warning MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 4 of 279

c

>

3

3

Gf

m

GENERAL INFORMATION

1MPORTANT INFORMATION

..................... GI- 2

BASIC ASSUMPTIONS ............................ a- 2 I

SAFETY RISK

........................................ Gl- 2

POSSIBLE LOSS OF WARRANTY

............. Gl- 2

WARNING ON LUBRICANTS

AND GREASES

.................................... GI- 2

HOW TO USE THIS MANUAL..

.................. GI- 3

PREPARATION

...................................... GI- 3

REPAtR PROCEDURE .............................

GI- 3

SYMBOLS .............................................

GI- 4

NOTES, CAUTIONS, AND WARNINGS.. .....

Gl- 4

FUNDAMENTAL PROCEDURES

................. GI- 4

PROTECTION OF THE VEHICLE .............. G1- 4

A WORD ABOUT SAFE-T-Y

....................... Gl- 5

PREPARATION OF TOOLS

AND MEASURING EQUIPMENT ............. Gi- 5

SPECIAL TOOLS ....................................

GI- 5

REMOVAL OF PARTS .............................

GI- 5

DISASSEMBLY ......................................

GI- 5

REASSEMBLY

....................................... GI- 6

ADJUSTMENTS .....................................

Gl- 7

RUBBER PARTS AND TUBtNG ................ GI- 7

JACK AND SAFETY STAND POStTlONS .... GI- 8

VEHICLE LIFT (20SUPPORT TYPE)

POSITIONS ............................................

GI- 6

MAINTENANCE NOTE ..............................

GI- 9

SPEEDOMETER TESTER CHECK

............. GI- 9

BRAKE TESTER CHECK

......................... GI- 9

CHASSIS DYNAMOMETER CHECK.. ......... Gl-I 0

WHEEL BALANCE.R ...............................

GI-I 0

TOWtNG ...............................................

GI-I 0

IDENTlFiCATlON NUMBER LOCATIONS

..... GI-I

2 .UNlTS .....................................................

GI-I 2

ABBREVIATIONS

.....................................

GI-12

CAUTION

................................................ GI-13

INSTALLATlON OF MOBILE TWO-WAY

RADIO SYSTEM ...................................

Gl-13

PRECAUTIONS TO TAKE WHEN

SERVICING AN ELECTRICAL SYSTEM ..i GI-f4

HANDLING CONNECTORS ..................... GI-f 5

USING ELECTRICAL

MEASURlNG EQUIPMENT ........................................

GI-16

13EGIX-30 1

Page 5 of 279

GI tMPORTANT INFORMATION

IMPORTANT INFORMATION

BASIC ASSUMPTIONS

This workshop manual assumes that you have certarn special tools that are necessary for the safe and

efficient performance of service operations on Mazda vehicles and that you know how to use them properly.

It also assumes that you are familiar with automobile systems and basic service and repair procedures.

YOU should not attempt to use this manual unless these assumpttons are correct and you understand the

consequences described below.

SAFETY RtSK

This manual contains certain notes, warnings, and other precautionary information that you should care-

fully read and follow to reduce the risk of personal injury to yourself or others and the risk of improper

service that may damage the vehicle or render it unsafe. If there IS no such information in regard to any

specific service method, this does not mean there is no possibility that personal safety or vehicle safety

wili be jeopardized by the use of incorrect methods or tools.

POSStBLE LOSS OF WARRANTY

The manufacturer’s warranty on Mazda vehicles and engines can be voided if improper service or repairs

are performed by persons other than those at an Authorked Mazda Dealer.

WARNtNG ON LUBRtCANTS AND GREASES

Avoid all prolonged and repeated contact with mineral oils, especially used oils. Used oils contaminated

during service (e+g., engine sump oils) are more irritating and more likely to cause serious effects, includ-

ing skin cancer, in the event of gross and prolonged skin contact.

Wash skin thoroughly after work involving 011.

Protective hand cleaners may be of value provided they can be removed from the skin with water Do

not use gasoline, paraffin, or other solvents to remove oil from the skrn.

Lubricants and greases may be slightly irritating to the eyes.

Repeated or protonged skin contact shoutd be avoided by wearing protective clothing if necessary. Par-

ticular care should be taken with used oils and greases containing lead. Do not allow work clothing .to

be contaminated with oil. Dry clean or launder such clothing at regular intervals.

