fuel MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 816 of 909

MULTIPLEX COMMUNICATION SYSTEM

T–5

T

End Of Sie

Cruise main indicator light

conditions (MZR-CD (RF

Turbo))OUT–––IN

Cruise set indicator light

conditions (MZR-CD (RF

Turbo))OUT–––IN

Desired gear/

selector lever

positionFN4A-EL OUT–IN–IN

JA5AX-EL IN OUT IN IN IN

ECT OUT IN–IN

Engine control condition OUT–IN––

Engine displacement OUT–IN––

Engine loss torque (except

MZR-CD (RF Turbo))OUT IN–––

Engine speed OUT IN IN IN IN

Engine torque (except

MZR-CD (RF Turbo))OUT IN–––

Fuel injection information OUT–IN––

Fuel type and delivery OUT–IN––

Gear position IN OUT IN IN IN

Generator warning light

conditions (except MZR-

CD (RF Turbo))OUT–––IN

Glow indicator light

condition (MZR-CD (RF

Turbo))OUT–––IN

HOLD indicator light

conditions (FN4A-EL)OUT–––IN

Idle speed up request IN OUT–––

MIL condition (except

MZR-CD (RF Turbo))OUT–––IN

MIL indicate request IN OUT–––

Number of cylinders OUT–IN––

Racing select

determinationIN OUT–––

TCC condition IN OUT–––

Tire circumference (front/

rear)OUT–IN––

Torque reduction inhibit OUT IN IN––

TP OUTINININ–

Transmission/axle type OUT–IN––

Travelled distanceIN–OUT––

IN OUT––IN

OUT–––IN

Torque

reduction

requestJA5AX-EL IN OUT–––

except

JA5AX-ELIN–OUT––

Turbine speed IN OUT–––

Upper torque limit IN OUT–––

Vehicle speedOUT–––IN

IN OUT–––

Wheel speed (front left/

front right/rear left/rear

right)IN IN OUT IN–

OUT–––IN

4WD system operating

condition (warning light

information)–––OUT IN SignalMultiplex module

PCM TCMABS (ABS/TCS)

HU/CM or

DSC HU/CM4WD control

moduleInstrument

cluster

Page 821 of 909

T–10

WARNING AND INDICATOR SYSTEM

OUTLINEA6E811801069201•In accordance with the 4WD setting, the following indicator light has been added:

—4WD indicator light

•In accordance with the MZR-CD (RF Turbo) setting, the following indicator lights have been added:

—Glow indicator light

—Sedimentor warning light

•A fuel gauge sender sub-unit has been adopted. (4WD)

End Of Sie

STRUCTURAL VIEWA6E811801069202

.

End Of Sie

WARNING AND INDICATOR SYSTEM

3

2

1

4

5

4WD

A6E81181101

1 Sedimentor warning light

2 4WD indicator light

3 Glow indicator light4 Fuel gauge sender unit

5 Fuel gauge sender sub-unit

Page 822 of 909

WARNING AND INDEICATOR SYSTEM, THEFT-DETERRENT SYSTEM

T–11

T

SYSTEM WIRING DIAGRAMA6E811801069203

.

End Of Sie

OUTLINEA6E812050000201•An intruder sensor has been adopted on the rear part of the roof. (WGN)

•The construction and operation of the theft-deterrent system is the same as that of the current Mazda6 (GG)

model.

End Of Sie

INTRUDER SENSORA6E812050000202Outline

•WGN models are equipped with intruder sensors in two places in the vehicle, due to the necessity of movement

detection in the all around wider vehicle interior. The intruder sensors are located in the roof at the front (with

sliding sunroof), or the center (without sliding sunroof), and the cargo space.

•The structure and operation of the rear intruder sensor is the same as that of the current front and center

intruder sensors.

IG1

B+

1

345

2

6

97

8

2H 2V

1C 2F 2D 2M 2X 2W

A6E81181004

1 Instrument cluster

2Microcomputer

3 Glow indicator light

4 Sedimentor warning light

5 4WD indicator light6 PCM, ABS (ABS/TCS) HU/CM or DSC HU/CM

7 Fuel gauge sender sub-unit (4WD)

8 Fuel gauge sender unit

9 Sedimentor switch

THEFT-DETERRENT SYSTEM

Page 825 of 909

T–14

OUTLINE

SUPPLEMENTAL SERVICE INFORMATIONA6E810201088203•The following changes and/or additions have been made since publication of the Mazda6 Workshop Manual

(1730-1*-02C).

