torque MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 770 of 909

R–8

WHEEL ALIGNMENT

FRONT WHEEL ALIGNMENT (WGN)A6E741201015201Specification (Unloaded)*1

2WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1 °30'.*3: Distance between wheel center and fender brim is 405 mm {15.94 in} (reference value).

4WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1 °30'.

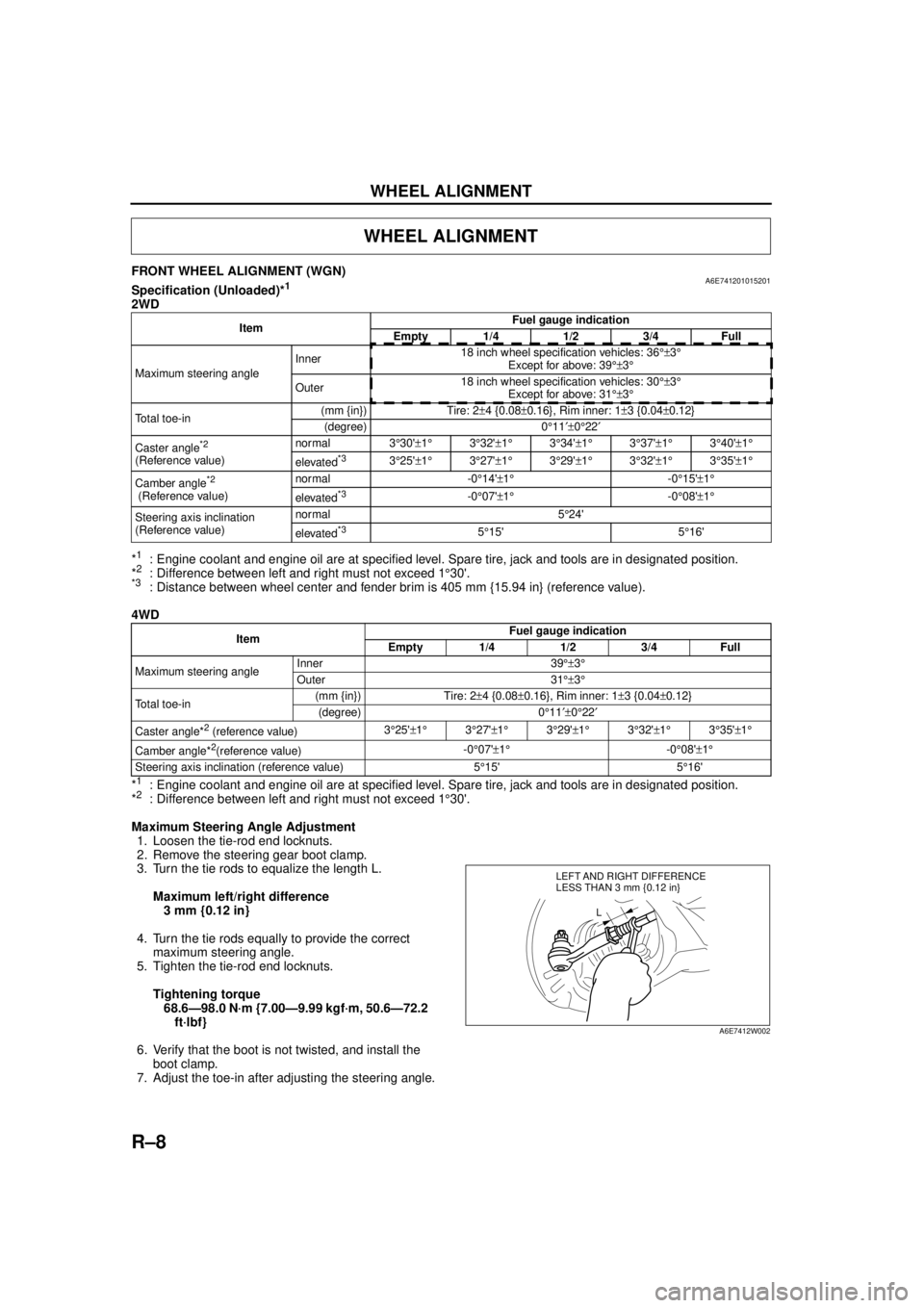

Maximum Steering Angle Adjustment 1. Loosen the tie-rod end locknuts.

