radiator MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 21 of 279

A PRE-DELIVERY INSPECTION TABLE

PRE-DELIVERY INSPECTION TABLE

[EXTERlORI

INSPECT and ADJUST, of necessary. the followlng Items to

specrfrcatron:

0 Glass, exterior bright metal and paint for damage

0 Wheel lug nuts

0 Tire pressures

0 All weatherstrips for damage or detachment

0 Operation of bonnet release and look

0 Operation of trunk Ild, hatch and fuel lbd opener

(of equipped)

0 Door operation and alignment

0 Headtrght aiming

INSTALL the foltowrng parts

0 Wheel caps or rrngs (if equipped)

0 Outsrde mirror(s)

1 UNDER BONNET-ENGINE OFF j

INSPECT and ADJUST. If necessary, the following items to

specrflcatlon.

0 Fuel, coolant and hydraulic tines, fittings, connectlons and

components for leaks

0 Engine 011 level

0 Power steering fluid level (of equipped)

0 Brake master cylinder fluky levels

0 Clutch master cylinder fturcl levels (If equipped)

0 Wtndshreld washer reservojr flurd level

0 Radiator coolant level and specrfic gravity

0 Tightness of water hose clamps

0 Tightness of battery terminals, electrolyte level and specific

gravity

0 Manual transaxle oil level

0 Drive belt(s) tension

Cl Carburetor lrnkage (choke control, wrde open throttle posi-

tion. etc ) (carburetor model only)

q Accelerator cable and linkage for free movement

0 Headlight cleaner and flurd level (if equipped)

BLEED air from fuel line (diesel engrne only)

CLEAN the spark plugs (except for diesel engine)

piEi6F]

INSTALL the following parts

0 Rubber stopper for rnsrde rear view mirror (if equjpped)

0 Fuse for accessories

CHECK the operation of the following items.

0 Seat controls (sliding and reclining) and head rest

0 Seat belts and warning system

Cl Ign&on switch and steering lock

0 Power window (if equipped)

D Door tacks including child proof door locks

Cl Inhibitor switch (ATX only)

Cl All Ikghts rncluding warning and Indicator lbghts

0 Ignition key reminder buzzer (If equipped)

A-Z

0 Horn, wbpers and washers (front and rear, If equipped)

0 Antenna (tf equipped)

0 Cigarette Ibghter and clock (if equipped)

0 Remote control outside mirror (if equrpped)

0 Heater, defogger and air conditioner at various mode selec-

tions (if equlppedj

0 Sunroof (If equipped)

CHECK the following items

0 Presence of spare fuse

0 Upholstery and Interior finish

CHECK and ADJUST, If necessary, the followjng items:

IJ Operation and fit of windows

0 Pedal height and free play of brake and clutch pedal

0 Parking brake UNDER BONNET-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

0 Operation of Idle-up system for air condbtroner or power steer-

ing (if equrpped)

0 Automatic transaxle flurd levet

0 tnltial ignrtlon timing (except disel engine)

0 Idle speed

0 Operation of throttle positron. sensor (EGI engrne)

0 Operation of cold start device and glow plug warning light

(diesel engine only)

0 Operation of dash pbt (EGI.engine)

fTiGGJ

CHECK the following items.

0 Underside fuel, coolant and hydraulic Irnes, ftttlngs, connec-

tions and components for leaks

0 Trres for cuts or brurses

0 Steering Itnkage, suspensron, exhaust system and all under-

side hardware for .looseness or damage 1 ROAD TEST j

CHECK the following items

0 8rake operation

0 Clutch operation

0 Steering control

!ZI Operation of meters and gauges

Cl Squeaks, rattles or unusual noises

Cl Engine general performance

0 Emergency locking retractors 1 AFTER ROAD TEST ]

REMOVE the seat and floor mat protective covers

CHECK for the necessary owner information materials, took

and spare tire

m vehicle

93EOAX-002

-- MAIN Char3 t: In

A: PC R: F!t T: Ti! Emis! The ed : to t!

Page 27 of 279

The following chart shows interchangeability of the main parts of the previous BP DOHC Turbo engine

and the new BP DOHC Turbo engine for 4WD models.