9MtlGIX-002

Gt-2 REP/

I. Mc

pai

2. &

illu:

3. Put

vir:

Exarr

SHOI

EXPE

PART

SHOW

REUl

PAGE

SEWI

‘1: T

*2: c

Page 7 of 279

GI HOW TO USE THIS MANUAL/FUNDAMENTAL PROCEDURES

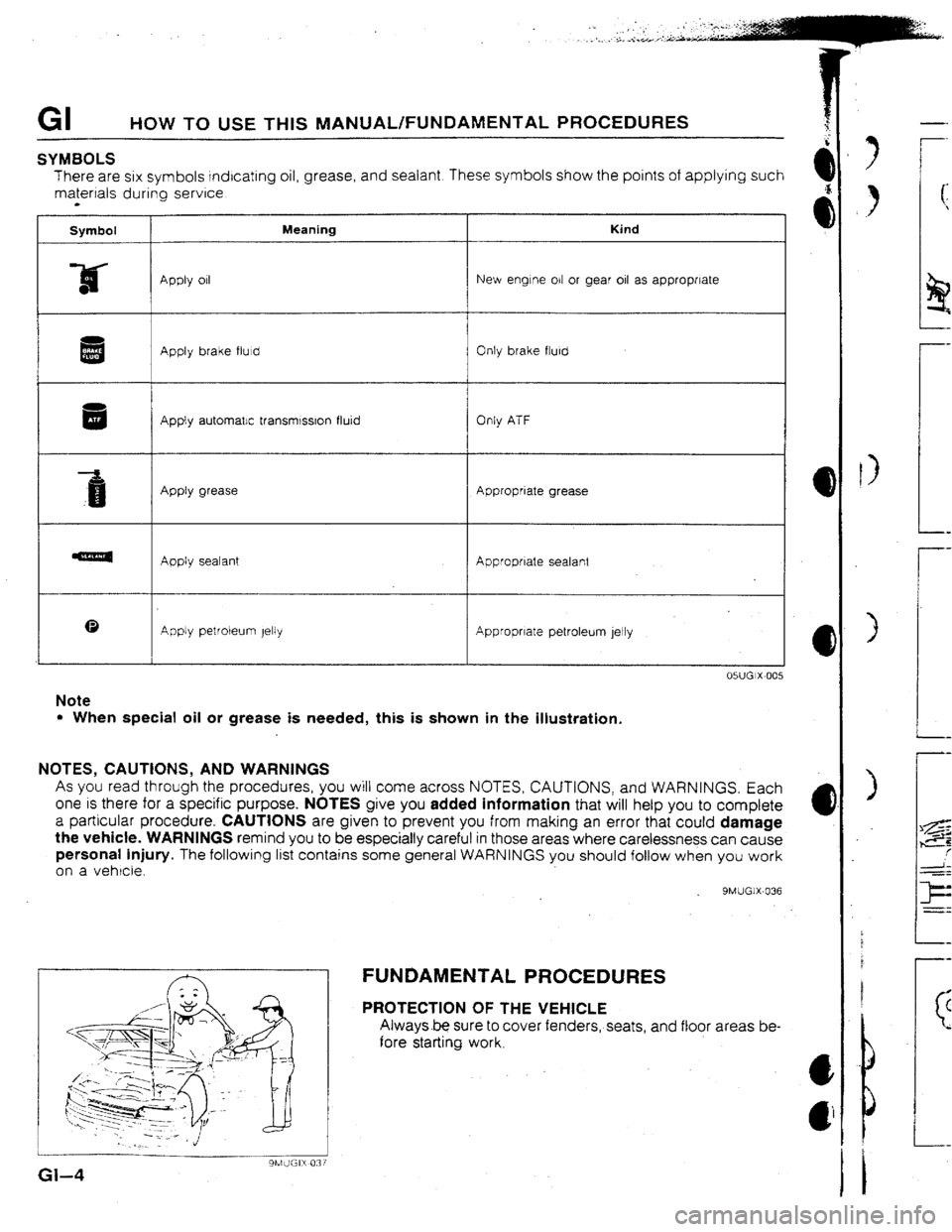

SYM00LS

There are six symbols indicating oil, grease, and sealant. These symbols show the points of applying such

matertals during service

*

Symbol

w-

l Apply otl Meaning Kind

New engtne 011 or gear 011 as approprkate

Apply brake fluid Only brake fluId

I

Apply automatic transmtsslon fluid Only ATF

Apply grease Appropriate grease

Apply sealant Approprrate sealant

0

Apply petroleum Jelly

Appropriate petroleum jetty

05UGIX-005 Note

l When special oil or grease is needed, this is shown in the illustration.

NOTES, CAUTIONS, AND WARNINGS

As you read through the procedures, you will come across NOTES, CAUTIONS, and WARNINGS. Each

one IS there fur a specific purpose.

