SELF TEST V0

-

8elow l*OV

1L - - - - - -

I

1M - - - - -

I -

lr ‘- l-7

f L.-

r

20 20 2M 2K 21 2G 2E 2c 2A IU 1S 10 10 ltvl tK II Ir; tE 1~ IA

1

22 2x 2v 2T ZR 2P 2N 2L 25 2H 2F 20 2B 1V IT 1R tP 1N IL 1J 1H IF 1~ 1~

1

J=3-46 --

4lways 4

--

AIways 4

--

Atways 1

--

Always 1

-a

Always ’

--

Always i

-e

Always I

2.5v

Always

Always (

-m

Always f

-a

Always 1

Always (

--

Always I

2.5V

Always 1

Always t

Always

--

Page 83 of 279

F3 CONTROL SYSTEM

Vs: Battery voltage

‘erminat Input Output Connected to Test condition

Correct voltage Remark

2A’ - - Ground (i nlector) Constant CIV -

26 - - Ground (output) Constant ov -

2C - - Ground (CPU) Constant ov -

2D - - Ground (input) Constant ov -

2E 0 Distributor Ignition switch ON QV or 5v

{NE-slgnal) -

f

r ldte

Approx. 2V

2F - - - -

- -

2G 0 Dstributor Ignition switch ON

ov or 5v

(G signal)

ldte Approx. 1.5V

a-l -I- - -

- -

21 - - - - - -

23 0 Knock control unit Idle Approx. 4.W -

I

2K 0 Throttle sensor/ Constant 4.5--5SV

Airflow meter

-

2L cl

2M 0 Speedometor

sensor

Throttle sensor Ignition switch UN

Accelerator pedal released

Accelerator pedal fully depressed 0 or 5V

Approx. 0.W

Approx. 4.W

-

2N 0

20 0

2P 0

2Q 0

2R Oxygen sensor Ignition switch ON ov

Idle (cold engine) ov

Idle (after warm-up) o- 1 .ov -

Increasing engine speed (after warm-up) 0.5-l .ov

Deceleration o--0.w

Airflow meter ignition switch ON Approx. 3.W

-

Idle Approx. 3.OV

Intake air Ambient air temperature 2O*C (68*F) Approx. 2.5V In arrflow meter

thermosensor

Water Engine’cooiant temperature 20°C (68OF) Approx. 2.W

thermosensor -

After warm-up Below 0.5V

0 Turbocharge Ignition switch ON VS

indicator -

7

r u-l 7 c Ul I-'

2y ?A’ 2u 25 20 20 2M 2K 21 ?G 2E 2C 2A 1u 1s 10 10 1M ?K 11 1G 1E 1C 1A

22 2x zv 2T 2R 2P 2N 2L 2J 2H 2F 20 28 1V 1T tR tP 1N IL 1.1 1~ qF 10 1~

F3-50

L --

4b&e (

--

Alway:

-a

--

Always

--

--

--

Always

--

Always

--

Below L

-I

--

Always

--

Alway:,

Alway:;

Alway:;

--

Alway:;

--

Always

--

Always

--

Always

Always

Page 85 of 279

F3 CONTROL SYSTEM

Terminal Input Dutpui

2s - 0

2T 0

2U 0

2v 0

2w 0

2x 0

2Y 0

22 0 t

I, Ve: Battery voltage I I I Connected to Test condition

Correct voltage Remark

Overboost warning lgnitron switch ON

VB

-

buzzer

Solenoid valve

(PRC low temp.) 180 sec. after engrne started with coolant Below 1.W No-load engine

temperature is above 9O*C { 194*F ] and condition

intake air temperature IS between 40°C

1104*FJ and 50°C {122OF

f Other condition at idle

I VS

tnjector {Nos. 1, 3) Ignition switch ON VS

Idle V0’

I Engine speed above 2,000 rpm during

I Ve

deceleration (after warm-up)

Injector (Nos 2, 4) Ignition switch

ON VS

Idle VS’ * Engine Signal

Monrtor: Green

and red lamps

flash

ISC valve Engine speed above 2,000 rpm during VS

deceleration (after warm-up)

Ignition switch ON Approx. 7V

-

Idle 1 Approx. 9V

Solenoid valve

(purge control) Ignition switch ON

Idle V0

-

VB

Ci rcuit-opening

relay ignition switch ON

tdle 1 VB

I 8elow l.OV -

Solenotd valve

(PRC high temp.) 210 sec. after engine started wrth coolant Below 1.5V

temperature above 90°C ]194*F] and

Intake atr temperature above 50°C

f t22*F1 No-load engine

cond$on

1 Other condition at idle

I VB

I -

7 I PI

I l-1 t

r

2'f 2W 2U 25 iQ 20 &A 2K 21 2G 2E 2C 2A 1U 1s 10 10 1M 1K 11 tG If 1C 1A

F3-52 --

A/w&

--

Alway

--

Alway

--

Alway

--

Alwaj

--

Alwa f

--

Alwas]

--

Alwa I’

