wheel MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 151 of 909

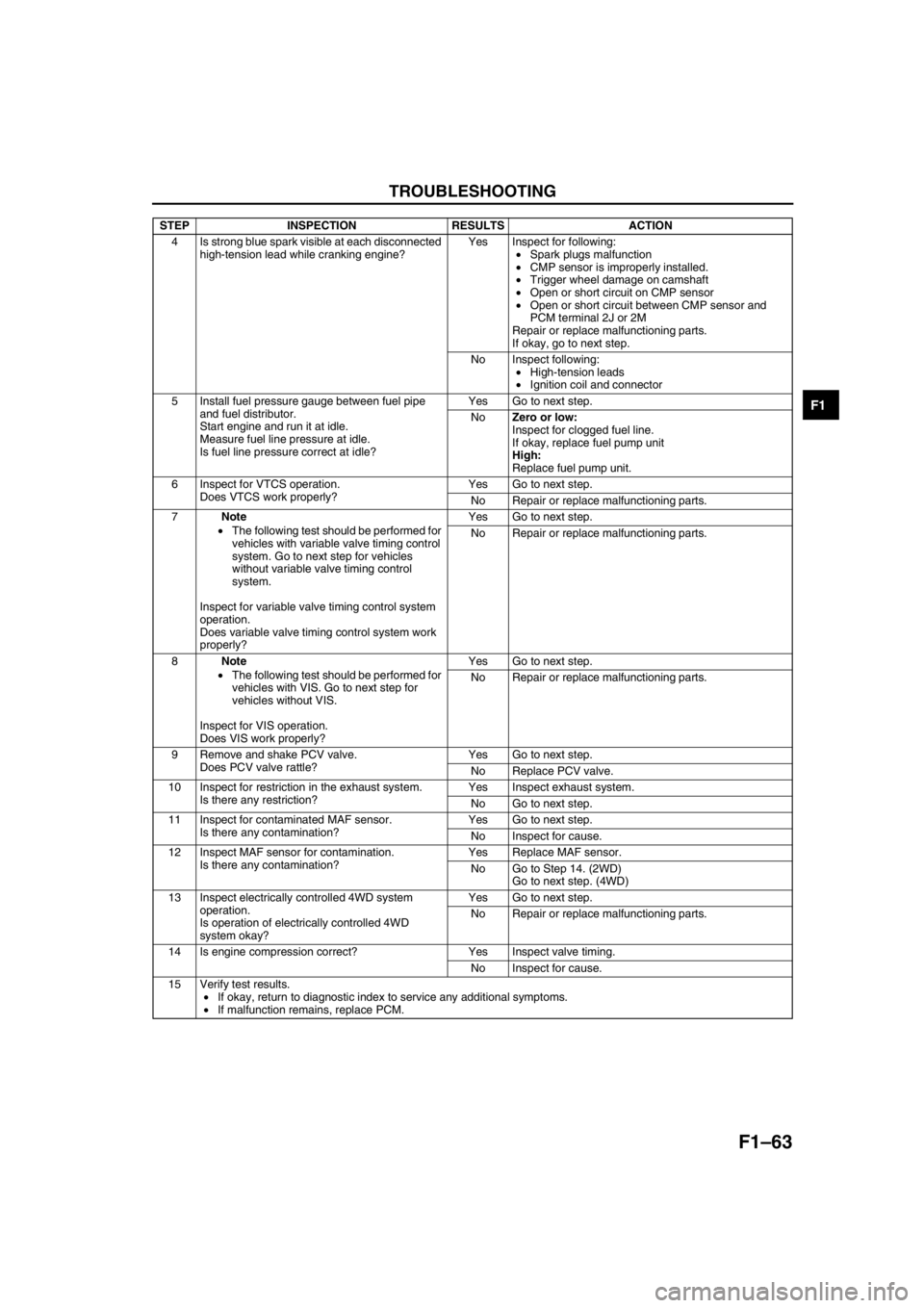

TROUBLESHOOTING

F1–63

F1

End Of Sie

4 Is strong blue spark visible at each disconnected

high-tension lead while cranking engine?Yes Inspect for following:

•Spark plugs malfunction

•CMP sensor is improperly installed.

•Trigger wheel damage on camshaft

•Open or short circuit on CMP sensor

•Open or short circuit between CMP sensor and

PCM terminal 2J or 2M

Repair or replace malfunctioning parts.

If okay, go to next step.

No Inspect following:

•High-tension leads

•Ignition coil and connector

5 Install fuel pressure gauge between fuel pipe

and fuel distributor.

Start engine and run it at idle.

Measure fuel line pressure at idle.

Is fuel line pressure correct at idle?Yes Go to next step.

NoZero or low:

Inspect for clogged fuel line.

If okay, replace fuel pump unit

High:

Replace fuel pump unit.

6 Inspect for VTCS operation.

Does VTCS work properly?Yes Go to next step.

No Repair or replace malfunctioning parts.

7Note

•The following test should be performed for

vehicles with variable valve timing control

system. Go to next step for vehicles

without variable valve timing control

system.

Inspect for variable valve timing control system

operation.

Does variable valve timing control system work

properly?Yes Go to next step.

No Repair or replace malfunctioning parts.

8Note

•The following test should be performed for

vehicles with VIS. Go to next step for

vehicles without VIS.

Inspect for VIS operation.

Does VIS work properly?Yes Go to next step.

No Repair or replace malfunctioning parts.

9 Remove and shake PCV valve.

Does PCV valve rattle?Yes Go to next step.

No Replace PCV valve.

10 Inspect for restriction in the exhaust system.

Is there any restriction?Yes Inspect exhaust system.

