water pump MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 8 of 909

NEW STANDARDS

GI–5

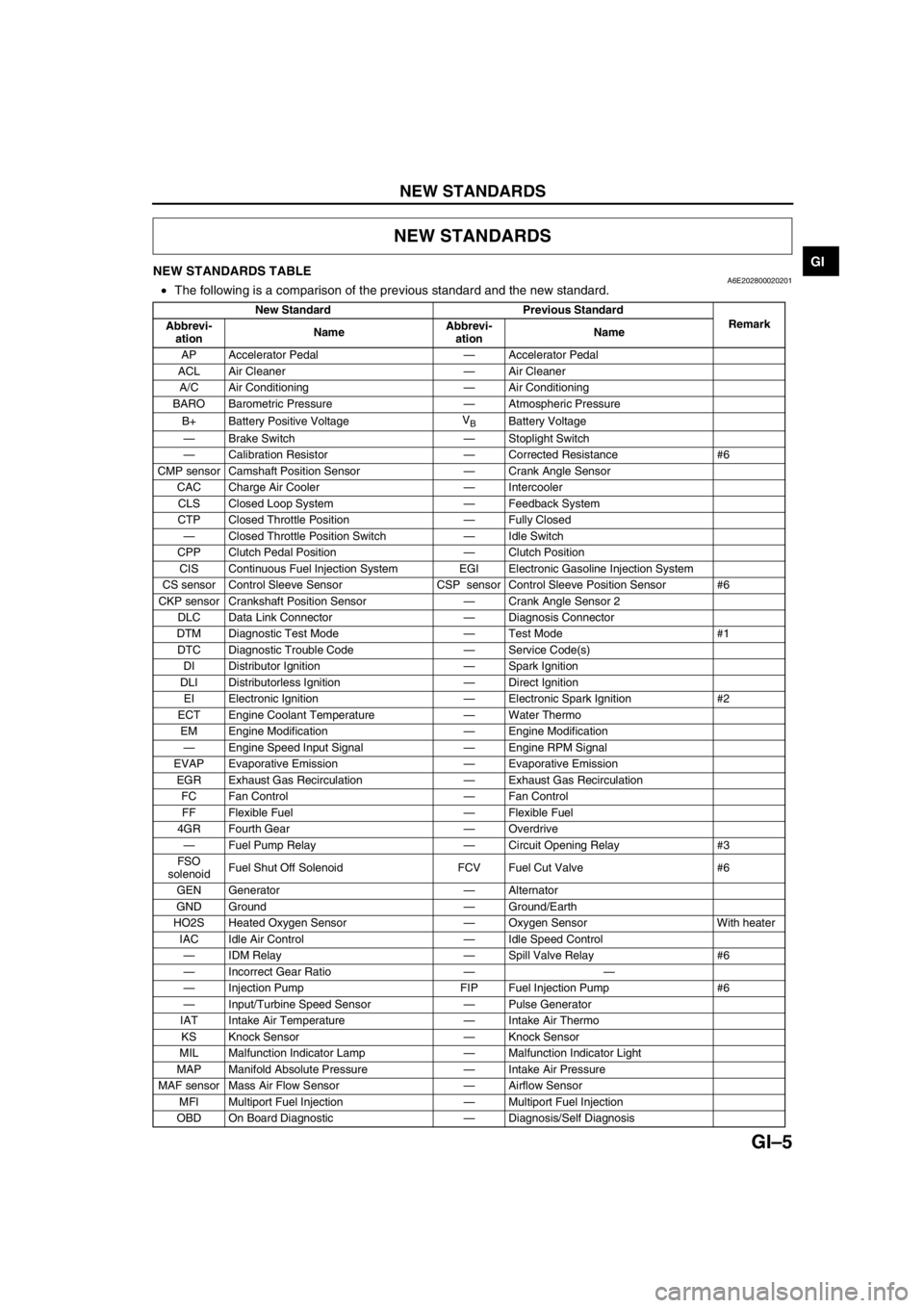

GINEW STANDARDS TABLEA6E202800020201•The following is a comparison of the previous standard and the new standard.

NEW STANDARDS

New Standard Previous Standard

Remark

Abbrevi-

ationNameAbbrevi-

ationName

AP Accelerator Pedal—Accelerator Pedal

ACL Air Cleaner—Air Cleaner

A/C Air Conditioning—Air Conditioning

BARO Barometric Pressure—Atmospheric Pressure

B+ Battery Positive VoltageV

BBattery Voltage

—Brake Switch—Stoplight Switch

—Calibration Resistor—Corrected Resistance #6

CMP sensor Camshaft Position Sensor—Crank Angle Sensor

CAC Charge Air Cooler—Intercooler

CLS Closed Loop System—Feedback System

CTP Closed Throttle Position—Fully Closed

—Closed Throttle Position Switch—Idle Switch

CPP Clutch Pedal Position—Clutch Position

CIS Continuous Fuel Injection System EGI Electronic Gasoline Injection System

CS sensor Control Sleeve Sensor CSP sensor Control Sleeve Position Sensor #6

CKP sensor Crankshaft Position Sensor—Crank Angle Sensor 2

DLC Data Link Connector—Diagnosis Connector

DTM Diagnostic Test Mode—Test Mode #1

DTC Diagnostic Trouble Code—Service Code(s)

