clutch MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 638 of 909

M–8

ELECTRONIC 4WD CONTROL SYSTEM

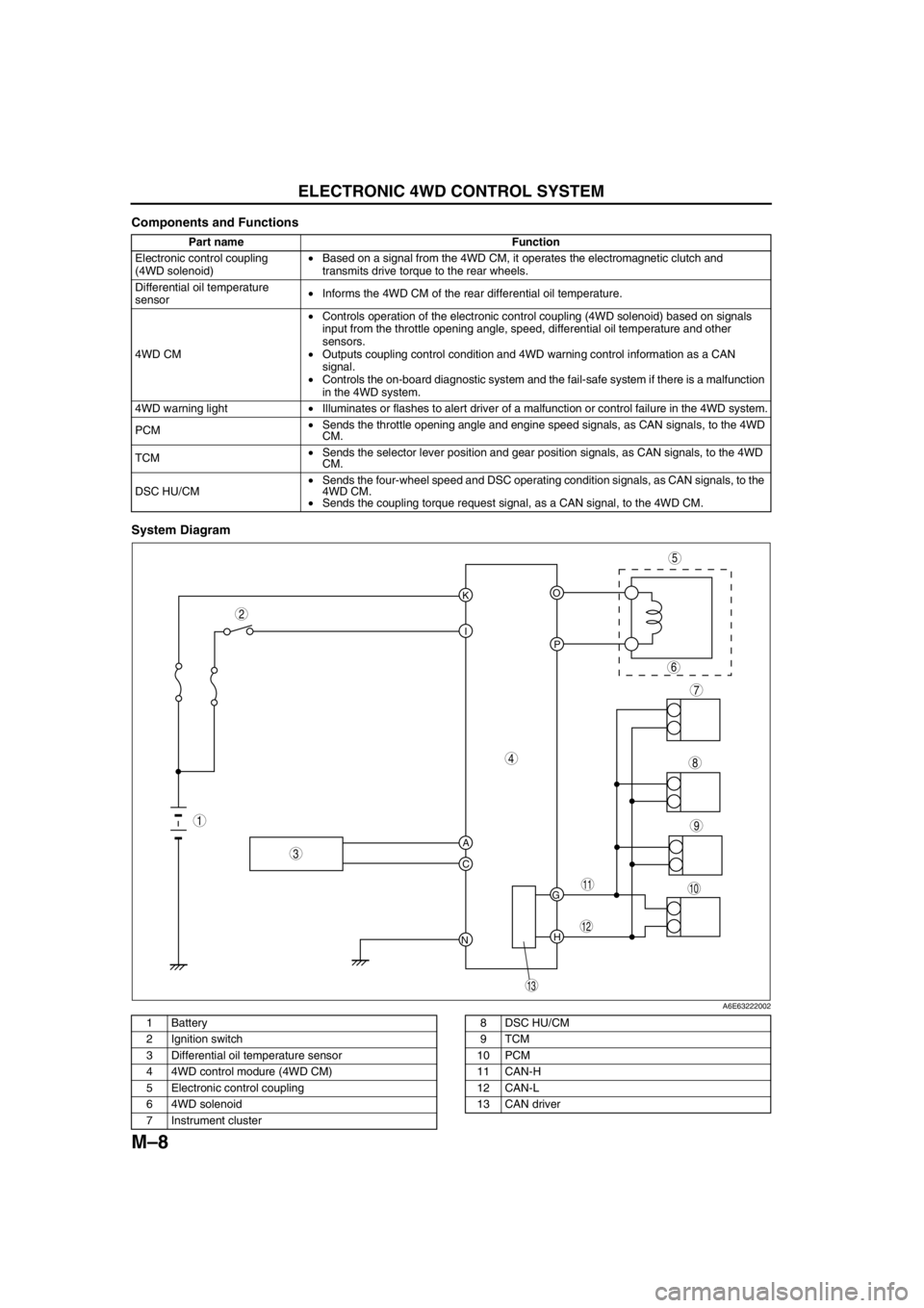

Components and Functions

System Diagram

.