S ymiols: 0 _. lnterc hangeable X . . . Not Interchangeable

Part name tnterchangeability

Remark

Cytlnder head 0

Camshaft 011 seal 0

Cvllnder head bolt 0

CB :

Cyh nder

blcck

related

Crankshaft

related

Timing belt

related

Valve

related

Lubrication

system

related Cylrnder head gasket 0

Wnder head cover 0

Cylinder head cover gasket

Cylinder block

MaEn bearina cao 0

0

0

Ma+n bearino suo~oFt elate I

0 I ” ,I I

Oil pan

Timrno belt cover I X

0 I

Turbocharger oil return pipe hole increased from

13mm IO.51 in) to 17mm IO.67 in)

Seal elate

Front orl seal I 0 I

I I 0

1

Rear 011 seal 0

Crankshaft 0

Marn bearina 0

Thrust bearing

Connectmg rod

Connecting rod beartng

Piston 0

;J

X

Shape different

Piston skirt shortened

I Piston pm cl

Tw

X Sectional shape different

Piston rrng Piston ring end gap increased from 0:?5--0.30mm

Second

X ~0.006-0.011 in ) to 0.35-0.50mm IO.01 4-0.019

in ] (Measured In cylinder)

Crankshaft pulley Shape different

Rear cover ;5

Flywheel

I 0

Flywheel bolt 0

Tbmlng belt 0

Timing belt crank pulley 0

Camshaft pulley 0

Timing belt tensioner and spring

0

Idler 0

Camshaft 0

AA

Valve Intake

Exhaust

cl

0

X Metallic sodium-filled valve

Valve spring Intake

I 0

and seat

Exhaust 0

Vatve wide I 0

Valve seal

Oil pump 0

Oil pump gasket 0

oil strainer 0

Oil strainer gasket 0

Oil cooler

X Heat dissi patlon capacity increased

Oil jet

Oil filter Shape different

1 Water pump 0

Coohng Thermostat 0

system

related Radiator 0

Cooling fan 0

I 3EO32.304

BZ-3.

Page 71 of 279

F3 TURBOCHARGERCONTROLSYSTEM

1. Radiator

2. Insulator 3. Air hose, and air pipe

4. Oxygen sensor connector

5. Front exhaust pipe

13EOF534

F3-38 6. Water hose

7. Oil pipe

8. Exhaust manifold and turbocharger

Removal Note ,.........I.....f.~.~l....... II.I.... below

Installation Note . . . . , , l.. . . . . . . , ,.. ,..*, , . . . . . . . . . below

13EOF3-339

Removal Note Exhaust

manifold and turbocharger 1. Remove the exhaust manifold and the turbocharger as an

assembly.

2. Separate the turbocharger assembly from the exhaust

manifold.

Installation Note

Exhaust manifold and turbocharger’ I I Remove .all old gaskets and

sealant. 2. Install new gaskets.

3. Supply 25 cc ( 1.5 cu in ] of oil through the oil passage

of the turbocharger.

4. Mount the turbocharger assembly to the exhaust manifold.

5. Install the turbocharger and the exhaust manifold assem-

bly to the engine and loosely tighten the nuts.

6. Install the bracket and the front exhaust pipe, and tighten

the turbocharger mounting nut%

WASTEGATE SOLENOD VALVE

Caution

l The wastegate solenoid valve must be replaced with

the turbocharger, it cannot be replaced by itself.

Inspection 1. Disconnect the connector.

2. Measure the resistance of the solenoid valve.

Resistance: 35-45 !‘l (at 20°C f68OFj) 3. M not as specified, replace the wastegate solenoid valve and

turbocharger as an assembly, if necessary.

(Refer to page F3-37.)

3. Instc

Page 136 of 279

S

BODY

INDEX . . . . . ..*.I........**........*.~*.~............*.......

s- 2

OUTLINE ..................................................

s- 3

UUJLINE OF CONSTRUCTION ..................

S- 3

BONNET BULGE

....................................

s- 3

RADIATOR GRILLE ................................. s- 4

FRONT BUMPER .................................... s- 4

REAR SKIRT ...........................................

s- 6

WHEEL ARCl-i MOLDING .........................

s- 5

( SERVICE j

SUPPLEMENTAL SERVICE fNFURMATION.. S- 6

BONNET BULGE

.......................................

s- 7

COMPONENTS ....................................... s- ‘7

FRONT BUMPER

.......................................

s- 8

COMPONENTS .......................................

s- 8

REAR SKIRT .............................................