DI Distributor Ignition—Spark Ignition

DLI Distributorless Ignition—Direct Ignition

EI Electronic Ignition—Electronic Spark Ignition #2

ECT Engine Coolant Temperature—Water Thermo

EM Engine Modification—Engine Modification

—Engine Speed Input Signal—Engine RPM Signal

EVAP Evaporative Emission—Evaporative Emission

EGR Exhaust Gas Recirculation—Exhaust Gas Recirculation

FC Fan Control—Fan Control

FF Flexible Fuel—Flexible Fuel

4GR Fourth Gear—Overdrive

—Fuel Pump Relay—Circuit Opening Relay #3

FSO

solenoidFuel Shut Off Solenoid FCV Fuel Cut Valve #6

GEN Generator—Alternator

GND Ground—Ground/Earth

HO2S Heated Oxygen Sensor—Oxygen Sensor With heater

IAC Idle Air Control—Idle Speed Control

—IDM Relay—Spill Valve Relay #6

—Incorrect Gear Ratio——

—Injection Pump FIP Fuel Injection Pump #6

—Input/Turbine Speed Sensor—Pulse Generator

IAT Intake Air Temperature—Intake Air Thermo

KS Knock Sensor—Knock Sensor

MIL Malfunction Indicator Lamp—Malfunction Indicator Light

MAP Manifold Absolute Pressure—Intake Air Pressure

MAF sensor Mass Air Flow Sensor—Airflow Sensor

MFI Multiport Fuel Injection—Multiport Fuel Injection

OBD On Board Diagnostic—Diagnosis/Self Diagnosis

Page 44 of 909

TIMING BELT

B2–13

B2

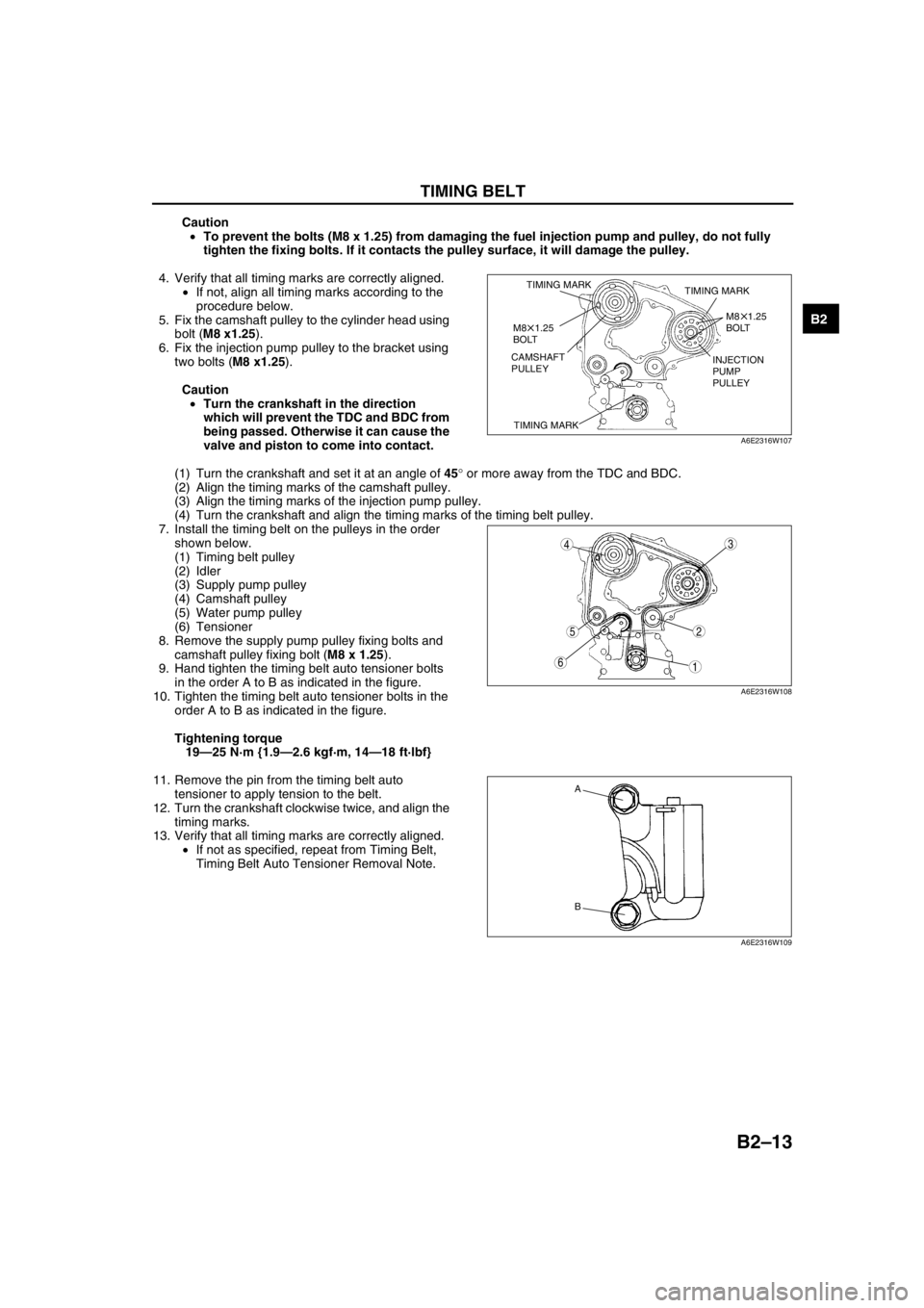

Caution

•To prevent the bolts (M8 x 1.25) from damaging the fuel injection pump and pulley, do not fully

tighten the fixing bolts. If it contacts the pulley surface, it will damage the pulley.

4. Verify that all timing marks are correctly aligned.

•If not, align all timing marks according to the

procedure below.

5. Fix the camshaft pulley to the cylinder head using

bolt (M8 x1.25).

6. Fix the injection pump pulley to the bracket using

two bolts (M8 x1.25).

Caution

•Turn the crankshaft in the direction

which will prevent the TDC and BDC from

being passed. Otherwise it can cause the

valve and piston to come into contact.

(1) Turn the crankshaft and set it at an angle of 45° or more away from the TDC and BDC.

(2) Align the timing marks of the camshaft pulley.

(3) Align the timing marks of the injection pump pulley.

(4) Turn the crankshaft and align the timing marks of the timing belt pulley.

7. Install the timing belt on the pulleys in the order

shown below.

