oil filter MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 73 of 909

OIL FILTER, OIL COOLER

D–9

D

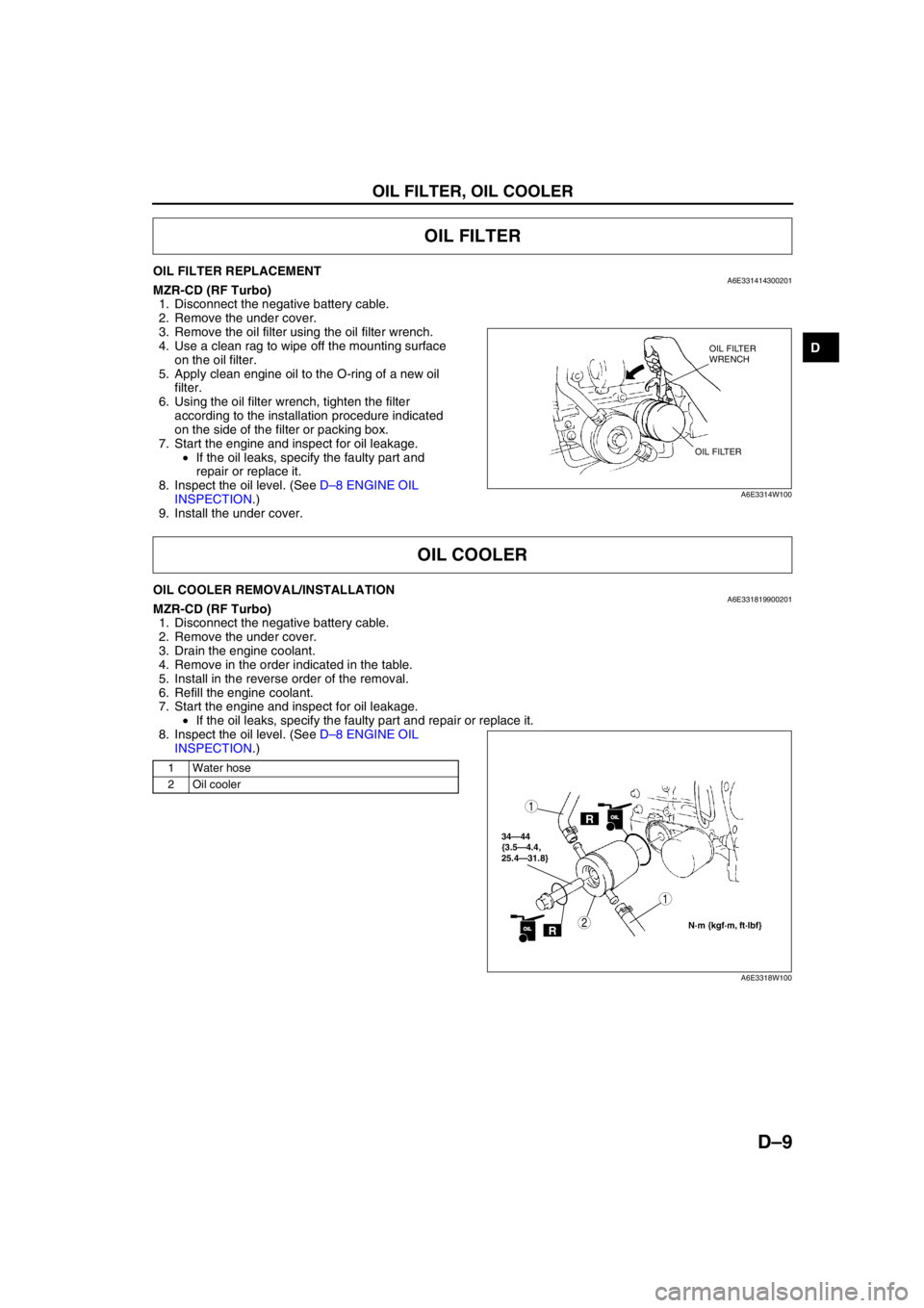

OIL FILTER REPLACEMENTA6E331414300201MZR-CD (RF Turbo)

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Remove the oil filter using the oil filter wrench.

4. Use a clean rag to wipe off the mounting surface

on the oil filter.

5. Apply clean engine oil to the O-ring of a new oil

filter.

6. Using the oil filter wrench, tighten the filter

according to the installation procedure indicated

on the side of the filter or packing box.

7. Start the engine and inspect for oil leakage.

•If the oil leaks, specify the faulty part and

repair or replace it.

8. Inspect the oil level. (See D–8 ENGINE OIL

INSPECTION.)