Relay

•Location has been changed.

•Inspection procedure has been modified.

Rear auto leveling sensor

•Removal/Installation procedure has been modified.

High-mount brake light

•Removal/Installation procedure has been modified.

Cargo compartment light

•Removal/Installation procedure has been modified.

•Inspection procedure has been modified.

Rear wiper motor

•Removal/Installation procedure has been modified.

•Inspection procedure has been modified.

Rear wiper arm and blade

•Removal/Installation procedure has been modified.

•Adjustment procedure has been modified.

Rear washer nozzle

•Removal/Installation procedure has been modified.

•Adjustment procedure has been modified.

Rear washer hose

•Removal/Installation procedure has been modified.

Intermittent rear wiper relay

•Removal/Installation procedure has been modified.

Fuel gauge sender unit

•Removal/Installation procedure has been modified.

•Inspection procedure has been modified.

Intruder sensor

•Removal/Installation procedure has been modified.

Noise filter

•Removal/Installation procedure has been modified.

Condenser

•Removal/Installation procedure has been modified.

Antenna feeder

•Location has been changed.

Rear antenna feeder

•Inspection procedure has been modified.

Curtain air bag module

•Removal/Installation procedure has been added.

Air bag module and pre-tensioner seat belt

•Deployment procedure has been modified.

On-board diagnostic

•Multiplex communication system procedure has been modified.

End Of Sie

OUTLINE

Page 828 of 909

LOCATION INDEX

T–17

T

End Of SieWARNING AND INDICATOR SYSTEMA6E810001067201

.

End Of SieTHEFT-DETERRENT SYSTEMA6E810050000201

.

End Of Sie

2

1

A6E81181112

1 Fuel gauge sender sub-unit

(See T–27 FUEL GAUGE SENDER UNIT

REMOVAL/INSTALLATION)

(See T–28 FUEL GAUGE SENDER UNIT

INSPECTION)2 Fuel gauge sender unit

(See T–27 FUEL GAUGE SENDER UNIT

REMOVAL/INSTALLATION)

(See T–28 FUEL GAUGE SENDER UNIT

INSPECTION)