(1) Timing belt pulley

(2) Idler

(3) Supply pump pulley

(4) Camshaft pulley

(5) Water pump pulley

(6) Tensioner

8. Remove the supply pump pulley fixing bolts and

camshaft pulley fixing bolt (M8 x 1.25).

9. Hand tighten the timing belt auto tensioner bolts

in the order A to B as indicated in the figure.

10. Tighten the timing belt auto tensioner bolts in the

order A to B as indicated in the figure.

Tightening torque

19—25 N·m {1.9—2.6 kgf·m, 14—18 ft·lbf}

11. Remove the pin from the timing belt auto

tensioner to apply tension to the belt.

12. Turn the crankshaft clockwise twice, and align the

timing marks.

13. Verify that all timing marks are correctly aligned.

•If not as specified, repeat from Timing Belt,

Timing Belt Auto Tensioner Removal Note.

TIMING MARK

TIMING MARKTIMING MARK

M8 1.25

BOLT

M8 1.25

BOLT

CAMSHAFT

PULLEYINJECTION

PUMP

PULLEY

A6E2316W107

5

43

1

2

6

A6E2316W108

A

B

A6E2316W109

Page 47 of 909

B2–16

CYLINDER HEAD GASKET

.

SST

SST

SSTR

R

R

R

R

SEALANTSEALANT

SEALANTSEALANT

SEALANTSEALANT

SEALANTSEALANT

SEALANTSEALANT

OILOIL

OILOIL

7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}

7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}

7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf} 7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}

7.9—10.7 N·m

{80—110 kgf·cm,

69.5—95.4 in·lbf}55—64

{5.6—6.6, 41—47}

38—51

{3.8—5.3,

28—38}

52—61

{5.3—6.3,

39—45}

29 {3.0, 22}

+90 105

+90 105

+90 105

50—60

{5.0—6.0,

37—44}

19—25

{1.9—2.6,

14—18}

50—60 {5.0—6.0, 37—44}

46—58 {4.6—6.0, 34—43} 59—68

{6.0—7.0, 44—50}25—30

{2.5—3.1, 18—22}

38—51

{3.8—5.3,

28—38}19—25

{1.9—2.6,

14—18}

N·m {kgf·m, ft·lbf}

98

7

54

3

1

2

10

19

18

17

15

16

14

13

11

12

20

25

24

2321

22

6

SST

55—64

{5.6—6.6, 41—47}

—

— —

39—44

{4.0—4.4,

28.8—32.4}

22—26

{2.2—2.7,

16—19}

SEALANTSEALANT

A6E2318W100

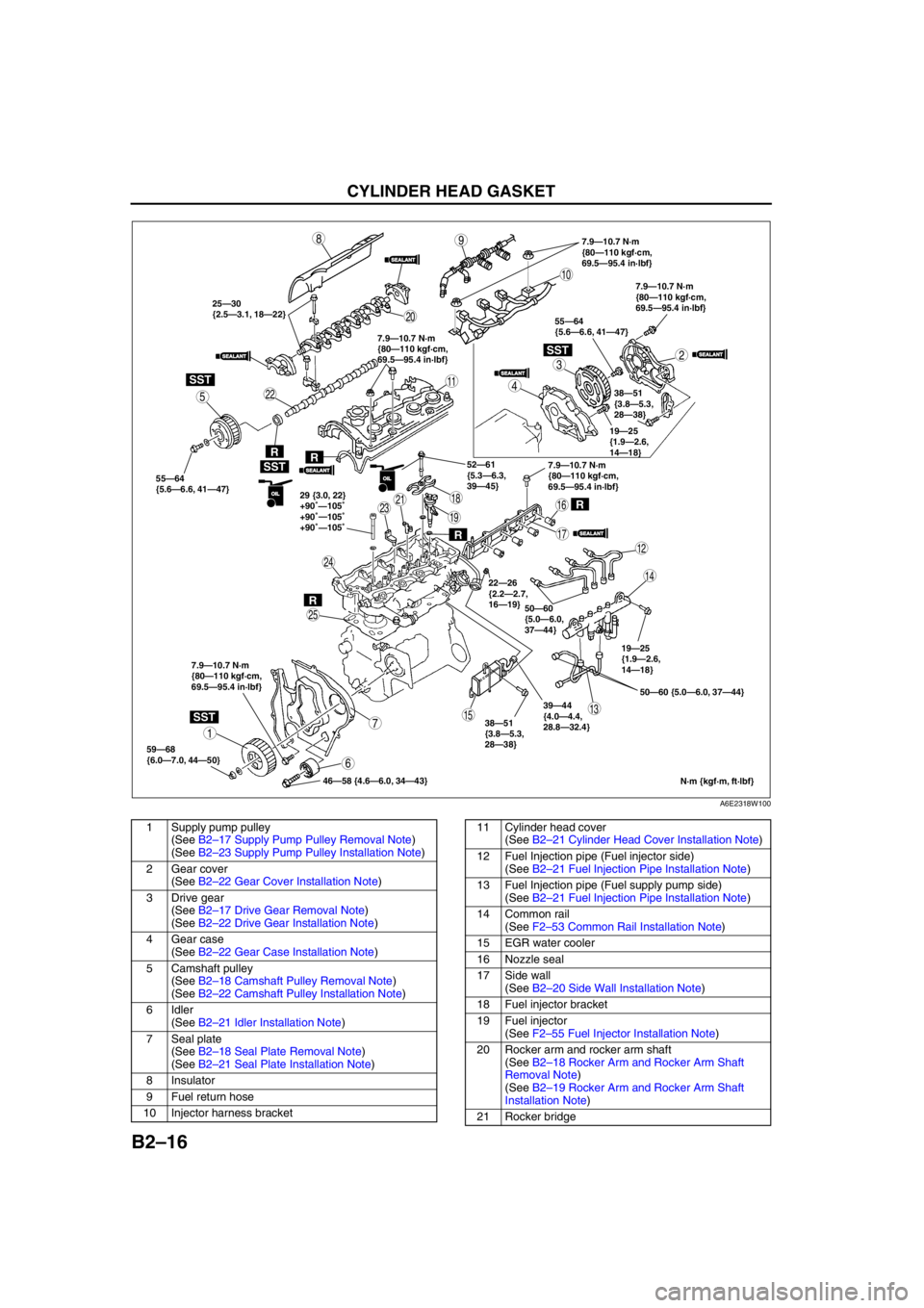

1 Supply pump pulley

(See B2–17 Supply Pump Pulley Removal Note)

