check engine MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 6 of 909

VIN CODE

GI–3

GIVIN CODEA6E200800021201European (L.H.D. U.K.) specs.GCC specs.End Of Sie

VIN CODE

Serial No.

0=Hiroshima

2=5MT For Europe(U.K.): Dummy

For Europe(L.H.D.): Dummy

For Israel: Model year0

3 to 9

3=2003

3=2.3L (L3)

8=1.8L (L8)

F=2.0L (LF)

R=MZR-CD(RF-Turbo)-Hi

T=MZR-CD(RF-Turbo)-Low5=4EAT

7=5EAT

8=4WD

1=2WD

GG=MAZDA6 (4SD, 5HB)

GY=MAZDA6 (WAGON)

JMZ=Europe(L.H.D. U.K.)2=4SD

4=5HB

9=WAGON 1=Hofu Plant

Engine typeWorld manufacturer identification

Body style

Remarks

Vehicle type

Transmission

A6E2021T101

J M 7 G Y 3 9 F * 3 # 1 2 3 4 5 6

Serial No.

0= Hiroshima

1= Hofu

0 to 9, X

F= 2.0L (LF)

9= WAGON 4= 5HB 2= 4SD

JM7= General (L.H.D.) 3= Without side air bag

4= With side air bag

GY= MAZDA6 (WAGON) GG= MAZDA6 (4SD, 5HB) Plant

For Saudi: Model year

For Model year: Dummy

Body style Engine typeCheck digit3

0 - 9

Restraint system

Vehicle type

World manufacturer identification

A6E2010T102

Page 13 of 909

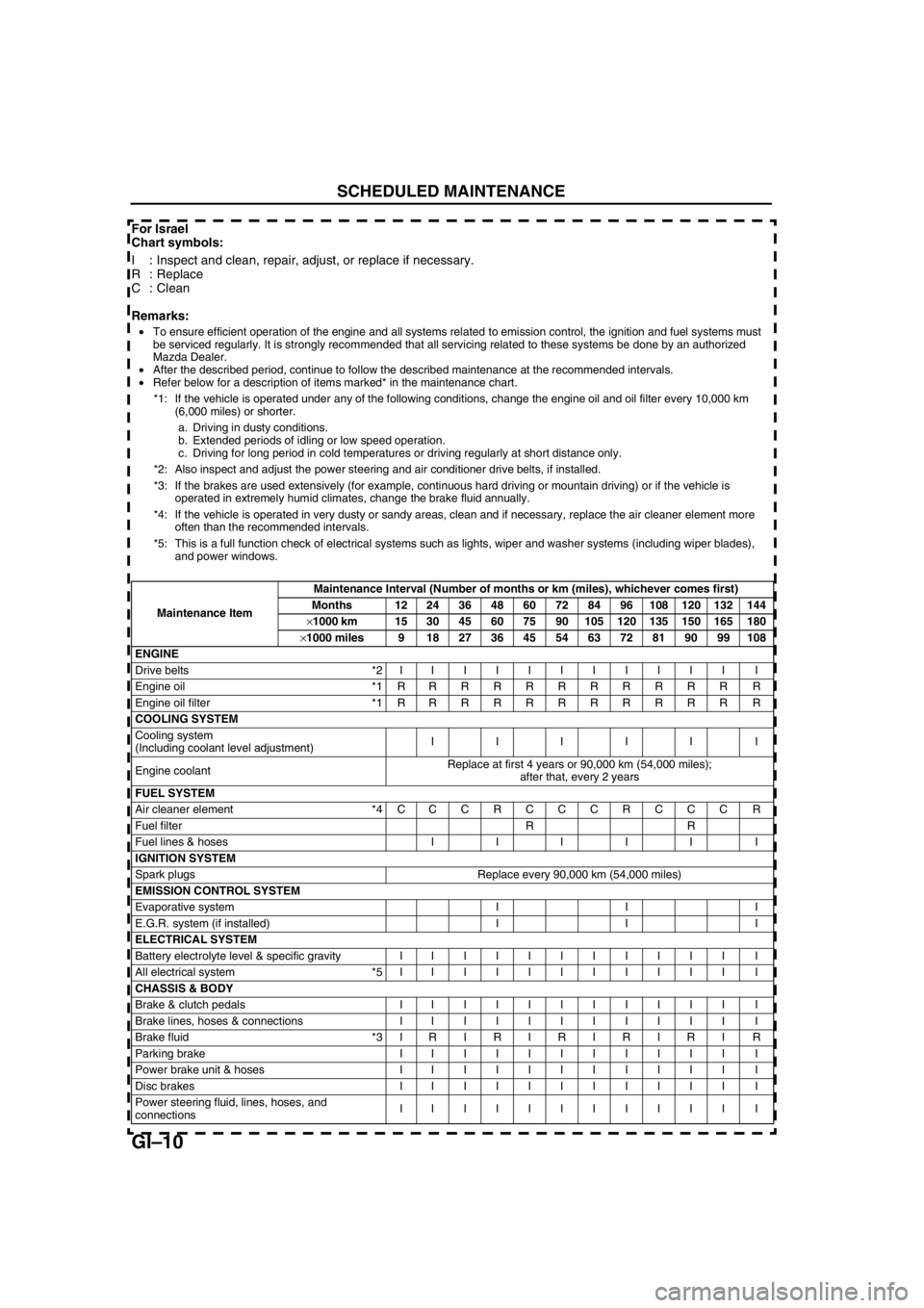

GI–10

SCHEDULED MAINTENANCE

For Israel

Chart symbols:

I : Inspect and clean, repair, adjust, or replace if necessary.

R:Replace

C : Clean

Remarks:

•To ensure efficient operation of the engine and all systems related to emission control, the ignition and fuel systems must

be serviced regularly. It is strongly recommended that all servicing related to these systems be done by an authorized

Mazda Dealer.

•After the described period, continue to follow the described maintenance at the recommended intervals.

•Refer below for a description of items marked* in the maintenance chart.

*1: If the vehicle is operated under any of the following conditions, change the engine oil and oil filter every 10,000 km

(6,000 miles) or shorter.

a. Driving in dusty conditions.

b. Extended periods of idling or low speed operation.

c. Driving for long period in cold temperatures or driving regularly at short distance only.

*2: Also inspect and adjust the power steering and air conditioner drive belts, if installed.

*3: If the brakes are used extensively (for example, continuous hard driving or mountain driving) or if the vehicle is

operated in extremely humid climates, change the brake fluid annually.

*4: If the vehicle is operated in very dusty or sandy areas, clean and if necessary, replace the air cleaner element more

often than the recommended intervals.