3

12

A6E81201102

1 Front intruder sensor (with sliding sunroof)

2 Center intruder sensor (without sliding sunroof)3 Rear intruder sensor (WGN)

Page 838 of 909

WARNING AND INDICATOR SYSTEM

T–27

T

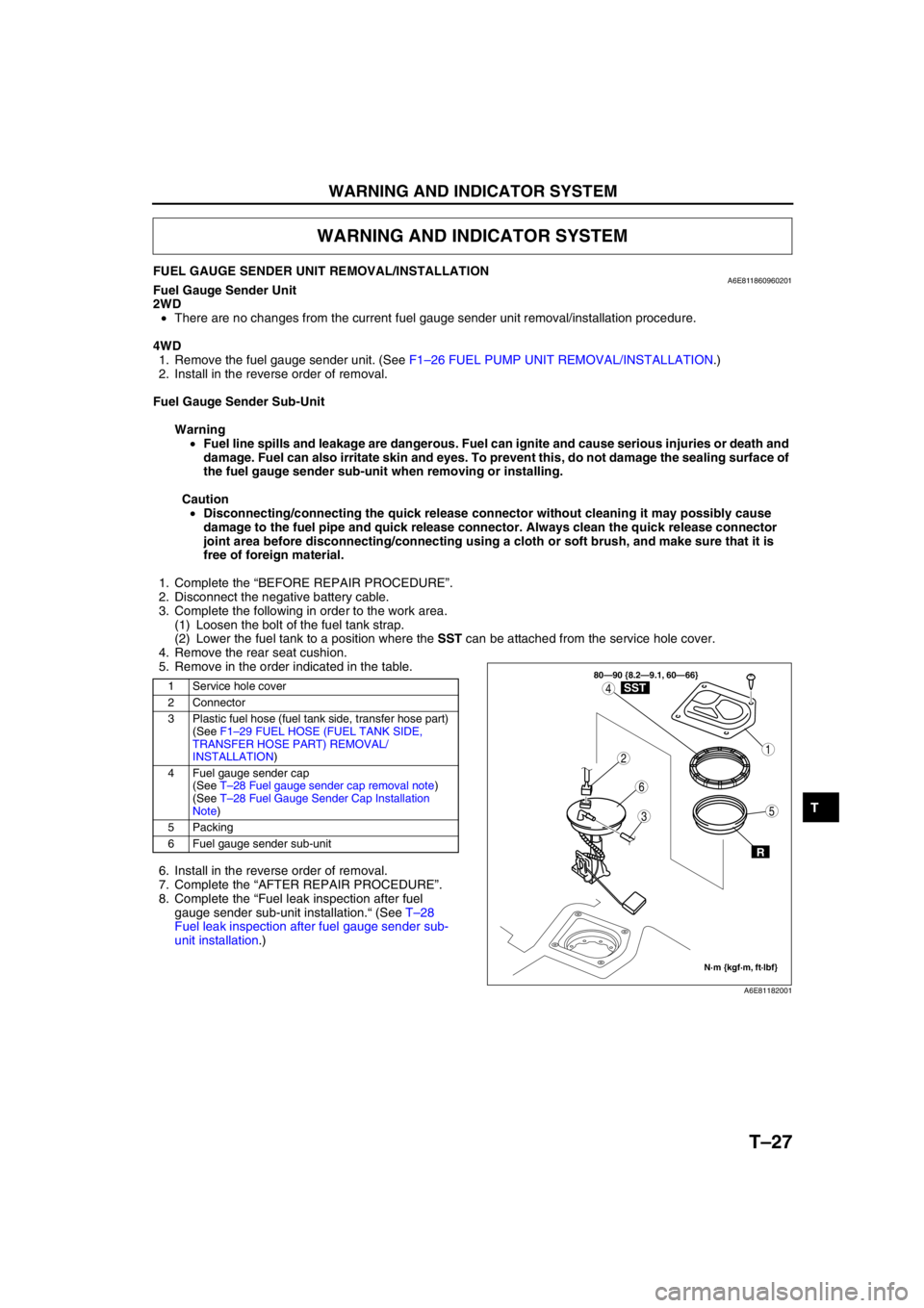

FUEL GAUGE SENDER UNIT REMOVAL/INSTALLATIONA6E811860960201Fuel Gauge Sender Unit

2WD

•There are no changes from the current fuel gauge sender unit removal/installation procedure.

4WD

1. Remove the fuel gauge sender unit. (See F1–26 FUEL PUMP UNIT REMOVAL/INSTALLATION.)

2. Install in the reverse order of removal.

Fuel Gauge Sender Sub-Unit

Warning

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, do not damage the sealing surface of

the fuel gauge sender sub-unit when removing or installing.

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

1. Complete the “BEFORE REPAIR PROCEDURE”.

2. Disconnect the negative battery cable.

3. Complete the following in order to the work area.

(1) Loosen the bolt of the fuel tank strap.

(2) Lower the fuel tank to a position where the SST can be attached from the service hole cover.

4. Remove the rear seat cushion.

5. Remove in the order indicated in the table.

6. Install in the reverse order of removal.

7. Complete the “AFTER REPAIR PROCEDURE”.

8. Complete the “Fuel leak inspection after fuel

gauge sender sub-unit installation.“ (See T–28

Fuel leak inspection after fuel gauge sender sub-

unit installation.)

WARNING AND INDICATOR SYSTEM

1 Service hole cover

2 Connector

3 Plastic fuel hose (fuel tank side, transfer hose part)

(See F1–29 FUEL HOSE (FUEL TANK SIDE,

TRANSFER HOSE PART) REMOVAL/

INSTALLATION)

4 Fuel gauge sender cap

(See T–28 Fuel gauge sender cap removal note)

(See T–28 Fuel Gauge Sender Cap Installation

Note)