(See B2–23 Supply Pump Pulley Installation Note)

2 Gear cover

(See B2–22 Gear Cover Installation Note)

3 Drive gear

(See B2–17 Drive Gear Removal Note)

(See B2–22 Drive Gear Installation Note)

4 Gear case

(See B2–22 Gear Case Installation Note)

5 Camshaft pulley

(See B2–18 Camshaft Pulley Removal Note)

(See B2–22 Camshaft Pulley Installation Note)

6 Idler

(See B2–21 Idler Installation Note)

7 Seal plate

(See B2–18 Seal Plate Removal Note)

(See B2–21 Seal Plate Installation Note)

8 Insulator

9 Fuel return hose

10 Injector harness bracket11 Cylinder head cover

(See B2–21 Cylinder Head Cover Installation Note)

12 Fuel Injection pipe (Fuel injector side)

(See B2–21 Fuel Injection Pipe Installation Note)

13 Fuel Injection pipe (Fuel supply pump side)

(See B2–21 Fuel Injection Pipe Installation Note)

14 Common rail

(See F2–53 Common Rail Installation Note)

15 EGR water cooler

16 Nozzle seal

17 Side wall

(See B2–20 Side Wall Installation Note)

18 Fuel injector bracket

19 Fuel injector

(See F2–55 Fuel Injector Installation Note)

20 Rocker arm and rocker arm shaft

(See B2–18 Rocker Arm and Rocker Arm Shaft

Removal Note)

(See B2–19 Rocker Arm and Rocker Arm Shaft

Installation Note)

21 Rocker bridge

Page 66 of 909

D–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E330202000201•The construction and the operation of the oil cooler and the oil filter for the new Mazda6 (GG, GY) MZR-CD (RF

Turbo) engine model is the same as the current Mazda MPV (LW) MZR-CD (RF Turbo) engine model. (See

Mazda MPV Workshop Manual Supplement 1737-1*-02D.)

•The construction and the operation of the lubrication system except for the oil cooler and oil filter for the new

Mazda6 (GG, GY) MZR-CD (RF Turbo) engine model is the same as the current Mazda 626, 626 Station

Wagon (GF, GW) RF Turbo engine model. (European specs.) (See Mazda 626, 626 Station Wagon RF Turbo

Workshop Manual Supplement 1614-10-98D.)

•The construction and the operation of the lubrication system for the new Mazda6 (GG, GY) L8, LF, and L3

engine models is the same as the current Mazda6 (GG) engine model L8, LF, and L3 engine models. (See

Mazda6 Training Manual 3359-1*-02C, Mazda6 Workshop Manual 1730-1*-02C.)

End Of Sie

SPECIFICATIONSA6E330202000202Gasoline engine

* : Always verify the oil level with the dipsticks since the engine oil capacity differs according to dipstick

specifications. (See Mazda6 Workshop Manual 1730-1*-02C Section D.)

Recommended Engine Oil (Gasoline Engine)

•The maintenance intervals on the scheduled maintenance table (See GI–8 SCHEDULED MAINTENANCE

TABLE) can only be supported with the use of following oils.

OUTLINE

ItemSpecification

New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)

L8 LF L3*

Lubrication system Force-fed type

Oil coolerWater-cooled

Oil pressure

(approximate quantity)

[oil temperature: 100°C

{212°F}](kPa {kgf/cm

2, psi})

min [rpm]234—521

{2.39—5.31, 33.9—75.5}

[3,000]395—649

{4.03—6.61,

57.3—94.1}

[3,000]

Oil pumpType Trochoid gear type

Relief pressure

(approximate

quantity) (kPa {kgf/cm

2,

psi})500—600

{5.09—6.11, 72.6—87.0}

Oil filterType Full-flow, Paper element

Bypass pressure

(approximate

quantity)(kPa kgf/cm

2, psi})80—120

{0.9—1.2, 12.8—17.0}

Oil capacity

(approximate

quantity)Total

(dry engine)(L {US qt, lmp qt}) 4.6 {4.8, 4.0} Dipstick A: 4.2 {4.4, 3.7}

Dipstick B: 5.1 {5.4, 4.5}

Oil replacement (L {US qt, lmp qt}) 3.9 {4.0, 3.4} Dipstick A: 3.1 {3.3, 2.7}

Dipstick B: 4.0 {4.2, 3.5}

Oil and oil filter

replacement(L {US qt, lmp qt}) 4.3 {4.5, 3.8} Dipstick A: 3.5 {3.7, 3.1}

Dipstick B: 4.4 {4.6, 3.9}

ItemSpecification

New Mazda6

(GG, GY), Current Mazda6

(GG)New Mazda6

(GG, GY), Current Mazda6

(GG)

L8, LF, L3

Engine oil GradeAPI SL

ACEA A3

Viscosity (SAE) 5W-30, 10W-40 5W-20

RemarksMazda genuine Dexelia oil e.g. —

Page 67 of 909

OUTLINE

D–3

D

Diesel engine

Bold frames: New specifications

Recommended Engine Oil (Diesel Engine)

•The maintenance intervals on the scheduled maintenance table (See GI–8 SCHEDULED MAINTENANCE

TABLE) can only be supported with the use of following oils.

