fuel filter MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 22 of 279

SCHEDULED MAINTENANCE SERVICES A

SCHEDULED MAINTENANCE SERVICES

MAINTENANCE TABLE

Chafi symbols:

1 : Inspect: Visual examination and/or functional measurement of system’s operation or

performance , A: Adjust: Examination resulting in adjustment or replacement

n

R: Replace or change

T: Tighten

REMARKS

After 80,000 km or 48 months, continue to follow the described maintenance at the recommended intervals.

As for * marked items in this maintenance chart, note the following points.

+ 1 Major service interval at 12 months/20,000 km (12,000 miles).

Lubrication service based on distance only 10,000 km (6,000 miles) not time.

l 2 Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

if equipped.

‘3 Replacement of the timing belt is required at every 100,000 km (60,000 mile). Failure to replace the tim-

ing bett may result in damage to the engine.

‘4 tf the vehicle is operated under any of the following conditions, it is suggested that the engine oil and

oil filter be changed more often than the recommended intervals.

a) Driving in dusty conditions. I

:

b) Extended periods of idling or low speed operation. i

i!

c) Driving for a prolonged periods in cold temperatures or regularly driving onty short distances.

*5 If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often

than at usual recommended intervals.

l 6 This IS a full function check of all electrical systems, i.e, atl

ltghts. washers (including condition of blades)

electric windows, sunroof, horn etc.

‘7 Replace every two years. $1

‘I

If there has been continuous hard driving, mountain

drivtng, or if the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the-emission control and relat-

ed system, as well as for efficient engine operation. It is strongly recommended that all servicing related

to these systems be done by your Authorised Mazda Dealer.

13EOAX-302 -4

I!

A-3

Page 23 of 279

A SCHEDULED MAtNTENANCE SERVtCES (Europe)

Maintenance Number of months or km (miles), whichever comes first

Months” - 6 12 18 24 30 36 42 48

Kllometers 1,000 10,000 20,000 30,000 40,000 50,000 60,000 70,000 80,000

{Miles)

(600) (6,000) f[t2,000) (18,000) (24,000) (3U,OOO) (36,000) (42,000) {48,000), Engine

Intake and exhaust manrfold nuts (Bolts)

Drive belts”

i Engine trmlng beltW3

Engine oil (Turbo)‘4

01 filter

l *

Cool!ng system (Includtng

coolant level adlustment)

Engrne coolant T T T

A A A

A A

Replace every 100,000 km (60,000 miles)

Replace every 5,000 km (3,000 miles) or 6 months

R R R R R 1 R R R

I I I I

I

Replace every 2 years Fuel system

Idle speed

Air cleaner element * 5

Fuel

falter

Fuel Ilnes and hoses Ignition system

A f 1

I R I R

R R

I I f t I ~

lnlttal rgnrtloh trmlng 1 I I I I I I I I

Spark plugs A

A. A A

Spark plugs (Only for Sweden) Adjust every 30.000 km (t8.000 mrls) Evaporative emission control system

Throttle sensor Throttle sensor (Only for Sweden)

Evaporative system

Evaporatrve system (Only for Sweden) 1 A 1 1 A 1 1 A 1 ) A

Adjust every 80,000 km (48,000 miles)

1 I 1 1 I’ 1 1 I 1 1 I

Inspect every 80,000 km (48,000 mites) Electrical system

Battery electrolyte level and specific gravity 1 I f I I I

All Electrical system

l ’ 1 I

I 1 I I I

1 . 1 I I

Headlight alrgnment 1 A A A . A. Chassis and body

t 3EOAX-303

A-4 Chas

SW31 Rear

Tires

Hing

Seat

Page 37 of 279

F3 OUTLINE

OUTLINE

OUTLINE OF CONSTRUCTION

Theefuel and emission control system of the new 323 4WD model 1s basically the same as that of the prevr-

ous 323 4WD model; however some parts are changed. The changed parts and interchangable parts

are shown betow.