2. Remove the steering gear boot clamp.

3. Turn the tie rods to equalize the length L.

Maximum left/right difference3 mm {0.12 in}

4. Turn the tie rods equally to provide the correct maximum steering angle.

5. Tighten the tie-rod end locknuts.

Tightening torque68.6—98.0 N·m {7.00—9.99 kgf·m, 50.6—72.2 ft·lbf}

6. Verify that the boot is not twisted, and install the boot clamp.

7. Adjust the toe-in after adjusting the steering angle.

WHEEL ALIGNMENT

Item Fuel gauge indication

Empty 1/4 1/2 3/4 Full

Maximum steering angle Inner

18 inch wheel specification vehicles: 36

°±3°

Except for above: 39 °±3°

Outer 18 inch wheel specification vehicles: 30

°±3°

Except for above: 31 °±3°

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Caster angle

*2

(Reference value) normal 3

°30' ±1 ° 3°32' ±1 ° 3°34' ±1° 3°37' ±1° 3°40' ±1 °

elevated*33 °25' ±1 ° 3°27' ±1 ° 3°29' ±1° 3°32' ±1° 3°35' ±1 °

Camber angle

*2

(Reference value) normal -0

°14' ±1 ° -0°15' ±1°

elevated*3-0 °07' ±1 ° -0°08' ±1°

Steering axis inclination

(Reference value) normal 5

°24'

elevated

*35 °15' 5 °16'

Item Fuel gauge indication

Empty 1/4 1/2 3/4 Full

Maximum steering angle Inner 39

°±3°

Outer 31 °±3°

Total toe-in (mm {in}) Tire: 2

±4 {0.08 ±0.16}, Rim inner: 1 ±3 {0.04 ±0.12}

(degree) 0 °11 ′±0°22 ′

Caster angle*

2 (reference value) 3

°25' ±1 ° 3°27' ±1 ° 3°29' ±1 ° 3°32' ±1 ° 3°35' ±1 °

Camber angle*

2(reference value) -0

°07' ±1 ° -0°08' ±1°

Steering axis inclination (reference value) 5 °15' 5 °16'

LEFT AND RIGHT DIFFERENCE

L

LESS THAN 3 mm {0.12 in}

A6E7412W002

Page 771 of 909

WHEEL ALIGNMENT

R–9

R

Total Toe-in Adjustment

1. Center the steering wheel and confirm that the vehicle wheels/tires are pointing straight.

2. Loosen the left and right tie-rod end locknuts and turn the tie-rods equally. Both tie rods are right threaded, so

turning the right tie-rod toward the front of the vehicle and the left toward the rear increases toe-in.

Note

•Turning both tie-rods one complete turn changes toe-in by about 6 mm {0.24 in} (0°36').

3. Tighten the tie-rod end locknuts to the specified torque.

Tightening torque

68.6—98.0 N·m {7.00—9.99 kgf·m, 50.6—72.2 ft·lbf}

4. Verify that the boot is not twisted, and install the boot clamp.

End Of Sie

REAR WHEEL ALIGNMENT (WGN)A6E741201016201Specification (Unloaded)*1

2WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1°30'.*3: Distance between wheel center and fender brim is 407 mm {16.02 in} (reference value).

4WD

*

1: Engine coolant and engine oil are at specified level. Spare tire, jack and tools are in designated position.

*2: Difference between left and right must not exceed 1°30'.

Note

•Adjust the toe-in after adjusting the camber.