NOTES give you added information that wilt help you to complete

a particular procedure. CAUTlONS are given to prevent you from making an error that could damage

the vehicle. WARNINGS remind you to be especially careful in those areas where carelessness can cause

personal injury. The following list contains some general WARNINGS you should follow when you work

on a vehrcle

. 9MUGlX.036

FUNDAMENTAL PROCEDURES PROTECTION OF THE VEHICLE

Always .be sure to cover fenders, seats, and

fore starting work. floor areas be-

1

T.

i

8

s

Q

8

e

Page 21 of 279

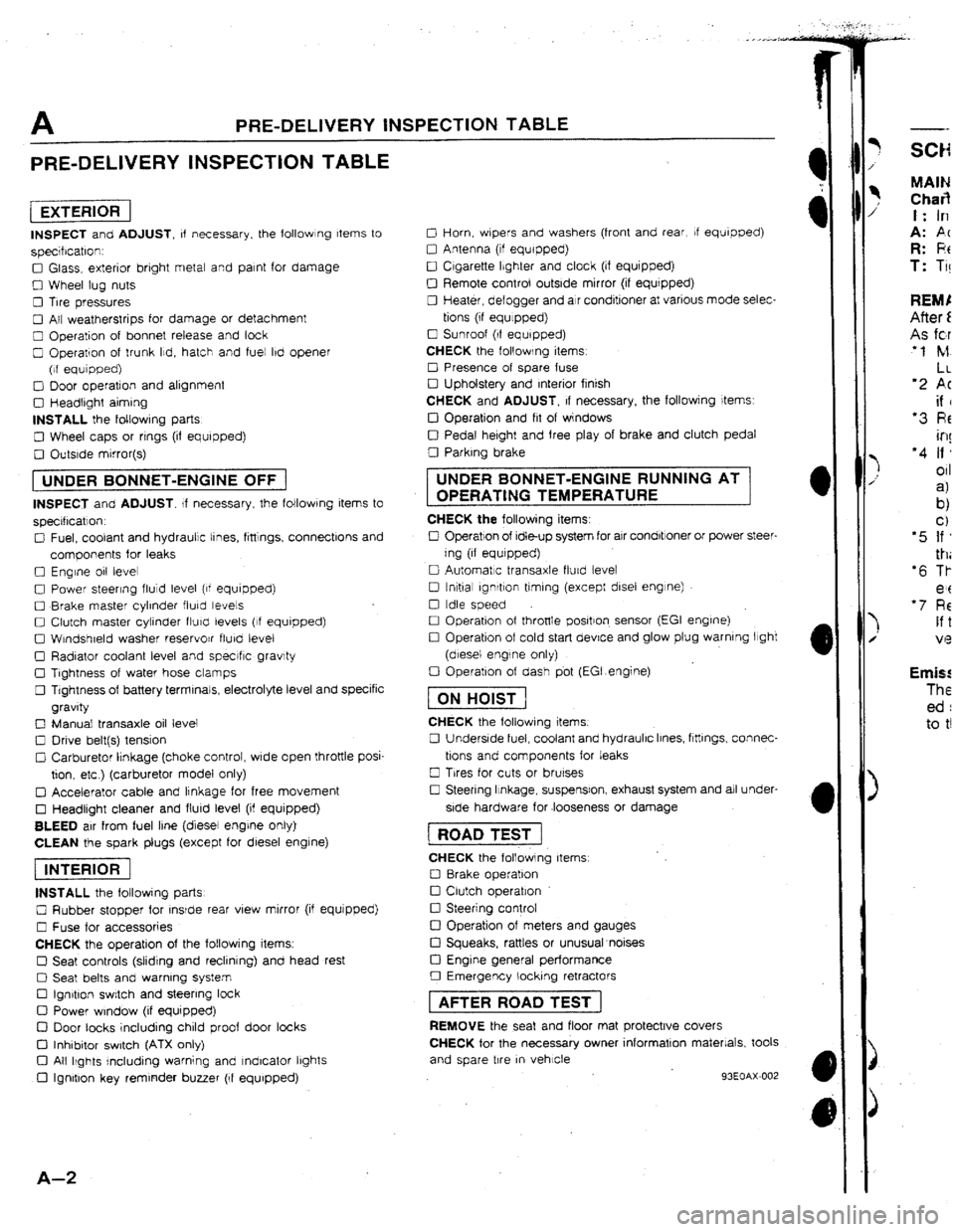

A PRE-DELIVERY INSPECTION TABLE

PRE-DELIVERY INSPECTION TABLE

[EXTERlORI

INSPECT and ADJUST, of necessary. the followlng Items to

specrfrcatron:

0 Glass, exterior bright metal and paint for damage

0 Wheel lug nuts

0 Tire pressures

0 All weatherstrips for damage or detachment

0 Operation of bonnet release and look

0 Operation of trunk Ild, hatch and fuel lbd opener

(of equipped)

0 Door operation and alignment

0 Headtrght aiming

INSTALL the foltowrng parts

0 Wheel caps or rrngs (if equipped)

0 Outsrde mirror(s)

1 UNDER BONNET-ENGINE OFF j

INSPECT and ADJUST. If necessary, the following items to

specrflcatlon.

