engine MAZDA 323 1992 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 159 of 279

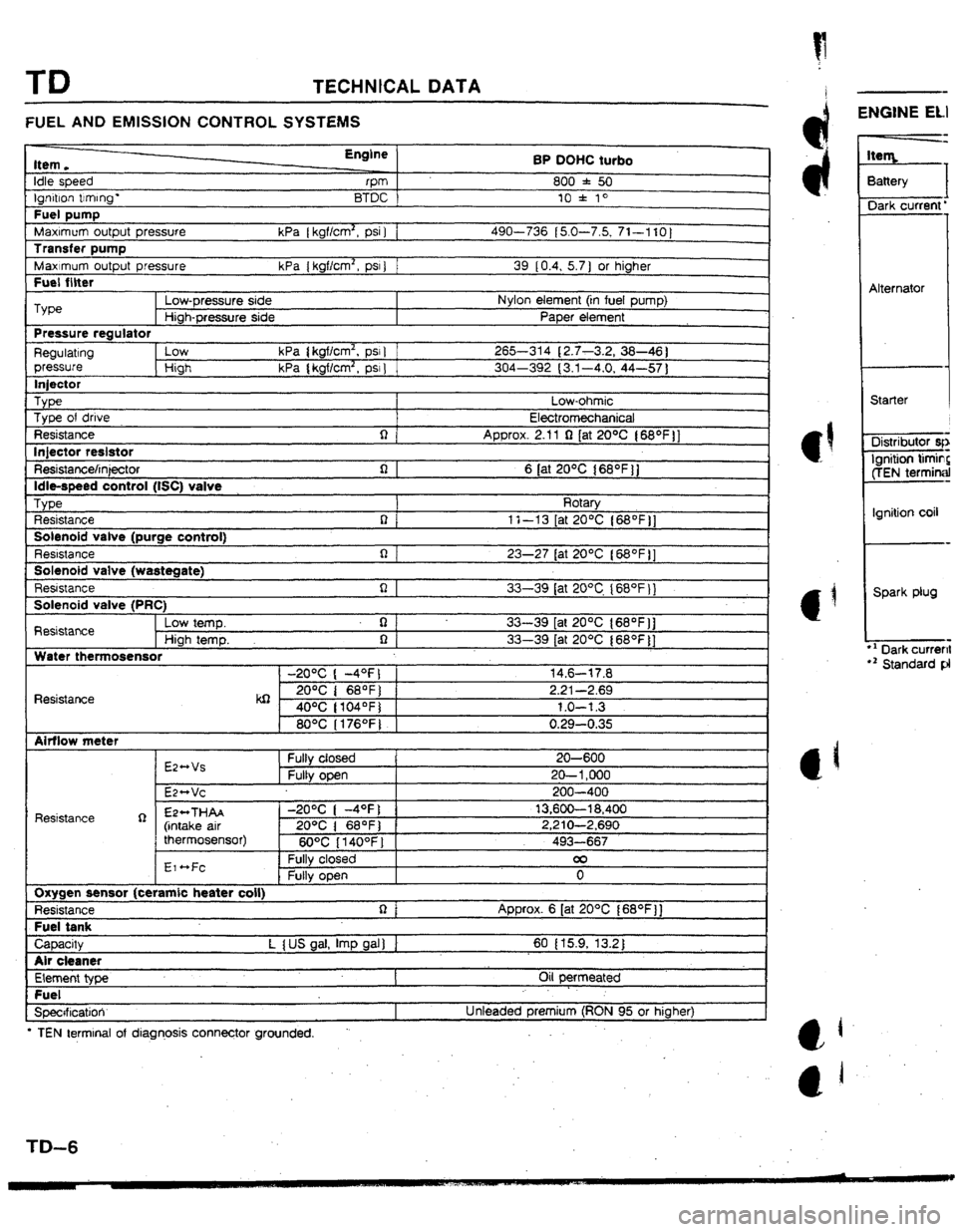

TO TECHNICAL DATA

FUEL AND EMISSION CONTROL SYSTEMS

Item.