*5: This is a full function check of electrical systems such as lights, wiper and washer systems (including wiper blades),

and power windows.

Maintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 12 24 36 48 60 72 84 96 108 120 132 144

×1000 km 15 30 45 60 75 90 105 120 135 150 165 180

×1000 miles 9 18 27 36 45 54 63 72 81 90 99 108

ENGINE

Drive belts *2IIIIIIIIIII I

Engine oil *1RRRRRRRRRRR R

Engine oil filter *1RRRRRRRRRRR R

COOLING SYSTEM

Cooling system

(Including coolant level adjustment)IIIII I

Engine coolantReplace at first 4 years or 90,000 km (54,000 miles);

after that, every 2 years

FUEL SYSTEM

Air cleaner element *4CCCRCCCRCCC R

Fuel filter R R

Fuel lines & hoses IIIII I

IGNITION SYSTEM

Spark plugs Replace every 90,000 km (54,000 miles)

EMISSION CONTROL SYSTEM

Evaporative system I I I

E.G.R. system (if installed) I I I

ELECTRICAL SYSTEM

Battery electrolyte level & specific gravity I I I I I I I I I I I I

All electrical system *5IIIIIIIIIII I

CHASSIS & BODY

Brake & clutch pedals IIIIIIIIIII I

Brake lines, hoses & connections I I I I I I I I I I I I

Brake fluid *3IRIRIRIRIRI R

Parking brake IIIIIIIIIII I

Power brake unit & hoses IIIIIIIIIII I

Disc brakes IIIIIIIIIII I

Power steering fluid, lines, hoses, and

connectionsIIIIIIIIIII I

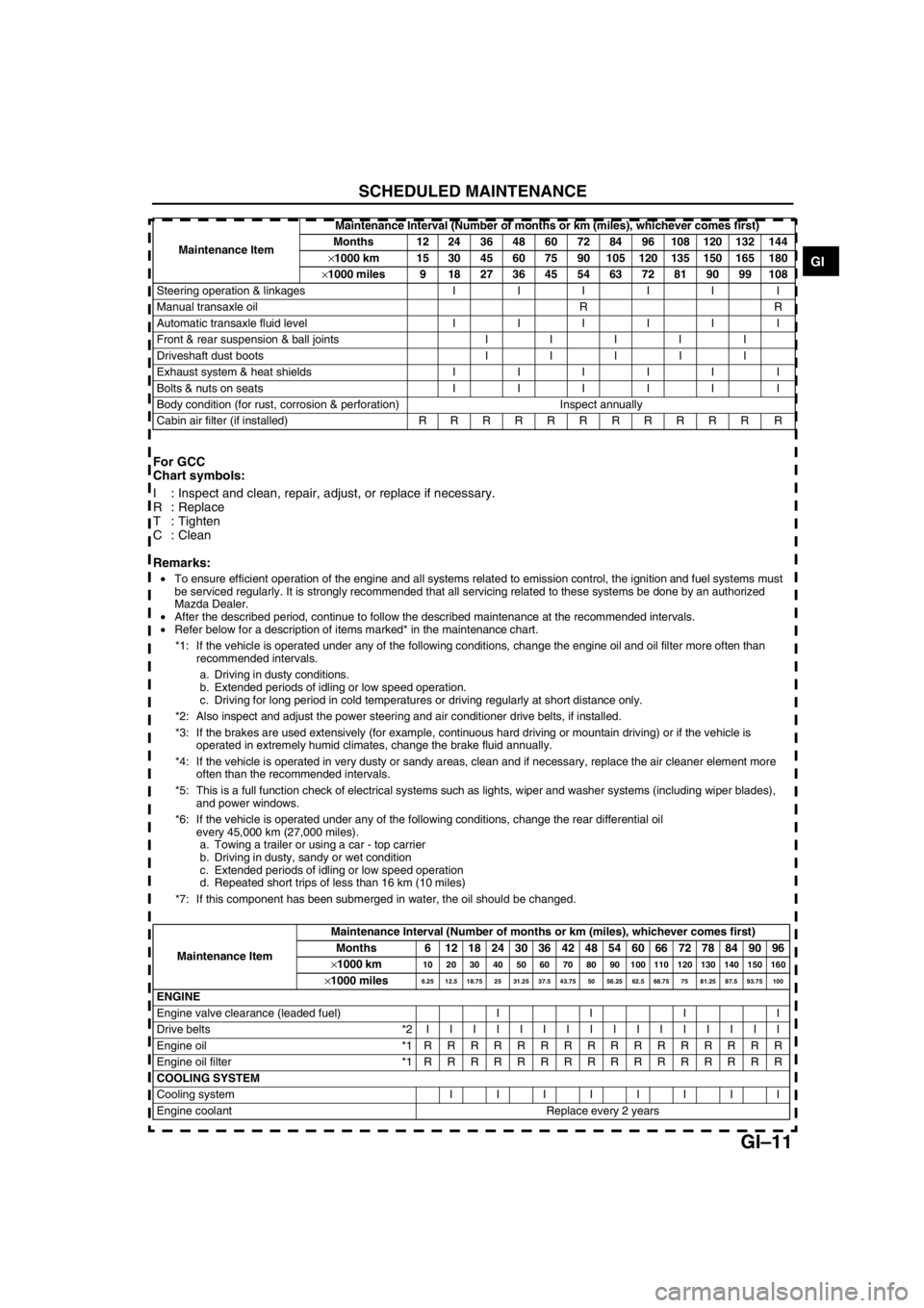

Page 14 of 909

SCHEDULED MAINTENANCE

GI–11

GI

For GCC

Chart symbols:

I : Inspect and clean, repair, adjust, or replace if necessary.

R : Replace

T:Tighten

C : Clean

Remarks:

End Of Sie

Steering operation & linkages IIIII I

Manual transaxle oil R R

Automatic transaxle fluid level IIIII I

Front & rear suspension & ball joints IIIII

Driveshaft dust boots IIIII

Exhaust system & heat shields IIIII I

Bolts & nuts on seats IIIII I

Body condition (for rust, corrosion & perforation) Inspect annually

Cabin air filter (if installed) R R R R R R R R R R R RMaintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 12 24 36 48 60 72 84 96 108 120 132 144

×1000 km 15 30 45 60 75 90 105 120 135 150 165 180

×1000 miles 9 18 27 36 45 54 63 72 81 90 99 108

•To ensure efficient operation of the engine and all systems related to emission control, the ignition and fuel systems must

be serviced regularly. It is strongly recommended that all servicing related to these systems be done by an authorized

Mazda Dealer.

