stop start MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 750 of 909

PARKING BRAKE SYSTEM, DYNAMIC STABILITY CONTROL

P–17

P

PARKING BRAKE (LEVER TYPE) ADJUSTMENTA6E6914440002011. Start the engine and depress the brake pedal several times.

2. Stop the engine.

3. For the 2WD model, remove the rear ashtray case behind the center console

4. For the 4WD model, remove the 4 screws (back side) and pull up the rear of the center console, then remove

the rear ashtray case.

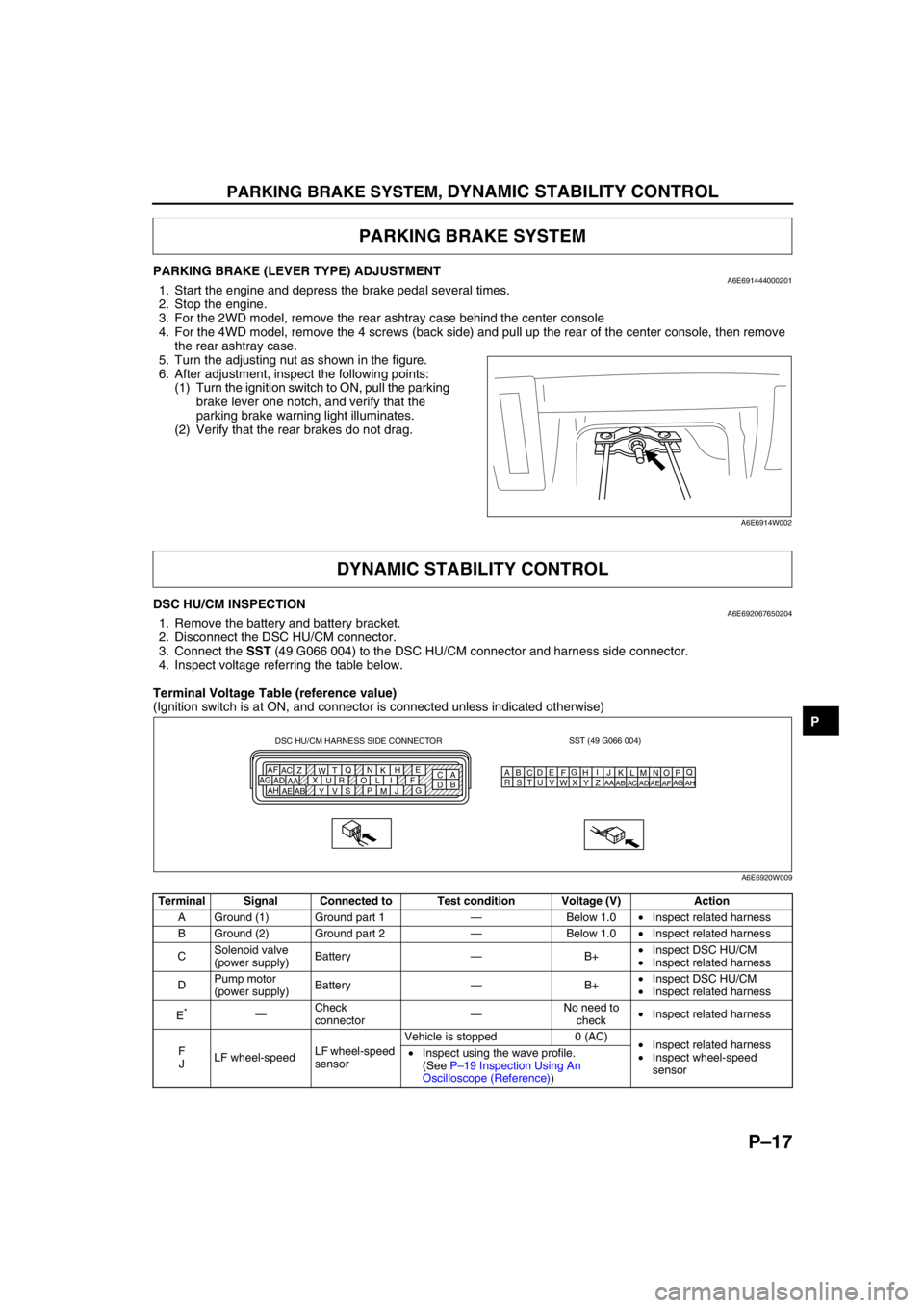

5. Turn the adjusting nut as shown in the figure.

6. After adjustment, inspect the following points:

(1) Turn the ignition switch to ON, pull the parking

brake lever one notch, and verify that the

parking brake warning light illuminates.