Idle speed

tgf-don trrmng-

Fuel pump

MaxImum output pressure

Transfer pump

Maximum output pressure

Fuel filter Engine

rPm

BTDC

kPa [ kgf/cm2, psi 1 1

kPa { kgflcm2, PSI ) 1 BP OUHC turbo

800 f 50

10 l 10

490-736 (5.0-7.5, 71-1 IO]

39 10.4, 5.7 ) or higher

I Type

Low-pressure side Nylon element (in fuel pump)

Hiah-Dressure side PaDer element

Pressure regulator

Regulating low kPa ( kgflcm2, psr 1 265-314 (2.7-3.2, 38-46 1

pressure High kPa { kgflcm2, psr 1 304-392 (3.1-4.0, 44-57 1

lniector

_ Type Low-ohmic

Type of drive

Electromechanical

Resistance q

Approx. 2.11 Q (at 20% ( 68*f )]

lniector reslstor

L - Resistance/injector

Idle-speed control (tSC) valve

TvDe n 1 6 [at 20°C 168OFjj

I Rotarv

Resistance

Solenoid valve (purge control)

Resbstance

Solenoid valve {wastegate)

Resistance n(

R I

i-l I 1 t-13 [at ZO*C {68OF j]

23-27 tat 20°C l68OFll

. r.

33-39 lat 20°C I68OF 11

Solenoid valve (PRC)

Resistance Low temp. q

33-39 [at 2O*C {SS*F]]

High temp. 0 1 33-39 [at 20°C (68OF]]

Water thermosensor

-20°C ( -4OFJ 1 14.6-17.8

Resistance kQ 2o”c I 68OF) 2.21-2.69

40°C ( tO4OF) 1.0-l 3

80°C I176OFJ 0.29-0.35

Airflow meter

Resistance R E244Vs

E2*Vc Fuity closed

Fully open I 20-600

20- 1,000

200-400

EP++THAA

(intake air

thermosensor) -2O*C ( -4OFj 1 13,600-l 8,400

20% 1 68OF) 1 2,210-2,690

6O*C 114OOFl i 493-667

EI ~Fc

I Fully closed 00

0 1

Oxygen sensor (ceramic beater coil)

Resistance

Fuel tank Approx. 6 [at 20°C f68OF)]

I CaDacW L I US oal. ImD aal I I 60 I 15.9, 13.2 I

I

Air cleaner

Element type

Fuel

Specrficatioir Oil permeated

Unteaded premium (RON 95 or higher)

l TEN terminal of diagnosis connector grounded. .

-

ENGINE ELI

3attery

I

Dark current’

Alternator

Starter

Distributor qr

Ignition timin?