0 Fuel, coolant and hydraulic tines, fittings, connectlons and

components for leaks

0 Engine 011 level

0 Power steering fluid level (of equipped)

0 Brake master cylinder fluky levels

0 Clutch master cylinder fturcl levels (If equipped)

0 Wtndshreld washer reservojr flurd level

0 Radiator coolant level and specrfic gravity

0 Tightness of water hose clamps

0 Tightness of battery terminals, electrolyte level and specific

gravity

0 Manual transaxle oil level

0 Drive belt(s) tension

Cl Carburetor lrnkage (choke control, wrde open throttle posi-

tion. etc ) (carburetor model only)

q Accelerator cable and linkage for free movement

0 Headlight cleaner and flurd level (if equipped)

BLEED air from fuel line (diesel engrne only)

CLEAN the spark plugs (except for diesel engine)

piEi6F]

INSTALL the following parts

0 Rubber stopper for rnsrde rear view mirror (if equjpped)

0 Fuse for accessories

CHECK the operation of the following items.

0 Seat controls (sliding and reclining) and head rest

0 Seat belts and warning system

Cl Ign&on switch and steering lock

0 Power window (if equipped)

D Door tacks including child proof door locks

Cl Inhibitor switch (ATX only)

Cl All Ikghts rncluding warning and Indicator lbghts

0 Ignition key reminder buzzer (If equipped)

A-Z

0 Horn, wbpers and washers (front and rear, If equipped)

0 Antenna (tf equipped)

0 Cigarette Ibghter and clock (if equipped)

0 Remote control outside mirror (if equrpped)

0 Heater, defogger and air conditioner at various mode selec-

tions (if equlppedj

0 Sunroof (If equipped)

CHECK the following items

0 Presence of spare fuse

0 Upholstery and Interior finish

CHECK and ADJUST, If necessary, the followjng items:

IJ Operation and fit of windows

0 Pedal height and free play of brake and clutch pedal

0 Parking brake UNDER BONNET-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

0 Operation of Idle-up system for air condbtroner or power steer-

ing (if equrpped)

0 Automatic transaxle flurd levet

0 tnltial ignrtlon timing (except disel engine)

0 Idle speed

0 Operation of throttle positron. sensor (EGI engrne)

0 Operation of cold start device and glow plug warning light

(diesel engine only)

0 Operation of dash pbt (EGI.engine)

fTiGGJ

CHECK the following items.

0 Underside fuel, coolant and hydraulic Irnes, ftttlngs, connec-

tions and components for leaks

0 Trres for cuts or brurses

0 Steering Itnkage, suspensron, exhaust system and all under-

side hardware for .looseness or damage 1 ROAD TEST j

CHECK the following items

0 8rake operation

0 Clutch operation

0 Steering control

!ZI Operation of meters and gauges

Cl Squeaks, rattles or unusual noises

Cl Engine general performance

0 Emergency locking retractors 1 AFTER ROAD TEST ]

REMOVE the seat and floor mat protective covers

CHECK for the necessary owner information materials, took

and spare tire

m vehicle

93EOAX-002

-- MAIN Char3 t: In

A: PC R: F!t T: Ti! Emis! The ed : to t!

Page 74 of 279

FUEL SYSTEM F3

13EOF3.34

c I 13EOF3-364 FUEL PUMP CONNECTOR

/

!NSTALL CLAMPS

I

l nspection

1, Disconnect the resistor/relay connector.

2. Ground the fuel pump resistor relay terminal D.

3. Apply battery voltage and check for continuity as shown.

Terminal C

Continuity between A and I3

Battery voltage applied NO

ov Yes

4. Measure the resistance between terminals E and F.

Resistance : 0.38--0.42Q (at 2O*C {6S°F 1)

PRESSURE REGULATOR

Inspection

Fuel line pressure

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page F3-21.)

1. Disconnect the negative battery terminal.

2. Connect a fuel pressure gauge between the fuel filter and

the fuel main hose. (install clamps as shown.) , .

I

3. Connect the negative battery terminal.

/t.

4, Start the engine and run it at idle.

5. Measure the fuel line pressure.

Fuel line pressure:

206-255 kPa [ 2.1-2.6 kgflcml, 30-37 psi )

6. Disconnect the upper vacuum hose from the pressure regu-

lator and measure the fuel line pressure.