9. Install the under cover.

End Of Sie

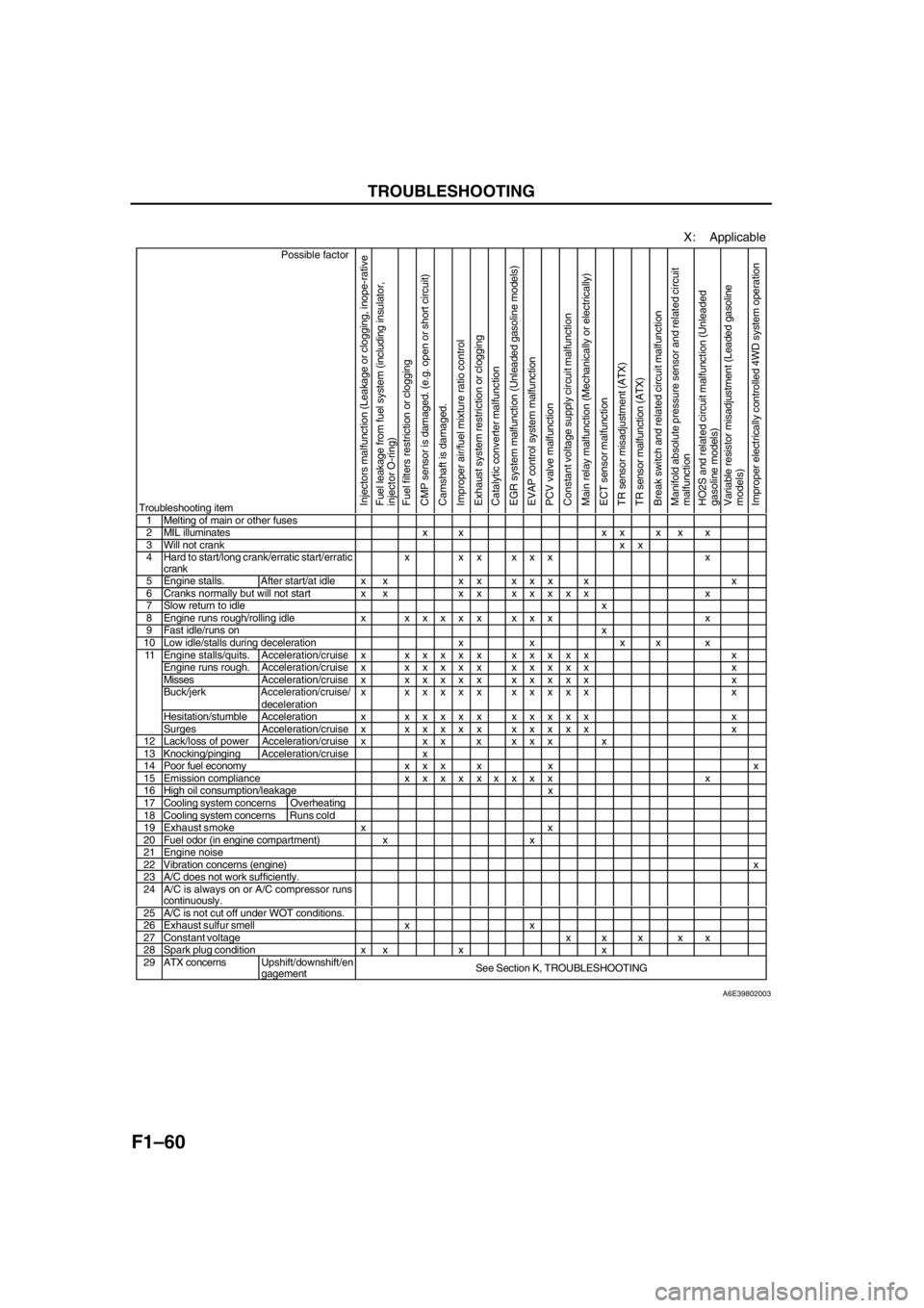

OIL COOLER REMOVAL/INSTALLATIONA6E331819900201MZR-CD (RF Turbo)

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Drain the engine coolant.

4. Remove in the order indicated in the table.

5. Install in the reverse order of the removal.

6. Refill the engine coolant.

7. Start the engine and inspect for oil leakage.

•If the oil leaks, specify the faulty part and repair or replace it.

8. Inspect the oil level. (See D–8 ENGINE OIL

INSPECTION.)

.

End Of Sie

OIL FILTER

OIL FILTER

WRENCH

OIL FILTER

A6E3314W100

OIL COOLER

1 Water hose

2 Oil cooler

ROILOIL

34—44

{3.5—4.4,

25.4—31.8}

1

2N·m {kgf·m, ft·lbf}ROILOIL

1

A6E3318W100

Page 91 of 909

OUTLINE

F1–3

F1

CONTROL SYSTEM DIAGRAM (4WD)A6E390218881204

.