ffEN terminal

Ignition coil

Spark plug

l ’ Dark current

r2 Standard pl

Page 160 of 279

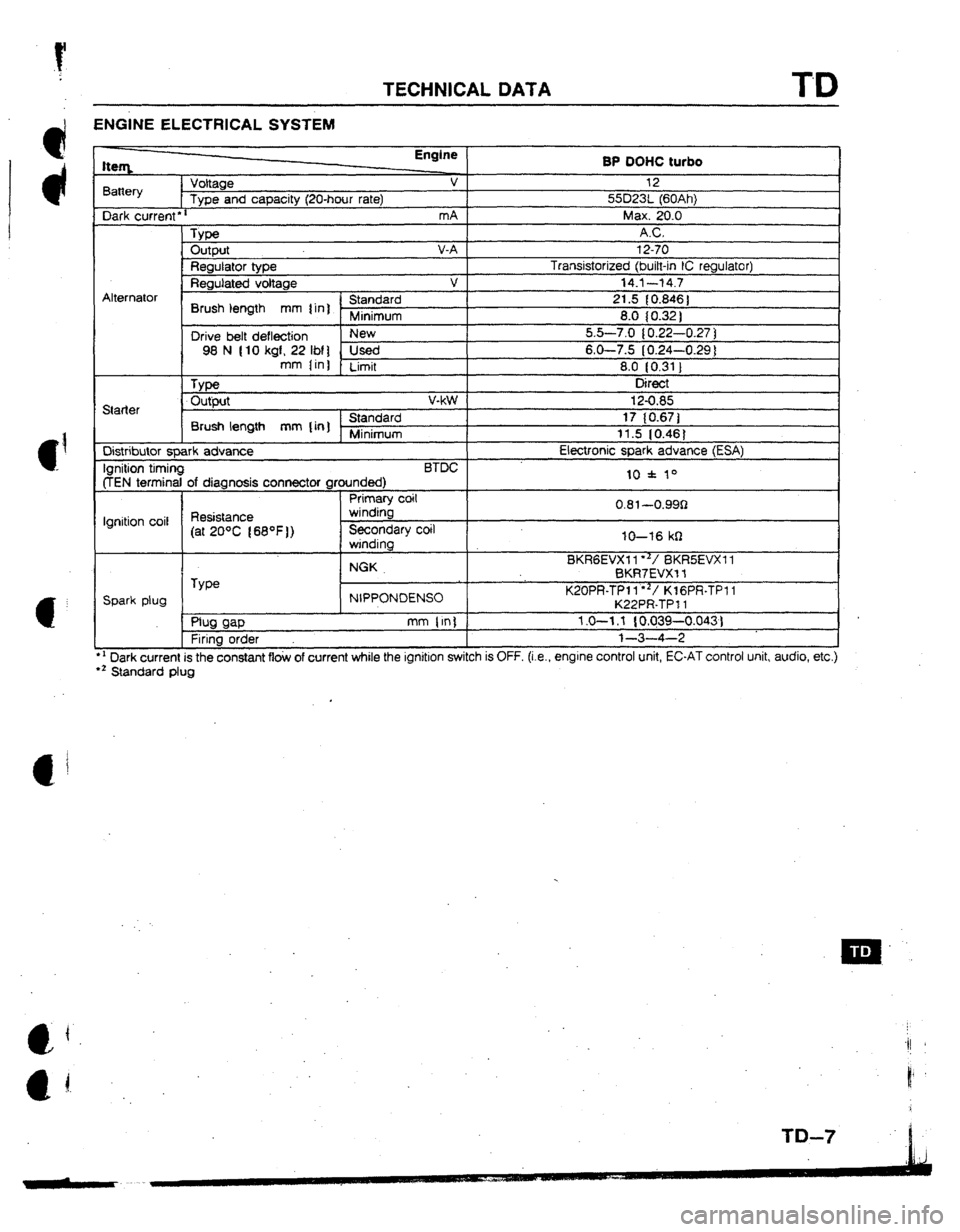

TECHNICAL DATA TD

ENGINE ELECTRICAL SYSTEM

l ’ Dark current is the constant flow of current while the ignition switch is OFF. (i.e., engrne control unit, EC-AT control unit, audio, etc.)

l z Standard plug tteq Engine

BP OOHC turbo

Battery Voltage v 12

Type and capacity (2U-hour rate) 55D23t (60Ah)

Dark current

l r mA Max. 20.0

_ Type AC.

Output V-A 12-70

Regulator type Transistorized (bitt-in IC regulator)

Regutated voltage v 14.1--t4.7

Alternator

’ Standard

Brush length mm 1 in] r 21.5 { 0.846 ]

Minimum 8.0 (0.32 )

Drive belt deflection New 5.5-7.0 10.22-0.27 ]

98 N (10 kgf, 22 IM] Used 6-O-7.5 (0.24-0.29 1

mm Iin)

Limit 8.0 IO.31 1

, Type Direct

Starter Output v-kW

Standard

Brush length mm {in] Minimum

Distributor spark advance

Ignition timing BTDC

(TEN terminal of diagnosis connector grounded)

Primary coit

Ignition coil Resistance winding

(at 20°C 168OF)) Secondary coil

winding

NGK

TYW

Spark plug NIPPONDENSO

, ml WP mm (in)

Firing order 12-0.85

17 (0.671

11.5 IO.481

Etectronic spark advance (ESA)

10 f 10

0.81~-0.99Q

IO-16 kfI

BKRGEVXI I**/ BKRSEVXI 1

BKR7EVX-f f

K20PR-TPl l”‘/ KlGPR-TPI 1

K22PR-TP 11

1.0-l .f { 0.039-0.043)

l-3-4-2

Page 161 of 279

![MAZDA 323 1992 Suplement Repair Manual TD TECHNICAL DATA

CLUTCH

Jmn -

Clutch control

Clutch oedat Engine/Transaxle BP DOW turbo

G25MX-R {G5MX-R)

Hydraulic Type I

Suspended

Pedal ratio mm [in) 6.55

Full stroke mm {in] 135 t5.311

H MAZDA 323 1992 Suplement Repair Manual TD TECHNICAL DATA

CLUTCH

Jmn -

Clutch control

Clutch oedat Engine/Transaxle BP DOW turbo

G25MX-R {G5MX-R)