13EOF3-304

Changed parts

1 ~ components Contents and purpose Reference pagl

INTAKE AlR

SYSTEM Turbocharger

Intercooler

l Size Increased for greater boost pressure l Wastegate solenord valve IS lozated on Intake port of F3-10

turbocharger to make system more compact F3-37

Volume increased for Improved F3-10

t F3-39

Wastegate sojenold valve

l Wastegate solenoid valve changed to duty solenoid

type for Increased engine power and response

l Wastegate solenoid valve is located on Intake port of

turbocharger to make system more compact F3-1 f

F3-38

I r

Pressure regulator One-stage operattlon changed to two-stage operatron F3-14

to improve hot restarting f3-41

L

FUEL SYSTEM High-ohmic type change to low-ohmrc type with exter-

Fuel qector na solenoid reslstor for improved fuel supply during F3-12

high-speed driving F3-42

Fuel pump reslstor Resistance reduced for

surer fuel supply F3-40

CONTROL

SYSTEM Pressure

regulator control system

Atr flow meter Two-stage operatton used to Improve hot restarting

Measures larger amount of air flow Increased power

Resistance values changed F3-t4

F3-43

F3- 9

f3EOF3-305 lnterchangable parts

tntake air system

l

Air valve

l Air bypass valve

l Air cleaner

l Air cleaner element

Fuel system

l Fuel filter assembly

l Fuel pu.mp (transfer

l Fuel vapor valve Control system

. l Throttle sensor

l Water thermosensor

l Knock sensor and control unit

l Oxygen sensor

l Fuel pump control unit

l Main relay

l Circuit opening relay

l Check valve (two-way) .

Evaporative system

l Charcoal canister

l Check valve (two-way)

13EOF3-306

F3-4

Page 38 of 279

CHECK VALVE SOLENOID VALVE

(PURGE CONTROL)

llll

*

SOLENOID VALVE

(PRC LOW TEMP.)

3 ~NTERCOOLERII’ I ,‘/ I

II II

’ f frrmvmlHHt-----lHt I -1 II II

IIt - --M:l, i -KNmK~[I~ ,

’ ISC VALVE

VALVE WATER CHAkCOAL

CANISTOR

CHECK VALVE

I FUEL FUEL FILTER

PUMP

I FUEL FILTER

TRANSFER

PUMP

AIRkLOW METER

(WITH INTAKE AIR THERMOSENSOR)

DISTRIBUTOR

CATALYTIC CONVERTER

l TO ENGINE CONTROL UNIT

Page 42 of 279

OUTLINE F3

SPEClFiCATlONS

Iten

Idle speed’

tgnltion trming * Engine

m

BTDC BP TURBO

800 f 50

IO f 10

Fuel pump

Maximum output pressure kPa { kgflcm’, psi 1 1 490-736 {SO-7.5, 7t-110)

Transfer pump

Maximum output pressure

Fuel filter kPa { kgf/cm2, psi ) 1 , 39 10.4, 5.7 1 or higher

Nylon element (in fuel pump)

Idle-speed control (fSC) valve

Type

Resistance I Rotary

nt

11-13 [at 2O*C [68*F)]

Solenoid va tve (purge contra I)

,I

Resistance -2o*c I -4Of 1 14.6-I 7.8

2.21-2.69

.kQ , 2o”c { 68OF)

40% f104*f 1 1.0-l .3

Resistance

Fuel tank

Capacity

Air cleaner

Etement type

Fuel

Specification L {US gal, Imp gal) [ Approx. 6 [at 20°C f 68*FJ]

60 (15.9, 13.2)

01 permeated

Unleaded premium (RON 95 or higher)

11FrlC?.7 11

l TEN terminal of diagnosis connector grounded.

The I; mark indicates newly equipped Parts. l”L”l “VI I

F3-9

Page 58 of 279

TROUBLESHOOTING GUIDE F3

4 CRANKS NORMALLY 8UT WILL NOT START (PARTfAL COMBUSTION) - AFTER WARM-UP

&RIP-

l Engine cranks at nurmal speed and shows partial combustion but will not Continue running after being hot