Fuel line pressure:

304-392 kPa (3.1-4.0 kgf/cm2, 44-57 psi )

F3-41

Page 75 of 279

F3 FUEL SYSTEM

13EOt=3-349

f3EOF3-350

0

0

ECU

G

0

0 i

13EOF3-35

tNJECTOR

t nspection

injector resistance

1. Disconnect the injector harness,

2. Measure resistance of the injector.

Resistance: l-3Q (at 20°C (68*F])

3. If

not as specified, replace the injector.

Volume Test

1, Remove the injectors and delivery pipe assembly with the

conectors con netted.

2. Affix the injectors to the delivery pipe by using wire.

Warning

l Be extremely careful when working with fuet. Al-

ways work away from sparks and open flames.

Caution

l Affix the injectors firmly to the detivery pipe so that

they do not move.

3. Turn the ignition switch ON and ground the F/P terminal

of the diagnosis connector.

4. Test the individual injectors by following the procedure out-

lined in the chart below.

Test inpctor no.

1

2

3

4 Disconnect injector connector no. Ground ECU terminal

3 2u

4 2v

1 2U

2 2v 5. Check the injection volume by using a graduated container.

Injection v&tie:

105-151 cc [6.40-9.22 cu in)/15 sec.

6. If the injection volume is not as specified, replace the injector.

INJECTOR REStSTOR

Inspection

I. Disconnect the injector harness.

?. Measure resistance of the injector resistor.. .

tnjector

No.1

No.2

No.3

No.4 Measured terminals

Resistance

gg 6 0 (at 2U°C

16PF))

3. If not as specified, replace ihe injector resistor.

F3-42 _

13EOF3-352

Page 85 of 279

F3 CONTROL SYSTEM

Terminal Input Dutpui

2s - 0

2T 0

2U 0

2v 0

2w 0

2x 0

2Y 0

22 0 t

I, Ve: Battery voltage I I I Connected to Test condition

Correct voltage Remark

Overboost warning lgnitron switch ON

VB

-

buzzer

Solenoid valve

(PRC low temp.) 180 sec. after engrne started with coolant Below 1.W No-load engine

temperature is above 9O*C { 194*F ] and condition

intake air temperature IS between 40°C

1104*FJ and 50°C {122OF

f Other condition at idle

I VS

tnjector {Nos. 1, 3) Ignition switch ON VS

Idle V0’

I Engine speed above 2,000 rpm during

I Ve

deceleration (after warm-up)

Injector (Nos 2, 4) Ignition switch

ON VS

Idle VS’ * Engine Signal

Monrtor: Green

and red lamps

flash

ISC valve Engine speed above 2,000 rpm during VS

deceleration (after warm-up)

Ignition switch ON Approx. 7V

-

Idle 1 Approx. 9V

Solenoid valve

(purge control) Ignition switch ON

Idle V0

-

VB

Ci rcuit-opening

relay ignition switch ON

tdle 1 VB

I 8elow l.OV -

Solenotd valve

(PRC high temp.) 210 sec. after engine started wrth coolant Below 1.5V

temperature above 90°C ]194*F] and

Intake atr temperature above 50°C

f t22*F1 No-load engine

cond$on

1 Other condition at idle

I VB

I -

7 I PI

I l-1 t

r

2'f 2W 2U 25 iQ 20 &A 2K 21 2G 2E 2C 2A 1U 1s 10 10 1M 1K 11 tG If 1C 1A

F3-52 --

A/w&

--

Alway

--

Alway

--

Alway

--

Alwaj

--

Alwa f

--

Alwas]

--

Alwa I’

Page 167 of 279

TD TECHNlCAt DATA -

BODY EtECTRtCAL SYSTEM

ttem

Headlight

Front fog light

Front turn signat light

Parking light

Front side turn light

StocYlailliaht Specifications (w)

ECE

I Swiss

60155

55

21

5

5

2115

Exterior tamps

Taillight &8) 5

Rear turn single tight 21

Back-up light

21

License plate light

5

Flash-to-pass light 55 (Austrra)

I -

Running Ilght

55 (Sweden, Norway, Iceland)

Rear fog light 21

Interior and spot lamp Interior 10

Spot 6

Interior Iamps

Interior lamp 10

Spot tamp (in overhead console) 8

Cargo compartment lamp

5

High beam

3.4

Turn light

3.4

Brake 3

Hold 3

Charge 3

011 pressure 3 -.

lndcator and n Washer 3

warning Iamps TUF~O 3

Fuel

1 3

Rear fog

I

! 3

1

ABS

Parktng brake

Illumination I 3

3 .

