brake fluid MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 7 of 279

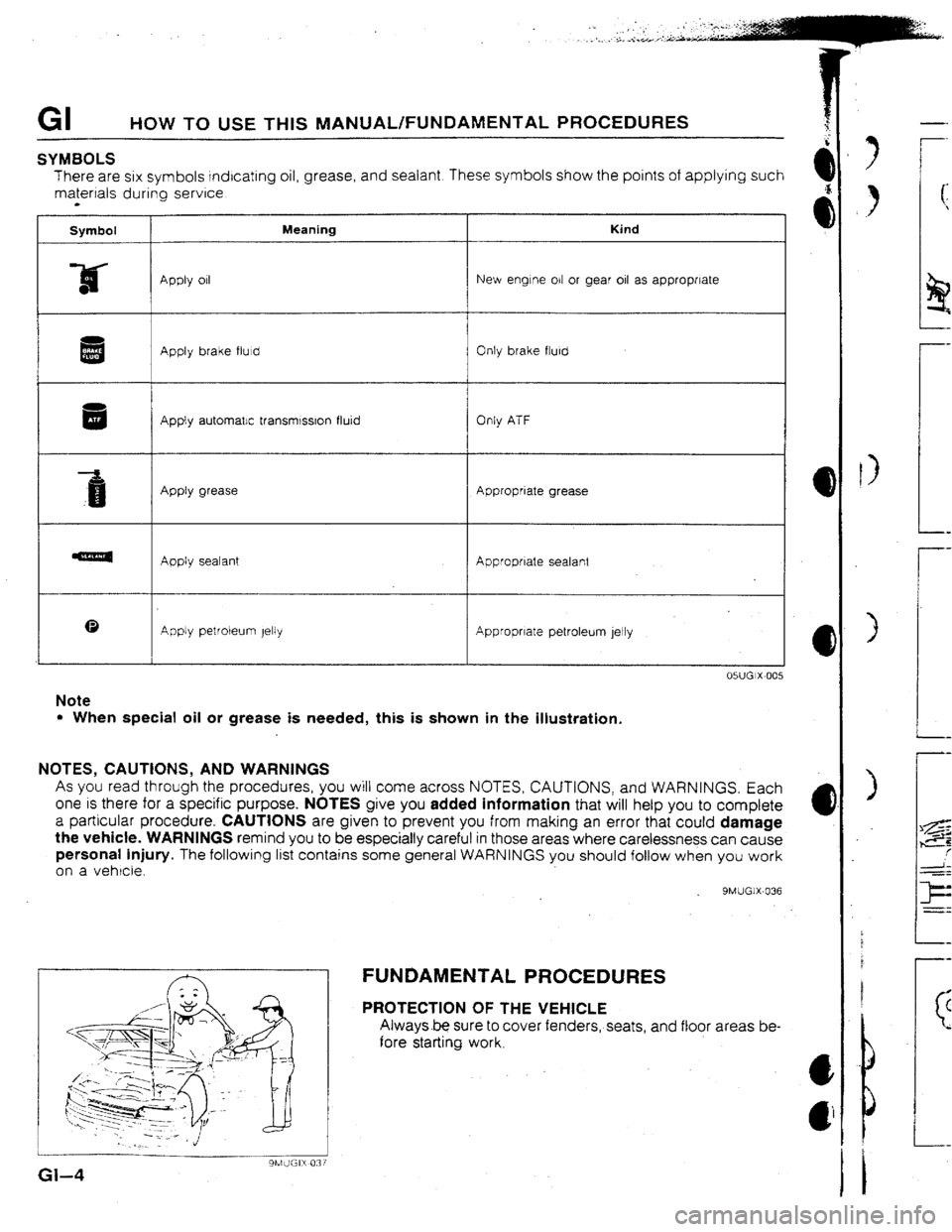

GI HOW TO USE THIS MANUAL/FUNDAMENTAL PROCEDURES

SYM00LS

There are six symbols indicating oil, grease, and sealant. These symbols show the points of applying such

matertals during service

*

Symbol

w-

l Apply otl Meaning Kind

New engtne 011 or gear 011 as approprkate

Apply brake fluid Only brake fluId

I

Apply automatic transmtsslon fluid Only ATF

Apply grease Appropriate grease

Apply sealant Approprrate sealant

0

Apply petroleum Jelly

Appropriate petroleum jetty

05UGIX-005 Note

l When special oil or grease is needed, this is shown in the illustration.