Bold frames: New specifications

End Of Sie

ItemSpecification

New Mazda6

(GG, GY)Current

Mazda 626, 626

Station Wagon

(GF, GW)Current

Mazda MPV

(LW)

MZR-CD (RF Turbo) RF TurboMZR-CD (RF

Turbo)

Lubrication system Force-fed type—

Oil cooler Water-cooled—

Oil pressure

(approximate quantity)

[oil temperature: 100°C {212°F}](kPa {kgf/cm

2, psi})

min [rpm]147 {1.5, 21} [1,000],

343 {3.5, 50} [3,000]—

Oil pumpType Trochoid gear type—Trochoid gear type

Relief pressure

(approximate

quantity)(kPa {kgf/cm

2, psi})

[rpm]580—700

{5.9—7.1,

84.1—101.5}

[3,000]—580—700

{5.9—7.1,

84.1—101.5}

[3,000]

Oil filterTypeFull-flow,

Paper element—Full-flow,

Paper element

Bypass pressure

(approximate

quantity)(kPa kgf/cm

2, psi})78—118

{0.8—1.2,

11.3—17.1} —78—118

{0.8—1.2,

11.3—17.1}

Oil capacity

(approximate

quantity)Total

(dry engine)(L {US qt, lmp qt}) 5.5 {5.8, 4.8} 5.4 {5.7, 4.8} —

Oil replacement (L {US qt, lmp qt}) 4.8 {5.1, 4.2} 4.5 {4.8, 4.0}—

Oil and oil filter

replacement(L {US qt, lmp qt}) 5.0 {5.3 ,4.4} 4.7 {5.0, 4.1} —

ItemSpecification

New Mazda6

(GG, GY)Current

Mazda 626, 626

Station Wagon

(GF, GW)