Part name Function

Electronic control coupling

(4WD solenoid)•Based on a signal from the 4WD CM, it operates the electromagnetic clutch and

transmits drive torque to the rear wheels.

Differential oil temperature

sensor•Informs the 4WD CM of the rear differential oil temperature.

4WD CM•Controls operation of the electronic control coupling (4WD solenoid) based on signals

input from the throttle opening angle, speed, differential oil temperature and other

sensors.

•Outputs coupling control condition and 4WD warning control information as a CAN

signal.

•Controls the on-board diagnostic system and the fail-safe system if there is a malfunction

in the 4WD system.

4WD warning light•Illuminates or flashes to alert driver of a malfunction or control failure in the 4WD system.

PCM•Sends the throttle opening angle and engine speed signals, as CAN signals, to the 4WD

CM.

TCM•Sends the selector lever position and gear position signals, as CAN signals, to the 4WD

CM.

DSC HU/CM•Sends the four-wheel speed and DSC operating condition signals, as CAN signals, to the

4WD CM.

•Sends the coupling torque request signal, as a CAN signal, to the 4WD CM.

KO

P I

A

C

NH G

9

8

7

5

4

3

10

13

11

12

6

1

2

A6E63222002

1 Battery

2 Ignition switch

3 Differential oil temperature sensor

4 4WD control modure (4WD CM)

5 Electronic control coupling

6 4WD solenoid

7 Instrument cluster8 DSC HU/CM

9TCM

10 PCM

11 CAN-H

12 CAN-L

13 CAN driver

Page 639 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–9

M

End Of SieELECTRONIC CONTROL COUPLINGA6E632227100202Outline

Features

•An electromagnetic clutch, which operates smoothly due to the lack influence from the front and rear wheel

traction force, has been adopted for the electronic control coupling system.

•The construction of the coupling enables the torque formed by the pilot clutch to be amplified by the cam

mechanism, thus allowing the main clutch to obtain a high degree of torque. Due to this, size and weight

reduction of the component parts has been achieved.

Construction

•The electronic control coupling basically consists of an electromagnetic clutch, a cam mechanism and a torque

transmission system.

•The electromagnetic clutch consists of a 4WD solenoid (electromagnetic coil), rear-housing that forms a

magnetic path, pilot clutch, and armature. The cam mechanism consists of a pilot cam, balls, and main cam.

The torque transmission system consists of a main clutch and hydraulic oil (ATF).

.

9

8

7

5

43

10

13

1112

6

12

A6E63222003

1 Front wheel side

2 Rear wheel side

3 Torque transmission system

4 Electromagnetic clutch

5 Rear housing

6 4WD solenoid (Electromagnetic coil)

7 Cam mechanism8Ball

9 Main clutch

10 Main cam

11 Armature

12 Pilot clutch

13 Pilot cam

Page 640 of 909

M–10

ELECTRONIC 4WD CONTROL SYSTEM

Operation

4WD solenoid control current is OFF

•When the 4WD solenoid control current is OFF, no torque is generated in the pilot clutch because there is no

current flowing to the 4WD solenoid. At the same time, the pilot cam and the main cam rotate in the same

direction via the balls, and the main cam does not exert any push force on the main clutch side. Therefore, the

traction from the front wheels is not transmitted to the rear wheels.

.

8

7

5

4

3

6

12

56

7

A6E63222004

1 Main clutch

2 Pilot clutch

3 4WD solenoid (Electromagnetic coil)

4 4WD control modure (4WD CM)5Main cam

6Pilot cam

7Ball

8 Armature

Page 641 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–11

M

4WD solenoid control current is ON

•When the 4WD solenoid control current is ON, current flows from the 4WD CM to the 4WD solenoid, and the

coupling operates in the following manner.

1. Magnetic flux forms at the electromagnetic coil of the 4WD solenoid.

2. Due to the magnetic flux in the armature, the pilot clutch is suctioned towards the magnetic coil side and

made to engage. This causes frictional torque to generate in the pilot clutch.