Page 87 of 279

ENGINE ELECTRICAL SYSTEM

OUTLINE ................................................... G- 2

SPECIFICATIONS .................................... G- 2

SUPPLEMENTAL SERVICE tNFORMATlON .m G- 2

13EOGX-30 t

G

Page 88 of 279

G OUTLINE, SUPPLEMENTAL SERVICE INFORMATION

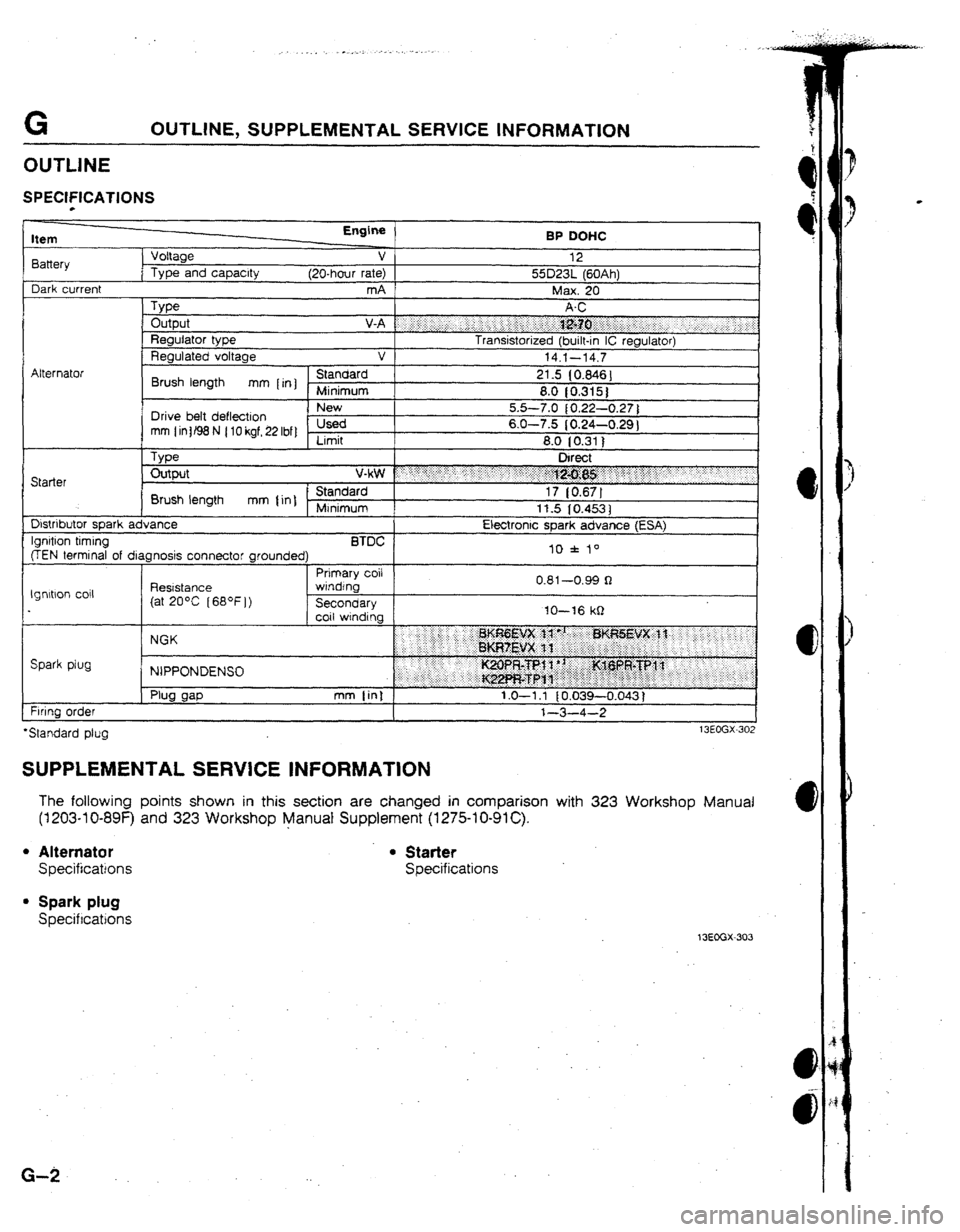

SPECIFfCATfUNS

Item

8attery

Dark current Voltage

Type and capacity Engine

v

(20-hour rate)

mA BP DOHC

12

55D23L (60Ah)

Max. 20

Type Output V-A f “‘i j.,: i .:.. ‘:.. ,, j j.: i.‘: ;:;:i :j;&?.:. .: .:.

__ : . . s.i-....‘:‘:. _.. j ;.’

Regulator type Transistorized (built-in IC regulator)

Regulated voltage v

14.1-14.7

I

C?*..*rlrrrl

Brush length mm [rn] }e 21.5 (0.846)

8.0 10.315)

I Drive belt deflection I 5.5-7.0 { 0.22-0.27 )

mm (intB8N (lOkgf,22Ibf) usea 6.0-7.5 (0.24-0.29 1

Limit 8.0 (0.311

, Type Direct

Starter Output v*$# : : ;..;. ‘:‘.. ._ .; : :‘: 7.:

.. .::“:.:j 1 ,5

. . . . .j$$g;g$y .“. :yy

Brush length mm {in] - Standard 17 [0.67]

Minimum

11.5 IO.4531

Dlstnbutor soark advance Electronic soark advance (ESA)

@EN termind of diagnosis connector grounded) II) f lo

I 1 Prtmary coil

**4 nn*

Ignltbon co11 Reststance 3

(at 20°C [68*F])

in IO-16 kQ lgnrtlon timing BTDC f ar

wrndfnb

I

Secondary 1

coil WindIn.. v.0 I

--v.yy 1

Spark plug NGK

NIPPONDENSU

Firing oraer

*Standard pfug

SUPPLEMENTAL SERVICE INFORMATION

The following points shown in this section are changed in comparison with 323 Workshop Manual

(1203-l O-89F) and 323 Workshop Manual Supplement (I 275-l O-91 C).

l Alternator . Starter

Specifications Specifications

l Spark plug

Specifications

13EGGX-303

G-2