S-10

COhiIPONENTS .......................................

S-10

Wt=fEEL ARCH MOLDING ............................

S-l 1

COMPONENTS .......................................

S-l 1

13EOSX301

Page 138 of 279

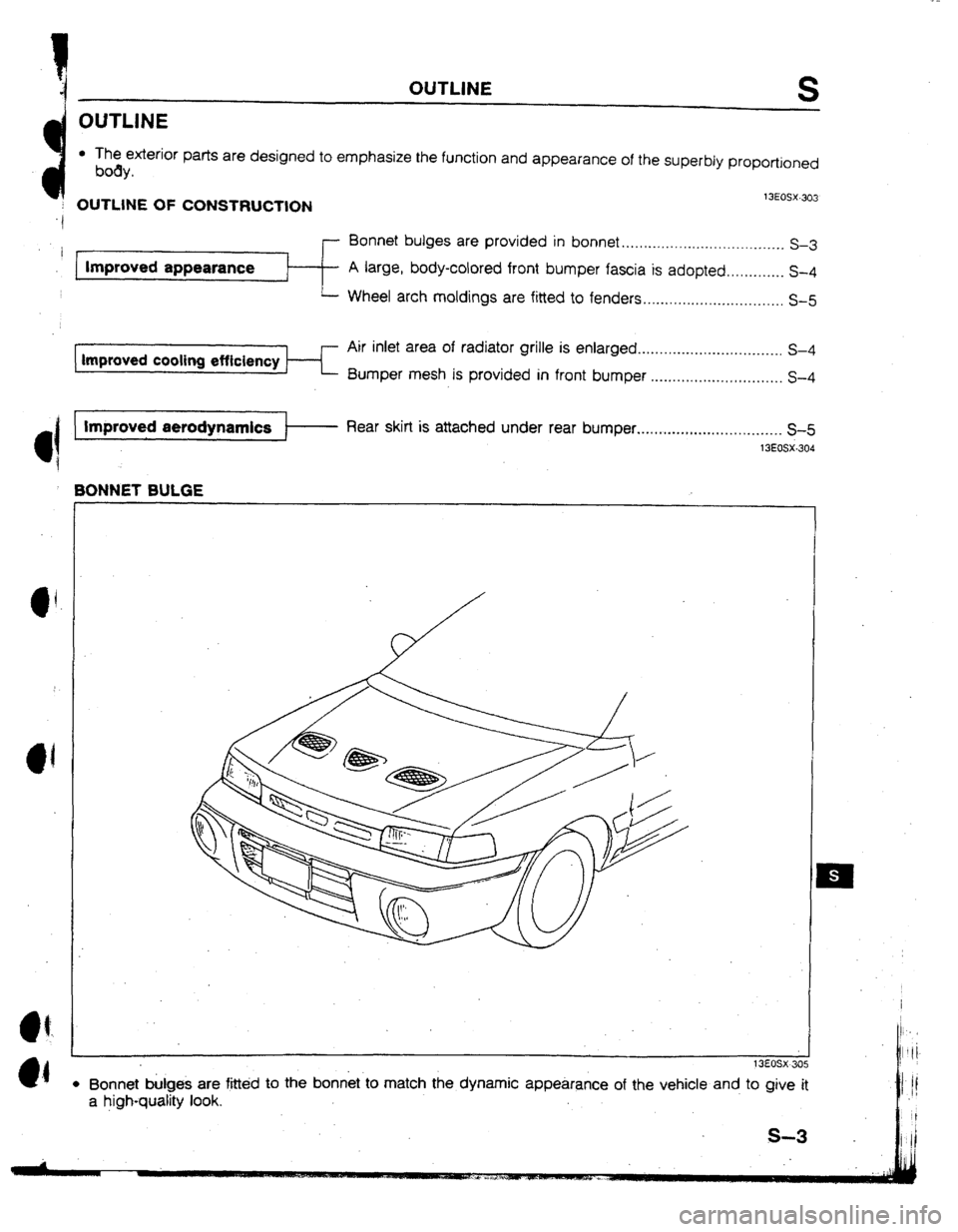

l The exterior parts are designed to emphasize the function and appearance of the superbly proportioned

body.