* : Equipped for L3 engine modelEnd Of Sie

9

8

7

54

3

10

19

18

17

15

16

14

13

11

12

20

29

28

27

25

26

24

23

21

22

30

3938

3735

33

36

31

32

40

6

1

2

3441

A6E39022000

1PCM

2 Ignition coil

3 Generator

4* VAD shutter valve

5 Air cleaner

6 MAF sensor

7* VAD shutter valve actuator

8* VAD control solenoid valve

9* Vacuum chamber

10* VAD check valve (one-way)

11 IAC valve

12 Purge solenoid valve

13 TP sensor

14 MAP sensor

15* VIS control solenoid valve

16 Variable tumble control solenoid valve

17* VIS shutter valve actuator

18* VIS shutter valve

19 VTCS shutter valve actuator

20 VTCS shutter valve

21 Fuel injector22* OCV

23 CMP sensor

24 EGR valve

25 Knock sensor

26 ECT sensor

27 PCV valve

28 CKP sensor

29 HO2S (front)

30 HO2S (rear)

31 Charcoal canister

32 Check valve (two-way)

33 Pressure regulator

34 Fuel filter (high-pressure)

35 Fuel pump

36 Fuel filter (low-pressure)

37 Fuel tank

38 Rollover valve

39 Pulsation damper

40 Fuel pump (transfer)

41 To PCM

Page 148 of 909

F1–60

TROUBLESHOOTING

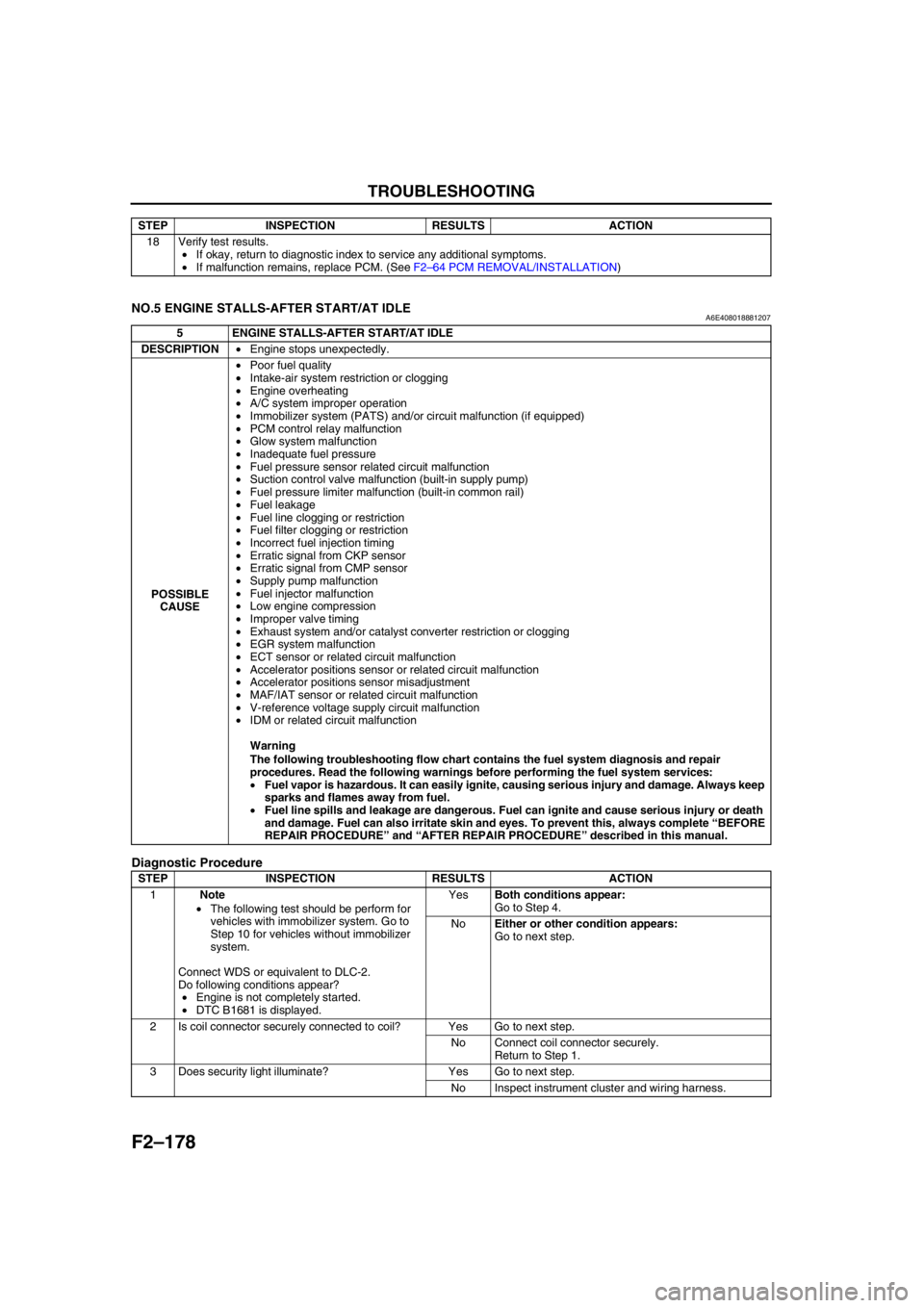

X: Applicable

Possible factor

Troubleshooting item

Injectors malfunction (Leakage or clogging, inope-rative

Fuel leakage from fuel system (including insulator,

injector O-ring)

Fuel filters restriction or clogging

CMP sensor is damaged. (e.g. open or short circuit)

Camshaft is damaged.