NOTES, CAUTIONS, AND WARNINGS

As you read through the procedures, you will come across NOTES, CAUTIONS, and WARNINGS. Each

one IS there fur a specific purpose.

NOTES give you added information that wilt help you to complete

a particular procedure. CAUTlONS are given to prevent you from making an error that could damage

the vehicle. WARNINGS remind you to be especially careful in those areas where carelessness can cause

personal injury. The following list contains some general WARNINGS you should follow when you work

on a vehrcle

. 9MUGlX.036

FUNDAMENTAL PROCEDURES PROTECTION OF THE VEHICLE

Always .be sure to cover fenders, seats, and

fore starting work. floor areas be-

1

T.

i

8

s

Q

8

e

Page 21 of 279

A PRE-DELIVERY INSPECTION TABLE

PRE-DELIVERY INSPECTION TABLE

[EXTERlORI

INSPECT and ADJUST, of necessary. the followlng Items to

specrfrcatron:

0 Glass, exterior bright metal and paint for damage

0 Wheel lug nuts

0 Tire pressures

0 All weatherstrips for damage or detachment

0 Operation of bonnet release and look

0 Operation of trunk Ild, hatch and fuel lbd opener

(of equipped)

0 Door operation and alignment

0 Headtrght aiming

INSTALL the foltowrng parts

0 Wheel caps or rrngs (if equipped)

0 Outsrde mirror(s)

1 UNDER BONNET-ENGINE OFF j

INSPECT and ADJUST. If necessary, the following items to

specrflcatlon.

0 Fuel, coolant and hydraulic tines, fittings, connectlons and

components for leaks

0 Engine 011 level

0 Power steering fluid level (of equipped)

0 Brake master cylinder fluky levels

0 Clutch master cylinder fturcl levels (If equipped)

0 Wtndshreld washer reservojr flurd level

0 Radiator coolant level and specrfic gravity

0 Tightness of water hose clamps

0 Tightness of battery terminals, electrolyte level and specific

gravity

0 Manual transaxle oil level

0 Drive belt(s) tension

Cl Carburetor lrnkage (choke control, wrde open throttle posi-

tion. etc ) (carburetor model only)

q Accelerator cable and linkage for free movement

0 Headlight cleaner and flurd level (if equipped)

BLEED air from fuel line (diesel engrne only)

CLEAN the spark plugs (except for diesel engine)

piEi6F]

INSTALL the following parts

0 Rubber stopper for rnsrde rear view mirror (if equjpped)

0 Fuse for accessories

CHECK the operation of the following items.

0 Seat controls (sliding and reclining) and head rest

0 Seat belts and warning system

Cl Ign&on switch and steering lock

0 Power window (if equipped)

D Door tacks including child proof door locks

Cl Inhibitor switch (ATX only)

Cl All Ikghts rncluding warning and Indicator lbghts

0 Ignition key reminder buzzer (If equipped)

A-Z

0 Horn, wbpers and washers (front and rear, If equipped)

0 Antenna (tf equipped)

0 Cigarette Ibghter and clock (if equipped)

0 Remote control outside mirror (if equrpped)

0 Heater, defogger and air conditioner at various mode selec-

tions (if equlppedj

0 Sunroof (If equipped)

CHECK the following items

0 Presence of spare fuse

0 Upholstery and Interior finish

CHECK and ADJUST, If necessary, the followjng items:

IJ Operation and fit of windows

0 Pedal height and free play of brake and clutch pedal

0 Parking brake UNDER BONNET-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

0 Operation of Idle-up system for air condbtroner or power steer-

ing (if equrpped)

0 Automatic transaxle flurd levet

0 tnltial ignrtlon timing (except disel engine)

0 Idle speed

0 Operation of throttle positron. sensor (EGI engrne)

0 Operation of cold start device and glow plug warning light

(diesel engine only)

0 Operation of dash pbt (EGI.engine)

fTiGGJ

CHECK the following items.