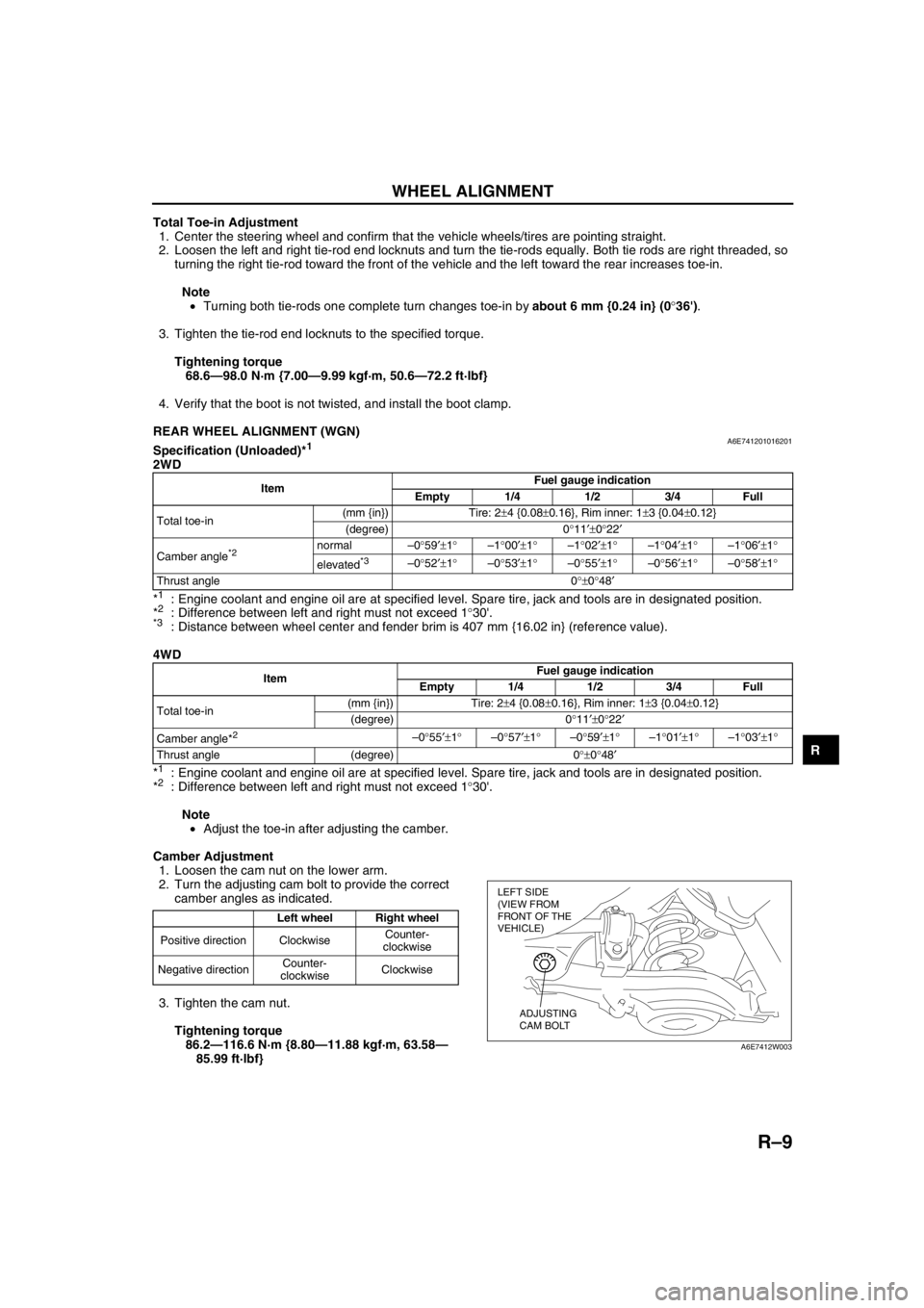

Camber Adjustment

1. Loosen the cam nut on the lower arm.

2. Turn the adjusting cam bolt to provide the correct

camber angles as indicated.