Improper air/fuel mixture ratio control

Exhaust system restriction or clogging

Catalytic converter malfunction

EGR system malfunction (Unleaded gasoline models)

EVAP control system malfunction

PCV valve malfunction

Constant voltage supply circuit malfunction

Main relay malfunction (Mechanically or electrically)

ECT sensor malfunction

TR sensor misadjustment (ATX)

TR sensor malfunction (ATX)

Break switch and related circuit malfunction

Manifold absolute pressure sensor and related circuit

malfunction

HO2S and related circuit malfunction (Unleaded

gasoline models)

Variable resistor misadjustment (Leaded gasoline

models)

Improper electrically controlled 4WD system operation

1 Melting of main or other fuses2 MIL illuminates x x x x x x x3 Will not crankxx4 Hard to start/long crank/erratic start/erratic

crankx xx xxx x

5 Engine stalls. After start/at idle x x x x x x x x x6 Cranks normally but will not start x x x xxxxxx x7 Slow return to idlex8 Engine runs rough/rolling idle xxxxxx xxx x9 Fast idle/runs onx10 Low idle/stalls during deceleration x x x x xEngine stalls/quits.Acceleration/cruisex xxxxx xxxxx xEngine runs rough. Acceleration/cruisex xxxxx xxxxx xMissesAcceleration/cruisex xxxxx xxxxx xBuck/jerk Acceleration/cruise/

decelerationx xxxxx xxxxx x

Hesitation/stumble Acceleration xxxxxx xxxxx x

11

Surges Acceleration/cruise xxxxxx xxxxx x

12 Lack/loss of power Acceleration/cruise x x x x x x x x13 Knocking/pingingAcceleration/cruise x14 Poor fuel economy x x x x x x15 Emission compliancexxxxxxxxx x16 High oil consumption/leakage x17 Cooling system concerns Overheating18 Cooling system concernsRuns cold19 Exhaust smoke x x20 Fuel odor (in engine compartment) x x21 Engine noise22 Vibration concerns (engine)x23 A/C does not work sufficiently.24 A/C is always on or A/C compressor runs

continuously.

25 A/C is not cut off under WOT conditions.26 Exhaust sulfur smell x x27 Constant voltage x x x x x28 Spark plug condition x x x x29 ATX concernsUpshift/downshift/en

gagementSee Section K, TROUBLESHOOTING

A6E39802003

Page 322 of 909

F2–170

TROUBLESHOOTING

×: Applicable

Troubleshooting item

1 Melting of main or other fuses

2 MIL illuminates××

3 Will not crank

4 Hard start/long crank/erratic start/erratic crank× × ××××× ×

5 Engine stalls After start/at idle×××××××××

6 Cranks normally but will not start× × ×××× × ×

7 Slow return to idle××××

8 Engine runs rough/rolling idle× × ×××× ××

9 Fast idle/runs on××

10 Low idle/stalls during deceleration× × ×××× ×

11Engine stalls/quits Acceleration/cruise× ××××× ×

Engine runs rough Acceleration/cruise× ××××× ×

Misses Acceleration/cruise× ××××× ×

Buck/jerk Acceleration/cruise/ deceleration× ××××× ×

Hesitation/stumble Acceleration× ××××× ×

Surges Acceleration/cruise× ××××× ×

12 Lack/loss of power Acceleration/cruise× ××××× ×

13 Knocking/pinging××××

14 Poor fuel economy×××××××

15 Emissions compliance× ×××××××

16 High oil consumption/leakage

17 Cooling system concerns Overheating×

18 Cooling system concerns Runs cold

19 Excessive black smoke××××

20 Fuel odor (in engine compartment)×

21 Engine noise××××

22 Vibration concerns (engine)×××

23 A/C does not work sufficiently

24 A/C always on or A/C compressor runs continuously

25 A/C does not cut off under wide open throttle conditions

26 Constant voltage×

Fuel injectors malfunction (Leakage or clogging,

inoperative)Fuel leakage from fuel system (including insulator,

fuel injector)Fuel filter restriction or cloggingCMP sensor is damaged (e.g: open or short circuit)CMP sensor pulse wheel is damagedIDM or related circuit malfunctionExhaust system restriction or cloggingCatalyst converter malfunctionEGR system malfunctionEGR water cooler malfunctionV-reference voltage supply circuit malfunction