3.4

Rear

Cliff. lock f 3

3 I STANDARD BOLT AND NUT TIGHTENING TORQUE

! Diameter Pkh I 41

8T f&lb N-m I 81 mm {tn] mm fin] N-m 1 m-kg

dsf Wtb 1 Nm

mkg ft4b 6 IO.2361 1 {0.039] 4.2-6.2 /0.43-O-63 3.1-4.6

6.9-9.8 0.7-1.0 5.0-7.2 7.8-11.8 O-8-1.2 5.8-8.8

8 IO.3151 1.25 (0.049) 9.8-14.7 1 1.0-1.5 7.2-10.8 16-23 1 1.6-2.3 12-17 18-26 1.8-2.7 13-20

10 IO.3941

It.25 10.04911 20-28 1 2.0-2.9 1 14-21 31-46 1 3.2-4.7

23-34 36-54 3.7-5.5 27-40

I r

12 IO.4721

1.5 lO.OSSj 34-50 3.5-5-l 25-37 1 55-80

5.6-8.2 41-59 63-93 6.4-9.5 46-69

14 {0.551] 1.5 IO.059) - - - 75-103 7.7-10.5 56-76 102-137 lo-14 75-101

16 #0.630] 1.5 {O.OSSl - -

- f16-157 12-16 85-116 156-211 16-22 115-156

t8 (0.709) 1.5 [0.059] - - - 167-225 17-23

123-166 221-299 23-31 163-221

20 IO.7871 I,5 {0.059]

- - - 231-314 24-32 171-231 308-417 31-43

227-307

22 (0.866) 1.5 IO.0591

- 1 - - 334-423 32-43 231-312 417-564 43-58

' 307-416

24 10.945) 1.5 10.059) - 1

- - 1475-5461 41-56 298-403 1536-7261 55-74

396-536

c)

c) I

-.

c’

c .