3. Tighten the cam nut.

Tightening torque

86.2—116.6 N·m {8.80—11.88 kgf·m, 63.58—

85.99 ft·lbf}

ItemFuel gauge indication

Empty 1/4 1/2 3/4 Full

Total toe-in(mm {in}) Tire: 2±4 {0.08±0.16}, Rim inner: 1±3 {0.04±0.12}

(degree) 0°11′±0°22′

Camber angle

*2 normal–0°59′±1°–1°00′±1°–1°02′±1°–1°04′±1°–1°06′±1°

elevated

*3–0°52′±1°–0°53′±1°–0°55′±1°–0°56′±1°–0°58′±1°

Thrust angle 0°±0°48′

ItemFuel gauge indication

Empty 1/4 1/2 3/4 Full

Total toe-in(mm {in}) Tire: 2±4 {0.08±0.16}, Rim inner: 1±3 {0.04±0.12}

(degree) 0°11′±0°22′

Camber angle*

2 –0°55′±1°–0°57′±1°–0°59′±1°–1°01′±1°–1°03′±1°

Thrust angle (degree) 0°±0°48′

Left wheel Right wheel

Positive direction ClockwiseCounter-

clockwise

Negative directionCounter-

clockwiseClockwise

LEFT SIDE

(VIEW FROM

FRONT OF THE

VEHICLE)

ADJUSTING

CAM BOLT

A6E7412W003

Page 772 of 909

R–10

WHEEL ALIGNMENT

Total Toe-in Adjustment

1. Loosen the locknut of the lateral link.

2. Adjust the toe-in turning the adjusting link.

Specification

Total Toe-in: 2±4 mm {0.08±0.16 in}

Note

•Toe change amount: 0°43′ / one rotation

3. Tighten the locknut.

Tightening torque

68.6—98.1 N·m {7.0—10.0 kgf·m, 50.6—72.3

ft·lbf}

End Of Sie

A6E7412W004

A6E7412W005

A6E7412W004

Page 778 of 909

R–16

REAR SUSPENSION

Bolt (Trailing Link Front Side) Removal Note

1. Support the trailing link with a jack.

Caution

•Removing the trailing link is dangerous.

The trailing link could fall and cause

serious injury or death. Verify that the

jack securely supports the trailing link.

2. Remove the bolts (trailing link front side).

Bolt (Lateral Link Outer Side) Removal Note

1. Loosen the bolt (lateral link inner side).

2. Remove the bolt (lateral link outer side).

Bolt (Lateral Link Outer Side) Installation Note

1. Tighten the bolt (lateral link outer side).

2. Tighten the bolt (lateral link inner side).

Tightening torque

86.2—116.6 N·m {8.80—11.88 kgf·m, 63.58—85.99 ft·lbf}

Bolt (Trailing Link Front Side) Installation Note

1. Support the trailing link with a jack.

2. Tighten the bolts (trailing link front side).

End Of SieREAR CROSSMEMBER REMOVAL/INSTALLATION (4WD)A6E741628400201

Caution

•Performing the following procedures without first removing the ABS wheel-speed sensor may

possibly cause an open circuit in the harness if it is pulled by mistake. Before performing the

following procedures, remove the ABS wheel-speed sensor (axle side) and fix it to an appropriate

place where the sensor will not be pulled by mistake while servicing the vehicle.

1. Remove the rear auto leveling sensor and harness.

(See T–20 REAR AUTO LEVELING SENSOR REMOVAL/INSTALLATION.)

2. Remove the middle pipe.

(See F1–30 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

5. Adjust the headlight zeroset.

6. Inspect the rear wheel alignment.

(See R–9 REAR WHEEL ALIGNMENT (WGN).)

JACK

A6E74162010

JACK

A6E74162010

Page 815 of 909

T–4

MULTIPLEX COMMUNICATION SYSTEM

SYSTEM WIRING DIAGRAMA6E811155430203

.