soaked

FION

l Battery in normal condltlon

*Engine starts normally when cold

TROUBLESHOOTING

HINTS] 3 Air/Fuel mixture too rich @ Vaporlock

ssure not held in fuel line after engrne IS

GND mth jumper wire tor 3

minutes with ignition

Fuel

line pressure: 265-314 kPs (2.7-3.2 kgflcm2, 38-46 psi 1

c3 If pressure

quickly increases,

check pressure regulator

4 If pressure

gradually increases,

check fuel line and filter lor

clogging

If hose is not clogged. check fuel

pump maximum pressure

High pressure Check if fuel return hose is clogged or

restricted

INSTALL CLAMPS e If rt is not, replace pressure

regulator

@ It It 6. repalr or replace it CT page F3-3

F3-25

Page 74 of 279

FUEL SYSTEM F3

13EOF3.34

c I 13EOF3-364 FUEL PUMP CONNECTOR

/

!NSTALL CLAMPS

I

l nspection

1, Disconnect the resistor/relay connector.

2. Ground the fuel pump resistor relay terminal D.

3. Apply battery voltage and check for continuity as shown.

Terminal C

Continuity between A and I3

Battery voltage applied NO

ov Yes

4. Measure the resistance between terminals E and F.

Resistance : 0.38--0.42Q (at 2O*C {6S°F 1)

PRESSURE REGULATOR

Inspection

Fuel line pressure

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page F3-21.)

1. Disconnect the negative battery terminal.

2. Connect a fuel pressure gauge between the fuel filter and

the fuel main hose. (install clamps as shown.) , .

I

3. Connect the negative battery terminal.

/t.

4, Start the engine and run it at idle.

5. Measure the fuel line pressure.

Fuel line pressure:

206-255 kPa [ 2.1-2.6 kgflcml, 30-37 psi )

6. Disconnect the upper vacuum hose from the pressure regu-

lator and measure the fuel line pressure.

Fuel line pressure:

304-392 kPa (3.1-4.0 kgf/cm2, 44-57 psi )