0 Underside fuel, coolant and hydraulic Irnes, ftttlngs, connec-

tions and components for leaks

0 Trres for cuts or brurses

0 Steering Itnkage, suspensron, exhaust system and all under-

side hardware for .looseness or damage 1 ROAD TEST j

CHECK the following items

0 8rake operation

0 Clutch operation

0 Steering control

!ZI Operation of meters and gauges

Cl Squeaks, rattles or unusual noises

Cl Engine general performance

0 Emergency locking retractors 1 AFTER ROAD TEST ]

REMOVE the seat and floor mat protective covers

CHECK for the necessary owner information materials, took

and spare tire

m vehicle

93EOAX-002

-- MAIN Char3 t: In

A: PC R: F!t T: Ti! Emis! The ed : to t!

Page 22 of 279

SCHEDULED MAINTENANCE SERVICES A

SCHEDULED MAINTENANCE SERVICES

MAINTENANCE TABLE

Chafi symbols:

1 : Inspect: Visual examination and/or functional measurement of system’s operation or

performance , A: Adjust: Examination resulting in adjustment or replacement

n

R: Replace or change

T: Tighten

REMARKS

After 80,000 km or 48 months, continue to follow the described maintenance at the recommended intervals.

As for * marked items in this maintenance chart, note the following points.

+ 1 Major service interval at 12 months/20,000 km (12,000 miles).

Lubrication service based on distance only 10,000 km (6,000 miles) not time.

l 2 Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

if equipped.

‘3 Replacement of the timing belt is required at every 100,000 km (60,000 mile). Failure to replace the tim-

ing bett may result in damage to the engine.

‘4 tf the vehicle is operated under any of the following conditions, it is suggested that the engine oil and

oil filter be changed more often than the recommended intervals.

a) Driving in dusty conditions. I

:

b) Extended periods of idling or low speed operation. i

i!

c) Driving for a prolonged periods in cold temperatures or regularly driving onty short distances.

*5 If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often

than at usual recommended intervals.

l 6 This IS a full function check of all electrical systems, i.e, atl

ltghts. washers (including condition of blades)

electric windows, sunroof, horn etc.

‘7 Replace every two years. $1

‘I

If there has been continuous hard driving, mountain

drivtng, or if the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the-emission control and relat-

ed system, as well as for efficient engine operation. It is strongly recommended that all servicing related

to these systems be done by your Authorised Mazda Dealer.

13EOAX-302 -4

I!

A-3

Page 95 of 279

OUTLINE M

OUTttNE

OUTLiNE OF CONSTRUCTION

l TKe construction and operation of the front and rear axles are basically the same as previous models.

l Because of the use of a high power engine, the following parts are modified to improve rigidity.

(I) Larger front and rear bearings are used.

(2) Larger front and rear knuckles are used.

(3) A five-stud wheel hub is used.

l An ice scraper is newly installed on the rear knuckle to prevent ice from building up on the brake caliper.

(Refer to page M-14.)

13EOMX-303

SPECIWCATIONS

Hem Speclficatlons

Front driveshaft

Joint type inside

Double offset joint

Outsrde Bell joint

Length of joint (between center of joint) Right

392 I15.4)

mm lrn)

Left 306 IO.831

Shaft drameter mm fin)

21.0 (0.83)

Rear driveshaft

Inside

Joint type Double offset joint

Outside 5ell joint

Length of joint (between center of joint) Right

519.5 [ 20.5 1

mm [in]

Left.

489.5 ( 19.3 )

Shaft diameter mm (in) 21.0 [O&3]

Joint shaft

I

Length of joint

Shaft diameter

Front axle

mm jin] 357.2 114.11

mm {in] 21.0 {0.83]

4

Bearing play axial direction mm tin)

0.05 IO.002 ]

I

Rear axle

Bearing play axial direction mm (inj

Rear dtfferentlal (viscous limited slip differential) 0.05 (0.002 1

Reduction aear Hypoid gear

Differentral gear

Drfferential ratio Straight bevel gear

3.909

Number of teeth Ring gear .

Drive binion aear

43

If

Fluid I Grade API Service GL-5

Above -t8*C (O*F) SAE 90

Viscosity .

Below -18*C i O*Fl SAE 8OW

1 I Capacity L I US qt, imp stl 1 0.65 !O.SS, 0.571

1

13EOMX-304

M-3

Page 114 of 279

OUTLlNE P

OUTLfNE

OUTLINE OF CONSTRUCTION

l The brake system remains similar to that of the previous model. l However, because all new models use a higher-horsepower engine, the brake system is enlarged as a whole.

l Vehicles without ABS use a portless-type master cylinder

13EOPX-303

SPECIFICATIONS

Brake pedal

Master cylinder

Front drsc brake

Rear disc brake

Power brake unit

Braking force control device

Brake fluid

Parking brake Item Specification

Type Suspended

I

PedaJ lever ratio 4.1

Max. stroke mm [in] 140 j5.511

I,

Type Tandem

Cylinder inner diameter mm {in] Without ABS: 25.4 j 1 .UO ]

With ABS: 23.8 to.941 3-

Type Ventilated disc ?