No Go to next step.

11 Inspect for contaminated MAF sensor.

Is there any contamination?Yes Go to next step.

No Inspect for cause.

12 Inspect MAF sensor for contamination.

Is there any contamination?Yes Replace MAF sensor.

No Go to Step 14. (2WD)

Go to next step. (4WD)

13 Inspect electrically controlled 4WD system

operation.

Is operation of electrically controlled 4WD

system okay?Yes Go to next step.

No Repair or replace malfunctioning parts.

14 Is engine compression correct? Yes Inspect valve timing.

No Inspect for cause.

15 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. STEP INSPECTION RESULTS ACTION

Page 152 of 909

F1–64

TROUBLESHOOTING

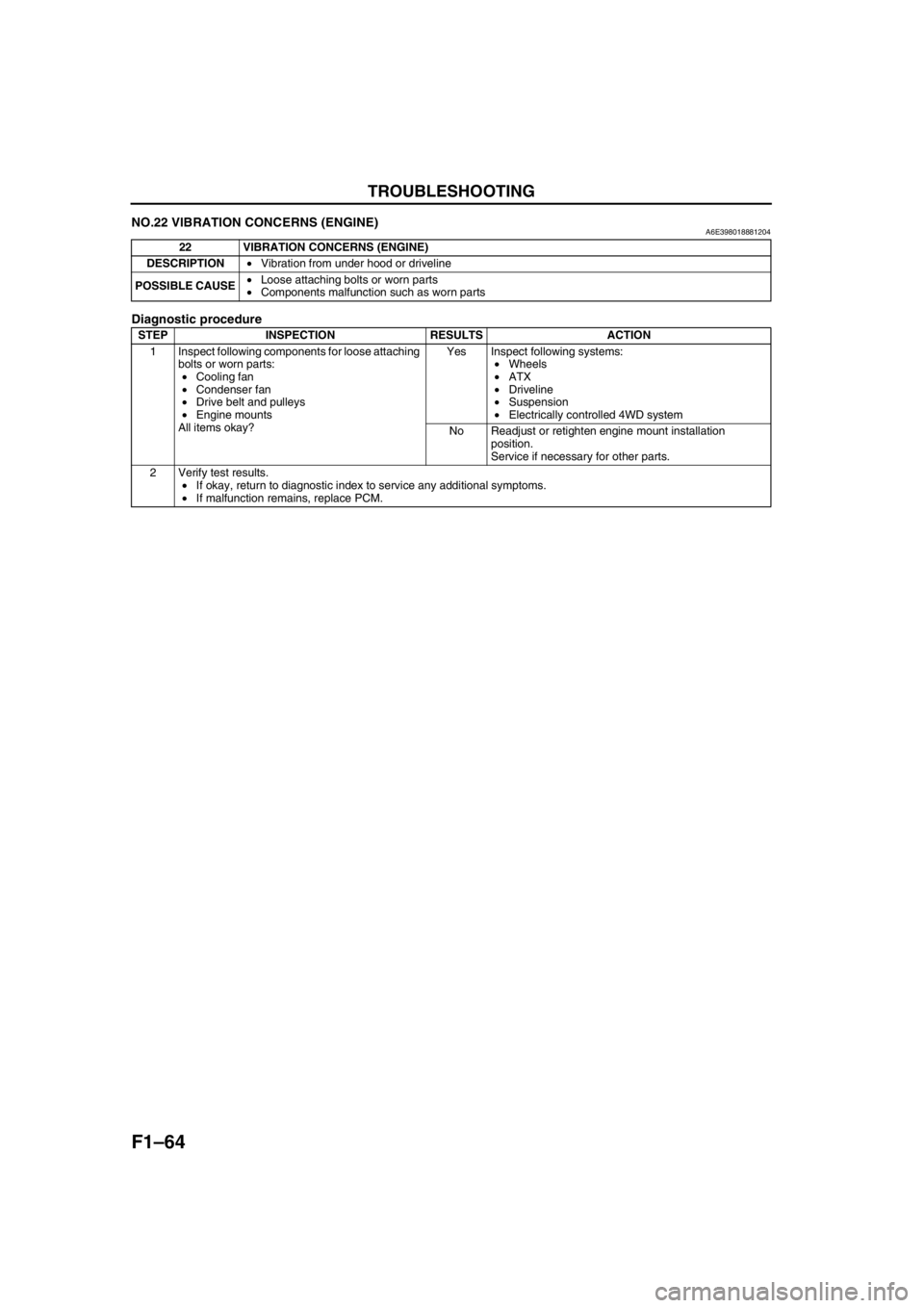

NO.22 VIBRATION CONCERNS (ENGINE)A6E398018881204

Diagnostic procedure

End Of Sie

22 VIBRATION CONCERNS (ENGINE)

DESCRIPTION•Vibration from under hood or driveline

POSSIBLE CAUSE•Loose attaching bolts or worn parts

•Components malfunction such as worn parts

STEP INSPECTION RESULTS ACTION

1 Inspect following components for loose attaching

bolts or worn parts:

•Cooling fan

•Condenser fan

•Drive belt and pulleys

•Engine mounts

All items okay?Yes Inspect following systems:

•Wheels

•ATX

•Driveline

•Suspension

•Electrically controlled 4WD system

No Readjust or retighten engine mount installation

position.

Service if necessary for other parts.

2 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM.