Hydraulic Type I

Suspended

Pedal ratio mm [in) 6.55

Full stroke mm {in] 135 t5.311

H](/img/28/57055/w960_57055-160.png)

TD TECHNICAL DATA

CLUTCH

Jmn -

Clutch control

Clutch oedat Engine/Transaxle BP DOW turbo

G25MX-R {G5MX-R)

Hydraulic Type I

Suspended

Pedal ratio mm [in) 6.55

Full stroke mm {in] 135 t5.311

Height (With carpet) mm [in] 196-204 (7.72-8.03 1

Free play mm (in] 5.5-l 7.4 {0.22-0.69 ]

Distance to carpet when clutch fully

disengaged mm [in) Minimum 41.0 (1.61 ]

Flywheel

Runout limit mm {in] 0.200 [ 0.0079)

Clutch disc

1

, Type I Single dry plate

Runout limit mm (in) 0.700 [ 0.0276 )

Wear limit mm {in] 0.3 [ 0.012 ] from rivet head

Outer diameter mm {in] 230 {9.05)

Inner diameter mm {in) 155 i6.10)

Facing thickness mm [in] Flywheel side

I 3.5 (0.14)

Pressure elate side 3.5 10.141

Clutch cover

Type

Set load

Ctutch fluid

Type I

N [kgf, Ibf) 1

I Diaphragm spring

5,494 1560, 1,232)

SAE J1793 or FMVSS116 DOT-3 MANUAL TRANSAXLE AND TRANSFER

SpecMcation

Transaxle type

Transaxle control

Transaxle shift control

Syncromesh system G25MX-R (G5MX-R)

Floor shift

Cable

Forward: Synchromesh

Reverse: Seiective sfidina and svnchromesh

I 1 st 3.454 a

2nd 1.833

3rd 1.310

Gear ratio

4th 0.970

5th 0.717

Reverse 3.166

Final gear ratio I . 4.214

Speedometer gear ratio (Driven gear/drive gear) 1.045 (23122)

Grade API service GL-4

011 Viscocity AkeaSQn: ATF Dexron@II or M-ID

Above -l8*C (OOF): SAE 75W-90

Capacity L {USqt, Imp itI 2.6 12.7, 2;2]

Runout

Primary shaft gear runout

Secondary shaft gear runout mm {in) 0.050. [ 0.0020 ]

mm [in] 0.015 { 0.0006 ]

Clearance

1st’ (Gear inner dia. -shaft puter dia)

2nd (Gear inner dia. -shaft outer dia)

3rd {Gear inner dia. -shaft outer dia)

4th (Gear inner dia. -shaft outer dia)

5th (Gear rnner dia. -shaft outer diaj mm {in] 1 0.030-0.080 { 0.0012-0.0~3 11

mm {in) 0.030~0.08C (-0.0012-0.0031 1

mm (in) 0.030-0.080 I 0:0012-0.003i 1

mm [in] 0.030-0.080 [ 0.0012-0.0031 ]

mm [lnl 0.030--0.080 ~0.0012-0.0031 1

1. TD-8

Lern

l-2 sift for

3-4 shift fri

5th shift f;t

Reverse iti

Thrust cli

1st gear

2nd gear

3rd gear

4th gear

5th gear

. .

Primary St

Seconda:

Center ci

Type :

Number

c

Number (

Number r

Number ;

Bearing ;

Bearing

1

End plai

Ring get

End pi&i

Sun gea

frltnsfe~

Final g&f

Number

Page 163 of 279

![MAZDA 323 1992 Suplement Repair Manual TD TECHNICAL DATA

Hem Engine

SP DOHC turbo

Note ) I

1 st and 2nd

Synchronizer ring outer diameter

’ I 67.7 I2.665)

mm [in] 3rd and 4th 67.7 12.665 )

5th and reverse 55.7 t2.192)

Synchronize MAZDA 323 1992 Suplement Repair Manual TD TECHNICAL DATA

Hem Engine

SP DOHC turbo

Note ) I

1 st and 2nd

Synchronizer ring outer diameter

’ I 67.7 I2.665)

mm [in] 3rd and 4th 67.7 12.665 )

5th and reverse 55.7 t2.192)

Synchronize](/img/28/57055/w960_57055-162.png)