: OUTtlNE OF CONSTRUCTION

1 xosx.303

.c

Bonnet bulges are provided in bonnet

. . . . . . . . . . . . ..I................~.....

s-3

A large, body-colored front bumper fascia is adopted., , ..,..,.... S-4

Wheel arch moldings are fitted to fenders . . . . . . . ,..*. l.. . . . . . . . . . . . . . . . . . S-5

- Air inlet area of radiator grille is enlarged

................................. S-4

- Bumper mesh is provided in front bumper

..............................

s-4 Rear skirt is attached under rear bumper.. ............................... S-5

13EOSX-304 BONNET BULGE

l Bonnet bulges are fittGd to the bonnet to match the dynamic appearance of the vehicle and to give it

a high-quality look.

Page 139 of 279

UUTLINE

RADfATOR GRfLtE

l The air inlet area of the radiator grille is enlarged for improved cooling efficiency.

FRONT BUMPER

l The large front bu,mper includes fog lights and bumper mesh to give the vehicle a dynamic appearance.

l tight and rigid polyurethane is used for the bumper fascia.

l The air inlet area is adopted for improved cooling efficiency.

s-4

REAR SKI

l The rear 5

l Light and

WHEEL AR4

l Wheel arc

Page 143 of 279

S

FRONT BUMPER FRONT BUMPER

COMPONENTS

Rem’ovat ! Installation

1. Removal in the order shown

2. Install in the reverse order of

1 in the figure.

removal.

-9-9.8 Nm 170-100 kgfem,

U-87 h.lbfJ

f4-m Ikgf-m, ft-lbf J

13EOSX-312

4. Front bumper

Disassembly / Assembly

. . . . . . . . . ..m... page S-9 1. Radiator grille

2. Front conbination light

3. Headlight

5-8

Disassembh

I . Disassemi

2. Assemble

t

1. Fog lights

-

a

-I. 2. Bumper rear

3. Bumper me

Page 153 of 279

T ~WPe~MENTAL SERVICE INFORMATION, EXTERIOR LIGHTING SYSTEM

SUPPLEMENTAL SERVICE INFORMATION

The following points shown in this section are changed in comparison with 323 Workshop manual supple-

menP(1229-1 O-89t) and 323 Workshop manual supplement (1275-l O-91 C>.

Front fog light

l Removal I Installation

13EOTX-305

EXTERIOR LIGHTING SYSTEM

FRONT FOG LIGHT

Removat / tnstaitation

I. Remove in the order shown in the figure.

2. Install in the reverse order of removal.

I. Radiator grille

2. Front combination light

3. Headlight 4. Front bumper

5. Front fog light

T-4

Page 158 of 279

TECHNICAL DATA TD

Engine

Item BP DOHC turbo

Engine oii

Total (dry engine} 4.0 14.2, 3.5)

Capacity

L IUS qt, Imp qtl Ott pan 3.6 (3.8, 3.2)

011 filter 0.17 (0.18, 0.15)

Grade API Service SD, SE, SF or SG

Above 30°C (86*F) SAE 40

O*C-40*C ~32°F-1040F 1 SAE 30

-1 OOC--2O*C [ 14OF-68OF ] SAE 2OW-20

Viscosity Above -10% [14*Fj SAE ZOW-40 or 2OW-50

number -25*C--3O*C I-1 3OF-86OF ] SAE 1 OW-30

Above -25OC (-13*F1 SAE low-40 or low-50

Below O*C (32*F] SAE 5W-30

Below -2O*C I-4*F] SAE 5W-20

COOLING SYSTEM

L

item

Zooling method - 1 Engine

BP DUHC turbo

I Water-cooled, forced crrcutation

water pump

Type

mpeller diameter

Number of impeller blades

Speed ratio

tiater seal type

rhermostat

bfpe

Opening temperature

Full-open temperature

Full-open lift mm [in)

OC (OF)

*C j*FJ

mm (in] Centrifugal, V-belt driven

75 12.95)

6

1 : 1.05

Unified mechanical seal

Wax, two-stage

Marn: 86.5-89.5 [ 788-I 93 1

Sub: 83.5-86.5 [182-i 88)

loo (212)

Main: 8.0 (0.31 1 min.

