wheel torque MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 638 of 909

M–8

ELECTRONIC 4WD CONTROL SYSTEM

Components and Functions

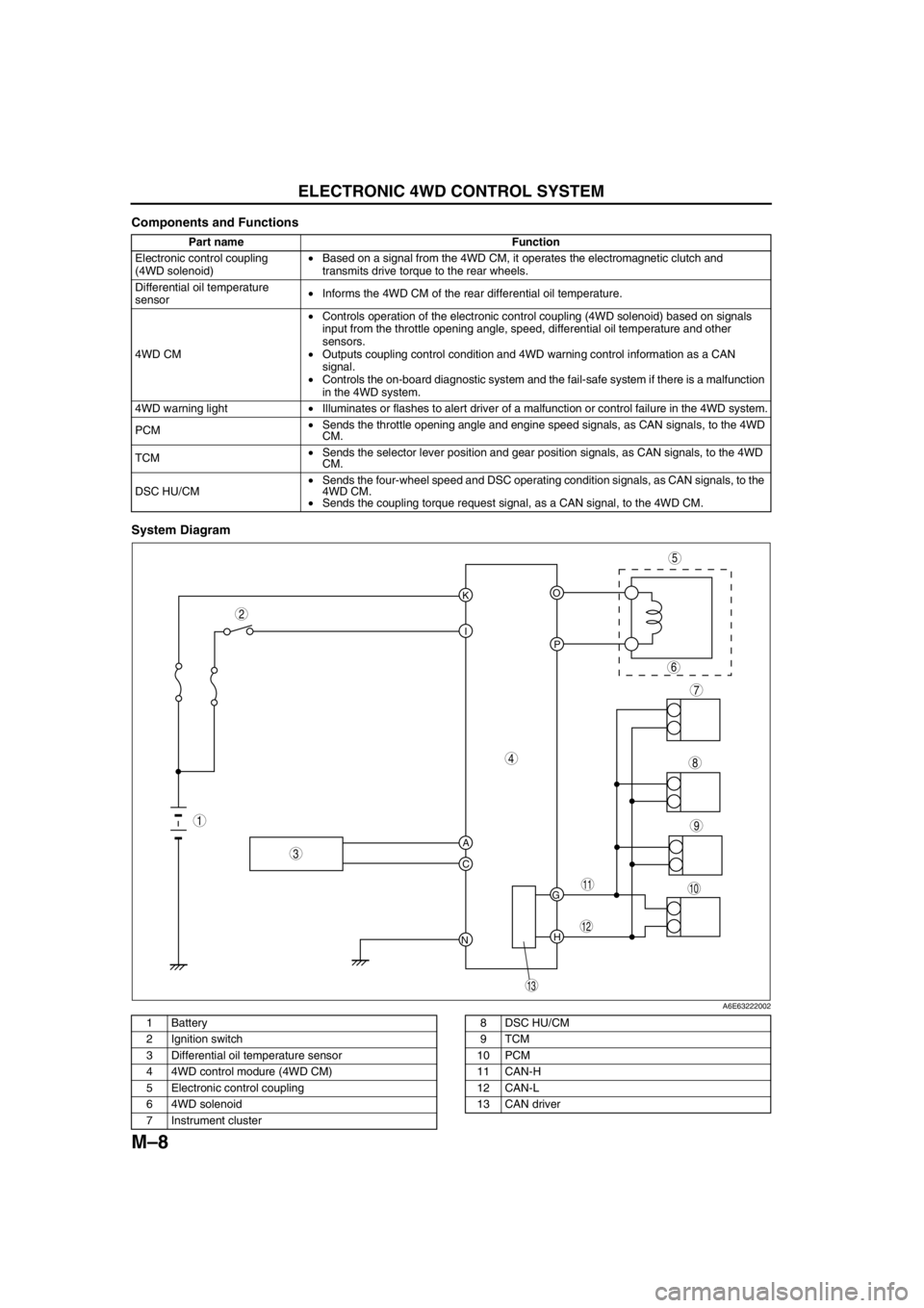

System Diagram

.

Part name Function

Electronic control coupling

(4WD solenoid)•Based on a signal from the 4WD CM, it operates the electromagnetic clutch and

transmits drive torque to the rear wheels.

Differential oil temperature

sensor•Informs the 4WD CM of the rear differential oil temperature.

4WD CM•Controls operation of the electronic control coupling (4WD solenoid) based on signals

input from the throttle opening angle, speed, differential oil temperature and other

sensors.