Page 176 of 909

F2–24

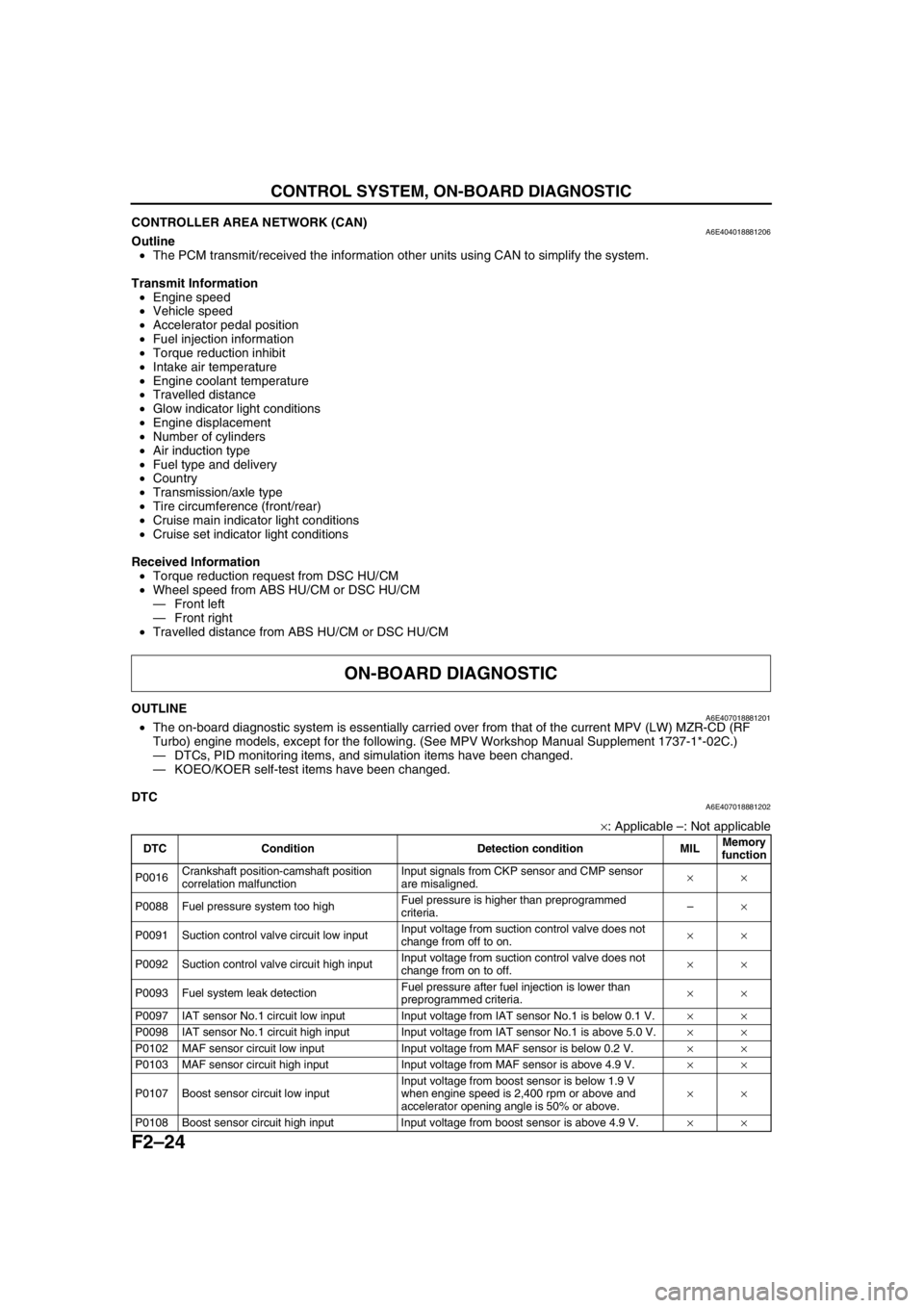

CONTROL SYSTEM, ON-BOARD DIAGNOSTIC

CONTROLLER AREA NETWORK (CAN)A6E404018881206Outline

•The PCM transmit/received the information other units using CAN to simplify the system.

Transmit Information

•Engine speed

•Vehicle speed

•Accelerator pedal position

•Fuel injection information

•Torque reduction inhibit

•Intake air temperature

•Engine coolant temperature

•Travelled distance

•Glow indicator light conditions

•Engine displacement

•Number of cylinders

•Air induction type

•Fuel type and delivery

•Country

•Transmission/axle type

•Tire circumference (front/rear)

•Cruise main indicator light conditions

•Cruise set indicator light conditions

Received Information

•Torque reduction request from DSC HU/CM

•Wheel speed from ABS HU/CM or DSC HU/CM

—Front left

—Front right

•Travelled distance from ABS HU/CM or DSC HU/CM

End Of Sie

OUTLINEA6E407018881201•The on-board diagnostic system is essentially carried over from that of the current MPV (LW) MZR-CD (RF

Turbo) engine models, except for the following. (See MPV Workshop Manual Supplement 1737-1*-02C.)

—DTCs, PID monitoring items, and simulation items have been changed.

—KOEO/KOER self-test items have been changed.