•After the described period, continue to follow the described maintenance at the recommended intervals.

•Refer below for a description of items marked* in the maintenance chart.

*1: If the vehicle is operated under any of the following conditions, change the engine oil and oil filter more often than

recommended intervals.

a. Driving in dusty conditions.

b. Extended periods of idling or low speed operation.

c. Driving for long period in cold temperatures or driving regularly at short distance only.

*2: Also inspect and adjust the power steering and air conditioner drive belts, if installed.

*3: If the brakes are used extensively (for example, continuous hard driving or mountain driving) or if the vehicle is

operated in extremely humid climates, change the brake fluid annually.

*4: If the vehicle is operated in very dusty or sandy areas, clean and if necessary, replace the air cleaner element more

often than the recommended intervals.

*5: This is a full function check of electrical systems such as lights, wiper and washer systems (including wiper blades),

and power windows.

*6: If the vehicle is operated under any of the following conditions, change the rear differential oil

every 45,000 km (27,000 miles).

a. Towing a trailer or using a car - top carrier

b. Driving in dusty, sandy or wet condition

c. Extended periods of idling or low speed operation

d. Repeated short trips of less than 16 km (10 miles)

*7: If this component has been submerged in water, the oil should be changed.

Maintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 6 121824303642485460667278849096

×1000 km

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

×1000 miles6.25 12.5 18.75 25 31.25 37.5 43.75 50 56.25 62.5 68.75 75 81.25 87.5 93.75 100

ENGINE

Engine valve clearance (leaded fuel) I I I I

Drive belts *2IIIIIIIIIIIIIIII

Engine oil *1RRRRRRRRRRRRRRRR

Engine oil filter *1RRRRRRRRRRRRRRRR

COOLING SYSTEM

Cooling system IIIIIIII

Engine coolant Replace every 2 years

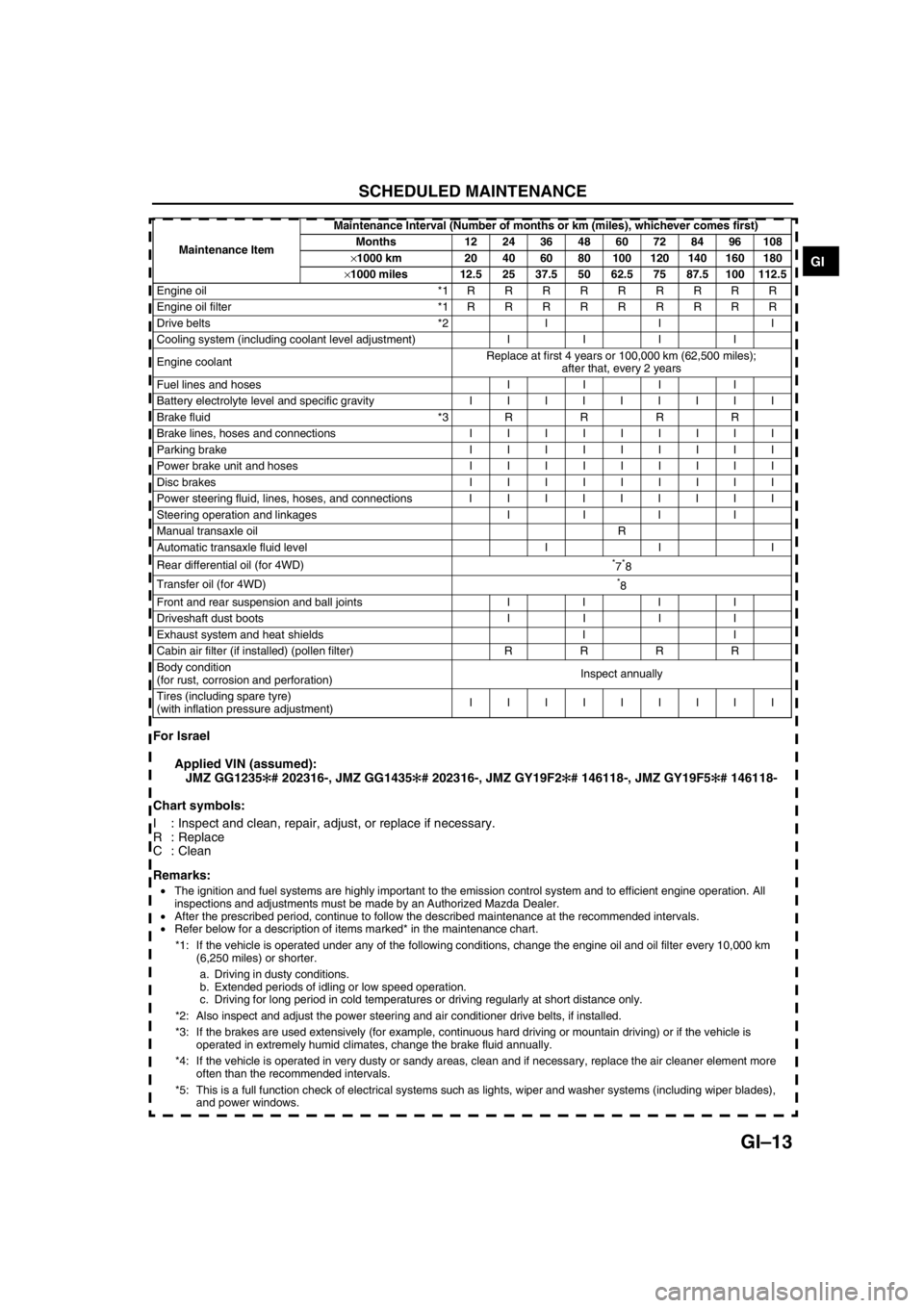

Page 17 of 909

SCHEDULED MAINTENANCE

GI–13

GI

For Israel

Applied VIN (assumed):

JMZ GG1235✻

✻✻ ✻

# 202316-, JMZ GG1435✻

✻✻ ✻

# 202316-, JMZ GY19F2✻

✻✻ ✻

# 146118-, JMZ GY19F5✻

✻✻ ✻

# 146118-

Chart symbols:

I : Inspect and clean, repair, adjust, or replace if necessary.