•Outputs coupling control condition and 4WD warning control information as a CAN

signal.

•Controls the on-board diagnostic system and the fail-safe system if there is a malfunction

in the 4WD system.

4WD warning light•Illuminates or flashes to alert driver of a malfunction or control failure in the 4WD system.

PCM•Sends the throttle opening angle and engine speed signals, as CAN signals, to the 4WD

CM.

TCM•Sends the selector lever position and gear position signals, as CAN signals, to the 4WD

CM.

DSC HU/CM•Sends the four-wheel speed and DSC operating condition signals, as CAN signals, to the

4WD CM.

•Sends the coupling torque request signal, as a CAN signal, to the 4WD CM.

KO

P I

A

C

NH G

9

8

7

5

4

3

10

13

11

12

6

1

2

A6E63222002

1 Battery

2 Ignition switch

3 Differential oil temperature sensor

4 4WD control modure (4WD CM)

5 Electronic control coupling

6 4WD solenoid

7 Instrument cluster8 DSC HU/CM

9TCM

10 PCM

11 CAN-H

12 CAN-L

13 CAN driver

Page 639 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–9

M

End Of SieELECTRONIC CONTROL COUPLINGA6E632227100202Outline

Features

•An electromagnetic clutch, which operates smoothly due to the lack influence from the front and rear wheel

traction force, has been adopted for the electronic control coupling system.

•The construction of the coupling enables the torque formed by the pilot clutch to be amplified by the cam

mechanism, thus allowing the main clutch to obtain a high degree of torque. Due to this, size and weight

reduction of the component parts has been achieved.

Construction

•The electronic control coupling basically consists of an electromagnetic clutch, a cam mechanism and a torque

transmission system.

•The electromagnetic clutch consists of a 4WD solenoid (electromagnetic coil), rear-housing that forms a

magnetic path, pilot clutch, and armature. The cam mechanism consists of a pilot cam, balls, and main cam.

The torque transmission system consists of a main clutch and hydraulic oil (ATF).

.

9

8

7

5

43

10

13

1112

6

12

A6E63222003

1 Front wheel side

2 Rear wheel side

3 Torque transmission system

4 Electromagnetic clutch

5 Rear housing

6 4WD solenoid (Electromagnetic coil)

7 Cam mechanism8Ball

9 Main clutch

10 Main cam

11 Armature

12 Pilot clutch

13 Pilot cam

Page 640 of 909

M–10

ELECTRONIC 4WD CONTROL SYSTEM

Operation

4WD solenoid control current is OFF

•When the 4WD solenoid control current is OFF, no torque is generated in the pilot clutch because there is no

current flowing to the 4WD solenoid. At the same time, the pilot cam and the main cam rotate in the same

direction via the balls, and the main cam does not exert any push force on the main clutch side. Therefore, the

traction from the front wheels is not transmitted to the rear wheels.

.

8

7

5

4

3

6

12

56

7

A6E63222004

1 Main clutch

2 Pilot clutch

3 4WD solenoid (Electromagnetic coil)

4 4WD control modure (4WD CM)5Main cam

6Pilot cam

7Ball

8 Armature

Page 641 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–11

M

4WD solenoid control current is ON

•When the 4WD solenoid control current is ON, current flows from the 4WD CM to the 4WD solenoid, and the

coupling operates in the following manner.

1. Magnetic flux forms at the electromagnetic coil of the 4WD solenoid.

2. Due to the magnetic flux in the armature, the pilot clutch is suctioned towards the magnetic coil side and

made to engage. This causes frictional torque to generate in the pilot clutch.

3. The torque is transmitted to the pilot cam, which is engaged with the pilot clutch.

4. A rotational difference is created between the pilot cam and the main cam. Due to this relative torsion, the

cam mechanism operates, transmitting torque from the pilot cam to the ball and then to the main cam. In

this way, the push force exerted on the main clutch is amplified.

5. As the main clutch engages, the drive torque from the front wheels is transmitted to the rear wheels.

•The amount of push force exerted on the main clutch by the main cam (that is, the strength of the drive torque

transmitted to the rear wheels) changes in accordance with the proportion of the force acting upon the pilot

cam, engaged with the pilot clutch. Therefore, by changing the periodicity of the electric current from the 4WD

CM to the 4WD solenoid (ON/OFF rate of the 4WD solenoid = force acting on the pilot cam), the module

controls the transmission of drive torque to the rear wheels.