End Of Sie

DTCA6E407018881202

×: Applicable –: Not applicable

ON-BOARD DIAGNOSTIC

DTC Condition Detection condition MILMemory

function

P0016Crankshaft position-camshaft position

correlation malfunctionInput signals from CKP sensor and CMP sensor

are misaligned.××

P0088 Fuel pressure system too highFuel pressure is higher than preprogrammed

criteria.–×

P0091 Suction control valve circuit low inputInput voltage from suction control valve does not

change from off to on.××

P0092 Suction control valve circuit high inputInput voltage from suction control valve does not

change from on to off.××

P0093 Fuel system leak detectionFuel pressure after fuel injection is lower than

preprogrammed criteria.××

P0097 IAT sensor No.1 circuit low input Input voltage from IAT sensor No.1 is below 0.1 V.××

P0098 IAT sensor No.1 circuit high input Input voltage from IAT sensor No.1 is above 5.0 V.××

P0102 MAF sensor circuit low input Input voltage from MAF sensor is below 0.2 V.××

P0103 MAF sensor circuit high input Input voltage from MAF sensor is above 4.9 V.××

P0107 Boost sensor circuit low inputInput voltage from boost sensor is below 1.9 V

when engine speed is 2,400 rpm or above and

accelerator opening angle is 50% or above.××

P0108 Boost sensor circuit high input Input voltage from boost sensor is above 4.9 V.××

Page 190 of 909

F2–38

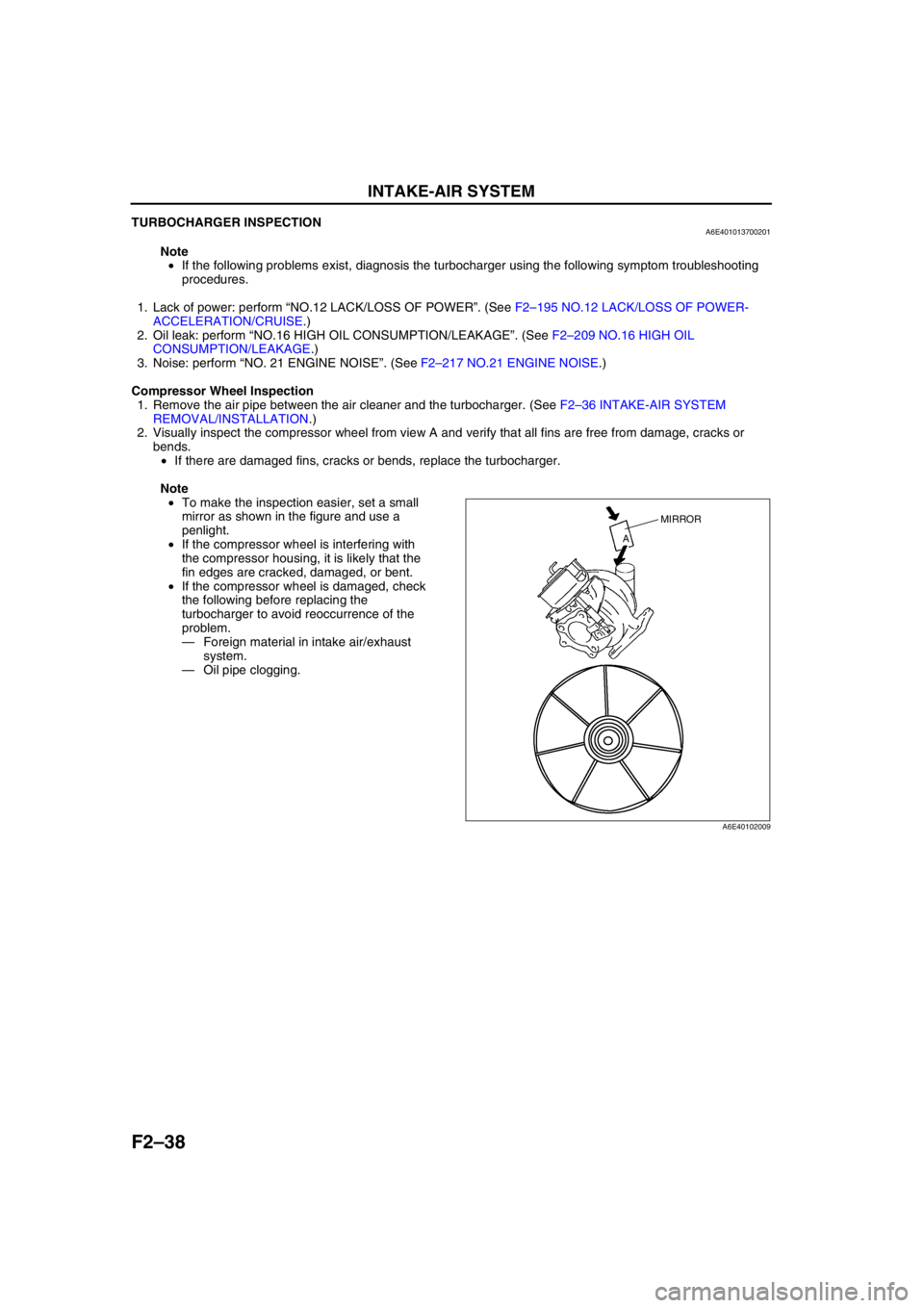

INTAKE-AIR SYSTEM

TURBOCHARGER INSPECTIONA6E401013700201

Note

•If the following problems exist, diagnosis the turbocharger using the following symptom troubleshooting

procedures.

1. Lack of power: perform “NO.12 LACK/LOSS OF POWER”. (See F2–195 NO.12 LACK/LOSS OF POWER-

ACCELERATION/CRUISE.)

2. Oil leak: perform “NO.16 HIGH OIL CONSUMPTION/LEAKAGE”. (See F2–209 NO.16 HIGH OIL

CONSUMPTION/LEAKAGE.)

3. Noise: perform “NO. 21 ENGINE NOISE”. (See F2–217 NO.21 ENGINE NOISE.)

Compressor Wheel Inspection

1. Remove the air pipe between the air cleaner and the turbocharger. (See F2–36 INTAKE-AIR SYSTEM

REMOVAL/INSTALLATION.)