R : Replace

C : Clean

Remarks:

Engine oil *1 R R R R R R R R R

Engine oil filter *1RRRRRRRRR

Drive belts *2 I I I

Cooling system (including coolant level adjustment) I I I I

Engine coolantReplace at first 4 years or 100,000 km (62,500 miles);

after that, every 2 years

Fuel lines and hoses I I I I

Battery electrolyte level and specific gravity IIIIIIIII

Brake fluid *3 R R R R

Brake lines, hoses and connections IIIIIIIII

Parking brake IIIIIIIII

Power brake unit and hoses IIIIIIIII

Disc brakes IIIIIIIII

Power steering fluid, lines, hoses, and connections IIIIIIIII

Steering operation and linkages I I I I

Manual transaxle oil R

Automatic transaxle fluid level I I I

Rear differential oil (for 4WD)

*7*8

Transfer oil (for 4WD)

*8

Front and rear suspension and ball joints I I I I

Driveshaft dust boots I I I I

Exhaust system and heat shields I I

Cabin air filter (if installed) (pollen filter) R R R R

Body condition

(for rust, corrosion and perforation)Inspect annually

Tires (including spare tyre)

(with inflation pressure adjustment)IIIIIIIII Maintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 12 24 36 48 60 72 84 96 108

×1000 km 20 40 60 80 100 120 140 160 180

×1000 miles 12.5 25 37.5 50 62.5 75 87.5 100 112.5

•The ignition and fuel systems are highly important to the emission control system and to efficient engine operation. All

inspections and adjustments must be made by an Authorized Mazda Dealer.

•After the prescribed period, continue to follow the described maintenance at the recommended intervals.

•Refer below for a description of items marked* in the maintenance chart.

*1: If the vehicle is operated under any of the following conditions, change the engine oil and oil filter every 10,000 km

(6,250 miles) or shorter.

a. Driving in dusty conditions.

b. Extended periods of idling or low speed operation.

c. Driving for long period in cold temperatures or driving regularly at short distance only.

*2: Also inspect and adjust the power steering and air conditioner drive belts, if installed.

*3: If the brakes are used extensively (for example, continuous hard driving or mountain driving) or if the vehicle is

operated in extremely humid climates, change the brake fluid annually.

*4: If the vehicle is operated in very dusty or sandy areas, clean and if necessary, replace the air cleaner element more

often than the recommended intervals.

*5: This is a full function check of electrical systems such as lights, wiper and washer systems (including wiper blades),

and power windows.

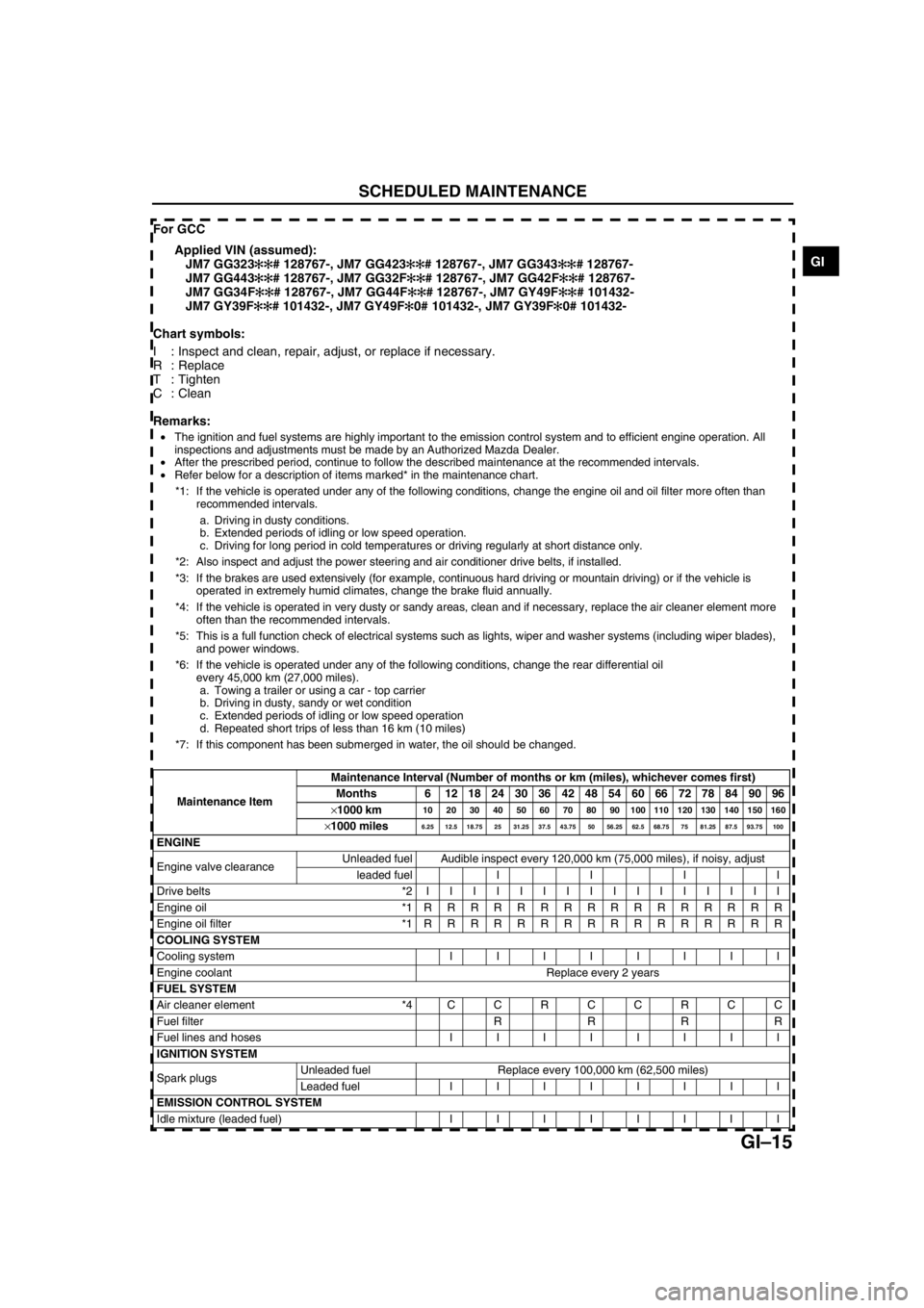

Page 19 of 909

SCHEDULED MAINTENANCE

GI–15

GI

For GCC

Applied VIN (assumed):

JM7 GG323✻✻

✻✻✻✻ ✻✻

# 128767-, JM7 GG423✻✻

✻✻✻✻ ✻✻

# 128767-, JM7 GG343✻✻

✻✻✻✻ ✻✻

# 128767-

JM7 GG443✻✻

✻✻✻✻ ✻✻

# 128767-, JM7 GG32F✻✻

✻✻✻✻ ✻✻

# 128767-, JM7 GG42F✻✻

✻✻✻✻ ✻✻

# 128767-

JM7 GG34F✻

✻✻ ✻✻

✻✻ ✻

# 128767-, JM7 GG44F✻

✻✻ ✻✻

✻✻ ✻

# 128767-, JM7 GY49F✻✻

✻✻✻✻ ✻✻

# 101432-

JM7 GY39F✻✻

✻✻✻✻ ✻✻

# 101432-, JM7 GY49F✻

✻✻ ✻

0# 101432-, JM7 GY39F✻

✻✻ ✻

0# 101432-

Chart symbols:

I : Inspect and clean, repair, adjust, or replace if necessary.