TD TECHNICAL DATA

Hem Engine

SP DOHC turbo

Note ) I

1 st and 2nd

Synchronizer ring outer diameter

’ I 67.7 I2.665)

mm [in] 3rd and 4th 67.7 12.665 )

5th and reverse 55.7 t2.192)

Synchronizer key dimension 1st and 2nd @ 19.0 {0.748], 04.3 (0.171, 05.0 10.20)

mm [in] 3rd and 4th @ 17.0 10.669J, 04.3 (0.171, @ 5.0 lO.20)

5th and reverse 0 17.0 10.6691, m4.3

10.171, @I 5.0 fO.201

PROPELLER SHAFT

Item

length

Outer diameter Engineflransaxie Model BP DOHC turbo

G25MX-R (GSMX-R)

Front 834.3 { 32.85 ]

mm fin] Center 584 122.99)

Rear

I 437 { 17.20)

Front 75 (2.95)

mm { in] Center 57 12.24) f

Rear 57 12.241

FRONT AND REAR AXLES

Item Specifications

Front driveshaft

Jomt type Inside Double oftset joint

Outside Bell jotnt

Length of joint (between center of joint) mm { rn t - Right 392 (15.4)

left 306 (0.83 ]

Shaft diameter mm {in] 21.0 to.831

I

Rear driveshaft

Joint type Inside 1

Outside 1

Length of joint (between center of joint) mm [in ] ’ Right

Left

Shaft diameter mm (in)

J&t shatt

Length of joint

Shaft diameter

Front axle

Bearing play axial direction mm [in] 1

Rear axle

Bearing play axial direction mm lin] 1

Rear differential (viscous limited slip differential) Double offset joint

Bell joint

519.5 (20.5 ]

489.5 [f9.3]

21.0 IO.831

357.2 1 t4.11

21 .O (0.83 )

0.050 IO.002 ]

0.050 (0.002 ]

*

Reduction gear

Different ia gear

Oifferential ratro

Number of teeth

Flurd

L Ring gear

Drive .pinion gear

Grade

Viscosity Above -18*C fO*F ]

Below -18*C lOoF)

, Capacity

L fUS qt, Imp c$l Hypoid gear

Straight bevel gear

3.909

43

11

API Service GL-5

SAE 90

SAE 80W

0.65 lQ.69, 0.571 STEERING SI

1 Free olav 8RAKING SY

Brake type

Brake pedat

Height

Free play 1

Reserve travel

Clearance whet

Master cylinde

Master cylinder

Front disc brai

. Tyl?e

Thickness of p&

Thickness of pa

Page 168 of 279

ST

SPECIAL TOOLS

c 1

GENERAL lNFORMATlON ........................ ST- 2

ENGINE

..................................................

ST- 3

CLUTCH AND MANUAL TRANSAXLE

........

ST- 4

FRONT AND REAR AXLES.

...................... ST-

5

STEERING ..............................................

ST- 6

BRAKING ...............................................

ST- 8

FRONT AND REAR SUSPENSION..

........... ST- 9

CHECKER AND OTHER EQWPMENT..

.......

ST-IO

13ESTX-301

c I

__

c I

Page 169 of 279

ST SPECIAL TOOLS

GENERAL INFORMATION

The letters A and B in the priority column indicate the degree of importance of each tool.

A. . . . . Indispensable

The toots ranked A in this list are indispensable for performing operations satisfactorily, easily, safely, and

efficiently. It is, therefore advisable that all service shops have these tools.

B.. . . .Selective

The tools in this list are not as necessary as tools ranked A, but all service shops should have these tools

to perform repairs more easily and more efficiently.

Note

l When ordering toot sets that consist of several tools, check the List in the Parts Catatogue

to make sure that some tools are not duplicated in other sets you may already have. tf they

are, instead of ordering the set, order only those new tools that are needed.

l There are new SST explanations in this tool chart.

These tools are indicated by “NEW SST” in description column.