4

Page 179 of 279

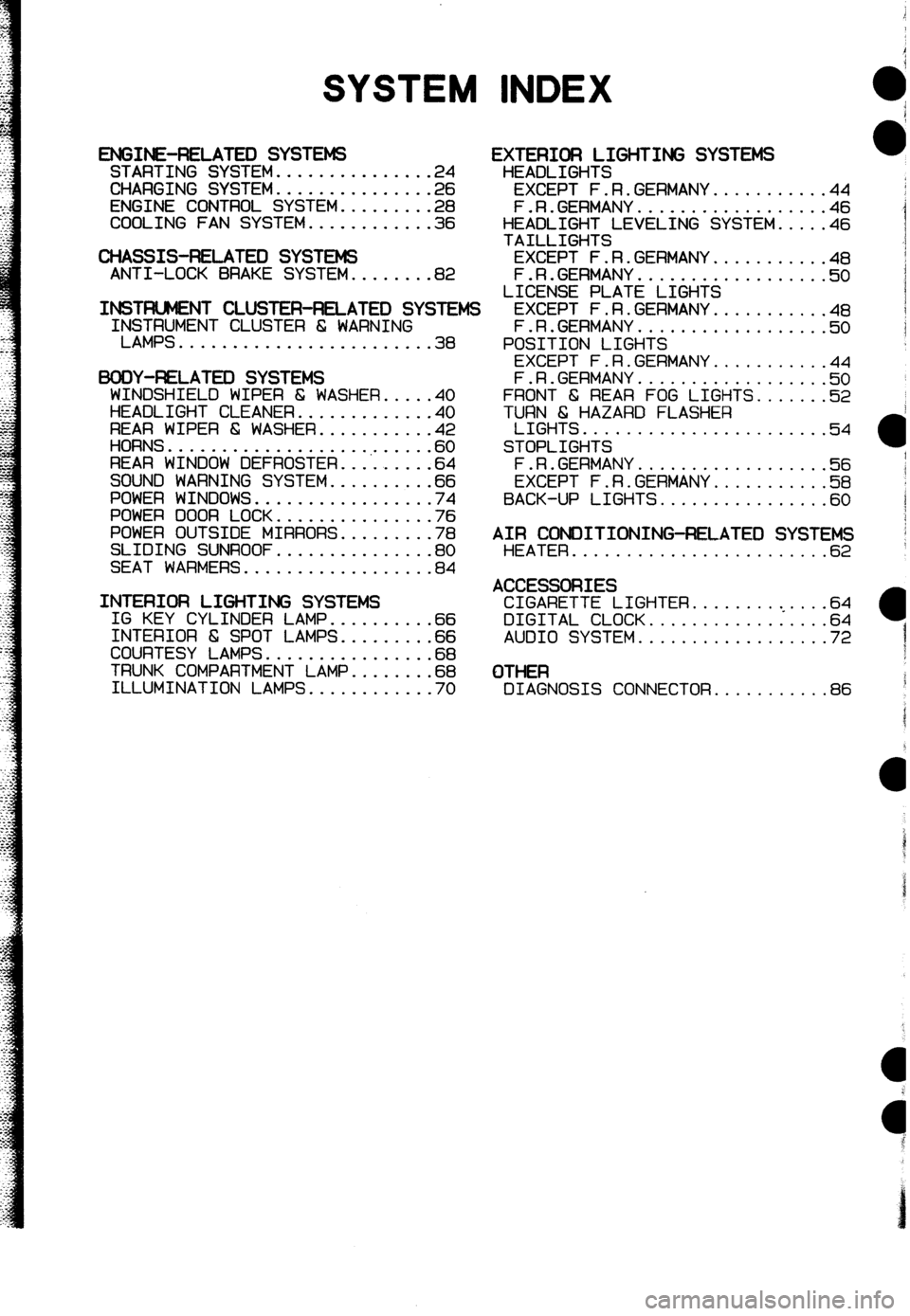

SYSTEM INDEX

ENGINE-RELATED SYSTEMS STARTING SYSTEM...............2 4

CHARGING SYSTEM...............2 6

ENGINE CONTROL SYSTEM.........2 8

COOLING FAN SYSTEM............3 6

CHASSIS-RELATED SYSTEMS ANTI-LOCK BRAKE SYSTEM........82

INSTFUJMENT CLUSTER-RELATED SYSIEMS IrS$;MENT CLUSTER 6 WARNING

........................ 38

BODY-F&LATEX) SYSTEMS

WINDSHIELD WIPER 6 WASHER.....4 0

HEADLIGHT CLEANER.............4 0

REAR WIPER & WASHER...........4 2

HORNS...................,......6 0

REAR WINDOW DEFROSTER.........6 4

SOUND WARNING SYSTEM..........6 6

POWER WINDOWS.................7 4

POWER DOOR LOCK...............7 6

POWER OUTSIDE MIRRORS.........7 8

SLIDING SUNROOF...............8 0

SEAT WARMERS..................8 4

INTERIOR LIGHTING SYSTEMS IG KEY CYLINDER LAMP..........6 6

INTERIOR 6 SPOT LAMPS.........6 6

COURTESY LAMPS................6 8

TRUNK COMPARTMENT LAMP........6 8

ILLUMINATION LAMPS............7 0

EXTERIOR LIGHTING SYSTEMS

HEADLIGHTS

EXCEPT F.R.GERMANY...........44

F.R.GERMANY..................46

HEADLIGHT LEVELING SYSTEM.....46

TAILLIGHTS

EXCEPT F.R.GERMANY...........48

F.R.GERMANY..................5 0

LICENSE PLATE LIGHTS

EXCEPT F.R.GERMANY...........4 8

F.R.GERMANY..................5 0

POSITION LIGHTS

EXCEPT F.R.GERMANY...........4 4

F.R.GERMANY..................!i? 0

FRONT 6 REAR FOG LIGHTS.......52

TURN 6 HAZARD FLASHER

LIGHTS.......................54

STOPLIGHTS

F.R.GERMANY.a................5 6

EXCEPT F.R.GERMANY...........5 8

BACK-UP LIGHTS................6 0