.

End Of Sie

98

75

4

3

10

11

6

12

56

7

12

A6E63222005

1 Main clutch

2Pilot clutch

3 4WD solenoid (Electromagnetic coil)

4 4WD control modure (4WD CM)

5Main cam

6Pilot cam7Ball

8Armature

9 Drive torque

10 Magnetic flux

11 Input

12 Output

Page 643 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–13

M

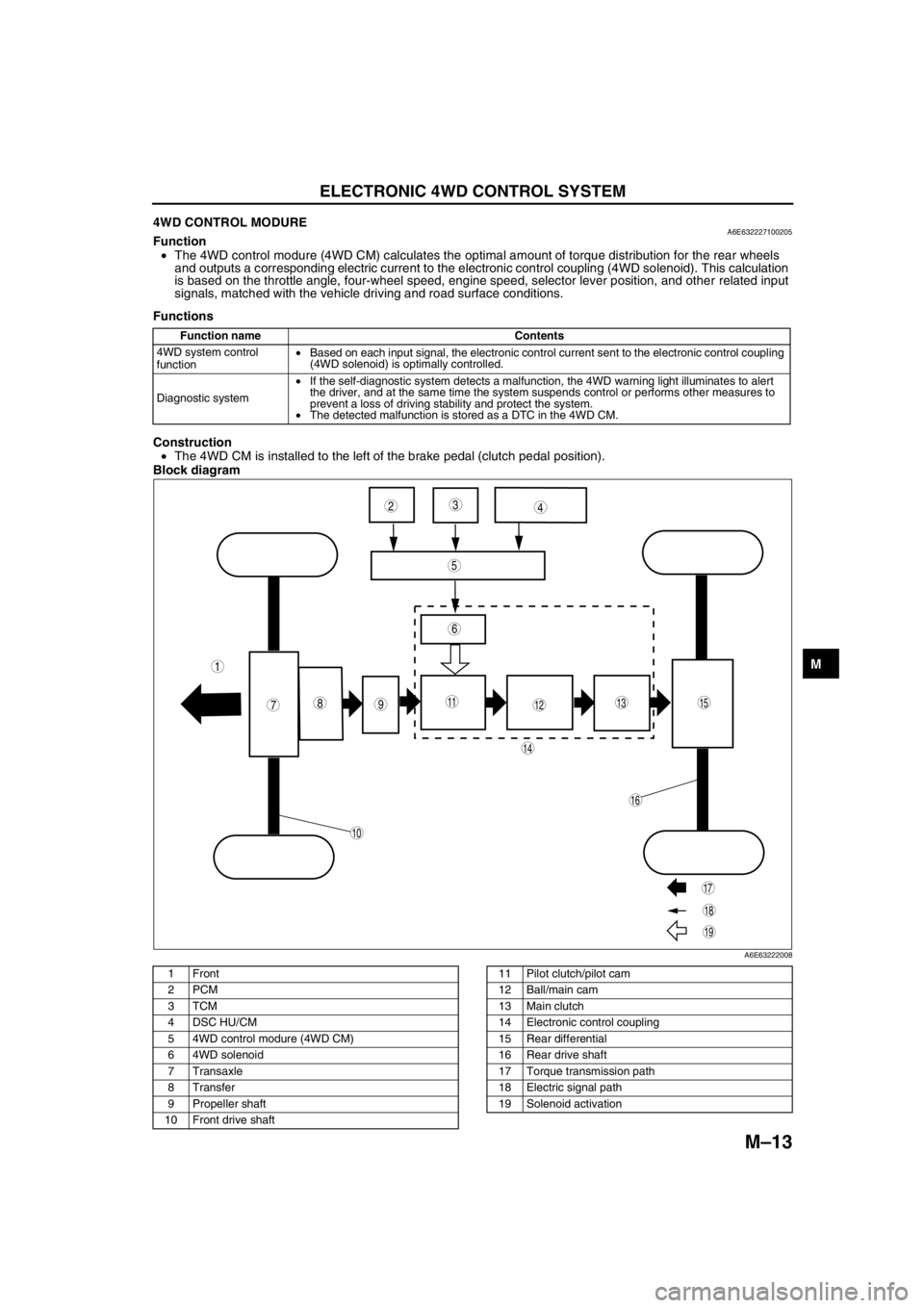

4WD CONTROL MODUREA6E632227100205Function

•The 4WD control modure (4WD CM) calculates the optimal amount of torque distribution for the rear wheels

and outputs a corresponding electric current to the electronic control coupling (4WD solenoid). This calculation

is based on the throttle angle, four-wheel speed, engine speed, selector lever position, and other related input

signals, matched with the vehicle driving and road surface conditions.