2. Visually inspect the compressor wheel from view A and verify that all fins are free from damage, cracks or

bends.

•If there are damaged fins, cracks or bends, replace the turbocharger.

Note

•To make the inspection easier, set a small

mirror as shown in the figure and use a

penlight.

•If the compressor wheel is interfering with

the compressor housing, it is likely that the

fin edges are cracked, damaged, or bent.

•If the compressor wheel is damaged, check

the following before replacing the

turbocharger to avoid reoccurrence of the

problem.

—Foreign material in intake air/exhaust

system.

—Oil pipe clogging.

MIRROR

A

A6E40102009

Page 191 of 909

INTAKE-AIR SYSTEM

F2–39

F2

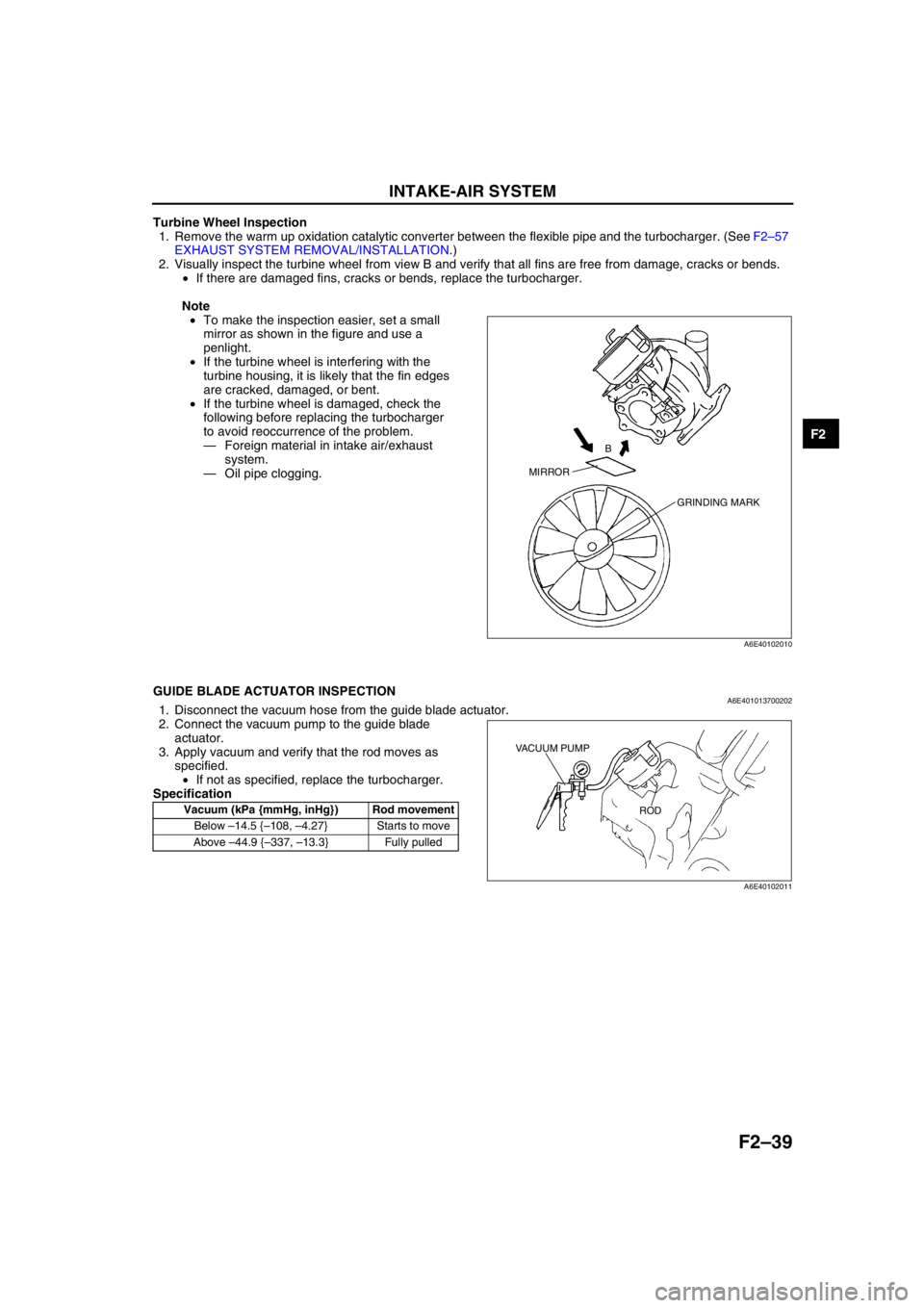

Turbine Wheel Inspection

1. Remove the warm up oxidation catalytic converter between the flexible pipe and the turbocharger. (See F2–57

EXHAUST SYSTEM REMOVAL/INSTALLATION.)

2. Visually inspect the turbine wheel from view B and verify that all fins are free from damage, cracks or bends.

•If there are damaged fins, cracks or bends, replace the turbocharger.

Note

•To make the inspection easier, set a small

mirror as shown in the figure and use a

penlight.

•If the turbine wheel is interfering with the

turbine housing, it is likely that the fin edges

are cracked, damaged, or bent.

•If the turbine wheel is damaged, check the

following before replacing the turbocharger

to avoid reoccurrence of the problem.

—Foreign material in intake air/exhaust

system.

—Oil pipe clogging.