13ESTX.302 49 OlC7

Engine

49 LOY~

Hanger

engiN

49 063

Arm, \I lifter

49

BO

Pivot

. .-

49 Sl

Rem

aeaf

Brakl

Page 170 of 279

SPECIAL TOOLS ST

ENGlNE

TOOL NUMBER

b DESCRIPTION PRlORlTY ILLUSTRATlON

49 0107 680A

Engine stand A

49 LO10 IA0

Hanger set,

engine stand

49 0636 IOOA

Arm, valve spring

lifter

49 8012 OA2

Prvot

A

49 5120 170

1 I

Remover, valve

seal

A ff==cB

49 E011 IA0

Brake, ring gear A Installer set, valve

seal & valve

Remover &

installer, valve

49 0221

061A

49 DO11

102

Lock tool,

crankshaft

- 49 GO14

001

Wrench, tit filter

49 9200 145

Adapter, radiator

Page 179 of 279

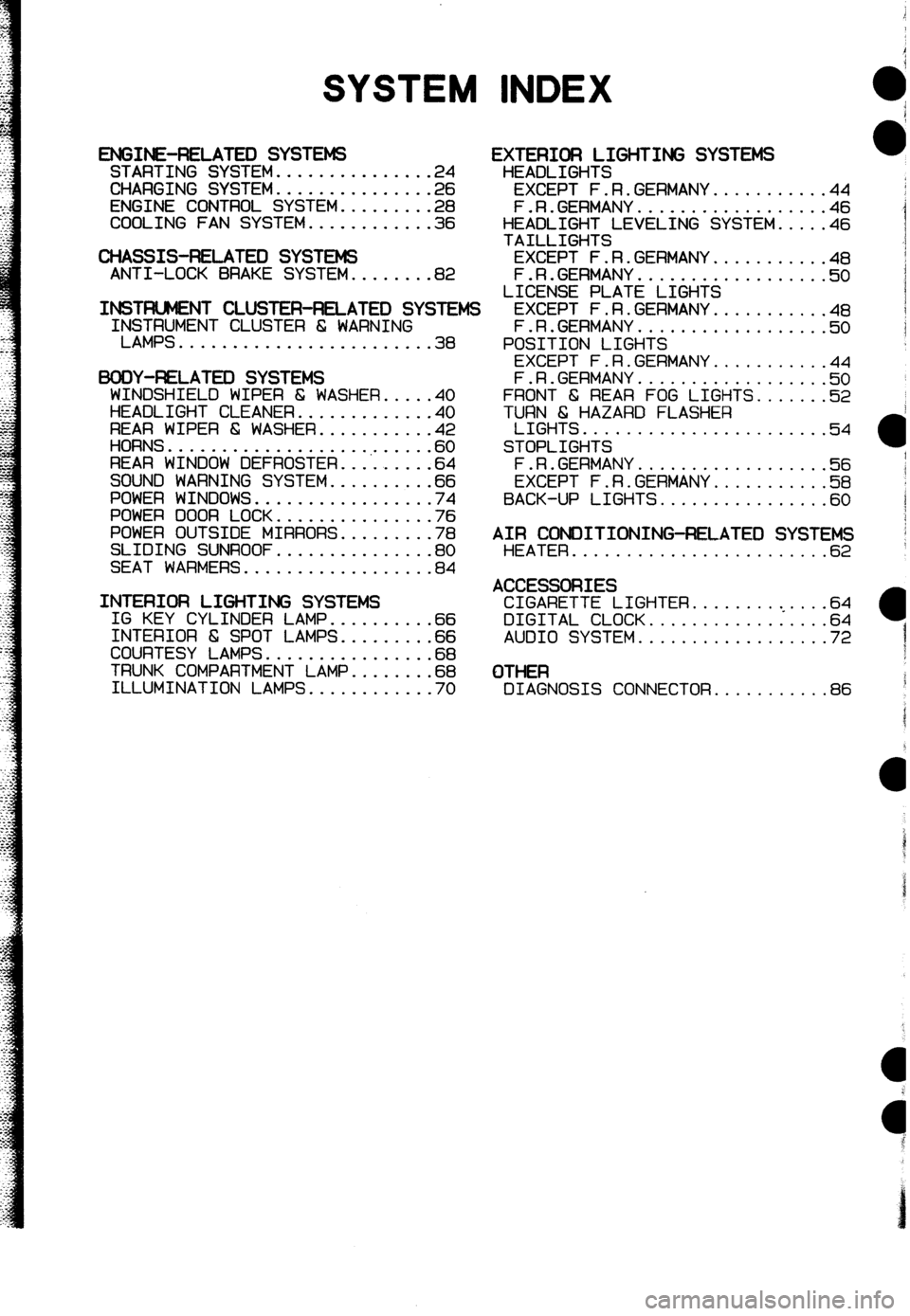

SYSTEM INDEX

ENGINE-RELATED SYSTEMS STARTING SYSTEM...............2 4

CHARGING SYSTEM...............2 6

ENGINE CONTROL SYSTEM.........2 8

COOLING FAN SYSTEM............3 6

CHASSIS-RELATED SYSTEMS ANTI-LOCK BRAKE SYSTEM........82

INSTFUJMENT CLUSTER-RELATED SYSIEMS IrS$;MENT CLUSTER 6 WARNING

........................ 38

BODY-F&LATEX) SYSTEMS

WINDSHIELD WIPER 6 WASHER.....4 0

HEADLIGHT CLEANER.............4 0

REAR WIPER & WASHER...........4 2

HORNS...................,......6 0

REAR WINDOW DEFROSTER.........6 4

SOUND WARNING SYSTEM..........6 6

POWER WINDOWS.................7 4

POWER DOOR LOCK...............7 6

POWER OUTSIDE MIRRORS.........7 8

SLIDING SUNROOF...............8 0

SEAT WARMERS..................8 4

INTERIOR LIGHTING SYSTEMS IG KEY CYLINDER LAMP..........6 6

INTERIOR 6 SPOT LAMPS.........6 6