5 Packing

6 Fuel gauge sender sub-unit

3

1

4

5

6

2

80—90 {8.2—9.1, 60—66}

N·m {kgf·m, ft·lbf}

R

SST

A6E81182001

Page 839 of 909

T–28

WARNING AND INDICATOR SYSTEM

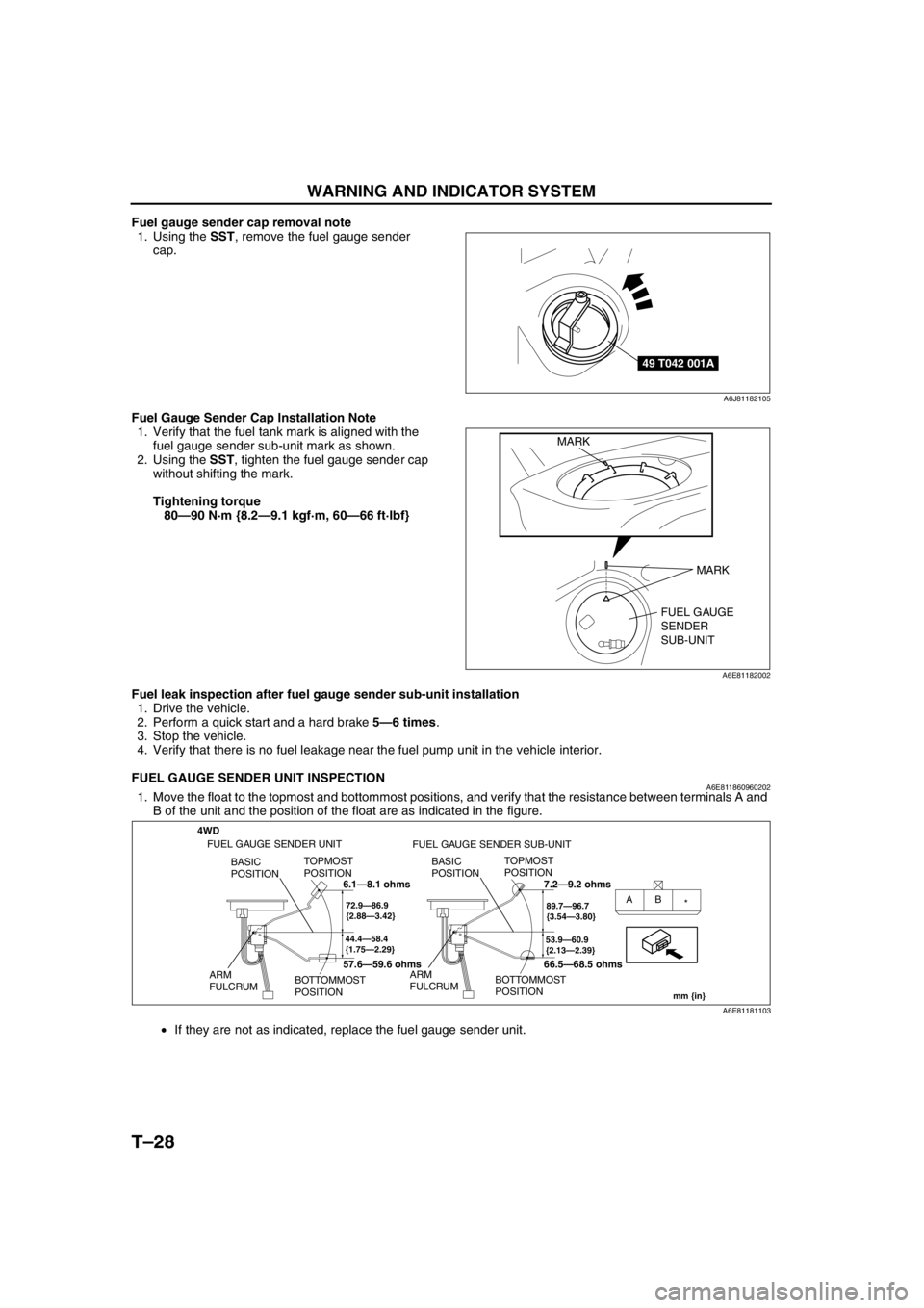

Fuel gauge sender cap removal note

1. Using the SST, remove the fuel gauge sender

cap.

Fuel Gauge Sender Cap Installation Note

1. Verify that the fuel tank mark is aligned with the

fuel gauge sender sub-unit mark as shown.

2. Using the SST, tighten the fuel gauge sender cap

without shifting the mark.

Tightening torque

80—90 N·m {8.2—9.1 kgf·m, 60—66 ft·lbf}

Fuel leak inspection after fuel gauge sender sub-unit installation

1. Drive the vehicle.

2. Perform a quick start and a hard brake 5—6 times.

3. Stop the vehicle.

4. Verify that there is no fuel leakage near the fuel pump unit in the vehicle interior.

End Of Sie

FUEL GAUGE SENDER UNIT INSPECTIONA6E8118609602021. Move the float to the topmost and bottommost positions, and verify that the resistance between terminals A and

B of the unit and the position of the float are as indicated in the figure.