End Of SieCAN SIGNAL-CHARTA6E811155430204

OUT: Output (sends signal)

IN: Input (receives signal)

1

2

67

3

8

4

5

ROAF AG

HG

2M2J2W

2X

9

10

CAN_L

CAN_H

A6E81111102

1PCM

2 DSC HU/CM (with DSC)

3 ABS (ABS/TCS) HU/CM (with ABS (ABS/TCS))

4 Data link connector-2

5 Instrument cluster

6 TCM (JA5AX-EL)7 4WD control module (4WD)

8Twist pair

9 2R (except MZR-CD (RF Turbo))

39 (MZR-CD (RF Turbo))

10 2U (except MZR-CD (RF Turbo))

13 (MZR-CD (RF Turbo))

SignalMultiplex module

PCM TCMABS (ABS/TCS)

HU/CM or

DSC HU/CM4WD control

moduleInstrument

cluster

Accelerator pedal position

(MZR-CD (RF Turbo))OUT IN IN–IN

Air induction type OUT–IN––

ATF temperature IN OUT–––

AT warning light conditions

(JA5AX-EL)IN OUT––IN

Battery reconnection

(except MZR-CD (RF

Turbo))OUT IN–––

Brake system configuration

(EBD/ABS/TCS/DSC)IN–OUT–IN

Brake system

statusABS IN–OUT––

EBD/ABS/

TCS/DSC––OUT IN IN

Brake system warning light

conditions (brake fluid level

sensor)––IN–OUT

Country OUT–IN––

Coupling torque (with

DSC)––IN OUT–

Coupling torque request

(with DSC)––OUT IN–

Page 816 of 909

MULTIPLEX COMMUNICATION SYSTEM

T–5

T

End Of Sie

Cruise main indicator light

conditions (MZR-CD (RF

Turbo))OUT–––IN

Cruise set indicator light

conditions (MZR-CD (RF

Turbo))OUT–––IN

Desired gear/

selector lever

positionFN4A-EL OUT–IN–IN

JA5AX-EL IN OUT IN IN IN

ECT OUT IN–IN

Engine control condition OUT–IN––

Engine displacement OUT–IN––

Engine loss torque (except

MZR-CD (RF Turbo))OUT IN–––

Engine speed OUT IN IN IN IN

Engine torque (except

MZR-CD (RF Turbo))OUT IN–––

Fuel injection information OUT–IN––

Fuel type and delivery OUT–IN––

Gear position IN OUT IN IN IN

Generator warning light

conditions (except MZR-

CD (RF Turbo))OUT–––IN

Glow indicator light

condition (MZR-CD (RF

Turbo))OUT–––IN

HOLD indicator light

conditions (FN4A-EL)OUT–––IN

Idle speed up request IN OUT–––

MIL condition (except

MZR-CD (RF Turbo))OUT–––IN

MIL indicate request IN OUT–––

Number of cylinders OUT–IN––

Racing select

determinationIN OUT–––

TCC condition IN OUT–––

Tire circumference (front/

rear)OUT–IN––

Torque reduction inhibit OUT IN IN––

TP OUTINININ–

Transmission/axle type OUT–IN––

Travelled distanceIN–OUT––

IN OUT––IN

OUT–––IN

Torque

reduction

requestJA5AX-EL IN OUT–––

except

JA5AX-ELIN–OUT––

Turbine speed IN OUT–––

Upper torque limit IN OUT–––

Vehicle speedOUT–––IN

IN OUT–––

Wheel speed (front left/

front right/rear left/rear

right)IN IN OUT IN–

OUT–––IN

4WD system operating

condition (warning light

information)–––OUT IN SignalMultiplex module

PCM TCMABS (ABS/TCS)