3. The torque is transmitted to the pilot cam, which is engaged with the pilot clutch.

4. A rotational difference is created between the pilot cam and the main cam. Due to this relative torsion, the

cam mechanism operates, transmitting torque from the pilot cam to the ball and then to the main cam. In

this way, the push force exerted on the main clutch is amplified.

5. As the main clutch engages, the drive torque from the front wheels is transmitted to the rear wheels.

•The amount of push force exerted on the main clutch by the main cam (that is, the strength of the drive torque

transmitted to the rear wheels) changes in accordance with the proportion of the force acting upon the pilot

cam, engaged with the pilot clutch. Therefore, by changing the periodicity of the electric current from the 4WD

CM to the 4WD solenoid (ON/OFF rate of the 4WD solenoid = force acting on the pilot cam), the module

controls the transmission of drive torque to the rear wheels.

.

End Of Sie

98

75

4

3

10

11

6

12

56

7

12

A6E63222005

1 Main clutch

2Pilot clutch

3 4WD solenoid (Electromagnetic coil)

4 4WD control modure (4WD CM)

5Main cam

6Pilot cam7Ball

8Armature

9 Drive torque

10 Magnetic flux

11 Input

12 Output

Page 643 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–13

M

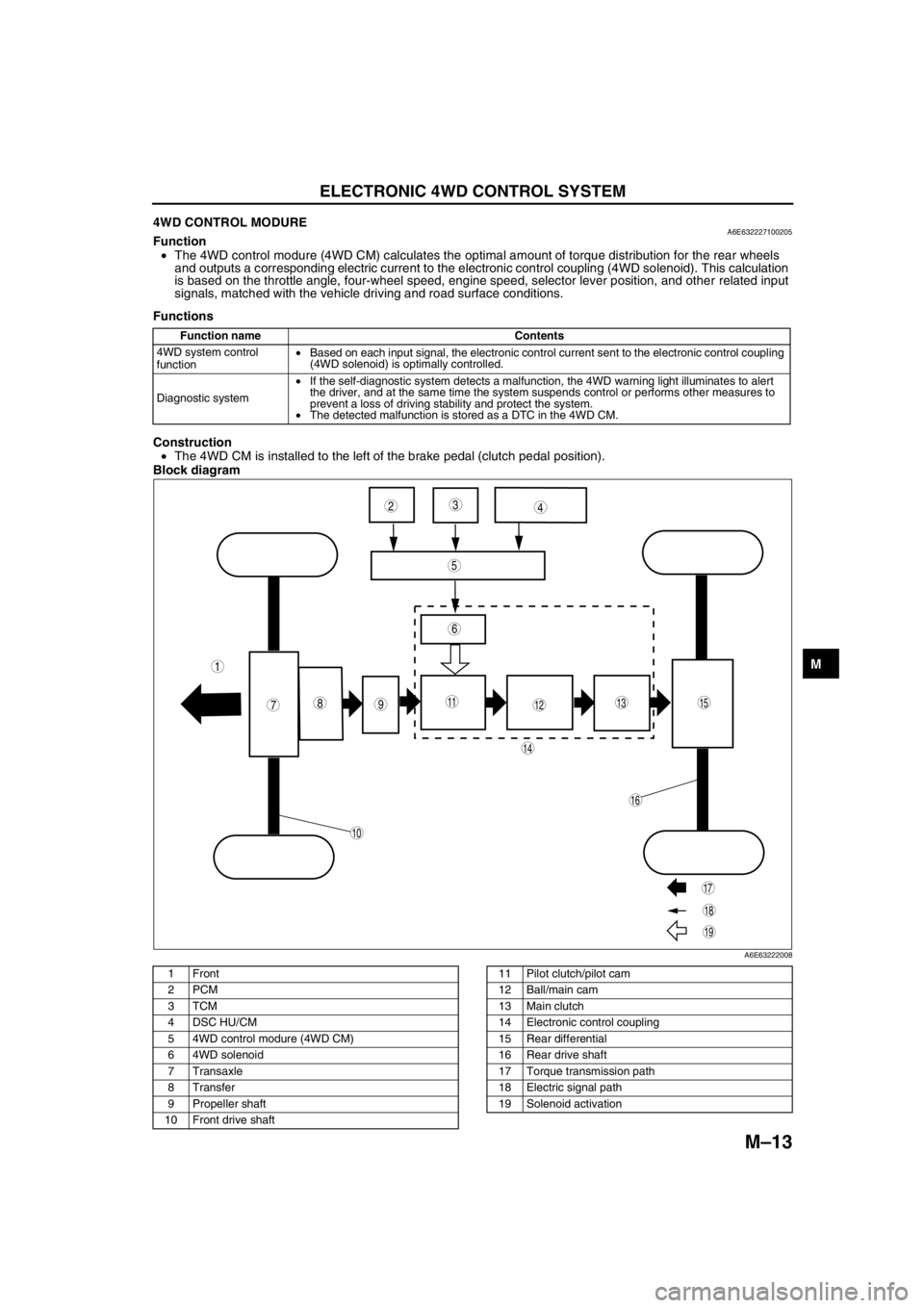

4WD CONTROL MODUREA6E632227100205Function

•The 4WD control modure (4WD CM) calculates the optimal amount of torque distribution for the rear wheels

and outputs a corresponding electric current to the electronic control coupling (4WD solenoid). This calculation

is based on the throttle angle, four-wheel speed, engine speed, selector lever position, and other related input

signals, matched with the vehicle driving and road surface conditions.

Functions

Construction

•The 4WD CM is installed to the left of the brake pedal (clutch pedal position).

Block diagram

.

Function name Contents

4WD system control