End Of Sie

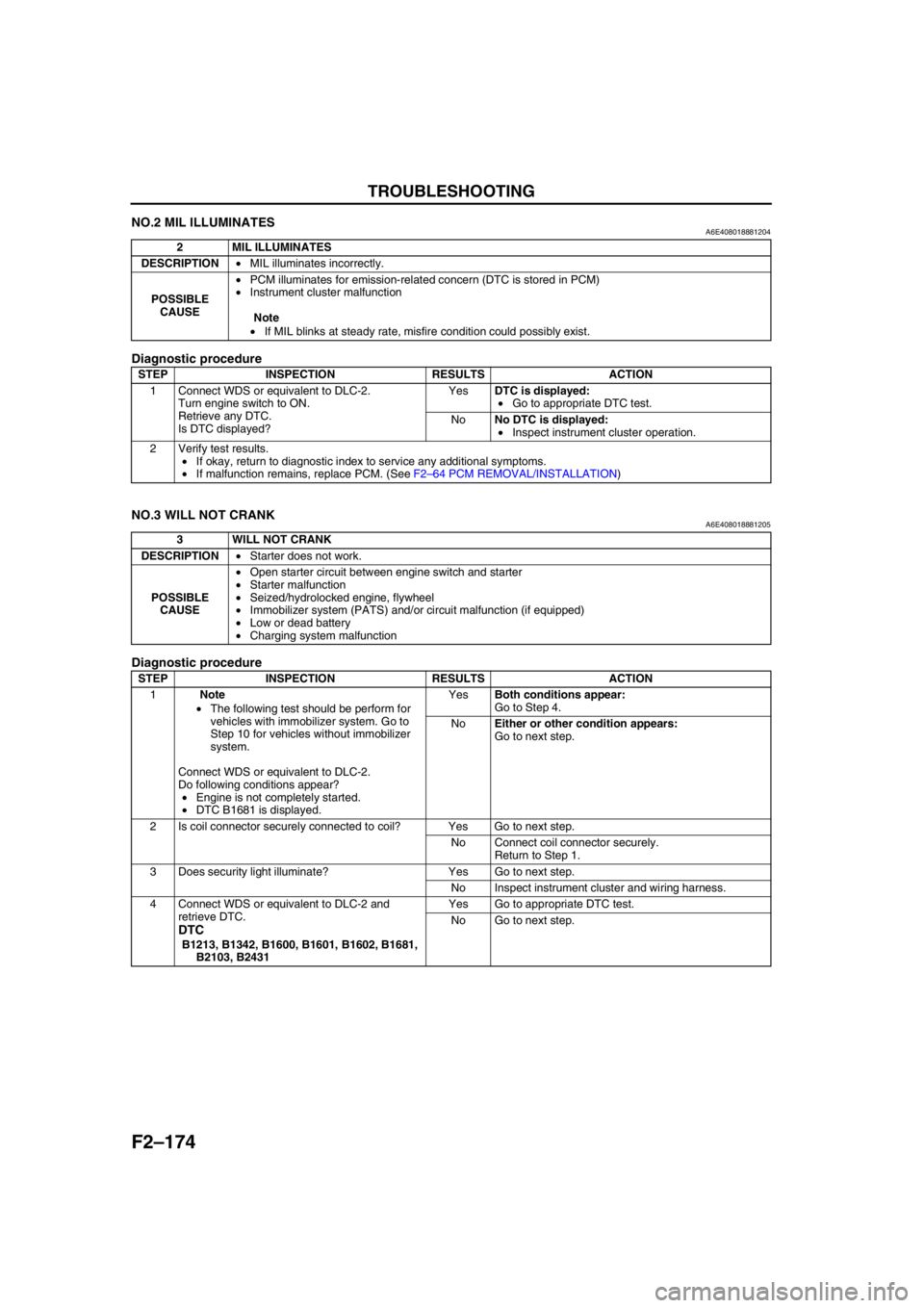

GUIDE BLADE ACTUATOR INSPECTIONA6E4010137002021. Disconnect the vacuum hose from the guide blade actuator.

2. Connect the vacuum pump to the guide blade

actuator.

3. Apply vacuum and verify that the rod moves as

specified.

•If not as specified, replace the turbocharger.

Specification

End Of Sie

MIRRORB

GRINDING MARK

A6E40102010

Vacuum (kPa {mmHg, inHg}) Rod movement

Below –14.5 {–108, –4.27} Starts to move

Above –44.9 {–337, –13.3} Fully pulled

VACUUM PUMP

ROD

A6E40102011

Page 319 of 909

TROUBLESHOOTING

F2–167

F2

SYMPTOM QUICK DIAGNOSIS CHARTA6E408018881202

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates

3 Will not crank×× ×× × ×

4 Hard start/long crank/erratic start/erratic crank×× ×

5 Engine stalls After start/at idle××

6 Cranks normally but will not start××

7 Slow return to idle

8 Engine runs rough/rolling idle××

9 Fast idle/runs on

10 Low idle/stalls during deceleration××

11Engine stalls/quits Acceleration/cruise××

Engine runs rough Acceleration/cruise××

Misses Acceleration/cruise××

Buck/jerk Acceleration/cruise/ deceleration××

Hesitation/stumble Acceleration××

Surges Acceleration/cruise××

12 Lack/loss of power Acceleration/cruise××

13 Knocking/pinging××

14 Poor fuel economy××

15 Emissions compliance×× ×

16 High oil consumption/leakage××××

17 Cooling system concerns Overheating××

18 Cooling system concerns Runs cold

19 Excessive black smoke×

20 Fuel odor (in engine compartment)

21 Engine noise×× × ×

22 Vibration concerns (engine)×

23 A/C does not work sufficiently

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage

Starter motor malfunction (Mechanical or electrical)Starter circuit including engine switch is openImproper engine oil levelLow or dead bateryCharging system malfunctionLow engine compressionImproper valve timingHydrolocked egineImproper engine oil viscosityImproper dipstickBase engine malfunctionSeized flywheelImproper tension or damaged drivebelts