Page 330 of 909

F2–178

TROUBLESHOOTING

End Of Sie

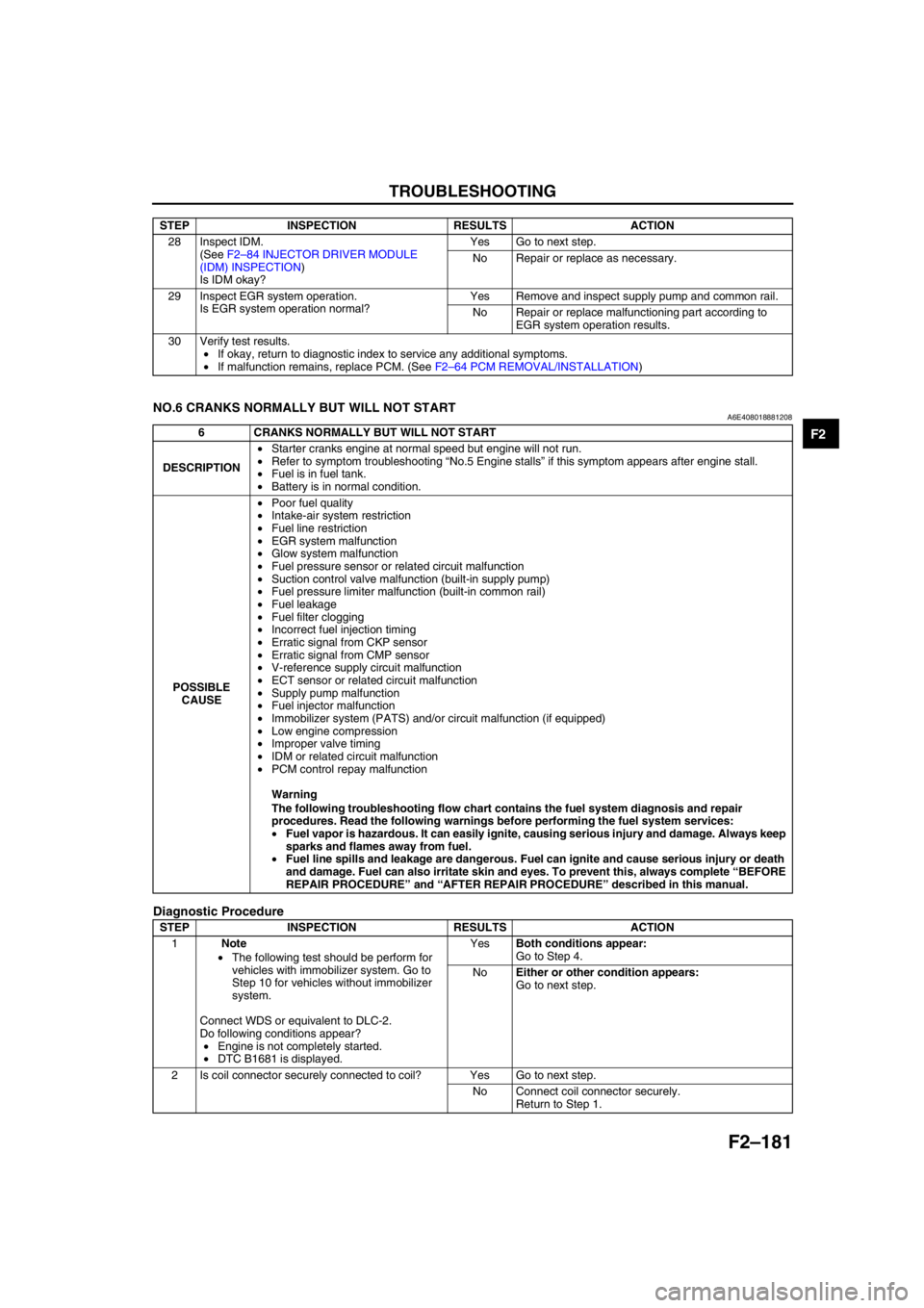

NO.5 ENGINE STALLS-AFTER START/AT IDLEA6E408018881207

Diagnostic Procedure

18 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION) STEP INSPECTION RESULTS ACTION

5 ENGINE STALLS-AFTER START/AT IDLE

DESCRIPTION•Engine stops unexpectedly.

POSSIBLE

CAUSE•Poor fuel quality

•Intake-air system restriction or clogging

•Engine overheating

•A/C system improper operation

•Immobilizer system (PATS) and/or circuit malfunction (if equipped)

•PCM control relay malfunction

•Glow system malfunction

•Inadequate fuel pressure

•Fuel pressure sensor related circuit malfunction

•Suction control valve malfunction (built-in supply pump)

•Fuel pressure limiter malfunction (built-in common rail)

•Fuel leakage

•Fuel line clogging or restriction

•Fuel filter clogging or restriction

•Incorrect fuel injection timing

•Erratic signal from CKP sensor

•Erratic signal from CMP sensor

•Supply pump malfunction

•Fuel injector malfunction

•Low engine compression

•Improper valve timing

•Exhaust system and/or catalyst converter restriction or clogging

•EGR system malfunction

•ECT sensor or related circuit malfunction

•Accelerator positions sensor or related circuit malfunction

•Accelerator positions sensor misadjustment

•MAF/IAT sensor or related circuit malfunction

•V-reference voltage supply circuit malfunction

•IDM or related circuit malfunction

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before performing the fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injury or death

and damage. Fuel can also irritate skin and eyes. To prevent this, always complete “BEFORE

REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this manual.