function•Based on each input signal, the electronic control current sent to the electronic control coupling

(4WD solenoid) is optimally controlled.

Diagnostic system•If the self-diagnostic system detects a malfunction, the 4WD warning light illuminates to alert

the driver, and at the same time the system suspends control or performs other measures to

prevent a loss of driving stability and protect the system.

•The detected malfunction is stored as a DTC in the 4WD CM.

987

5

43

10

19

18

17

15

16

14

131112

6

1

2

A6E63222008

1Front

2PCM

3TCM

4 DSC HU/CM

5 4WD control modure (4WD CM)

6 4WD solenoid

7Transaxle

8Transfer

9 Propeller shaft

10 Front drive shaft11 Pilot clutch/pilot cam

12 Ball/main cam

13 Main clutch

14 Electronic control coupling

15 Rear differential

16 Rear drive shaft

17 Torque transmission path

18 Electric signal path

19 Solenoid activation

Page 865 of 909

U–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E850201038201•The construction and operation of the air conditioner system is essentially carried over from that of the previous

Mazda6 (GG) model, except for the following features. (See Mazda6 Training Manual 3359-1*-02C.)

End Of Sie

FEATURESA6E850201038202Improved Comfort

•The water heater system has been adopted. (For MZR-CD (RF Turbo) European (L.H.D.) specs.)

End Of Sie

SPECIFICATIONSA6E850201038203Manual Air Conditioner

OUTLINE

ItemSpecification

L3, L8, LF MZR-CD (RF Turbo)

Heating capacity (kW {kcal/h}) 4.400 {3,784}4.400 {3,784} (L.H.D.)

5.120 {4,403} (R.H.D.)

Airflow volume

(during heater operation)Blower motor

(m

3/h)310 (L.H.D.)

300 (R.H.D.)

Electricity consumption

(during heater operation)Blower motor (W) 184

Cooling capacity (kW {kcal/h}) 4.200 {3,612}

Airflow volume (during air

conditioner operation)Blower motor

(m

3/h)460

Electricity consumption

(during air conditioner

operation)Blower motor (W) 225

Magnetic clutch (W) 46 45

Fan type Blower motor Sirocco fan

RefrigerantType R-134a

Regular amount

(approximate quantity)470 {16.6} (L.H.D.)