HU/CM or

DSC HU/CM4WD control

moduleInstrument

cluster

Page 839 of 909

T–28

WARNING AND INDICATOR SYSTEM

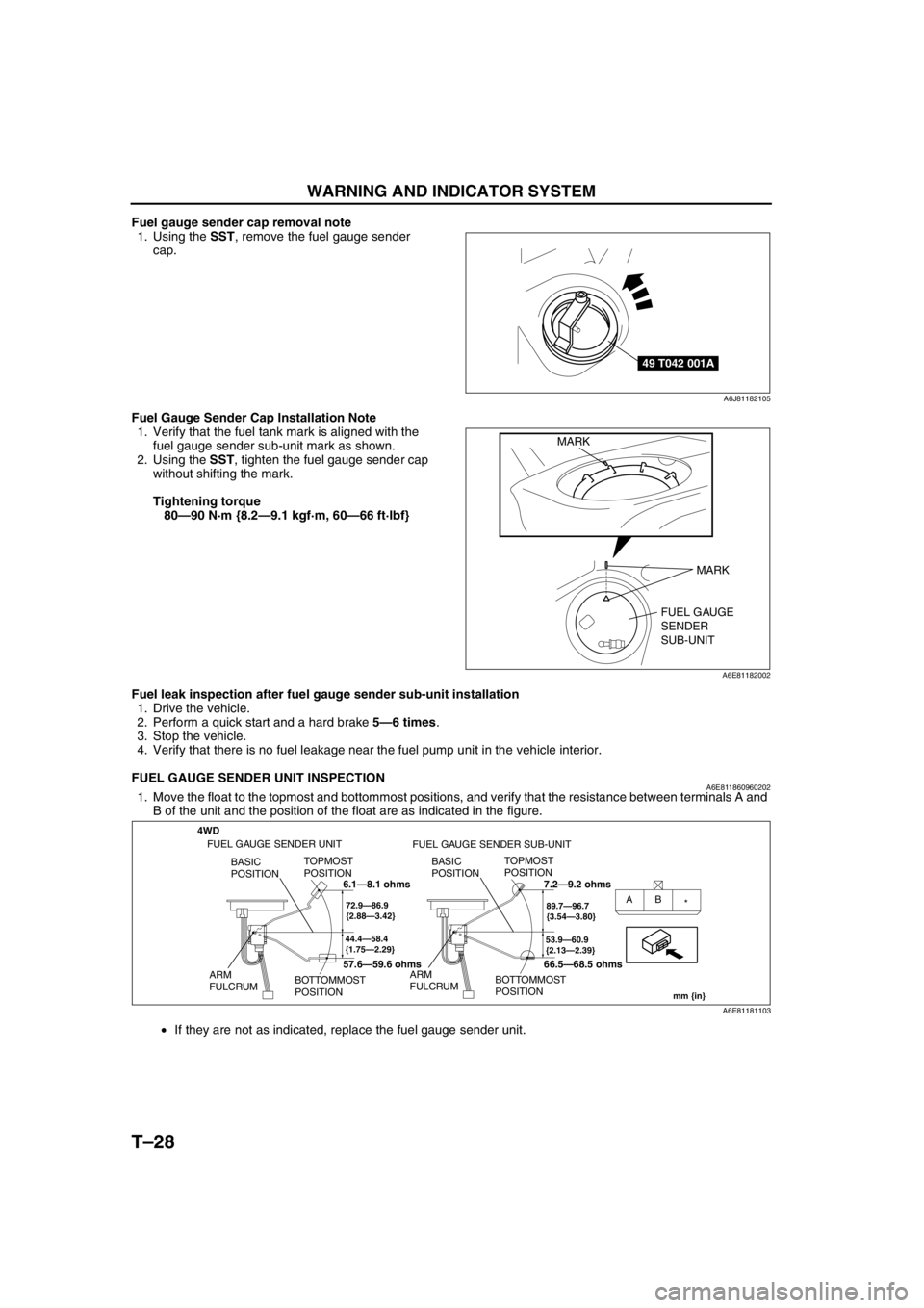

Fuel gauge sender cap removal note

1. Using the SST, remove the fuel gauge sender

cap.

Fuel Gauge Sender Cap Installation Note

1. Verify that the fuel tank mark is aligned with the

fuel gauge sender sub-unit mark as shown.

2. Using the SST, tighten the fuel gauge sender cap

without shifting the mark.