COURTESY LAMPS................6 8

TRUNK COMPARTMENT LAMP........6 8

ILLUMINATION LAMPS............7 0

EXTERIOR LIGHTING SYSTEMS

HEADLIGHTS

EXCEPT F.R.GERMANY...........44

F.R.GERMANY..................46

HEADLIGHT LEVELING SYSTEM.....46

TAILLIGHTS

EXCEPT F.R.GERMANY...........48

F.R.GERMANY..................5 0

LICENSE PLATE LIGHTS

EXCEPT F.R.GERMANY...........4 8

F.R.GERMANY..................5 0

POSITION LIGHTS

EXCEPT F.R.GERMANY...........4 4

F.R.GERMANY..................!i? 0

FRONT 6 REAR FOG LIGHTS.......52

TURN 6 HAZARD FLASHER

LIGHTS.......................54

STOPLIGHTS

F.R.GERMANY.a................5 6

EXCEPT F.R.GERMANY...........5 8

BACK-UP LIGHTS................6 0

AIR CONDITIONING-RELATED SYSTEMS HEATER........................6 2

ACCESSORIES CIGARETTE LIGHTER.........<....64

DIGITAL CLOCK.................64

AUDIO SYSTEM..................72

OTHER DIAGNOSIS CONNECTOR...........86

Page 185 of 279

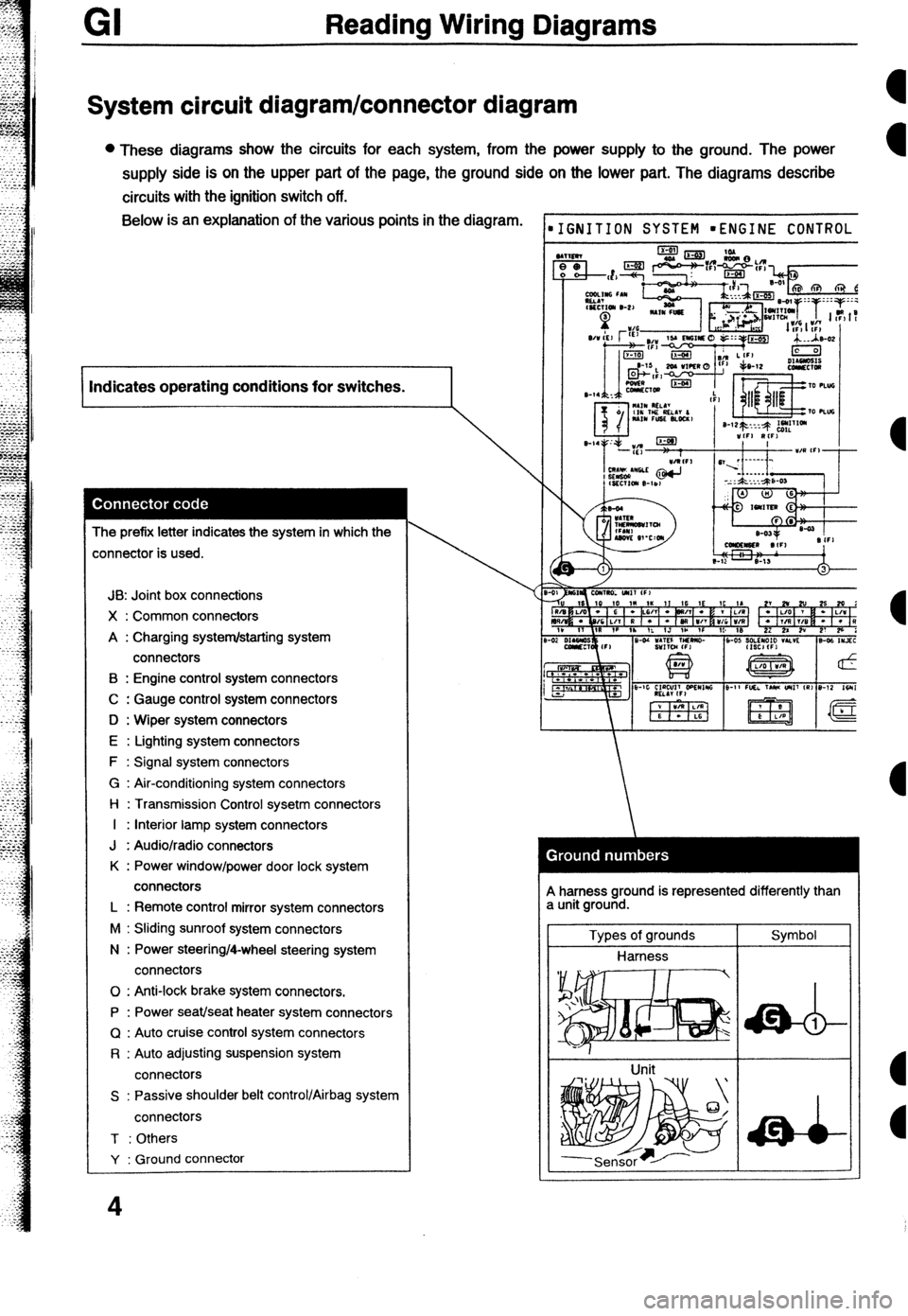

GI Reading Wiring Diagrams

System circuit diagram/connector diagram

l These diagrams show the circuits for each system, from the power supply to the ground. The power

supply side is on the upper part of the page, the ground side on the lower part. The diagrams describe

circuits with the ignition switch off. Below is an explanation of the various points in the diagram.

I Indicates operating conditions for switches.

I

The prefix letter indicates the system in which the