•If they are not as indicated, replace the fuel gauge sender unit.

End Of Sie

49 T042 001A

A6J81182105

FUEL GAUGE

SENDER

SUB-UNIT MARK

MARK

A6E81182002

4WD

44.4—58.4

{1.75—2.29}

TOPMOST

POSITION

BOTTOMMOST

POSITION BASIC

POSITION

ARM

FULCRUM

72.9—86.9

{2.88—3.42}AB

*

53.9—60.9

{2.13—2.39}

TOPMOST

POSITION

BOTTOMMOST

POSITION BASIC

POSITION

ARM

FULCRUM

89.7—96.7

{3.54—3.80}

mm {in}

FUEL GAUGE SENDER UNIT

FUEL GAUGE SENDER SUB-UNIT

6.1—8.1 ohms

57.6—59.6 ohms7.2—9.2 ohms

66.5—68.5 ohms

A6E81181103

Page 864 of 909

U–1

U

UHEATER AND AIR CONDITIONER SYSTEMS

OUTLINE................................................................ U-2

OUTLINE OF CONSTRUCTION.......................... U-2

FEATURES .......................................................... U-2

SPECIFICATIONS ............................................... U-2

CONTROL SYSTEM............................................... U-6

WATER HEATER SYSTEM................................. U-6

OUTLINE................................................................ U-7

SUPPLEMENTAL SERVICE INFORMATION .....U-7

LOCATION INDEX.................................................U-8

BASIC SYSTEM................................................... U-8

CONTROL SYSTEM ............................................ U-9

BASIC SYSTEM................................................... U-10

A/C UNIT REMOVAL/INSTALLATION...............U-10

A/C COMPRESSOR

REMOVAL/INSTALLATION ............................U-11

CONDENSER REMOVAL/INSTALLATION ....... U-12

REFRIGERANT LINES

REMOVAL/INSTALLATION ............................U-13

CONTROL SYSTEM............................................. U-15

WATER HEATER UNIT

REMOVAL/INSTALLATION ............................U-15

FUEL PUMP (WATER HEATER SYSTEM)

INSPECTION .................................................. U-16

CLIMATE CONTROL UNIT INSPECTION.........U-16

ON-BOARD DIAGNOSTIC...................................U-22

FOREWORD ......................................................U-22

DTC TABLE ................................................... U-22-2

PID/DATA MONITOR AND RECORD ........... U-22-2

DTC B1317 .................................................... U-22-3

DTC B1318 ........................................................ U-23

DTC B1342, B2463, B2537, B2538, B2547 ....... U-23

DTC B2449, B2450 ............................................ U-24

DTC B2451, B2452 ............................................ U-24

DTC B2453, B2454 ............................................ U-25

DTC B2548 ........................................................ U-25

TROUBLESHOOTING.......................................... U-26

FOREWORD ......................................................U-26

TROUBLESHOOTING INDEX ...........................U-26 FEATURES

SERVICE

Page 869 of 909

U–6

CONTROL SYSTEM

WATER HEATER SYSTEMA6E854000169201Outline

•The function, structure and operation of the water heater system is essentially carried over from that of the

current MPV (LW) model, except for following:

—Full/half switching temperature has been changed.

Structural View

.

Operation

Full/half switching

•Depending on the engine coolant temperature, the CPU sets the flame to either full or half strength settings.

.

End Of Sie

CONTROL SYSTEM

1

2

A6E85402002

1 Water heater unit2 Fuel pump (water heater system)

3

1

2

68

{154}74

{165}75

{167}78

{172}˚C

{˚F}

A6E85402003

1 Full mode

2 Half mode3 Idle mode

Page 870 of 909

OUTLINE

U–7

U

SUPPLEMENTAL SERVICE INFORMATIONA6E850201038204•The following additions have been made for the MZR-CD (RF Turbo) since the publication of the Mazda6

Workshop Manual (1730-1*-02C).

A/C unit

•Removal/installation procedure has been modified.

A/C compressor

•Removal/installation procedure has been modified.

Condenser

•Removal/installation procedure has been modified.

Refrigerant lines

•Removal/installation procedure has been modified.

Water heater unit

•Removal/installation procedure has been added.

Fuel pump (water heater system)

•Inspection procedure has been added.

Climate control unit

•Inspection procedure has been modified.

Water heater system

•On-board diagnostic system has been added.

End Of Sie

OUTLINE