Cylinder bore mm [in)

57.2 12.253

Pad dimensions (area x thickness)

mm2 {rn2) xmm [In) 5,200 (8.OSl x 10 (0.39)

Disc plate dimensions mm (in]

(outer diameter x thickness) 274x24 (10.79x0.94)

Type Solid disc

Cylinder bore mm Jon]

34.9 j 1.37 ]

Pad dimensions (area x thrckness)

mm’ (in21 xmm [in) 3,200 I4.961 x8 (0.31)

DISC plate dimensions mm t,n]

(outer diameter x thickness) 280x10 (tl.02xu.39]

il

Type Without ABS: Vacuum multIplier

With ABS: Hydraulrc muttiplier

Diameter mm Iln]

(without ABS) 188.4 17.42) +215.2 t8.47)

We Without ABS: Dual proportioning valve

With ASS: Proportioning valve

FMVSS 116, DOT-3, SAE J1703

Mechanical twGrear-wheel control

Type

Operation system Center lever

13EOPX.304 t

Page 116 of 279

I :

;!

i

I

I

CONVENTIONAL BRAKE SYSTEM P

CONVENTIONAL BRAKE SYSTEM

PREPARATION

SST

49 0259 770B

Wrench, fiare nut For

removal and 49 U043 OAO

Gauge set, oil

pressure For

Inspectron of

brake fluId

pressure

49 uo43 004

Gauge, oil

pressure

{Part 04

49 U043 OAO) For

inspection of

brake fluid

pressure 49 UO43 005

Joint

(Part of

49 UO43 OAO) For

inspection of

brake fluid

o pressure

49 0208 70tA

Air-out tool, boot For

removal of

piston seal 49 FAf8 602

Wrench, disc

brake piston For

removal and

installat!on of disc

call per piston

49 1258 071

Puller, bearing For 49 0221 600C

removal of caliper

a-- E;.;d tool, disc needle bearing For

installation of

brake pads

Page 117 of 279

P CONVENTIONAL BRAKE SYSTEM

93GOW74:

13EOPX-307

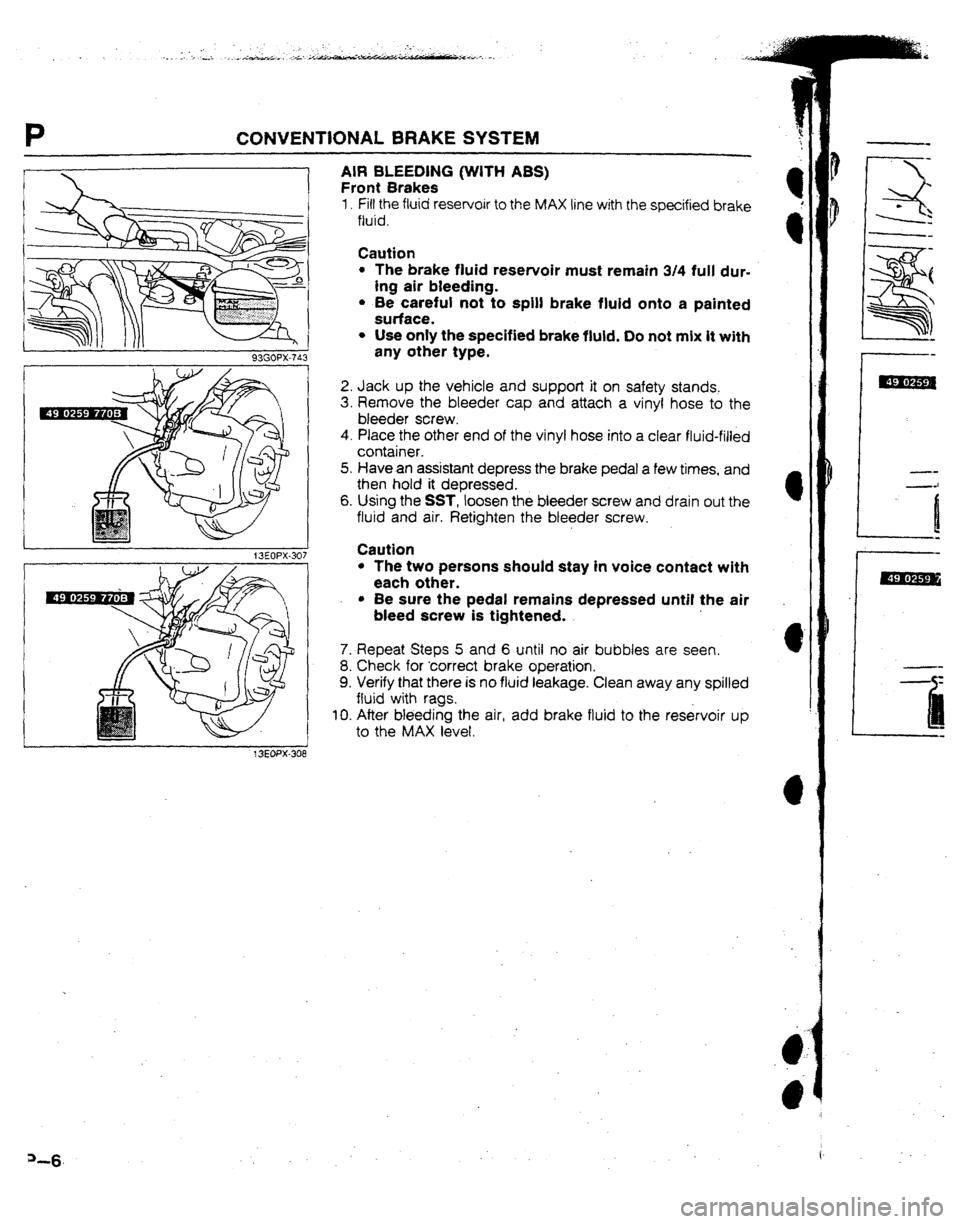

AIR BLEEDlNG (WITH ABS)

Front Brakes

1. Fill the fluid reservoir to the MAX line with the specified brake

fluid.

Caution

l The brake fluid reservoir must remain 3/4 full dur-

ing air bleeding.

l Be careful not to spill brake fluid onto a painted

surface.

l Use only the specified brake fluid. Do not mix it with

any other type.

2. Jack up the vehicle and support it on safety stands.

3. Remove the bleeder cap and attach a vinyl hose to the

bleeder screw.

4. PIace the other end of the vinyl hose into a clear fluid-filled

container.

5. Have an assistant depress the brake pedal a few times, and

then hold it depressed.

6. Using the SST, loosen the bleeder screw and drain out the

fluid and air. Retighten the bleeder screw.

Caution

l The two persons should stay in voice contact with

each other.

l Be sure the pedal remains depressed until the air

bleed screw is tightened.

7. Repeat Steps 5 and 6 until no air bubbles are seen.

8. Check for ‘correct brake operation.

9. Verify that there is no fluid leakage. Clean away any spilled

fluid with rags.

IO. After bleeding the air, add brake fluid to the reservoir up

to the MAX level.