R : Replace

T:Tighten

C : Clean

Remarks:

•The ignition and fuel systems are highly important to the emission control system and to efficient engine operation. All

inspections and adjustments must be made by an Authorized Mazda Dealer.

•After the prescribed period, continue to follow the described maintenance at the recommended intervals.

•Refer below for a description of items marked* in the maintenance chart.

*1: If the vehicle is operated under any of the following conditions, change the engine oil and oil filter more often than

recommended intervals.

a. Driving in dusty conditions.

b. Extended periods of idling or low speed operation.

c. Driving for long period in cold temperatures or driving regularly at short distance only.

*2: Also inspect and adjust the power steering and air conditioner drive belts, if installed.

*3: If the brakes are used extensively (for example, continuous hard driving or mountain driving) or if the vehicle is

operated in extremely humid climates, change the brake fluid annually.

*4: If the vehicle is operated in very dusty or sandy areas, clean and if necessary, replace the air cleaner element more

often than the recommended intervals.

*5: This is a full function check of electrical systems such as lights, wiper and washer systems (including wiper blades),

and power windows.

*6: If the vehicle is operated under any of the following conditions, change the rear differential oil

every 45,000 km (27,000 miles).

a. Towing a trailer or using a car - top carrier

b. Driving in dusty, sandy or wet condition

c. Extended periods of idling or low speed operation

d. Repeated short trips of less than 16 km (10 miles)

*7: If this component has been submerged in water, the oil should be changed.

Maintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 6 121824303642485460667278849096

×1000 km

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

×1000 miles6.25 12.5 18.75 25 31.25 37.5 43.75 50 56.25 62.5 68.75 75 81.25 87.5 93.75 100

ENGINE

Engine valve clearance Unleaded fuel Audible inspect every 120,000 km (75,000 miles), if noisy, adjust

leaded fuel I I I I

Drive belts *2IIIIIIIIIIIIIIII

Engine oil *1RRRRRRRRRRRRRRRR

Engine oil filter *1RRRRRRRRRRRRRRRR

COOLING SYSTEM

Cooling system IIIIIIII

Engine coolant Replace every 2 years

FUEL SYSTEM

Air cleaner element *4CCRCCRCC

Fuel filter R R R R

Fuel lines and hoses IIIIIIII

IGNITION SYSTEM

Spark plugs Unleaded fuel Replace every 100,000 km (62,500 miles)

Leaded fuel IIIIIIII

EMISSION CONTROL SYSTEM

Idle mixture (leaded fuel) IIIIIIII

Page 21 of 909

SCHEDULED MAINTENANCE

GI–17

GI

Scheduled Maintenance Service (Specific Work Required)

•The specific work required for each maintenance item is listed in the following table. (Please refer to the section

applicable to the model serviced.)

For Europe (L.H.D. U.K.)

Bold frames: New item

Maintenance Item Specific Work Required

ENGINE

Engine valve clearance Measure clearance

Drive beltsInspect for wear, cracks and fraying, and check tension.

Replace drive belt.

Engine timing belt Replace engine timing belt.

Engine oil Replace engine oil and inspect for leakage.

Oil filter Replace oil filter and inspect for leakage.

COOLING SYSTEM

Cooling system

(including coolant level adjustment)Check coolant level and quality, and inspect for leakage.

Engine coolant Replace coolant.

FUEL SYSTEM

Air cleaner elementInspect for dirt, oil and damage.

Clean air cleaner element (by blowing air).

Replace air cleaner element.

Fuel filter Replace fuel filter.

Fuel lines and hoses Inspect for cracks, leakage and loose connection.

Fuel injection system (for MZR-CD (RF Turbo)) Update to injection amount correction with WDS. (see W/M)

IGNITION SYSTEM (FOR GASOLINE)

Spark plugsInspect for wear, damage, carbon, high-tension lead condition and measure

plug gap.

Replace spark plugs.

EMISSION CONTROL SYSTEM

Evaporative system (for gasoline)Check system operation (see W/M), vapor lines, vacuum fitting hoses and

connection.

E.G.R. system (MZR-CR (RF Turbo))Check system operation (see W/M), vacuum fitting hoses and connection.

Update to MAF correction for E.G.R control with WDS. (see W/M)

ELECTRICAL SYSTEM

Battery electrolyte level and specific gravity Check level and specific gravity.

CHASSIS AND BODY

Brake fluidCheck fluid level and inspect for leakage.

Replace brake fluid.

Brake lines, hoses and connectionsInspect for cracks, damage, chafing, corrosion, scars, swelling and fluid

leakage.

Parking brake Check lever stroke.

Power brake unit and hosesCheck vacuum lines, connections and check valve for improper attachment,

air tightness, cracks chafing and deterioration.

Disc brakesTest for judder and noise. Inspect caliper for correct operation and fluid

leakage, brake pads for wear. Check disc plate condition and thickness.

Power steering fluid and linesCheck fluid level and lines for improper attachment, leakage, cracks,

damage, loose connections, chafing and deterioration.

Power steering fluid Check fluid level.

Power steering system and hosesCheck lines for improper attachment, leakage, cracks, damage, loose

connections, chafing and deterioration.

Steering operation and gear housingCheck that the steering wheel has the specified play. Be sure to check for

changes, such as excessive play, hard steering or strange noises.

Check gear housing and boots for looseness, damage and grease/gear oil

leakage.

Steering linkages tie rod ends and armsCheck ball joint, dust cover and other components for looseness, wear,

damage and grease leakage.

Front and rear suspension and ball joints Inspect for grease leakage, cracks, damage and looseness.

Manual transmission/transaxle oilCheck oil level and inspect for leakage.

Replace manual transmission/transaxle oil.

Automatic transmission/transaxle fluid level Check fluid level.