Functions

Construction

•The 4WD CM is installed to the left of the brake pedal (clutch pedal position).

Block diagram

.

Function name Contents

4WD system control

function•Based on each input signal, the electronic control current sent to the electronic control coupling

(4WD solenoid) is optimally controlled.

Diagnostic system•If the self-diagnostic system detects a malfunction, the 4WD warning light illuminates to alert

the driver, and at the same time the system suspends control or performs other measures to

prevent a loss of driving stability and protect the system.

•The detected malfunction is stored as a DTC in the 4WD CM.

987

5

43

10

19

18

17

15

16

14

131112

6

1

2

A6E63222008

1Front

2PCM

3TCM

4 DSC HU/CM

5 4WD control modure (4WD CM)

6 4WD solenoid

7Transaxle

8Transfer

9 Propeller shaft

10 Front drive shaft11 Pilot clutch/pilot cam

12 Ball/main cam

13 Main clutch

14 Electronic control coupling

15 Rear differential

16 Rear drive shaft

17 Torque transmission path

18 Electric signal path

19 Solenoid activation

Page 644 of 909

M–14

ELECTRONIC 4WD CONTROL SYSTEM

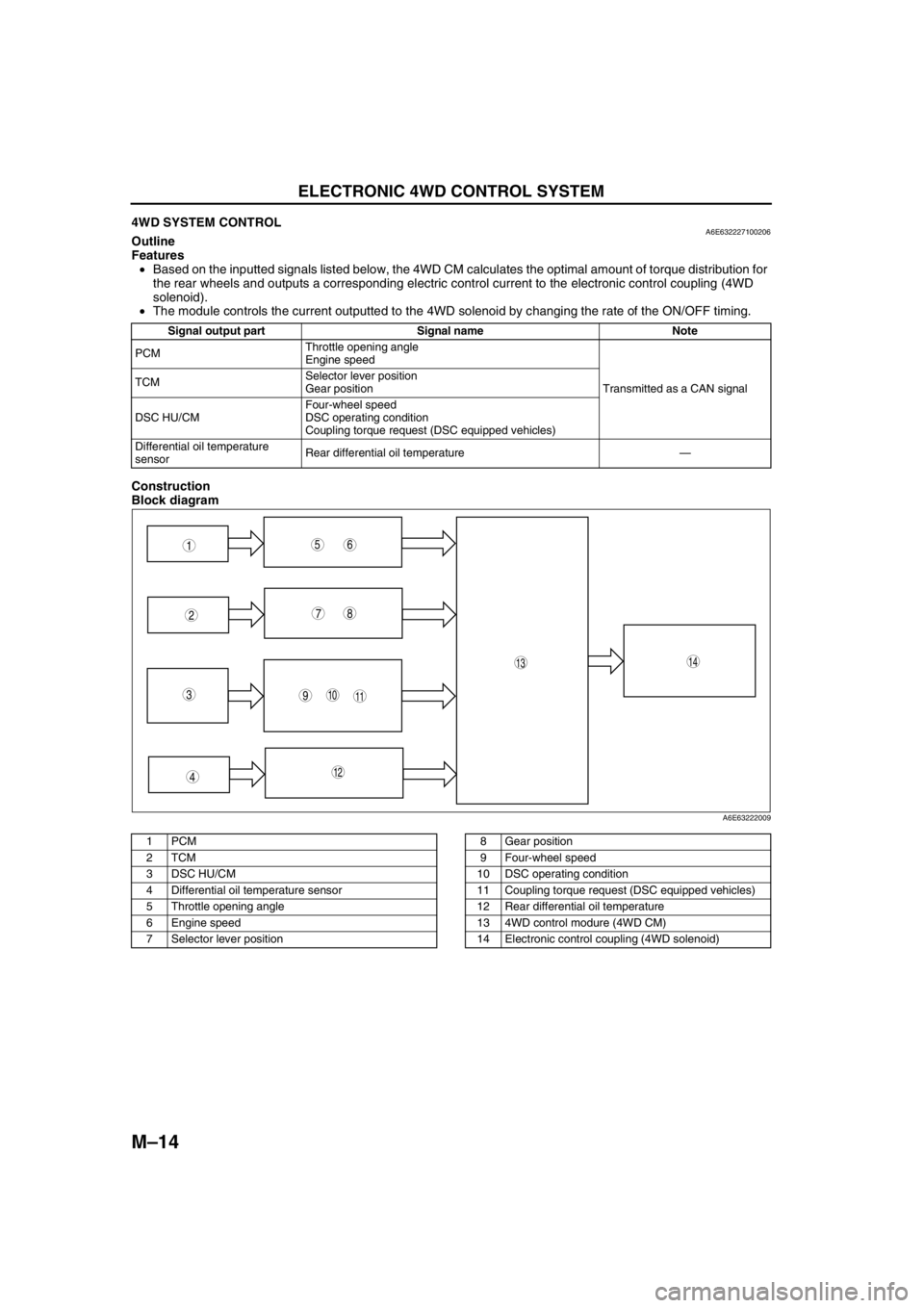

End Of Sie4WD SYSTEM CONTROLA6E632227100206Outline

Features

•Based on the inputted signals listed below, the 4WD CM calculates the optimal amount of torque distribution for

the rear wheels and outputs a corresponding electric control current to the electronic control coupling (4WD

solenoid).

•The module controls the current outputted to the 4WD solenoid by changing the rate of the ON/OFF timing.

Construction

Block diagram

.

Signal output part Signal name Note

PCMThrottle opening angle

Engine speed

Transmitted as a CAN signal TCMSelector lever position

Gear position

DSC HU/CMFour-wheel speed

DSC operating condition

Coupling torque request (DSC equipped vehicles)

Differential oil temperature

sensorRear differential oil temperature—

9

87

5

4

310

1413

11

12

61

2

A6E63222009

1PCM

2TCM

3 DSC HU/CM

4 Differential oil temperature sensor

5 Throttle opening angle

6 Engine speed

7 Selector lever position8 Gear position

9 Four-wheel speed

10 DSC operating condition

11 Coupling torque request (DSC equipped vehicles)

12 Rear differential oil temperature

13 4WD control modure (4WD CM)

14 Electronic control coupling (4WD solenoid)

Page 645 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–15

M

Operation

Normal control