430 {15.2} (R.H.D.)

(g {oz})

A/C compressorType Vane-rotary

Discharge capacity

120 {120, 4.06}

(ml {cc, fl oz})

Max. allowable speed

6,400

(rpm)

Lube

oilType ATMOS GU10

Sealed volume

(approximate quantity)

120 {120, 4.06} 150 {150, 5.07}

(ml {cc, fl oz})

Magnetic clutch clearance

0.3—0.5 {0.012—0.019}

(mm {in})

CondenserType Multiflow (sub-cooling type)

Radiated heat (kW {kcal/h})4.69 {4,030}: European (L.H.D.) specs.

5.96 {5,130}: European (U.K.), GCC specs.

Receiver/drier

capacity(ml {cc, fl oz}) 190 {190, 6.42}

Desiccant Synthetic zeolite

Expansion valve Type Block type

Evaporator Type Double-tank drawn cup

Page 867 of 909

U–4

OUTLINE

Full-auto Air Conditioner

ItemSpecification

L3, L8, LF MZR-CD (RF Turbo)

Heating capacity (kW {kcal/h}) 4.400 {3,784}4.400 {3,784} (L.H.D.)

5.120 {4,403} {R.H.D.)

Airflow volume

(during heater operation)Blower motor

(m

3/h)310 (L.H.D.)

300 (R.H.D.)

Electricity consumption

(during heater operation)Blower motor (W) 184

Cooling capacity (kW {kcal/h}) 4.200 {3,612}

Airflow volume (during air

conditioner operation)Blower motor

(m

3/h)460

Electricity consumption

(during air conditioner

operation)Blower motor (W) 225

Magnetic clutch (W) 46 45

Fan type Blower motor Sirocco fan

RefrigerantType R-134a

Regular amount

(approximate quantity)470 {16.6} (L.H.D.)

430 {15.2} (R.H.D.)

(g {oz})

A/C compressorType Vane-rotary

Discharge capacity

120 {120, 4.06}

(ml {cc, fl oz})

Max. allowable speed

6,400

(rpm)

Lube

oilType ATMOS GU10

Sealed volume

(approximate quantity)

120 {120, 4.06} 150 {150, 5.07}

(ml {cc, fl oz})

Magnetic clutch clearance

0.3—0.5 {0.012—0.019}

(mm {in})

CondenserType Multiflow (sub-cooling type)

Radiated heat (kW {kcal/h})4.69 {4,030}: European (L.H.D.) specs.

5.96 {5,130}: European (U.K.), GCC specs.

Receiver/drier

capacity(ml {cc, fl oz}) 190 {190, 6.42}

Desiccant Synthetic zeolite

Expansion valve Type Block type

Evaporator Type Double-tank drawn cup

Page 874 of 909

BASIC SYSTEM

U–11

U

7. Install in the reverse order of removal.

8. Perform the refrigerant system performance test.

A/C Unit Installation Note

1. When installing a new A/C unit or evaporator, add a supplemental amount of ATMOS GU10 compressor oil into

the refrigerant cycle.

Supplemental amount (approximate quantity)

40 ml {40 cc, 1.4 fl oz}

End Of Sie

A/C COMPRESSOR REMOVAL/INSTALLATIONA6E8516614502011. Disconnect the negative battery cable.

2. Discharge the refrigerant from the system.

3. Remove the right side splash shield.

4. Loosen the drive belt and remove it.

Caution

•If moisture or foreign material enters the refrigeration cycle, cooling ability will be lowered and

abnormal noise will occur. Always immediately plug open fittings after removing any refrigeration

cycle parts to keep moisture or foreign material out of the cycle.

5. Remove in the order indicated in the table. Do not

allow compressor oil to spill.

.

6. Install in the reverse order of removal.

7. Adjust the drive belt.

8. Perform the refrigerant system performance test.

A/C Compressor Installation Note

1. Remove the following amount of compressor oil from the new A/C compressor when replacing the A/C

compressor.