Page 72 of 909

D–8

ENGINE OIL

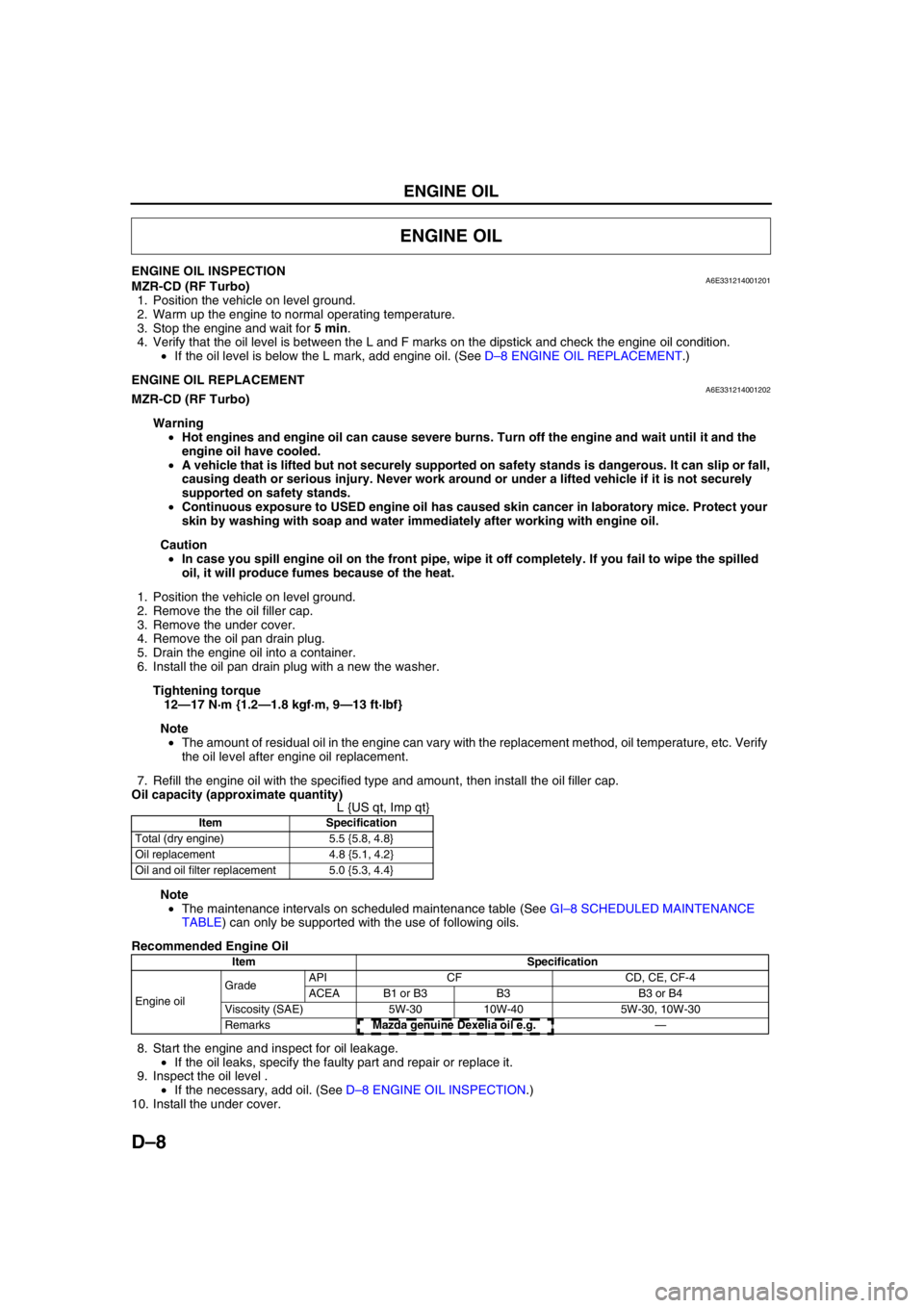

ENGINE OIL INSPECTIONA6E331214001201MZR-CD (RF Turbo)

1. Position the vehicle on level ground.

2. Warm up the engine to normal operating temperature.

3. Stop the engine and wait for 5 min.

4. Verify that the oil level is between the L and F marks on the dipstick and check the engine oil condition.

•If the oil level is below the L mark, add engine oil. (See D–8 ENGINE OIL REPLACEMENT.)

End Of SieENGINE OIL REPLACEMENTA6E331214001202MZR-CD (RF Turbo)

Warning

•Hot engines and engine oil can cause severe burns. Turn off the engine and wait until it and the

engine oil have cooled.

•A vehicle that is lifted but not securely supported on safety stands is dangerous. It can slip or fall,

causing death or serious injury. Never work around or under a lifted vehicle if it is not securely

supported on safety stands.

•Continuous exposure to USED engine oil has caused skin cancer in laboratory mice. Protect your

skin by washing with soap and water immediately after working with engine oil.

Caution

•In case you spill engine oil on the front pipe, wipe it off completely. If you fail to wipe the spilled

oil, it will produce fumes because of the heat.

1. Position the vehicle on level ground.

2. Remove the the oil filler cap.

3. Remove the under cover.

4. Remove the oil pan drain plug.

5. Drain the engine oil into a container.

6. Install the oil pan drain plug with a new the washer.

Tightening torque

12—17 N·m {1.2—1.8 kgf·m, 9—13 ft·lbf}

Note

•The amount of residual oil in the engine can vary with the replacement method, oil temperature, etc. Verify

the oil level after engine oil replacement.

7. Refill the engine oil with the specified type and amount, then install the oil filler cap.

Oil capacity (approximate quantity)

L {US qt, Imp qt}

Note

•The maintenance intervals on scheduled maintenance table (See GI–8 SCHEDULED MAINTENANCE

TABLE) can only be supported with the use of following oils.

Recommended Engine Oil

8. Start the engine and inspect for oil leakage.

•If the oil leaks, specify the faulty part and repair or replace it.

9. Inspect the oil level .

•If the necessary, add oil. (See D–8 ENGINE OIL INSPECTION.)

10. Install the under cover.

End Of Sie

ENGINE OIL

Item Specification

Total (dry engine) 5.5 {5.8, 4.8}

Oil replacement 4.8 {5.1, 4.2}

Oil and oil filter replacement 5.0 {5.3, 4.4}

Item Specification

Engine oil GradeAPI CF CD, CE, CF-4

ACEA B1 or B3 B3 B3 or B4

Viscosity (SAE) 5W-30 10W-40 5W-30, 10W-30

RemarksMazda genuine Dexelia oil e.g. —

Page 91 of 909

OUTLINE

F1–3

F1

CONTROL SYSTEM DIAGRAM (4WD)A6E390218881204

.