•When starting off or accelerating during straight-ahead driving, torque transmitted to the rear wheels is

optimally controlled to ensure sufficient acceleration performance. Due to this, standing-start and acceleration

performance is improved.

•Also, in order to improve fuel economy when driving at a stable, consistent speed, torque transmitted to the

rear wheels is damped, and rear-wheel drive is controlled to maintain it close to that of the front wheels.

Tight cornering control

•When the 4WD CM determines, based on the four-wheel speed signal, that the vehicle is in tight cornering, it

reduces the torque transmitted to the rear wheels to avoid tight corner braking characteristics.

Integrated DSC control

•If a signal from the DSC HU/CM input to the 4WD CM indicates that ABS control is activated, the module

controls the torque transmitted to the rear wheels to prevent undue influence on ABS control.

•Also, when a coupling torque request signal is received from the DSC HU/CM, the module controls the torque

transmitted to the rear wheels to match the amount of requested torque.

Other control

•In case the rear differential oil temperature exceeds the specified amount, or when there is an unusually large

variation in the rotation speed of the front and rear wheels (ex. when trying to get unstuck), control is

temporarily suspended in order to protect the 4WD system. When this occurs the 4WD warning light flashes to

indicate the situation to the driver.

End Of Sie

CONTROLLER AREA NETWORK (CAN)A6E632227100207Outline

•The 4WD CM transmits/receives information using the CAN system. See Section T for detailed information

regarding the CAN system.

Operation

Transmitted information

•Coupling torque

•4WD system operating condition (warning light information)

Received information

•Four-wheel speed

•Throttle opening angle

•Engine speed

•ABS/DSC operating condition

•Gear position

•Selector lever position

•Coupling torque request

End Of Sie

Page 651 of 909

GENERAL PROCEDURES

M–21

M

PRECAUTION (FRONT AND REAR AXLE)A6E631001018201Wheel and Tire Removal/Installation

1. The removal and installation procedures for the wheels and tires are not mentioned in this section. When a

wheel is removed, tighten it to 88—118 N·m {9.0—12.0 kgf·m, 65.0—87.0 ft·lbf}

Brake Line Disconnection/Connection

Caution

•Brake fluid will damage painted surfaces. If brake fluid gets on a painted surface, wipe it off

immediately.