:onnector is used.

JB: Joint box connections

X : Common connectors

A : Charging system/starting system

connectors

B : Engine control system connectors

C : Gauge control system connectors

D : Wiper system connectors

E : Lighting system connectors

F : Signal system connectors

G : Air-conditioning system connectors

l-l : Transmission Control sysetm connectors

I : Interior lamp system connectors

J : Audio/radio connectors

K : Power window/power door lock system

connectors

L : Remote control mirror system connectors

M : Sliding sunroof system connectors

N : Power steering/4-wheel steering system

connectors

0 : Anti-lock brake system connectors.

P : Power seat/seat heater system connectors

Q : Auto cruise control system connectors

R : Auto adjusting suspension system

connectors

S : Passive shoulder belt control/Airbag system

connectors

T : Others

Y : Ground connector

4

IGNITION SYSTEM mENGINE CONTROL

A harness ground is represented differently than

a unit ground.

Types of grounds

Harness

Unit Symbol

Page 188 of 279

Reading Wiring Diagrams GI

HARNESS SYMBOLS

DESCRIPTION OF HARNESS

FRONT HARNESS

ENGINE HARNESS

INSTRUMENT PANEL HARNESS

REARHARNESS

REAR NO.2 HARNESS

REAR NO.3 HARNESS SYMBOL

F) TTT

E) m

(1) %4l

(W

VW m

(R3) DESCRIPTION OF HARNESS

EMISSION HARNESS

INJECTOR HARNESS

INTERIOR LAMP HARNESS

FLOOR HARNESS

DOOR NO.1 HARNESS

DOOR NO.2 HARNESS

NSTRUMEN\T\PANEL HARNESS (I)

FROM; HARNESS(F) SYMBOL

INTERIOR LAMP HARNESS (IN)