Tightening torque

80—90 N·m {8.2—9.1 kgf·m, 60—66 ft·lbf}

Fuel leak inspection after fuel gauge sender sub-unit installation

1. Drive the vehicle.

2. Perform a quick start and a hard brake 5—6 times.

3. Stop the vehicle.

4. Verify that there is no fuel leakage near the fuel pump unit in the vehicle interior.

End Of Sie

FUEL GAUGE SENDER UNIT INSPECTIONA6E8118609602021. Move the float to the topmost and bottommost positions, and verify that the resistance between terminals A and

B of the unit and the position of the float are as indicated in the figure.

•If they are not as indicated, replace the fuel gauge sender unit.

End Of Sie

49 T042 001A

A6J81182105

FUEL GAUGE

SENDER

SUB-UNIT MARK

MARK

A6E81182002

4WD

44.4—58.4

{1.75—2.29}

TOPMOST

POSITION

BOTTOMMOST

POSITION BASIC

POSITION

ARM

FULCRUM

72.9—86.9

{2.88—3.42}AB

*

53.9—60.9

{2.13—2.39}

TOPMOST

POSITION

BOTTOMMOST

POSITION BASIC

POSITION

ARM

FULCRUM

89.7—96.7

{3.54—3.80}

mm {in}

FUEL GAUGE SENDER UNIT

FUEL GAUGE SENDER SUB-UNIT

6.1—8.1 ohms

57.6—59.6 ohms7.2—9.2 ohms

66.5—68.5 ohms

A6E81181103

Page 897 of 909

TECHNICAL DATA

TD–5

TD

End Of SieAUTOMATIC TRANSAXLEA6E931001024203

End Of Sie

PROPELLER SHAFTA6E931001024204

End Of Sie

Item Specification

Transaxle typeJA5AX-EL

Line pressure

(kPa {kgf/cm

2, psi})D range, M range (2GR)Idle 290—490 {3.0—5.0, 42—71}

Stall 1,550—1,750 {15.8—17.8, 225—254}

M range (1GR), R positionIdle 550—750 {5.6—7.6, 80—109}

Stall 1,550—1,750 {15.8—17.8, 225—254}

Engine stall speed

D, M (1GR, 2GR), R 2,200—2,600

(rpm)

Time lag (second)N-D Approx. 0.5—1.0

N-R Approx. 0.6—1.0

Transaxle fluid

temperature (TFT)

sensor-20 °C {−4 °F} 15.87—17.54

0 °C {32 °F} 5.73—6.33

20 °C {68 °F} 2.38—2.63

40 °C {104 °F} 1.10—1.22

60 °C {140 °F} 0.56—0.62

80 °C {176 °F} 0.31—0.34

(kilohm) 100 °C {212 °F} 0.18—0.20

120 °C {248 °F} 0.11—0.12

130 °C {266 °F} 0.09—0.10

Input/turbine

speed sensor(ohm) ATF temperature: 20 °C {68 °F} 513—627

Intermediate

sensor(ohm) ATF temperature: 20 °C {68 °F} 513—627

Vehicle

speedometer

sensor(ohm) ATF temperature: 20 °C {68 °F} 513—627

Solenoid valves (ohm)Shift solenoid A 14—18

Shift solenoid B 14—18

Shift solenoid C 14—18

Neutral shift solenoid valve 14—18

Reduction timing solenoid valve 14—18

TCC solenoid valve 12.0—13.2

2-4 brake solenoid valve 2.6—3.2

High clutch solenoid valve 2.6—3.2

Pressure control solenoid 2.6—3.2

Automatic transaxle fluid

(ATF)Type

M-

III or equivalent (e.g. Dexron ® III )

Capacity (Approximate quantity) (L {US qt, Imp qt}) 8.3 {8.8, 7.3}

Transfer oilGrade API service GL-5

Viscosity SAE 80W-90

Capacity (Approximate quantity) (L {US qt, Imp qt}) 0.62 {0.65, 0.54}

Item Specification

Runout limit mm {in} 0.3 {0.01}

Starting torqueN·m

{kgf·cm}0.29—0.78 {3.0—7.9}