1. Tighten the brake pipe flare nut using the SST (49 0259 770B). Be sure to modify the brake pipe flare nut

tightening torque to allow for use of a torque wrench-SST combination.

2. If any brake line has been disconnected any time during the procedure, add brake fluid, bleed the brakes, and

inspect for leakage after the procedure has been completed.

Suspension Arm Removal/Installation

1. Tighten any part of the suspension that uses rubber bushings only after vehicle has been lowered and

unloaded.

Note

•Unloaded: Fuel tank is full. Engine coolant and engine oil are at specified level. Spare tire, jack, and tools

are in designated position.

Connector Disconnection

1. Disconnect the negative (-) battery cable before disconnecting connectors.

Electronic Control 4WD System Parts

1. After servicing the electronic control 4WD system parts, verify that no DTC has been stored. Clear any DTCs

remaining in the memory.

End Of Sie

GENERAL PROCEDURES

Page 710 of 909

M–80

ON-BOARD DIAGNOSTIC

End Of Sie

DTC U0100A6E637027100205

Diagnostic Procedure

•Inspect according to the diagnostic procedure in Section T. (See T–39 MULTIPLEX COMMUNICATION

SYSTEM.)

End Of Sie

DTC U0101A6E637027100206

Diagnostic Procedure

•Inspect according to the diagnostic procedure in Section T. (See T–39 MULTIPLEX COMMUNICATION

SYSTEM.)

End Of Sie

DTC U0121A6E637027100207

Diagnostic Procedure

•Inspect according to the diagnostic procedure in Section T. (See T–39 MULTIPLEX COMMUNICATION

SYSTEM.)