Page 321 of 909

TROUBLESHOOTING

F2–169

F2

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates×× × ×

3 Will not crank

4 Hard start/long crank/erratic start/erratic crank×× ×××××××

5 Engine stalls After start/at idle×× ×××××××

6 Cranks normally but will not start×× ×××××××

7 Slow return to idle××××××××

8 Engine runs rough/rolling idle×××××××××

9 Fast idle/runs on×

10 Low idle/stalls during deceleration××××××××××

11Engine stalls/quits Acceleration/cruise× × ×××××××

Engine runs rough Acceleration/cruise× ××××××××××

Misses Acceleration/cruise× ××××××××××

Buck/jerk Acceleration/cruise/ deceleration× ××××××××××

Hesitation/stumble Acceleration× ××××××××××

Surges Acceleration/cruise× ×× ×××××××

12 Lack/loss of power Acceleration/cruise××× ×××××××××

13 Knocking/pinging××××× ××× × ×

14 Poor fuel economy××× ×××××× ×

15 Emissions compliance×××××××××××××

16 High oil consumption/leakage×

17 Cooling system concerns Overheating×

18 Cooling system concerns Runs cold

19 Excessive black smoke××× × ××× ×××

20 Fuel odor (in engine compartment)××

21 Engine noise× ××× ×

22 Vibration concerns (engine)

23 A/C does not work sufficiently

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage

Turbocharger malfunctionCarge air cooler malfunctionVBC system malfunctionGlow system malfunctionIncorrect fuel injection timingIncorrect idle speedCKP sensor is damaged (e.g.: open or short circuits)CKP sensor pulse wheel is damagedImproper gap between CKP sensor and pulse wheelSupply pump malfunctionSuction control valve malfunctionFuel pressure limiter malfunctionFuel line restriction or clogging

Page 322 of 909

F2–170

TROUBLESHOOTING

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates××

3 Will not crank

4 Hard start/long crank/erratic start/erratic crank× × ××××× ×

5 Engine stalls After start/at idle×××××××××

6 Cranks normally but will not start× × ×××× × ×

7 Slow return to idle××××

8 Engine runs rough/rolling idle× × ×××× ××

9 Fast idle/runs on××

10 Low idle/stalls during deceleration× × ×××× ×

11Engine stalls/quits Acceleration/cruise× ××××× ×

Engine runs rough Acceleration/cruise× ××××× ×

Misses Acceleration/cruise× ××××× ×

Buck/jerk Acceleration/cruise/ deceleration× ××××× ×

Hesitation/stumble Acceleration× ××××× ×

Surges Acceleration/cruise× ××××× ×

12 Lack/loss of power Acceleration/cruise× ××××× ×

13 Knocking/pinging××××

14 Poor fuel economy×××××××

15 Emissions compliance× ×××××××

16 High oil consumption/leakage

17 Cooling system concerns Overheating×

18 Cooling system concerns Runs cold

19 Excessive black smoke××××

20 Fuel odor (in engine compartment)×

21 Engine noise××××

22 Vibration concerns (engine)×××

23 A/C does not work sufficiently

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage×

Fuel injectors malfunction (Leakage or clogging,

inoperative)Fuel leakage from fuel system (including insulator,

fuel injector)Fuel filter restriction or cloggingCMP sensor is damaged (e.g: open or short circuit)CMP sensor pulse wheel is damagedIDM or related circuit malfunctionExhaust system restriction or cloggingCatalyst converter malfunctionEGR system malfunctionEGR water cooler malfunctionV-reference voltage supply circuit malfunction