Page 118 of 279

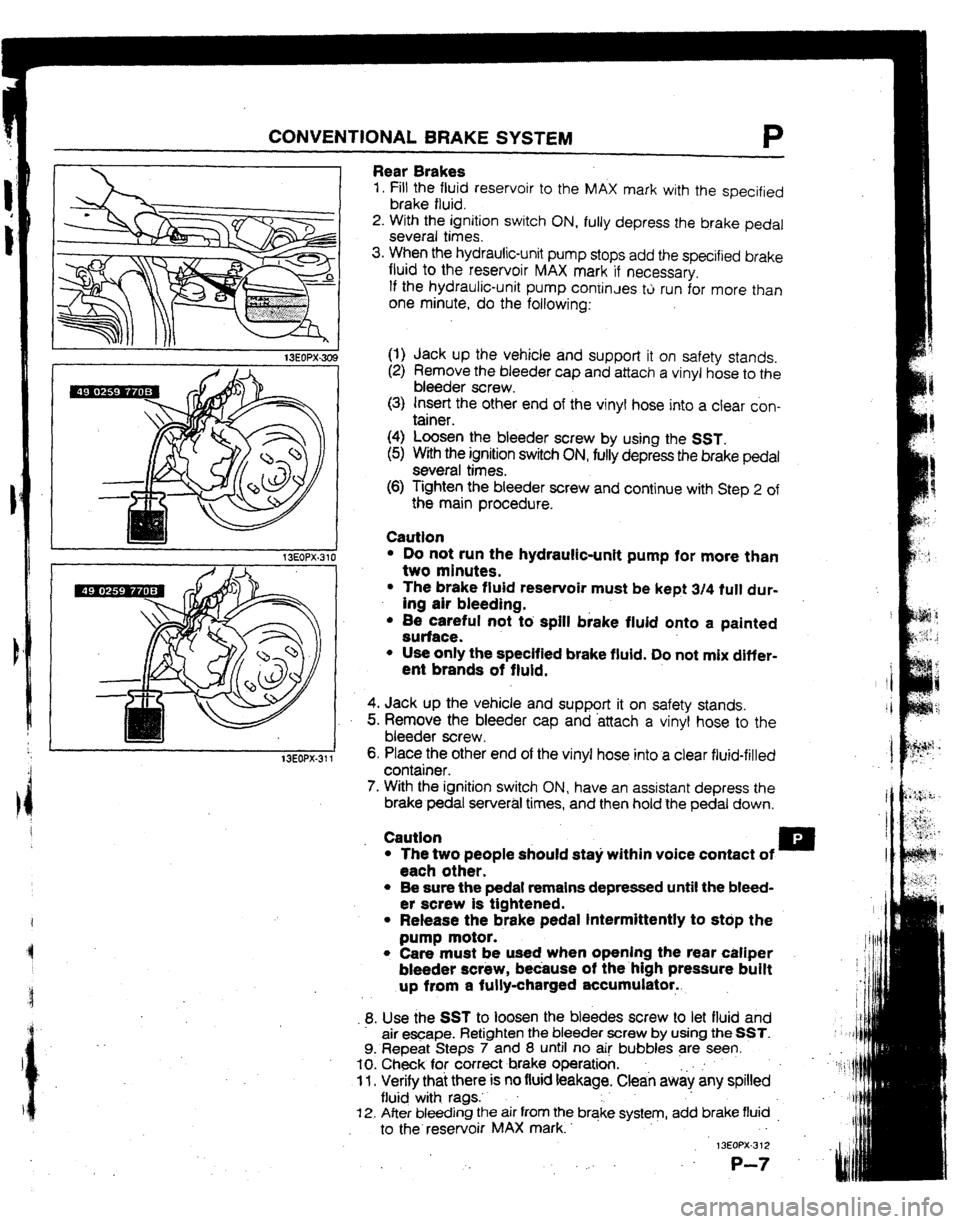

CONVENTlONAL BRAKE SYSTEM P

13EOPX-309

f3EOPX-310

13EOPX-311

Rear Brakes

1. Fill the fluid reservoir to the MAX mark with the specified

brake fluid.

2. With the ignition switch ON, fully depress the brake pedal

several times.

3. When the hydraulic-unit pump stops add the specified brake

fluid to the reservoir MAX mark if necessary,

If the hydraulic-unit pump coniinJes tti run for more than

one minute, do the following:

(1) Jack up the vehicle and support it on safety stands.

(2) Remove the bleeder cap and attach a vinyl hose to the

bleeder screw.

(3) Insert the other end of the vinyl hose into a clear con-

tainer.

(4) Loosen the bleeder screw by using the SST.

(5) With the ignition switch ON, fully depress the brake pedal

several times.

(6) Tighten the bleeder screw and continue with Step 2 of

the main procedure.

Cautfon

l Do not run the hydraulic-unit pump for more than

two minutes.

l The brake fluid reservoir must be kept 3/4 fult dur-

ing air bleeding.

l 8e careful not tb spill brake fluid onto a painted

surface.

l Use only the specified brake fluid. Do not mix differ-

ent brands of fluid.

4. Jack up the vehicle and support it on safety stands.

5. Remove the bleeder cap and -attach a vinyl hose to the

bleeder screw I

6, Place the other end of the vinyl hose into a clear fluid-filled

container.

7. With the ignition switch ON, have an assistant depress the

brake pedal serveral times, and then hold the pedal down.