End Of Sie

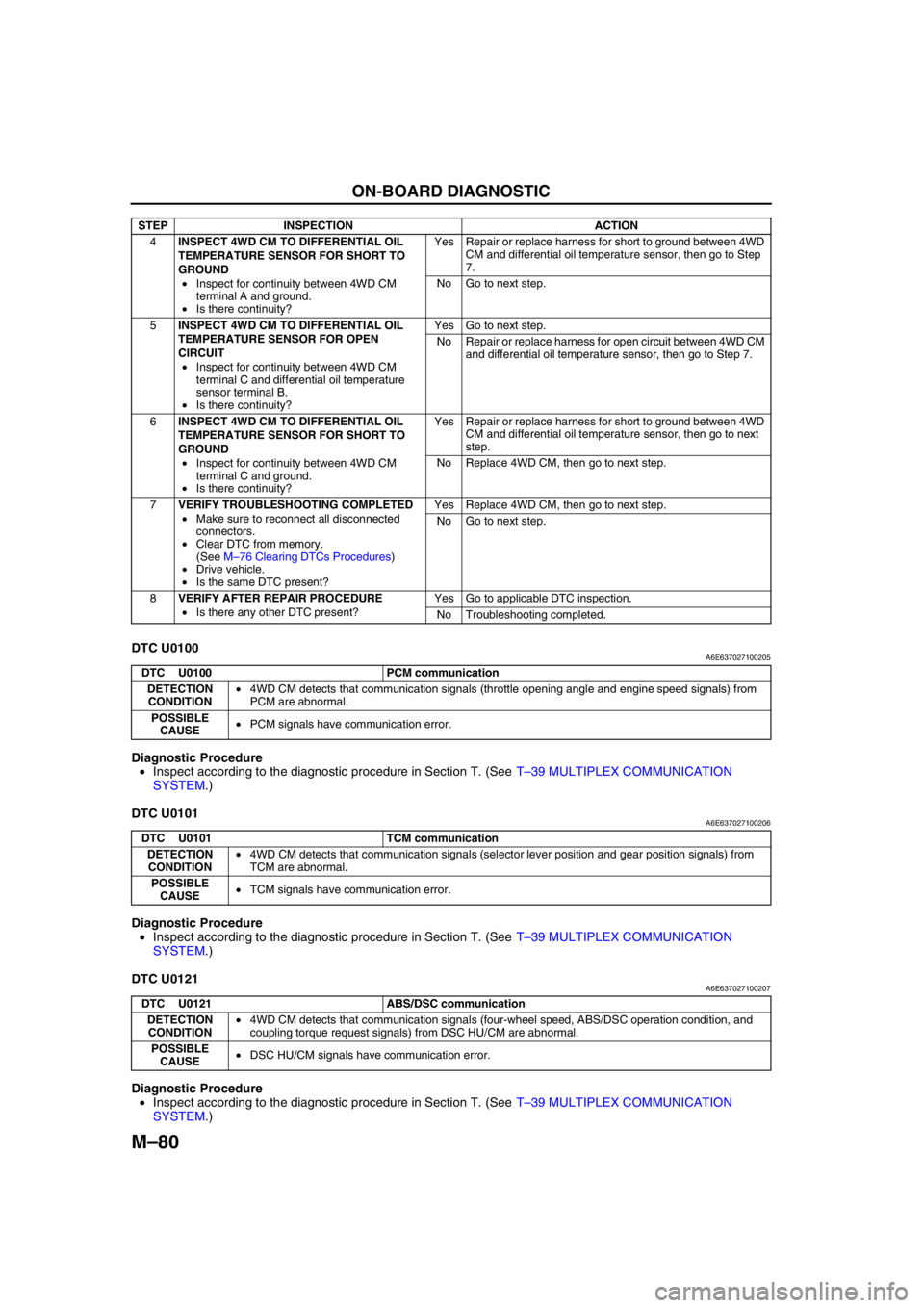

4INSPECT 4WD CM TO DIFFERENTIAL OIL

TEMPERATURE SENSOR FOR SHORT TO

GROUND

•Inspect for continuity between 4WD CM

terminal A and ground.

•Is there continuity?Yes Repair or replace harness for short to ground between 4WD

CM and differential oil temperature sensor, then go to Step

7.

No Go to next step.

5INSPECT 4WD CM TO DIFFERENTIAL OIL

TEMPERATURE SENSOR FOR OPEN

CIRCUIT

•Inspect for continuity between 4WD CM

terminal C and differential oil temperature

sensor terminal B.

•Is there continuity?Yes Go to next step.

No Repair or replace harness for open circuit between 4WD CM

and differential oil temperature sensor, then go to Step 7.

6INSPECT 4WD CM TO DIFFERENTIAL OIL

TEMPERATURE SENSOR FOR SHORT TO

GROUND

•Inspect for continuity between 4WD CM

terminal C and ground.

•Is there continuity?Yes Repair or replace harness for short to ground between 4WD

CM and differential oil temperature sensor, then go to next

step.

No Replace 4WD CM, then go to next step.

7VERIFY TROUBLESHOOTING COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory.

(See M–76 Clearing DTCs Procedures)

•Drive vehicle.

•Is the same DTC present?Yes Replace 4WD CM, then go to next step.

No Go to next step.

8VERIFY AFTER REPAIR PROCEDURE

•Is there any other DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC U0100 PCM communication

DETECTION

CONDITION•4WD CM detects that communication signals (throttle opening angle and engine speed signals) from

PCM are abnormal.

POSSIBLE

CAUSE•PCM signals have communication error.

DTC U0101 TCM communication

DETECTION

CONDITION•4WD CM detects that communication signals (selector lever position and gear position signals) from

TCM are abnormal.

POSSIBLE

CAUSE•TCM signals have communication error.

DTC U0121 ABS/DSC communication

DETECTION

CONDITION•4WD CM detects that communication signals (four-wheel speed, ABS/DSC operation condition, and

coupling torque request signals) from DSC HU/CM are abnormal.

POSSIBLE

CAUSE•DSC HU/CM signals have communication error.