STEP INSPECTION RESULTS ACTION

1Note

•The following test should be perform for

vehicles with immobilizer system. Go to

Step 10 for vehicles without immobilizer

system.

Connect WDS or equivalent to DLC-2.

Do following conditions appear?

•Engine is not completely started.

•DTC B1681 is displayed.YesBoth conditions appear:

Go to Step 4.

NoEither or other condition appears:

Go to next step.

2 Is coil connector securely connected to coil? Yes Go to next step.

No Connect coil connector securely.

Return to Step 1.

3 Does security light illuminate? Yes Go to next step.

No Inspect instrument cluster and wiring harness.

Page 331 of 909

TROUBLESHOOTING

F2–179

F2

4 Connect WDS or equivalent to DLC-2 and

retrieve DTC.

DTC

B1213, B1342, B1600, B1601, B1602, B1681,

B2103, B2431Yes Go to appropriate DTC test.

No Go to next step.

5 Is there continuity between PCM GND terminals

65, 85, 103, 104 and GND?Yes Go to next step.

No Repair or replace wiring harness.

6 Measure voltage between PCM GND terminals

65, 85, 103, 104 and coil terminal C.

Is the voltage below 1.0?Yes Go to next step.

No Repair or replace wiring harness.

7 Turn engine switch to ON.

Access VPWR PID.

Is VPWR PID okay?

Specification

Battery voltageYes Go to next step.

No Repair or replace wiring harness.

8 Disconnect coil connector.

Turn engine switch to ON.

Is there battery voltage at coil connector terminal

D (harness-side)?Yes Inspect for following:

•Open or short circuit between coil terminal A and

PCM terminal 80

•Open or short circuit between coil terminal B and

PCM terminal 28

No Repair or replace wiring harness between coil

connector terminal D and fuse panel.

9 Is there continuity between PCM terminal 57 and

starter relay?Yes Go to next step.

No Repair replace wiring harness.

10 Inspect for following:

•Fuel quality (e.g.: include water

contamination, winter/summer blend)

•Fuel line/fuel filter clogging

•Intake-air system restriction

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 10.

11 Is engine overheating? Yes Go to symptom troubleshooting “NO.17 COOLING

SYSTEM CONCERNS-OVERHEATING”.

No Go to next step.

12Note

•Ignore DTC P0122, P0123, P0222 or

P0223 while performing this test.

Disconnect accelerator position sensor

connector.

Measure voltage at accelerator position sensor

connector VREF terminal (terminal D) with

engine switch ON.

Specification

4.5—5.5 V

Is voltage okay?Yes Go to next step.

No Go to symptom troubleshooting “NO.26 CONSTANT

VOLTAGE”.

13 Connect WDS or equivalent to DLC-2.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to next step.

14 Does engine start normally after warm-up? Yes Inspect glow system operation.

(See T–19 RELAY INSPECTION)

Replace any malfunctioning part as necessary.

If glow system is okay, go to next step.

No Go to next step. STEP INSPECTION RESULTS ACTION

Page 333 of 909

TROUBLESHOOTING

F2–181

F2

End Of Sie

NO.6 CRANKS NORMALLY BUT WILL NOT STARTA6E408018881208

Diagnostic Procedure

28 Inspect IDM.

(See F2–84 INJECTOR DRIVER MODULE

(IDM) INSPECTION)

Is IDM okay?Yes Go to next step.

No Repair or replace as necessary.

29 Inspect EGR system operation.

Is EGR system operation normal?Yes Remove and inspect supply pump and common rail.

No Repair or replace malfunctioning part according to

EGR system operation results.

30 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION) STEP INSPECTION RESULTS ACTION

6 CRANKS NORMALLY BUT WILL NOT START

DESCRIPTION•Starter cranks engine at normal speed but engine will not run.

•Refer to symptom troubleshooting “No.5 Engine stalls” if this symptom appears after engine stall.

•Fuel is in fuel tank.

•Battery is in normal condition.

POSSIBLE

CAUSE•Poor fuel quality

•Intake-air system restriction

•Fuel line restriction

•EGR system malfunction

•Glow system malfunction

•Fuel pressure sensor or related circuit malfunction

•Suction control valve malfunction (built-in supply pump)

•Fuel pressure limiter malfunction (built-in common rail)

•Fuel leakage

•Fuel filter clogging

•Incorrect fuel injection timing

•Erratic signal from CKP sensor

•Erratic signal from CMP sensor

•V-reference supply circuit malfunction

•ECT sensor or related circuit malfunction

•Supply pump malfunction

•Fuel injector malfunction

•Immobilizer system (PATS) and/or circuit malfunction (if equipped)

•Low engine compression

•Improper valve timing

•IDM or related circuit malfunction

•PCM control repay malfunction

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before performing the fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injury or death

and damage. Fuel can also irritate skin and eyes. To prevent this, always complete “BEFORE

REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this manual.