F3-41

Page 159 of 279

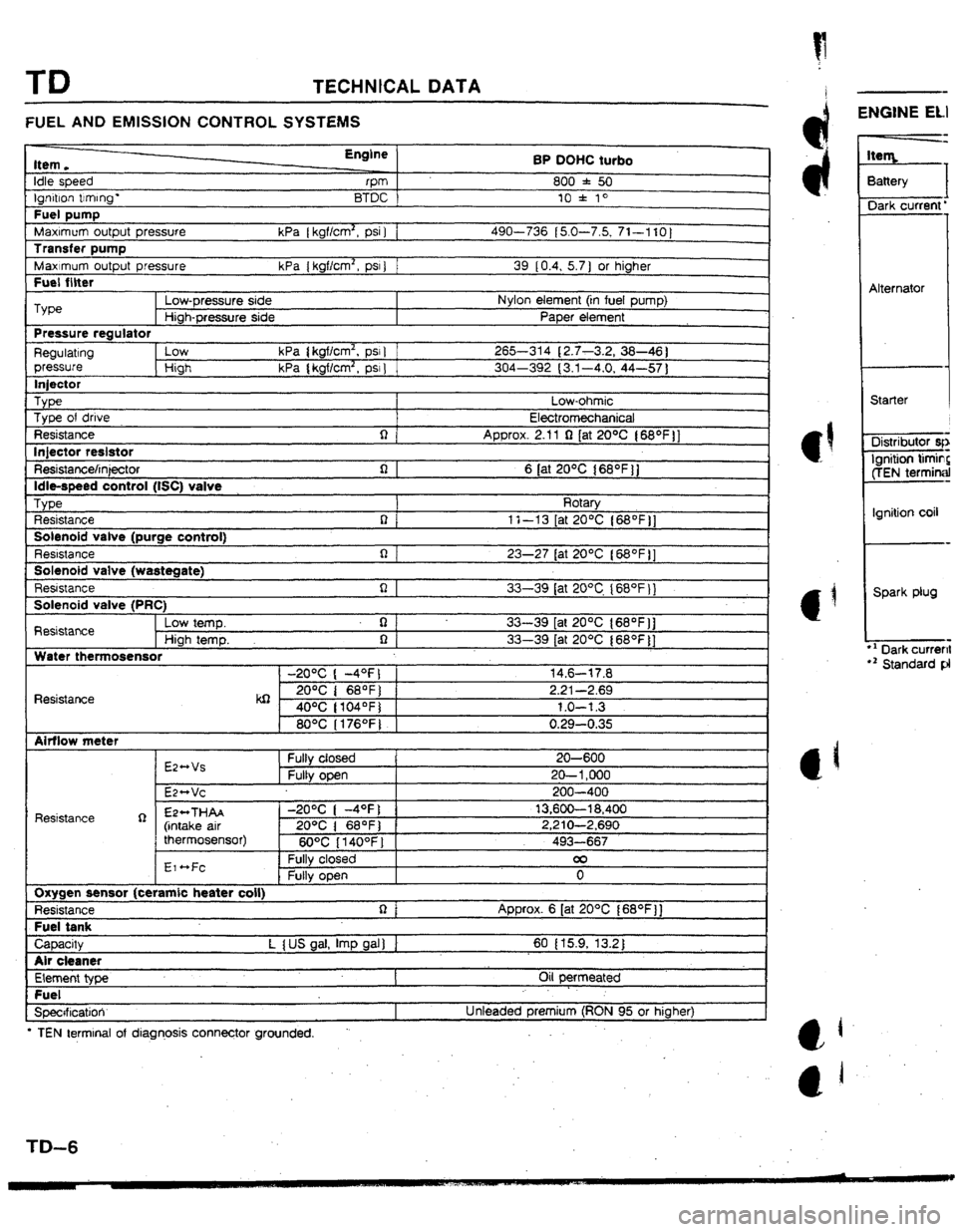

TO TECHNICAL DATA

FUEL AND EMISSION CONTROL SYSTEMS

Item.

Idle speed

tgf-don trrmng-

Fuel pump

MaxImum output pressure

Transfer pump

Maximum output pressure

Fuel filter Engine

rPm

BTDC

kPa [ kgf/cm2, psi 1 1

kPa { kgflcm2, PSI ) 1 BP OUHC turbo

800 f 50

10 l 10

490-736 (5.0-7.5, 71-1 IO]

39 10.4, 5.7 ) or higher

I Type

Low-pressure side Nylon element (in fuel pump)

Hiah-Dressure side PaDer element

Pressure regulator

Regulating low kPa ( kgflcm2, psr 1 265-314 (2.7-3.2, 38-46 1

pressure High kPa { kgflcm2, psr 1 304-392 (3.1-4.0, 44-57 1

lniector

_ Type Low-ohmic

Type of drive

Electromechanical

Resistance q

Approx. 2.11 Q (at 20% ( 68*f )]

lniector reslstor

L - Resistance/injector

Idle-speed control (tSC) valve

TvDe n 1 6 [at 20°C 168OFjj

I Rotarv

Resistance

Solenoid valve (purge control)

Resbstance

Solenoid valve {wastegate)

Resistance n(

R I

i-l I 1 t-13 [at ZO*C {68OF j]

23-27 tat 20°C l68OFll

. r.

33-39 lat 20°C I68OF 11

Solenoid valve (PRC)

Resistance Low temp. q

33-39 [at 2O*C {SS*F]]

High temp. 0 1 33-39 [at 20°C (68OF]]

Water thermosensor

-20°C ( -4OFJ 1 14.6-17.8

Resistance kQ 2o”c I 68OF) 2.21-2.69

40°C ( tO4OF) 1.0-l 3

80°C I176OFJ 0.29-0.35

Airflow meter

Resistance R E244Vs

E2*Vc Fuity closed

Fully open I 20-600

20- 1,000

200-400

EP++THAA

(intake air

thermosensor) -2O*C ( -4OFj 1 13,600-l 8,400

20% 1 68OF) 1 2,210-2,690

6O*C 114OOFl i 493-667

EI ~Fc

I Fully closed 00

0 1

Oxygen sensor (ceramic beater coil)

Resistance

Fuel tank Approx. 6 [at 20°C f68OF)]

I CaDacW L I US oal. ImD aal I I 60 I 15.9, 13.2 I

I

Air cleaner

Element type

Fuel

Specrficatioir Oil permeated

Unteaded premium (RON 95 or higher)

l TEN terminal of diagnosis connector grounded. .

-

ENGINE ELI

3attery

I

Dark current’

Alternator

Starter

Distributor qr

Ignition timin?

ffEN terminal

Ignition coil

Spark plug

l ’ Dark current

r2 Standard pl