Compressor oil to be removed (approximate quantity)

150 ml {150 cc, 5.07 fl oz} – [compressor oil from old A/C compressor + 15 ml {15 cc, 0.5 fl oz}]

End Of Sie

1 Cooler hose (HI)

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION)

2 Cooler hose (LO)

(See U–13 REFRIGERANT LINES REMOVAL/

INSTALLATION)

3 Magnetic clutch connector

4A/C compressor

(See U–11 A/C Compressor Installation Note)

4

3

1

2

N·m {kgf·cm, in·lbf} 6.86—9.80

{70.0—99.9,

60.8—86.7}

R

R

6.86—9.80

{70.0—99.9,

60.8—86.7}

17.6—26.5 N·m

{1.80—2.70 kgf·m,

13.0—19.5 ft·lbf}

A6E85162005

Page 893 of 909

TD–1

TD

TDTECHNICAL DATA

TECHNICAL DATA............................................. TD-2

ENGINE ............................................................ TD-2

LUBRICATION SYSTEM .................................. TD-2

COOLING SYSTEM .......................................... TD-3

FUEL AND EMISSION CONTROL

SYSTEM ........................................................ TD-3

ENGINE ELECTRICAL SYSTEM ..................... TD-4

CLUTCH............................................................ TD-4

MANUAL TRANSAXLE ..................................... TD-4

AUTOMATIC TRANSAXLE............................... TD-5

PROPELLER SHAFT ........................................ TD-5

FRONT AND REAR AXLE ................................ TD-6

STEERING SYSTEM ........................................ TD-6

BRAKING SYSTEM .......................................... TD-7

SUSPENSION................................................... TD-7

BODY ELECTRICAL SYSTEM ......................... TD-8

HEATER AND AIR CONDITIONER

SYSTEMS ...................................................... TD-9