(2) Verify that the rear brakes do not drag.

End Of Sie

DSC HU/CM INSPECTIONA6E6920676502041. Remove the battery and battery bracket.

2. Disconnect the DSC HU/CM connector.

3. Connect the SST (49 G066 004) to the DSC HU/CM connector and harness side connector.

4. Inspect voltage referring the table below.

Terminal Voltage Table (reference value)

(Ignition switch is at ON, and connector is connected unless indicated otherwise)

PARKING BRAKE SYSTEM

A6E6914W002

DYNAMIC STABILITY CONTROL

Terminal Signal Connected to Test condition Voltage (V) Action

A Ground (1) Ground part 1—Below 1.0•Inspect related harness

B Ground (2) Ground part 2—Below 1.0•Inspect related harness

CSolenoid valve

(power supply)Battery—B+•Inspect DSC HU/CM

•Inspect related harness

DPump motor

(power supply)Battery—B+•Inspect DSC HU/CM

•Inspect related harness

E

*—Check

connector—No need to

check•Inspect related harness

F

JLF wheel-speedLF wheel-speed

sensorVehicle is stopped 0 (AC)

•Inspect related harness

•Inspect wheel-speed

sensor •Inspect using the wave profile.

(See P–19 Inspection Using An

Oscilloscope (Reference))

SST (49 G066 004)

AQ

B

CDE

FG

HI

J DSC HU/CM HARNESS SIDE CONNECTOR

A

C E

H

K N Q

T

W Z AC AF

F I L O R U X

AA AD AG

G

J

M P S

V

Y AB AE AHB

DKN

T

WZ

AC

AFLO

RU

XAA

ADAGMP

SV

YAB

AEAH

A6E6920W009

Page 839 of 909

T–28

WARNING AND INDICATOR SYSTEM

Fuel gauge sender cap removal note

1. Using the SST, remove the fuel gauge sender

cap.

Fuel Gauge Sender Cap Installation Note

1. Verify that the fuel tank mark is aligned with the

fuel gauge sender sub-unit mark as shown.

2. Using the SST, tighten the fuel gauge sender cap

without shifting the mark.