Sub: 1.5 IO.061 min.

Radbtor

Type

Cap valve opening pressure kPa { kgflcm2, psi)

Cooling circuit checkrng pressure kPa ( kgflcm2, psi 1

Cooling fan

Type

Number of blades

Outer diameter mm {in 1

Capacity w-v

Current A

Water thermoswitch

OFF-+ON “C 1°F) 1

Radiator thermoswitch

OFFdON OC (OF]

Coolant

Capacity LWS qt,

Imp qt) Coolant protection

Above -16*C (3OF]

Antifreeze solutron

.Above -26*C t-1 5*F ) -

Above -4UOC I-40°F) Corrugated fin

74-103 {0.75--1.05, 11-15)

103 11.05, 15)

Electric

5

340 (13.41

160-12

Hi: 13.3+ 10% max., Lo: 8.8+ 10% max.

97 f207)

105 [221)

6.0 16.3, 5.3)

Specific gravity at 20*C (68*f)

1.054

1.066

1.078 -.ep

1

Page 166 of 279

![MAZDA 323 1992 Workshop Manual Suplement SUSPENSION i

TECHNICAL DATA TD

I

Item

Specifications

Front suspension

Suspension type

strut

Sprrng type

Coil spring

Type Oil 1

Shock absorber

Damping force Extended

1,470 1150, 3N]

N [ k MAZDA 323 1992 Workshop Manual Suplement SUSPENSION i

TECHNICAL DATA TD

I

Item

Specifications

Front suspension

Suspension type

strut

Sprrng type

Coil spring

Type Oil 1

Shock absorber

Damping force Extended

1,470 1150, 3N]

N [ k](/img/28/57055/w960_57055-165.png)

SUSPENSION i

TECHNICAL DATA TD

I

Item

Specifications

Front suspension

Suspension type

strut

Sprrng type

Coil spring

Type Oil 1

Shock absorber

Damping force Extended

1,470 1150, 3N]

N [ kgf, Ibf ] at 0.3 mls

Compressed 1

686 (70, 154)

Stabilizer Type Torsion bar

Oiameter mm {in]

23.0 (0.91 )

Total toe-in mm (in>

2 f 3 (0.08 f 0.12)

degree

0*12’ f 18’

Front wheel Turning angle Inner

38* f 3*

alignment

degree Outer

300 f 30

(* Unladen)

Camber angle degree

-u045’ f 45’

Caster angle degree

2035 f 45’

Kingpin angle

degree 12010’

Rear suspension

Suspension type

I Strut

Spring type

Coil spring

Type Oil

Shock absorber

Damping force Extended

882 (90. 1981

N I kgf, Ibf t at 0.3 mis Compressed

392 140, 88 1

Stabilizer , Type Torsion bar

Diameter mm [in] ?9.? { 0.75 1

Rear wheel

Totat toe-in mm {ini

2 f 3 (0.08 f 0.12)

alignment degree

0°t2’ f 18’

(‘Unladen)

Camber angle degree

-0020’ f 45’

l Fuel tank Ml; radiator coolant and engrne oil at speciffed levels; and spare tire, jack, and tools in designated poations.

Coil Spring Specifications

Item Wire diameter Coil center diameter Free length Coil identification mark coler

mm [in] mm (in) mm (in] number

M” Ae2

Front With sunroof 14.5

IO.57 1 l32.5-158.5 15.22-6.24 ) 271.5 1 IO.69 ] 3.35 Pink

Green

.

WIthout sunroof 14.4 IO.561 1 132.6-158.6 (5.22-6.241 267.0 I IO.51 ] 3.24 Light blue Red

With sunroof 8.8-l 2.5

[ 1 0.34-0.49 128.5-131.2 15.0~5.17) 334 { 13.151 6.19 Cream -

Rear .

I 1 Without sunroof I ff;;y;4”81 I t28.6-13t.j [5.06--5.16) / 335 113.19) 1 6.23 1 Pink 1 - I

l I Main rdentrficatlon mark color: Indicated on second coil from bottom.’ l 2 Auxiliary identification mark color: Indicated on third coil from buttom.

TD-13