Page 896 of 909

TD–4

TECHNICAL DATA

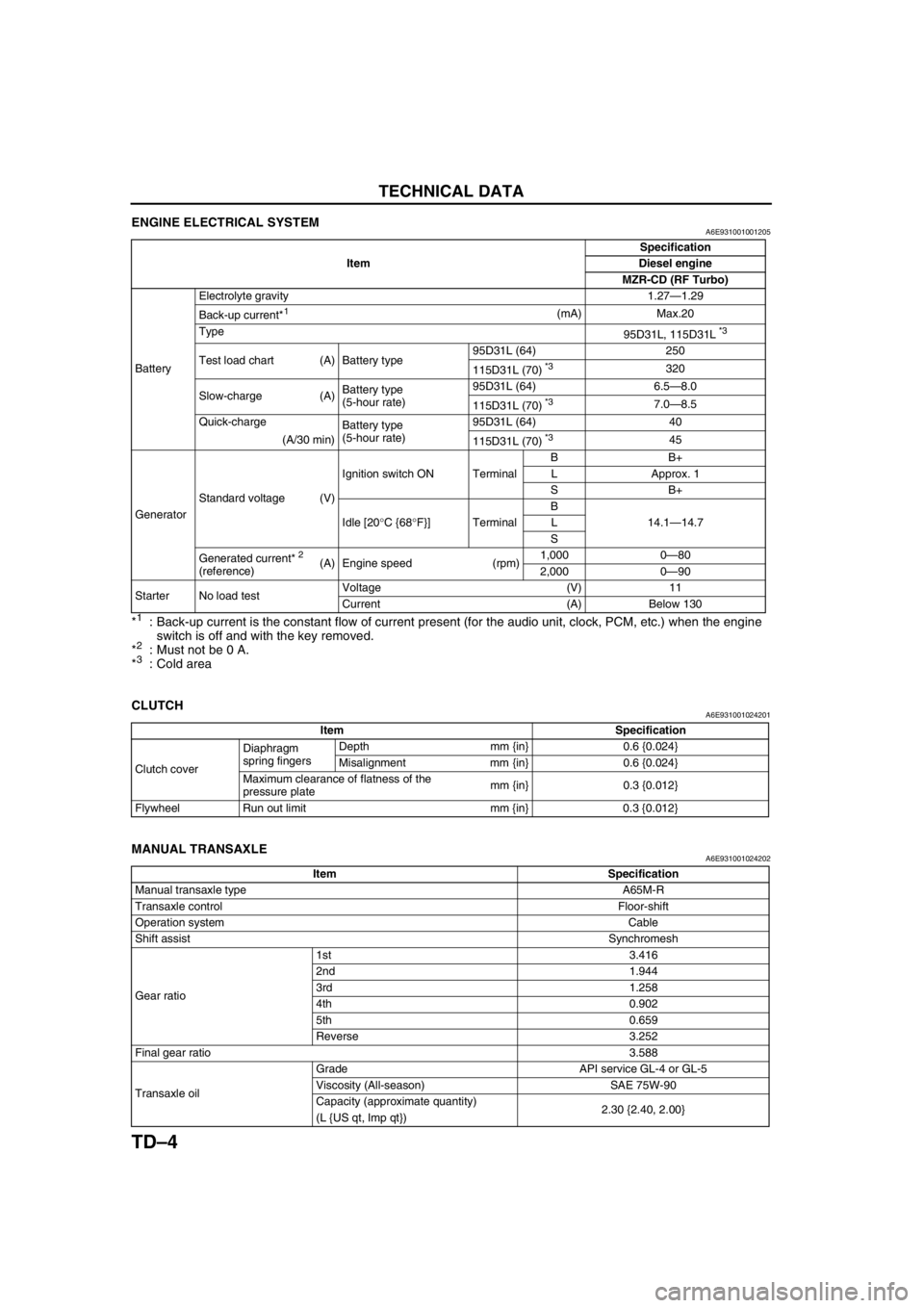

ENGINE ELECTRICAL SYSTEMA6E931001001205

*1: Back-up current is the constant flow of current present (for the audio unit, clock, PCM, etc.) when the engine

switch is off and with the key removed.

*

2: Must not be 0 A.

*3: Cold area

End Of Sie

CLUTCHA6E931001024201

End Of Sie

MANUAL TRANSAXLEA6E931001024202

ItemSpecification

Diesel engine

MZR-CD (RF Turbo)

BatteryElectrolyte gravity 1.27—1.29

Back-up current*

1(mA) Max.20

Type

95D31L, 115D31L

*3

Test load chart (A) Battery type95D31L (64) 250

115D31L (70) *3320

Slow-charge (A)Battery type

(5-hour rate)95D31L (64) 6.5—8.0

115D31L (70)

*37.0—8.5

Quick-charge

Battery type

(5-hour rate)95D31L (64) 40

(A/30 min)

115D31L (70)

*345

GeneratorStandard voltage (V)Ignition switch ON TerminalBB+

L Approx. 1

SB+

Idle [20°C {68°F}] TerminalB

14.1—14.7 L

S

Generated current*

2

(reference) (A) Engine speed (rpm)1,000 0—80

2,000 0—90

Starter No load testVoltage (V) 11

Current (A) Below 130

Item Specification

Clutch coverDiaphragm

spring fingersDepth mm {in} 0.6 {0.024}

Misalignment mm {in} 0.6 {0.024}

Maximum clearance of flatness of the

pressure platemm {in} 0.3 {0.012}

Flywheel Run out limit mm {in} 0.3 {0.012}

Item Specification

Manual transaxle typeA65M-R

Transaxle controlFloor-shift

Operation systemCable

Shift assistSynchromesh

Gear ratio1st 3.416

2nd 1.944

3rd 1.258

4th 0.902

5th 0.659

Reverse 3.252

Final gear ratio3.588

Transaxle oilGrade API service GL-4 or GL-5

Viscosity (All-season) SAE 75W-90

Capacity (approximate quantity)

2.30 {2.40, 2.00}

(L {US qt, Imp qt})