* : Equipped for L3 engine modelEnd Of Sie

9

8

7

54

3

10

19

18

17

15

16

14

13

11

12

20

29

28

27

25

26

24

23

21

22

30

3938

3735

33

36

31

32

40

6

1

2

3441

A6E39022000

1PCM

2 Ignition coil

3 Generator

4* VAD shutter valve

5 Air cleaner

6 MAF sensor

7* VAD shutter valve actuator

8* VAD control solenoid valve

9* Vacuum chamber

10* VAD check valve (one-way)

11 IAC valve

12 Purge solenoid valve

13 TP sensor

14 MAP sensor

15* VIS control solenoid valve

16 Variable tumble control solenoid valve

17* VIS shutter valve actuator

18* VIS shutter valve

19 VTCS shutter valve actuator

20 VTCS shutter valve

21 Fuel injector22* OCV

23 CMP sensor

24 EGR valve

25 Knock sensor

26 ECT sensor

27 PCV valve

28 CKP sensor

29 HO2S (front)

30 HO2S (rear)

31 Charcoal canister

32 Check valve (two-way)

33 Pressure regulator

34 Fuel filter (high-pressure)

35 Fuel pump

36 Fuel filter (low-pressure)

37 Fuel tank

38 Rollover valve

39 Pulsation damper

40 Fuel pump (transfer)

41 To PCM

Page 116 of 909

F1–28

FUEL SYSTEM

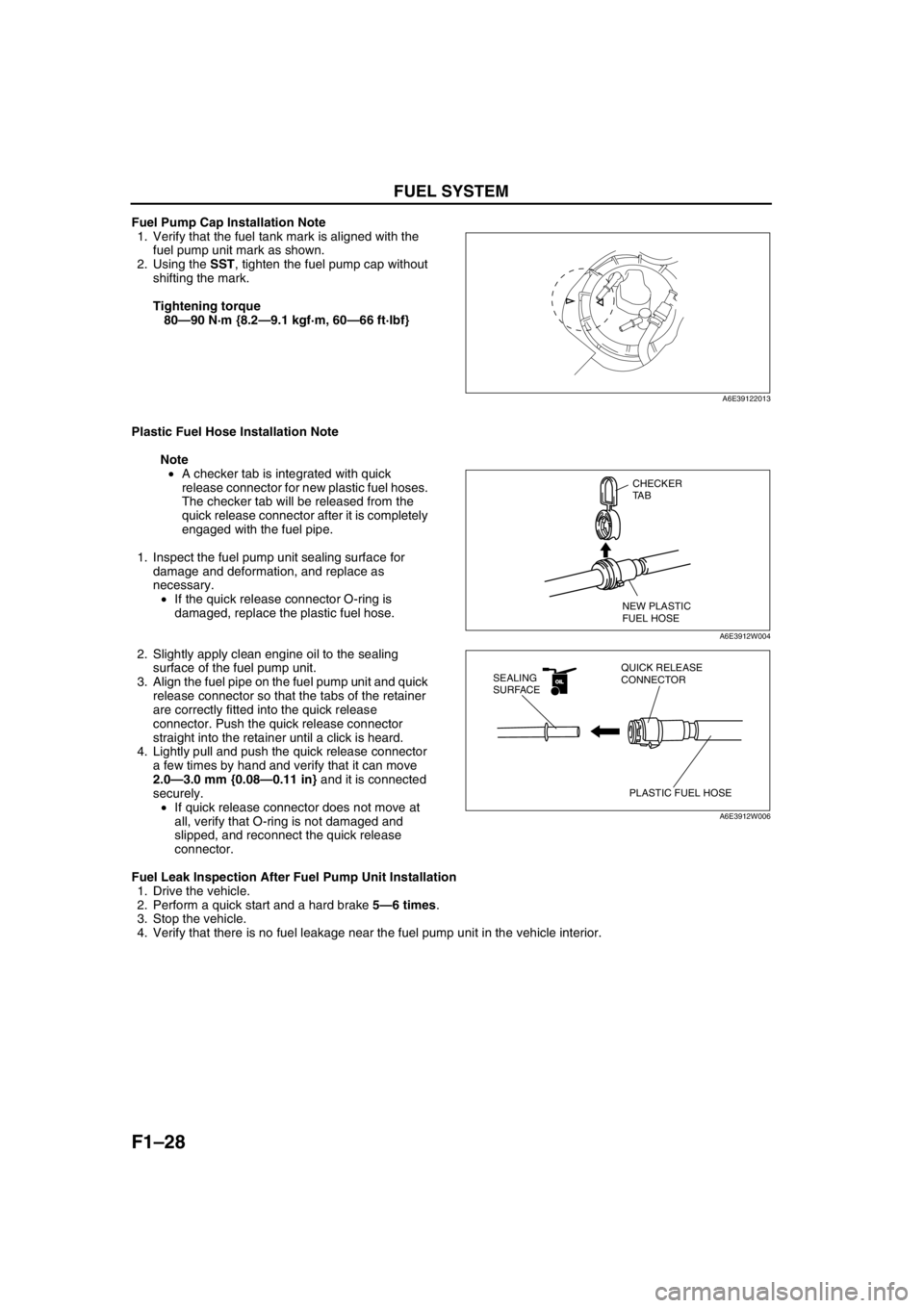

Fuel Pump Cap Installation Note

1. Verify that the fuel tank mark is aligned with the

fuel pump unit mark as shown.

2. Using the SST, tighten the fuel pump cap without

shifting the mark.

Tightening torque

80—90 N·m {8.2—9.1 kgf·m, 60—66 ft·lbf}

Plastic Fuel Hose Installation Note

Note

•A checker tab is integrated with quick

release connector for new plastic fuel hoses.

The checker tab will be released from the

quick release connector after it is completely

engaged with the fuel pipe.

1. Inspect the fuel pump unit sealing surface for

damage and deformation, and replace as

necessary.

•If the quick release connector O-ring is

damaged, replace the plastic fuel hose.

2. Slightly apply clean engine oil to the sealing

surface of the fuel pump unit.

3. Align the fuel pipe on the fuel pump unit and quick

release connector so that the tabs of the retainer

are correctly fitted into the quick release

connector. Push the quick release connector

straight into the retainer until a click is heard.

4. Lightly pull and push the quick release connector

a few times by hand and verify that it can move

2.0—3.0 mm {0.08—0.11 in} and it is connected

securely.

•If quick release connector does not move at

all, verify that O-ring is not damaged and

slipped, and reconnect the quick release

connector.