Page 721 of 909

ENGINE SPEED SENSING POWER STEERING

N–7

N

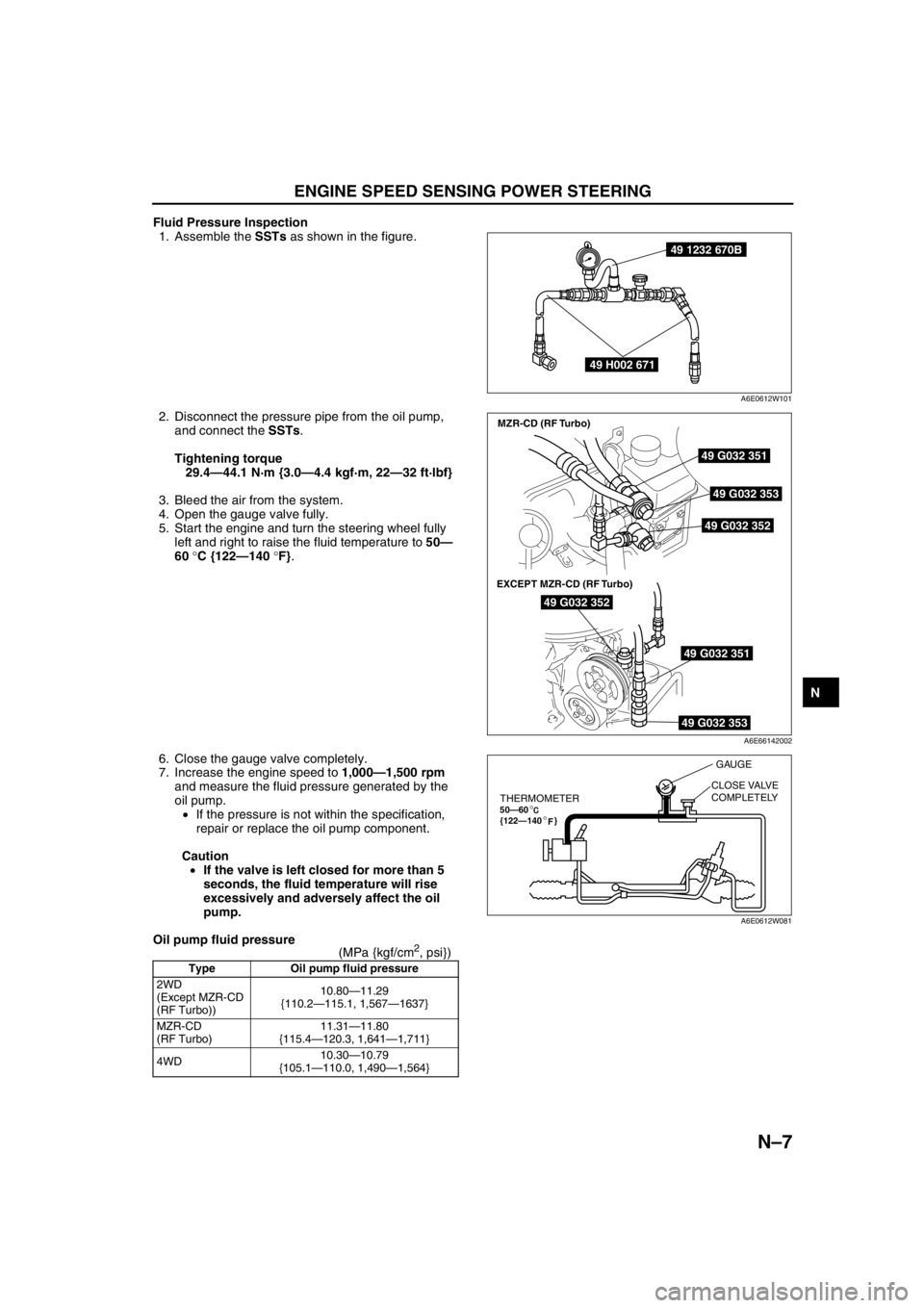

Fluid Pressure Inspection

1. Assemble the SSTs as shown in the figure.

2. Disconnect the pressure pipe from the oil pump,

and connect the SSTs.

Tightening torque

29.4—44.1 N·m {3.0—4.4 kgf·m, 22—32 ft·lbf}

3. Bleed the air from the system.

4. Open the gauge valve fully.

5. Start the engine and turn the steering wheel fully

left and right to raise the fluid temperature to 50—

60 °C {122—140 °F}.

6. Close the gauge valve completely.

7. Increase the engine speed to 1,000—1,500 rpm

and measure the fluid pressure generated by the

oil pump.

•If the pressure is not within the specification,

repair or replace the oil pump component.

Caution

•If the valve is left closed for more than 5

seconds, the fluid temperature will rise

excessively and adversely affect the oil

pump.

Oil pump fluid pressure

(MPa {kgf/cm

2, psi})

Type Oil pump fluid pressure

2WD

(Except MZR-CD

(RF Turbo))10.80—11.29

{110.2—115.1, 1,567—1637}

MZR-CD

(RF Turbo)11.31—11.80

{115.4—120.3, 1,641—1,711}

4WD10.30—10.79

{105.1—110.0, 1,490—1,564}

49 1232 670B

49 H002 671

A6E0612W101

49 G032 351

49 G032 353

49 G032 352

49 G032 352

49 G032 351

49 G032 353

MZR-CD (RF Turbo)

EXCEPT MZR-CD (RF Turbo)

A6E66142002

THERMOMETER50—60

{122—140 }°

°F

GAUGE

CLOSE VALVE

COMPLETELY

A6E0612W081