STEP INSPECTION RESULTS ACTION

1Note

•The following test should be perform for

vehicles with immobilizer system. Go to

Step 10 for vehicles without immobilizer

system.

Connect WDS or equivalent to DLC-2.

Do following conditions appear?

•Engine is not completely started.

•DTC B1681 is displayed.YesBoth conditions appear:

Go to Step 4.

NoEither or other condition appears:

Go to next step.

2 Is coil connector securely connected to coil? Yes Go to next step.

No Connect coil connector securely.

Return to Step 1.

Page 334 of 909

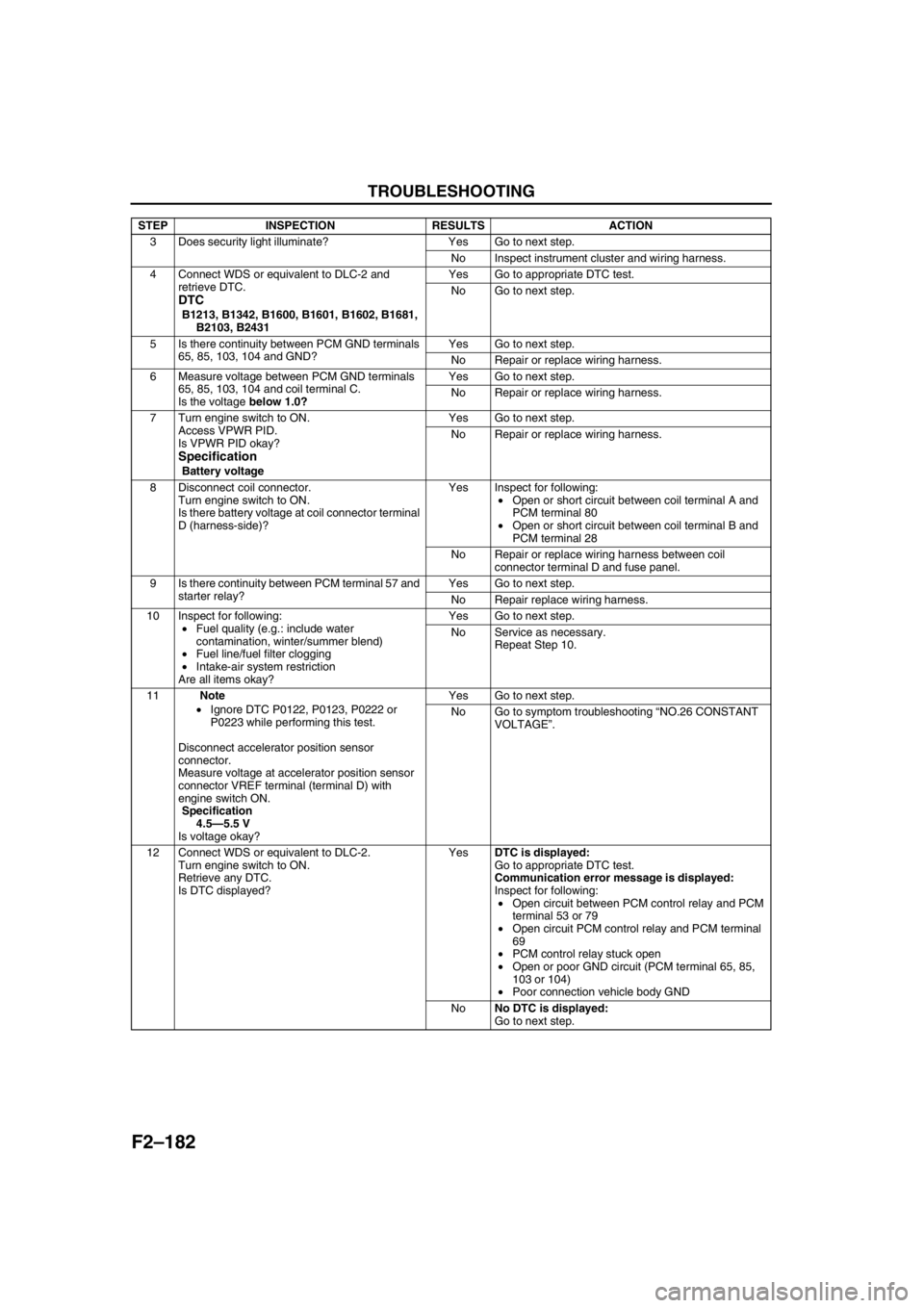

F2–182

TROUBLESHOOTING

3 Does security light illuminate? Yes Go to next step.

No Inspect instrument cluster and wiring harness.

4 Connect WDS or equivalent to DLC-2 and

retrieve DTC.

DTC

B1213, B1342, B1600, B1601, B1602, B1681,

B2103, B2431Yes Go to appropriate DTC test.

No Go to next step.

5 Is there continuity between PCM GND terminals

65, 85, 103, 104 and GND?Yes Go to next step.