MZR-CD (RF Turbo) RF Turbo

Engine oil GradeAPI CF CD, CE, CF-4 CD

ACEA B1 or B3 B3 B3 or B4—

Viscosity (SAE) 5W-30 10W-40 5W-30, 10W-30 5W-30, 10W-30

RemarksMazda genuine

Dexelia oil e.g.——

Page 76 of 909

E–1

E

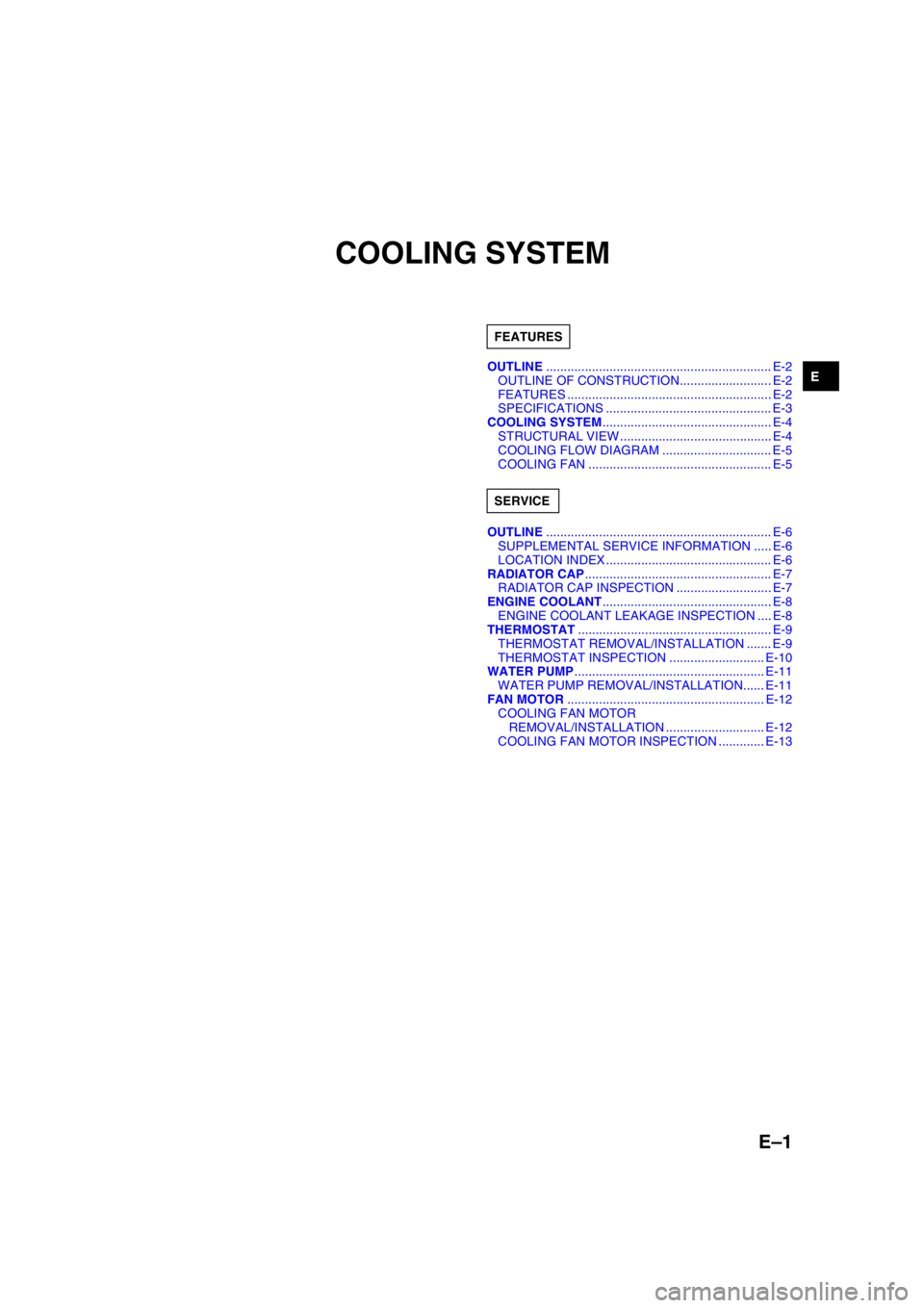

ECOOLING SYSTEM

OUTLINE................................................................ E-2

OUTLINE OF CONSTRUCTION.......................... E-2

FEATURES .......................................................... E-2

SPECIFICATIONS ............................................... E-3

COOLING SYSTEM................................................ E-4

STRUCTURAL VIEW ........................................... E-4

COOLING FLOW DIAGRAM ............................... E-5

COOLING FAN .................................................... E-5

OUTLINE................................................................ E-6

SUPPLEMENTAL SERVICE INFORMATION ..... E-6

LOCATION INDEX ............................................... E-6

RADIATOR CAP..................................................... E-7

RADIATOR CAP INSPECTION ........................... E-7

ENGINE COOLANT................................................ E-8

ENGINE COOLANT LEAKAGE INSPECTION .... E-8

THERMOSTAT....................................................... E-9

THERMOSTAT REMOVAL/INSTALLATION ....... E-9

THERMOSTAT INSPECTION ........................... E-10

WATER PUMP...................................................... E-11

WATER PUMP REMOVAL/INSTALLATION...... E-11

FAN MOTOR........................................................ E-12

COOLING FAN MOTOR

REMOVAL/INSTALLATION ............................ E-12

COOLING FAN MOTOR INSPECTION ............. E-13 FEATURES

SERVICE

Page 77 of 909

E–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E360202000205•The construction and operation of the water pump and the thermostat for the new Mazda6 (GG, GY) MZR-CD

(RF Turbo) engine model are the same as the current Mazda 323 (BJ) RF Turbo engine model. (European

specs.) (See Mazda 323 RF Turbo Workshop Manual Supplement 1633-10-98G.)

•The construction and operation of the cooling system except for the water pump and the thermostat for the new

Mazda6 (GG, GY) MZR-CD (RF Turbo) engine model are the same as the current Mazda6 (GG) L3 engine

model except for the following features. (See Mazda6 Training Manual 3359-1*-02C.)

•The construction and operation of the engine cooling system for the new Mazda6 (GG, GY) L8, LF, and L3

engine models is the same as the current Mazda6 (GG) L8, LF, and L3 engine models. (See Mazda6 Training

Manual 3359-1*-02C.)

End Of Sie

FEATURESA6E360202000206Modification to fit the engine performance

•Cooling fan motor output has been changed. (MZR-CD (RF Turbo) engine model)

End Of Sie

OUTLINE

Page 78 of 909

OUTLINE

E–3

E

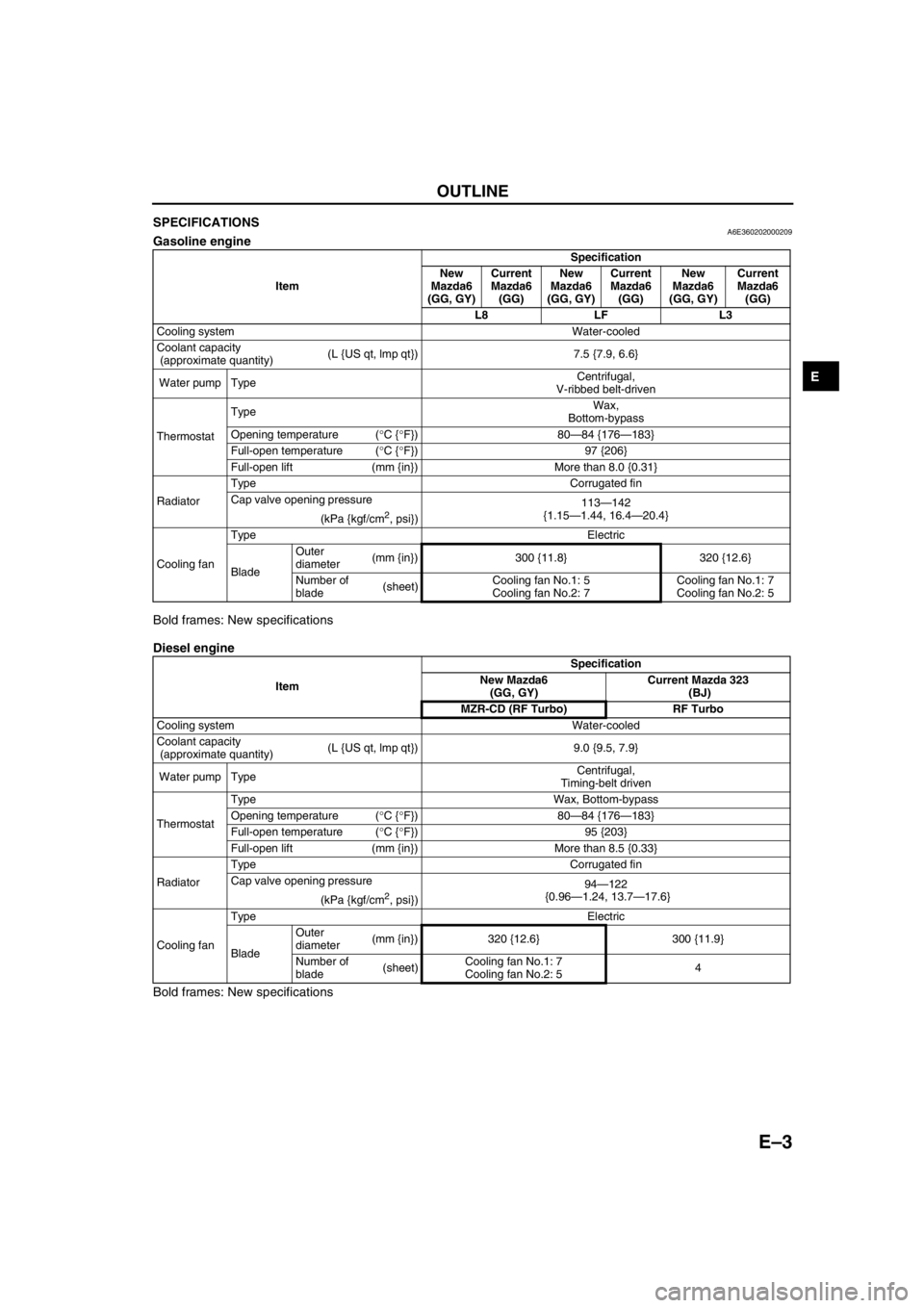

SPECIFICATIONSA6E360202000209Gasoline engine

Bold frames: New specifications

Diesel engine

Bold frames: New specifications

End Of Sie

ItemSpecification

New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)New

Mazda6

(GG, GY)Current

Mazda6

(GG)