Caution .

l The two people should sta)i within voice contact of u

each other.

l Be sure the pedal remains depressed until the bleed-

er screw is tightened.

l Release the brake pedal intermittently to stdp the

pump motor.

l Care must be used when opening the rear caliper

bleeder screw, because of the.high pressure buift

up from a fully-charged accumulator..

9. Use the SST to loosen the bleedes screw to let fluid and

air e-ape. Retighten the bleeder screw by using the SST.

9. Repeat Steps 7 and 8 until no ai! bubbles are seen.

IO. Check for correct brake operation. .

11 l Verify thai there is no fluid feakage. Clean aw& any spilled

flu@ with rags.’ .

f 2. After bleeding the air from the brqke system, add brake fluid _

to the reservoir MAX mark. . -

13EOPX-3 12

,: .

P-7

Page 119 of 279

P CONVENTIONAL BRAKE SYSTEM

1 t3EOPX.314

@ 66.7 kPa

Iso0 mmHg.

19.7 inHg)

16EOPX-05t

1

13EOPX.315

P-8

POWER BRAKE UNIT

Quick Inspection (On-vehicle)

Power brake unit function check

(Method-using tester)

Connect the SST, vacuum gauge A, and pedal depression

force gauge B as shown in the figure. After bleeding the

air from the SST, conduct the test as described in the 3steps

below.

Note l

Use commercMty available vacuum gauge and ped.

al depression force gauge.

a) Checking for vacuum loss

Unloaded condition

1. Start the engine.

2. Stop the engine when the vacuum gauge reading reaches

66.7 kPa (500 mmHg, 19.7 inHg ) .

3. Observe the vacuum gauge for 15 seconds. If the gauge

shows 63.3-66.7 kPa [475--500 mmHg, 18.7-19.7

inHg 1, the unit is operating.

Loaded condition

1. Start the engine.

2. Depress the brake pedal with a fdrrce of 196 N I20 kgf,

44 Ibfj.

3. With the brake pedal depressed, stop the engine when the

vacuum gauge reading reaches 66.7 kPa {SO0 mmlig,

19.7 inHg].

4. Observe the vacuum gauge for 15 seconds. If the gauge

shows 63.3-66.7 kPa I475--500 mmHg; 18.7-l 9.7

inHg 1, the unit is operating.

b) Checking for hydraulic pressure

1, If with the engine stopped (vacuum 0 kPa (0 mmHg, 0

hltlg 1) the fluid pressure is within specification, the unit is

operating.

Pedal force N fkgf. Ibf]

Fluid pressure kPa (kgf/cm2, psi)

196 LZO. 441 1080 111. 1561 min.

2, Start the engine. Depress the brake pedal when.the vacu-

urn reaches 66.7 kPa 1500 mmHg, 19.7 intlg 1. If the flu-

id pressure is within specification, the unit is operating.

Pedal force N 1 kgf, fbf I Fluid pressure .kPa { kgflcm’. ps 1

196 I20,441 6670 {68, 967

1 min.

-- WlTHOU

&

d

I=-

-

1 MASTER CYUh

.

i_

Page 120 of 279

CONVENTIONAL BRAKE SYSTEM P

WlfH ABS

1 f3EOPX-3 I 7

I* 44 44’

/

13EOPX-318

MASTER CYLINDER PRESSURE kPa f kgffcm2, psi 1

16AOPX-m 0

PRUPORTIONING VALVE

Inspection

1. Connect the SST to the brake pipes with adapters as shown

in the figure.

Adapter and flare nut tightening torque:

12.8-21.5 Nsm f 130-220 kgfcm, I 134 90 inlbf 1

Note

l Disconnect and connect the brake pipes with SST.

2. Bleed the air from the brake system.

3. Depress the brake pedal until the master cylinder pressure

equals A; then record rear brake pressure A’.

4. Depress the brake pedal again, apply additional pressure

until the pressure equals B; then record pressure B’.

Fluid pressure

kPa { kgVcm2, psi]

A

A’ 8

8’

WITHOUT 1960

1960

ABS 120, 284 (20,284] 5880

1 al96 12, 28)

(60, 853) 2750 (28, 3881

*I96 12,281

WITH ABS $;;4 1960 f 20,284) 5880

1 *196 12,261 160, 853 3140 {32, 455)

1

*294 [3,42)

-,

--.

. p-g.’