No Repair or replace wiring harness.

6 Measure voltage between PCM GND terminals

65, 85, 103, 104 and coil terminal C.

Is the voltage below 1.0?Yes Go to next step.

No Repair or replace wiring harness.

7 Turn engine switch to ON.

Access VPWR PID.

Is VPWR PID okay?

Specification

Battery voltageYes Go to next step.

No Repair or replace wiring harness.

8 Disconnect coil connector.

Turn engine switch to ON.

Is there battery voltage at coil connector terminal

D (harness-side)?Yes Inspect for following:

•Open or short circuit between coil terminal A and

PCM terminal 80

•Open or short circuit between coil terminal B and

PCM terminal 28

No Repair or replace wiring harness between coil

connector terminal D and fuse panel.

9 Is there continuity between PCM terminal 57 and

starter relay?Yes Go to next step.

No Repair replace wiring harness.

10 Inspect for following:

•Fuel quality (e.g.: include water

contamination, winter/summer blend)

•Fuel line/fuel filter clogging

•Intake-air system restriction

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 10.

11Note

•Ignore DTC P0122, P0123, P0222 or

P0223 while performing this test.

Disconnect accelerator position sensor

connector.

Measure voltage at accelerator position sensor

connector VREF terminal (terminal D) with

engine switch ON.

Specification

4.5—5.5 V

Is voltage okay?Yes Go to next step.

No Go to symptom troubleshooting “NO.26 CONSTANT

VOLTAGE”.

12 Connect WDS or equivalent to DLC-2.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to next step. STEP INSPECTION RESULTS ACTION

Page 392 of 909

STARTING SYSTEM

G–9

G

STARTER REMOVAL/INSTALLATIONA6E471418400202

Warning

•When the battery cables are connected, touching the vehicle body with starter terminal B will

generate sparks. This can cause personal injury, fire, and damage to the electrical components.

Always disconnect the battery negative cables before performing the following operation.

1. Disconnect the negative battery cable.

2. Remove the plug hole plate. (L8, LF, and L3 engine models)

3. Remove the engine cover. (MZR-CD (RF Turbo) engine model) (See B2–9 TIMING BELT REMOVAL/

INSTALLATION.)

4. Remove the air cleaner assembly. (L8, LF, and L3 engine models).

5. Remove the under cover.

6. Remove the oil filter and oil cooler component with the cooling hose connected. Position the oil filter and oil

cooler component so that it is out of the way. (L3 engine model (4WD))

7. Remove the solenoid valve assembly with the vacuum hose and the connector connected. Position the

solenoid valve assembly so that it is out of the way. (MZR-CD (RF Turbo) engine model)

8. Remove the release cylinder with the oil pipe connected. Position the release cylinder so that it is out of the

way. (MTX)

9. Remove in the order indicated in the table.

10. Install in the reverse order of removal.

STARTING SYSTEM

Page 894 of 909

MECHANICAL

Valve clearance

[engine cold](mm {](/img/28/57057/w960_57057-893.png)

TD–2

TECHNICAL DATA

ENGINEA6E931001001201

End Of Sie

LUBRICATION SYSTEMA6E931001001202

TECHNICAL DATA

ItemSpecification

Diesel engine

MZR-CD (RF Turbo)

MECHANICAL

Valve clearance

[engine cold](mm {in})IN0.12—0.18

{0.005—0.007}

(0.15±0.03 {0.006±0.0011})

EX0.32—0.38

{0.013—0.014}

(0.35±0.03 {0.014±0.0011})

Compression pressure(kPa {kgf/cm

2, psi}) [rpm]Standard3,500

{35.7, 507.7}

[250]

Minimum3,100

{31.6, 449.4}

[250]

Maximum difference

between cylinders196.1 {1.999, 28.44}

Cylinder head bolt length (mm {in})Standard 159.7—160.3 {6.288—6.311}

Maximum 161.0 {6.338}

Pushing distance of the front oil seal

(from the edge of the oil pump body)(mm {in})0—0.5

{0—0.019}

Pushing distance of the rear oil seal

(from the edge of the rear cover)(mm {in})0—0.5

{0—0.019}

Pushing distance of the camshaft oil seal

(from the edge of the cylinder head)(mm {in})0.5—1.5

{0.020—0.059}

Timing belt auto tensioner rod projection (free length) (mm {in})12.9—14.6

{0.508—0.574}

ItemSpecification

Diesel engine

MZR-CD (RF Turbo)

Oil pressure

(approximate quantity)

[oil temperature: 100°C {212°F}](kPa {kgf/cm

2, psi}) min [rpm]147 {1.5, 21} [1,000],

343 {3.5, 50} [3,000]

Oil capacity

(approximate quantity)Total (dry engine)

5.5 {5.8, 4.8}

(L {US qt, Imp qt})

Oil replacement

4.8 {5.1, 4.2}

(L {US qt, Imp qt})

Oil and oil filter replacement

5.0 {5.3, 4.4}

(L {US qt, Imp qt})