L8 LF L3

Cooling system Water-cooled

Coolant capacity

(approximate quantity)(L {US qt, lmp qt}) 7.5 {7.9, 6.6}

Water pump TypeCentrifugal,

V-ribbed belt-driven

ThermostatTypeWax,

Bottom-bypass

Opening temperature (°C {°F}) 80—84 {176—183}

Full-open temperature (°C {°F}) 97 {206}

Full-open lift (mm {in}) More than 8.0 {0.31}

RadiatorType Corrugated fin

Cap valve opening pressure

113—142

{1.15—1.44, 16.4—20.4}

(kPa {kgf/cm

2, psi})

Cooling fanType Electric

BladeOuter

diameter(mm {in}) 300 {11.8} 320 {12.6}

Number of

blade(sheet)Cooling fan No.1: 5

Cooling fan No.2: 7Cooling fan No.1: 7

Cooling fan No.2: 5

ItemSpecification

New Mazda6

(GG, GY)Current Mazda 323

(BJ)

MZR-CD (RF Turbo) RF Turbo

Cooling system Water-cooled

Coolant capacity

(approximate quantity)(L {US qt, lmp qt}) 9.0 {9.5, 7.9}

Water pump TypeCentrifugal,

Timing-belt driven

ThermostatType Wax, Bottom-bypass

Opening temperature (°C {°F}) 80—84 {176—183}

Full-open temperature (°C {°F}) 95 {203}

Full-open lift (mm {in}) More than 8.5 {0.33}

RadiatorType Corrugated fin

Cap valve opening pressure

94—122

{0.96—1.24, 13.7—17.6}

(kPa {kgf/cm

2, psi})

Cooling fanType Electric

BladeOuter

diameter(mm {in}) 320 {12.6} 300 {11.9}

Number of

blade(sheet)Cooling fan No.1: 7

Cooling fan No.2: 54

Page 79 of 909

E–4

COOLING SYSTEM

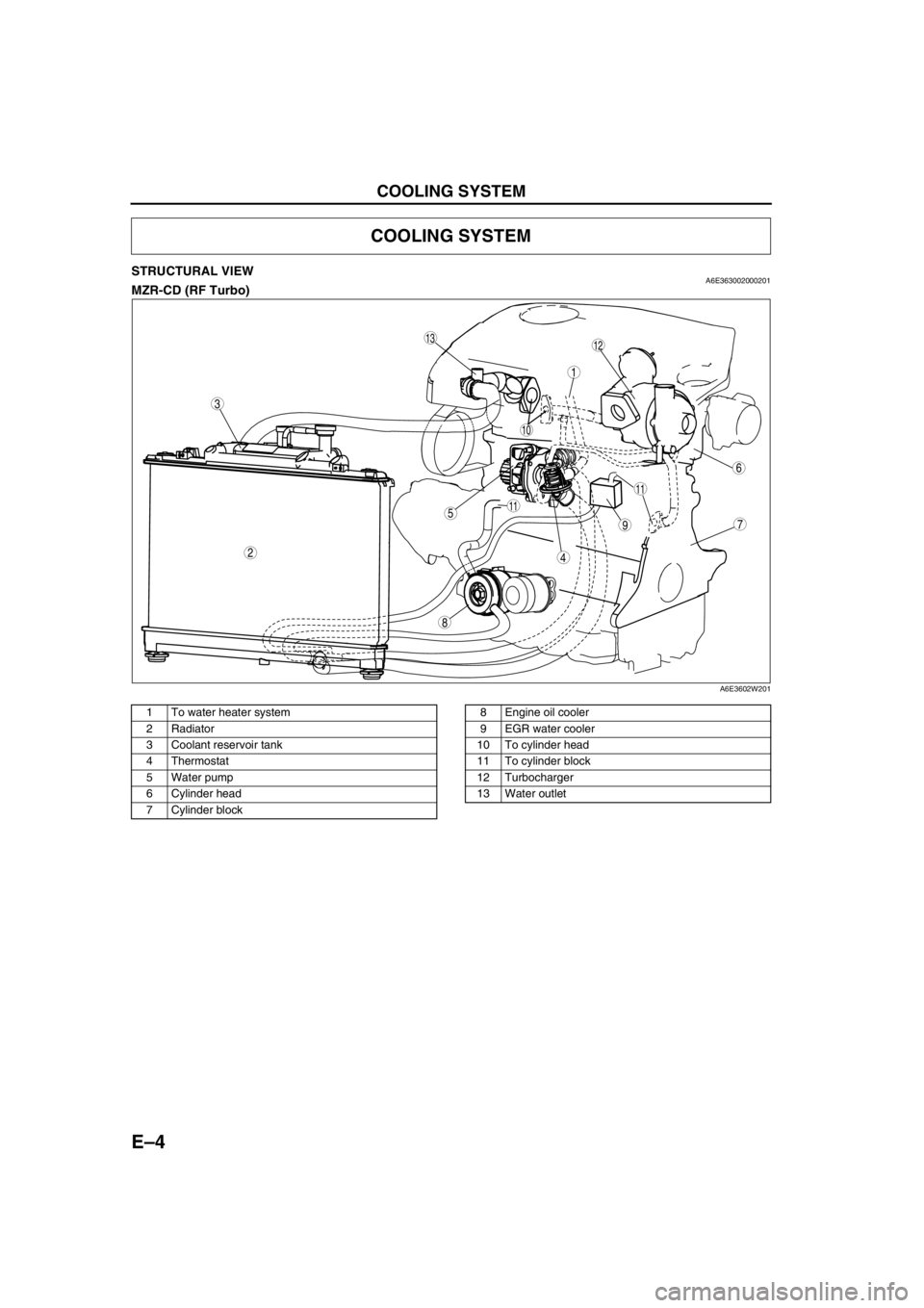

STRUCTURAL VIEWA6E363002000201MZR-CD (RF Turbo)

.