Tightening torque

80—90 N·m {8.2—9.1 kgf·m, 60—66 ft·lbf}

Fuel leak inspection after fuel gauge sender sub-unit installation

1. Drive the vehicle.

2. Perform a quick start and a hard brake 5—6 times.

3. Stop the vehicle.

4. Verify that there is no fuel leakage near the fuel pump unit in the vehicle interior.

End Of Sie

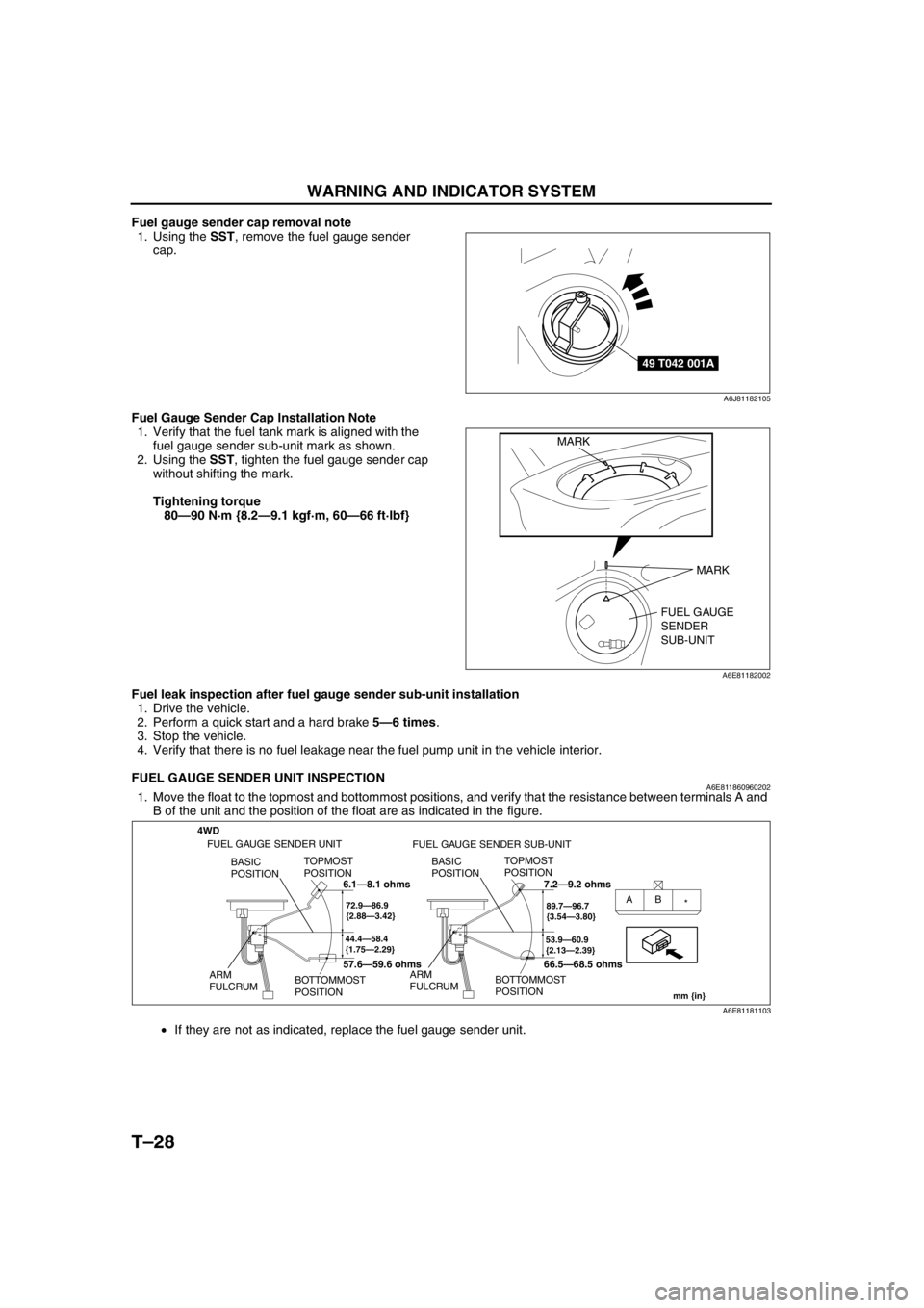

FUEL GAUGE SENDER UNIT INSPECTIONA6E8118609602021. Move the float to the topmost and bottommost positions, and verify that the resistance between terminals A and

B of the unit and the position of the float are as indicated in the figure.

•If they are not as indicated, replace the fuel gauge sender unit.

End Of Sie

49 T042 001A

A6J81182105

FUEL GAUGE

SENDER

SUB-UNIT MARK

MARK

A6E81182002

4WD

44.4—58.4

{1.75—2.29}

TOPMOST

POSITION

BOTTOMMOST

POSITION BASIC

POSITION

ARM

FULCRUM

72.9—86.9

{2.88—3.42}AB

*

53.9—60.9

{2.13—2.39}

TOPMOST

POSITION

BOTTOMMOST

POSITION BASIC

POSITION

ARM

FULCRUM

89.7—96.7

{3.54—3.80}

mm {in}

FUEL GAUGE SENDER UNIT

FUEL GAUGE SENDER SUB-UNIT

6.1—8.1 ohms

57.6—59.6 ohms7.2—9.2 ohms

66.5—68.5 ohms

A6E81181103