Page 324 of 909

F2–172

TROUBLESHOOTING

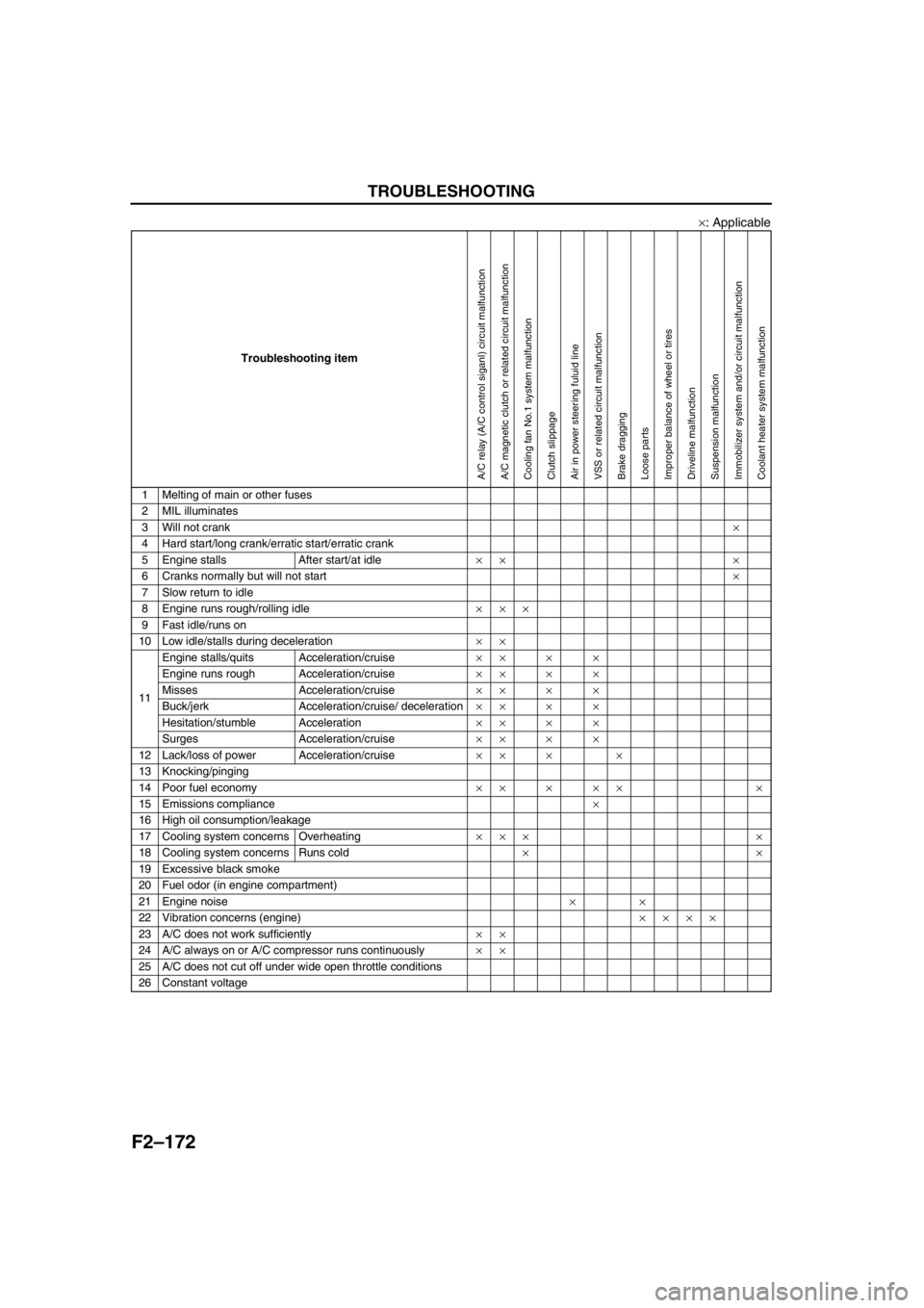

×: Applicable

End Of Sie

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates

3 Will not crank×

4 Hard start/long crank/erratic start/erratic crank

5 Engine stalls After start/at idle×× ×

6 Cranks normally but will not start×

7 Slow return to idle

8 Engine runs rough/rolling idle×××

9 Fast idle/runs on

10 Low idle/stalls during deceleration××

11Engine stalls/quits Acceleration/cruise××××

Engine runs rough Acceleration/cruise××××

Misses Acceleration/cruise××××

Buck/jerk Acceleration/cruise/ deceleration××××

Hesitation/stumble Acceleration××××

Surges Acceleration/cruise××××

12 Lack/loss of power Acceleration/cruise×× × ×

13 Knocking/pinging

14 Poor fuel economy××××× ×

15 Emissions compliance×

16 High oil consumption/leakage

17 Cooling system concerns Overheating××× ×

18 Cooling system concerns Runs cold××

19 Excessive black smoke

20 Fuel odor (in engine compartment)

21 Engine noise××

22 Vibration concerns (engine)××××

23 A/C does not work sufficiently××

24 A/C always on or A/C compressor runs continuously××

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage

A/C relay (A/C control siganl) circuit malfunctionA/C magnetic clutch or related circuit malfunctionCooling fan No.1 system malfunctionClutch slippageAir in power steering fuluid lineVSS or related circuit malfunctionBrake draggingLoose partsImproper balance of wheel or tiresDriveline malfunctionSuspension malfunctionImmobilizer system and/or circuit malfunctionCoolant heater system malfunction

Page 326 of 909

F2–174

TROUBLESHOOTING

NO.2 MIL ILLUMINATESA6E408018881204

Diagnostic procedure

End Of Sie

NO.3 WILL NOT CRANKA6E408018881205

Diagnostic procedure

2 MIL ILLUMINATES

DESCRIPTION•MIL illuminates incorrectly.

POSSIBLE

CAUSE•PCM illuminates for emission-related concern (DTC is stored in PCM)

•Instrument cluster malfunction

Note

•If MIL blinks at steady rate, misfire condition could possibly exist.

STEP INSPECTION RESULTS ACTION

1 Connect WDS or equivalent to DLC-2.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

•Go to appropriate DTC test.

NoNo DTC is displayed:

•Inspect instrument cluster operation.

2 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION)

3 WILL NOT CRANK

DESCRIPTION•Starter does not work.

POSSIBLE

CAUSE•Open starter circuit between engine switch and starter

•Starter malfunction

•Seized/hydrolocked engine, flywheel

•Immobilizer system (PATS) and/or circuit malfunction (if equipped)

•Low or dead battery

•Charging system malfunction

STEP INSPECTION RESULTS ACTION

1Note

•The following test should be perform for

vehicles with immobilizer system. Go to

Step 10 for vehicles without immobilizer

system.

Connect WDS or equivalent to DLC-2.

Do following conditions appear?

•Engine is not completely started.

•DTC B1681 is displayed.YesBoth conditions appear:

Go to Step 4.

NoEither or other condition appears:

Go to next step.

2 Is coil connector securely connected to coil? Yes Go to next step.

No Connect coil connector securely.

Return to Step 1.

3 Does security light illuminate? Yes Go to next step.

No Inspect instrument cluster and wiring harness.

4 Connect WDS or equivalent to DLC-2 and

retrieve DTC.

DTC

B1213, B1342, B1600, B1601, B1602, B1681,

B2103, B2431Yes Go to appropriate DTC test.

No Go to next step.