AIR CONDITIONING-RELATED SYSTEMS HEATER........................6 2

ACCESSORIES CIGARETTE LIGHTER.........<....64

DIGITAL CLOCK.................64

AUDIO SYSTEM..................72

OTHER DIAGNOSIS CONNECTOR...........86

Page 201 of 279

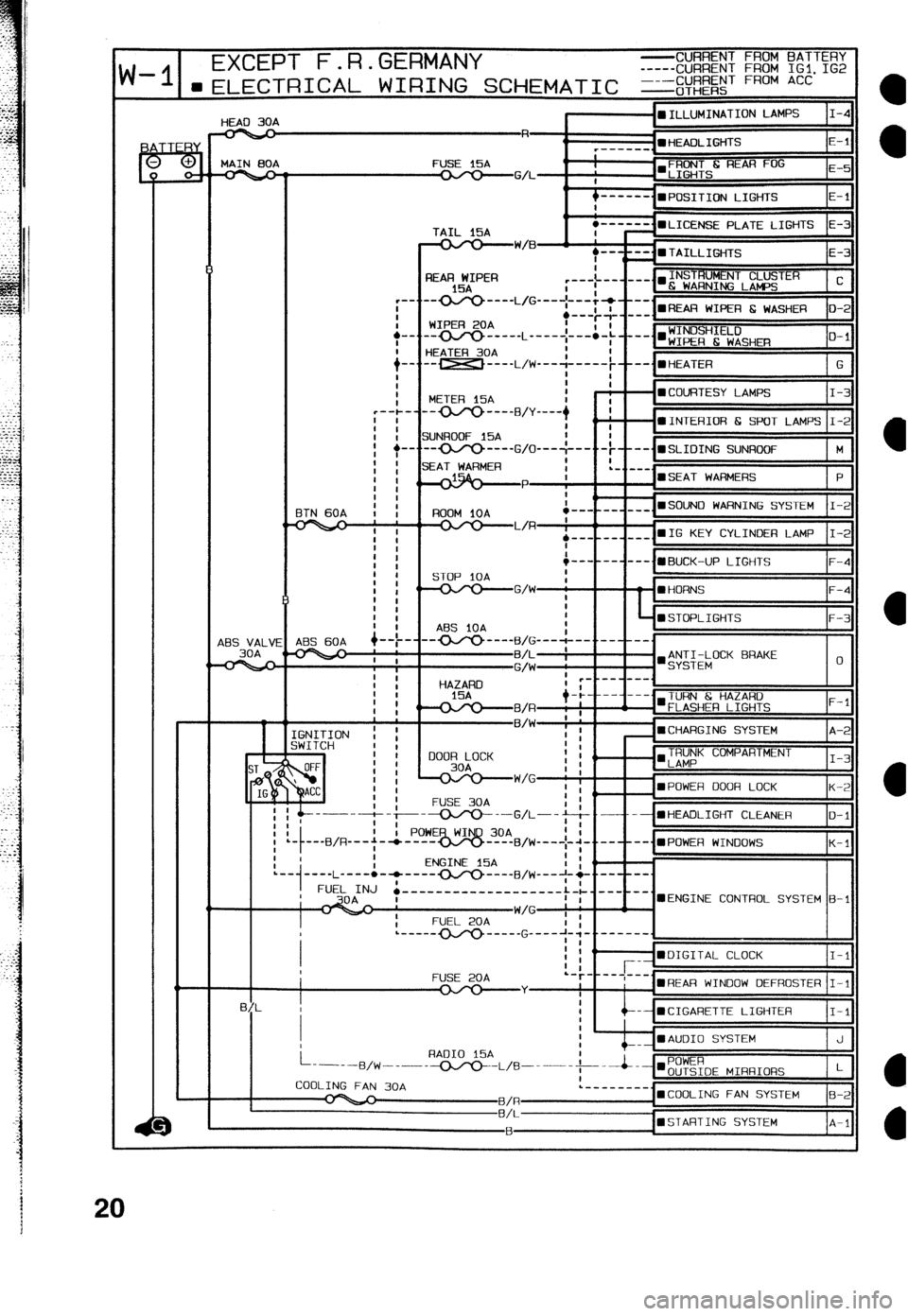

d-II __ EXCEPT F.R.GERMANY -CURRENT FROM BATTERY

-----CURRENT FROM IGl. IG2

-I 1--~-l-l-a-r-~ A, ,.,TiTl-TLITr r-.-a ar.1. ?I,-% ----CIJARENT FROM ACC

“-‘e 30A

I -mILLUMINATION LAMPS I-4

HiZP

r--- “f E-l

MAIN 00A FUSE l5A

q

-GA- I’LIE iHTS

---mm_

n POSITION LIGHTS E-l

TAIL 15A

-W/B

I

+-.

i-. I

i REAR WIPER

15A

-0J‘o ---- L/G _--- ;-.-&+v ---.

WIPER 20A .---$- ---. l REAR WIPER E WASHER o-2

m--c____ L _____ ;--:-; ____. l ;:E;H;E:;SHm

O-l

HEATER 30A

-- _-__ ,,,-j __-__; --me., HEATER

G

t

METER 15A : - - l COURTESY LAMPS I-3

-------B/y ---- + I

ZiUNROOF 15A : --•INTERIOR 6 SPOT LAMPS I-2

t

-oJy)--

G/O---:--- -t----.mSLIOING SUNROOF M

~~~~ .--- __ ___ n SOUN0 WARNING SYSTEM I-2

48s VALV

30A I

i

AES 60A +--t-

I mSTOF’LIGHTS F-3

ABS iOA

--- ’ ‘I ---

GNITION ! ;

iWITCH 1 I

TRUNK COMPARTMENT

‘LAMP I-3

‘mPOWER DOOR LOCK A

K-2

FUSE 30A

y-------t- --~--G/!---j--& .--- - l HEADLIGHT CLEANER O-l

I

’ . ---B/R---+-* ----

K-l

I PowE~~om!,IJ,+~~ -..---- -...;PO,.,ER WI,.,,,OWS

! I ENGINE 15A

’ I (’ I :

:.

.--

1 ----L ---- l -* ---- OJY) ---- FJ,w----l-q -..--

FUEL INJ ’ .-------------------:-L.---

’ I UENGINE CONTROL SYSTEM B-l

FUSE 20A

l REAR WINOOW DEFROSTER I-l

-- mCIGARETTE LIGHTER I-l

mAUOI0 SYSTEM J

aSTARTING SYSTEM A-l