End Of Sie

COOLING SYSTEM

8

75

4

3

1

2

6

10

11

11

9

1312

A6E3602W201

1 To water heater system

2 Radiator

3 Coolant reservoir tank

4Thermostat

5 Water pump

6 Cylinder head

7 Cylinder block8 Engine oil cooler

9EGR water cooler

10 To cylinder head

11 To cylinder block

12 Turbocharger

13 Water outlet

Page 80 of 909

COOLING SYSTEM

E–5

E

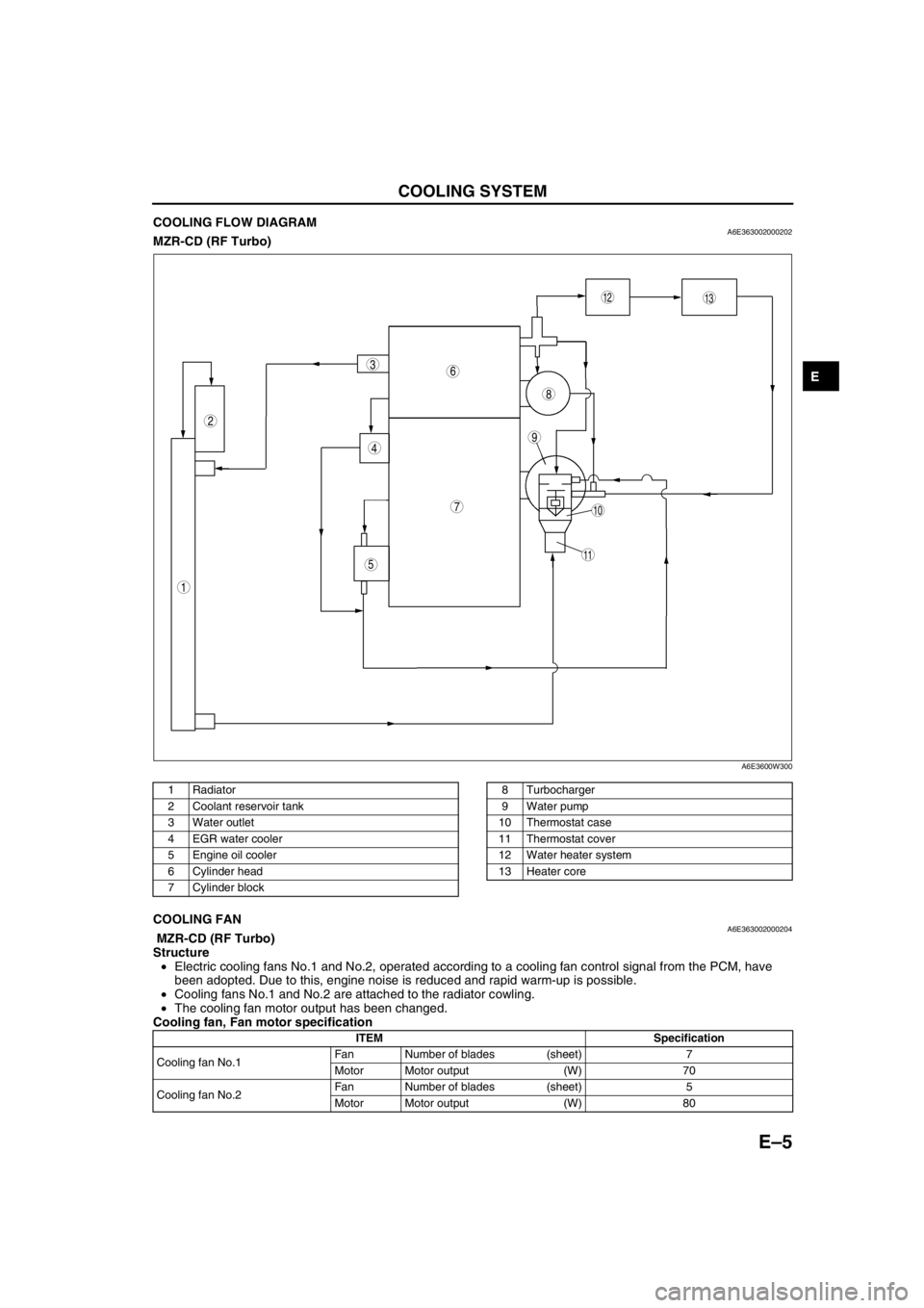

COOLING FLOW DIAGRAMA6E363002000202MZR-CD (RF Turbo)

.

End Of SieCOOLING FANA6E363002000204 MZR-CD (RF Turbo)

Structure

•Electric cooling fans No.1 and No.2, operated according to a cooling fan control signal from the PCM, have

been adopted. Due to this, engine noise is reduced and rapid warm-up is possible.

•Cooling fans No.1 and No.2 are attached to the radiator cowling.

•The cooling fan motor output has been changed.

Cooling fan, Fan motor specification

End Of Sie

9

8

7

5

4

3

1

2

10

13

11

12

6

A6E3600W300

1Radiator

2 Coolant reservoir tank

3 Water outlet

4EGR water cooler

5 Engine oil cooler

6 Cylinder head

7 Cylinder block8 Turbocharger

9 Water pump

10 Thermostat case

11 Thermostat cover

12 Water heater system

13 Heater core

ITEM Specification

Cooling fan No.1Fan Number of blades (sheet) 7

Motor Motor output (W) 70

Cooling fan No.2Fan Number of blades (sheet) 5

Motor Motor output (W) 80