Fuel Leak Inspection After Fuel Pump Unit Installation

1. Drive the vehicle.

2. Perform a quick start and a hard brake 5—6 times.

3. Stop the vehicle.

4. Verify that there is no fuel leakage near the fuel pump unit in the vehicle interior.

End Of Sie

A6E39122013

CHECKER

TA B

NEW PLASTIC

FUEL HOSE

A6E3912W004

OILOIL

PLASTIC FUEL HOSE QUICK RELEASE

CONNECTOR SEALING

SURFACE

A6E3912W006

Page 153 of 909

![MAZDA 6 2002 Workshop Manual Suplement F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATUR MAZDA 6 2002 Workshop Manual Suplement F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATUR](/img/28/57057/w960_57057-152.png)

F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATURES ........................................................ F2-3

SPECIFICATIONS ............................................. F2-3

CONTROL SYSTEM DIAGRAM ........................ F2-4

CONTROL SYSTEM WIRING DIAGRAM.......... F2-5

INTAKE-AIR SYSTEM.......................................... F2-8

OUTLINE ........................................................... F2-8

STRUCTURAL VIEW......................................... F2-9

FUEL SYSTEM................................................... F2-10

OUTLINE ......................................................... F2-10

STRUCTURAL VIEW....................................... F2-11

EXHAUST SYSTEM........................................... F2-13

OUTLINE ......................................................... F2-13

STRUCTURAL VIEW....................................... F2-13

EMISSION SYSTEM........................................... F2-14

OUTLINE ......................................................... F2-14

STRUCTURAL VIEW....................................... F2-15

WARM UP OXIDATION CATALYTIC

CONVERTER DESCRIPTION ...................... F2-16

CONTROL SYSTEM........................................... F2-16

OUTLINE ......................................................... F2-16

STRUCTURAL VIEW....................................... F2-18

BLOCK DIAGRAM ........................................... F2-20

CONTROL DEVICE AND CONTROL

RELATIONSHIP CHART .............................. F2-22

CRUISE CONTROL SYSTEM ......................... F2-23

CONTROLLER AREA NETWORK (CAN) ....... F2-24

ON-BOARD DIAGNOSTIC................................. F2-24

OUTLINE ......................................................... F2-24

DTC.................................................................. F2-24

KOEO/KOER SELF-TEST ............................... F2-26

PID/DATA MONITOR AND RECORD ............. F2-27

SIMULATION TEST ......................................... F2-27

LOCATION INDEX............................................. F2-28

INTAKE-AIR SYSTEM ..................................... F2-28

FUEL SYSTEM ................................................ F2-29

EMISSION SYSTEM........................................ F2-31

CONTROL SYSTEM........................................ F2-32

ENGINE TUNE-UP............................................. F2-34

ENGINE TUNE-UP PREPARATION ............... F2-34

IDLE SPEED INSPECTION ............................. F2-34

CORRECTION PROCEDURE ......................... F2-34

INTAKE-AIR SYSTEM........................................ F2-35

VACUUM TUBE ROUTING DIAGRAM............ F2-35

INTAKE-AIR SYSTEM

REMOVAL/INSTALLATION .......................... F2-36

AIR CLEANER ELEMENT INSPECTION ........ F2-37

TURBOCHARGER INSPECTION ................... F2-38

GUIDE BLADE ACTUATOR INSPECTION ..... F2-39

VARIABLE BOOST CONTROL (VBC)

SOLENOID VALVE INSPECTION ................ F2-40VARIABLE BOOST CONTROL (VBC)

CHECK VALVE INSPECTION ...................... F2-41

VARIABLE SWIRL CONTROL (VSC)

VALVE ACTUATOR INSPECTION ............... F2-41

VARIABLE SWIRL CONTROL (VSC)

SOLENOID VALVE INSPECTION ................ F2-42

GLOW PLUG REMOVAL/INSTALLATION ...... F2-42

GLOW PLUG INSPECTION ............................ F2-43

GLOW PLUG LEAD INSPECTION .................. F2-43

ACCELERATOR PEDAL COMPONENT

REMOVAL/INSTALLATION .......................... F2-44

ACCELERATOR PEDAL COMPONENT

DISASSEMBLY/ASSEMBLY ........................ F2-44

FUEL SYSTEM................................................... F2-45

BEFORE REPAIR PROCEDURE .................... F2-45

AFTER REPAIR PROCEDURE ....................... F2-45

FUEL TANK REMOVAL/INSTALLATION ........ F2-45

FUEL TANK INSPECTION .............................. F2-49

NONRETURN VALVE INSPECTION............... F2-50

FUEL FILTER COMPONENT

REMOVAL/INSTALLATION .......................... F2-50

FUEL FILTER COMPONENT

DISASSEMBLY/ASSEMBLY ........................ F2-51

FUEL WARMER INSPECTION........................ F2-51

SEDIMENTOR WATER DRAINING................. F2-52

SEDIMENTOR SWITCH INSPECTION ........... F2-52

SUPPLY PUMP REMOVAL/INSTALLATION .. F2-53

SUPPLY PUMP INSPECTION......................... F2-54

SUCTION CONTROL VALVE INSPECTION ... F2-54

COMMON RAIL INSPECTION ........................ F2-54

FUEL INJECTOR REMOVAL/INSTALLATION F2-55

FUEL INJECTOR INSPECTION ...................... F2-56

EXHAUST SYSTEM........................................... F2-57

EXHAUST SYSTEM INSPECTION ................. F2-57

EXHAUST SYSTEM

REMOVAL/INSTALLATION .......................... F2-57

EMISSION SYSTEM........................................... F2-59

EGR VALVE REMOVAL/INSTALLATION........ F2-59

EGR VALVE INSPECTION .............................. F2-59

EGR SOLENOID VALVE (VACUUM)

INSPECTION ................................................ F2-60

EGR SOLENOID VALVE (VENT)

INSPECTION ................................................ F2-60

EGR CONTROL SOLENOID VALVE

INSPECTION ................................................ F2-61

INTAKE SHUTTER VALVE ACTUATOR

INSPECTION ................................................ F2-62

INTAKE SHUTTER SOLENOID VALVE

INSPECTION ................................................ F2-63

CONTROL SYSTEM........................................... F2-64

PCM REMOVAL/INSTALLATION .................... F2-64

PCM INSPECTION .......................................... F2-65

PCM CONFIGURATION .................................. F2-68

CLUTCH SWITCH INSPECTION .................... F2-68

NEUTRAL SWITCH INSPECTION .................. F2-69

IDLE SWITCH INSPECTION ........................... F2-70

IDLE SWITCH ADJUSTMENT ......................... F2-71

ACCELERATOR POSITION SENSOR

INSPECTION ................................................ F2-72

ACCELERATOR POSITION SENSOR

ADJUSTMENT .............................................. F2-73 FEATURES

SERVICE