boot MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 12 of 909

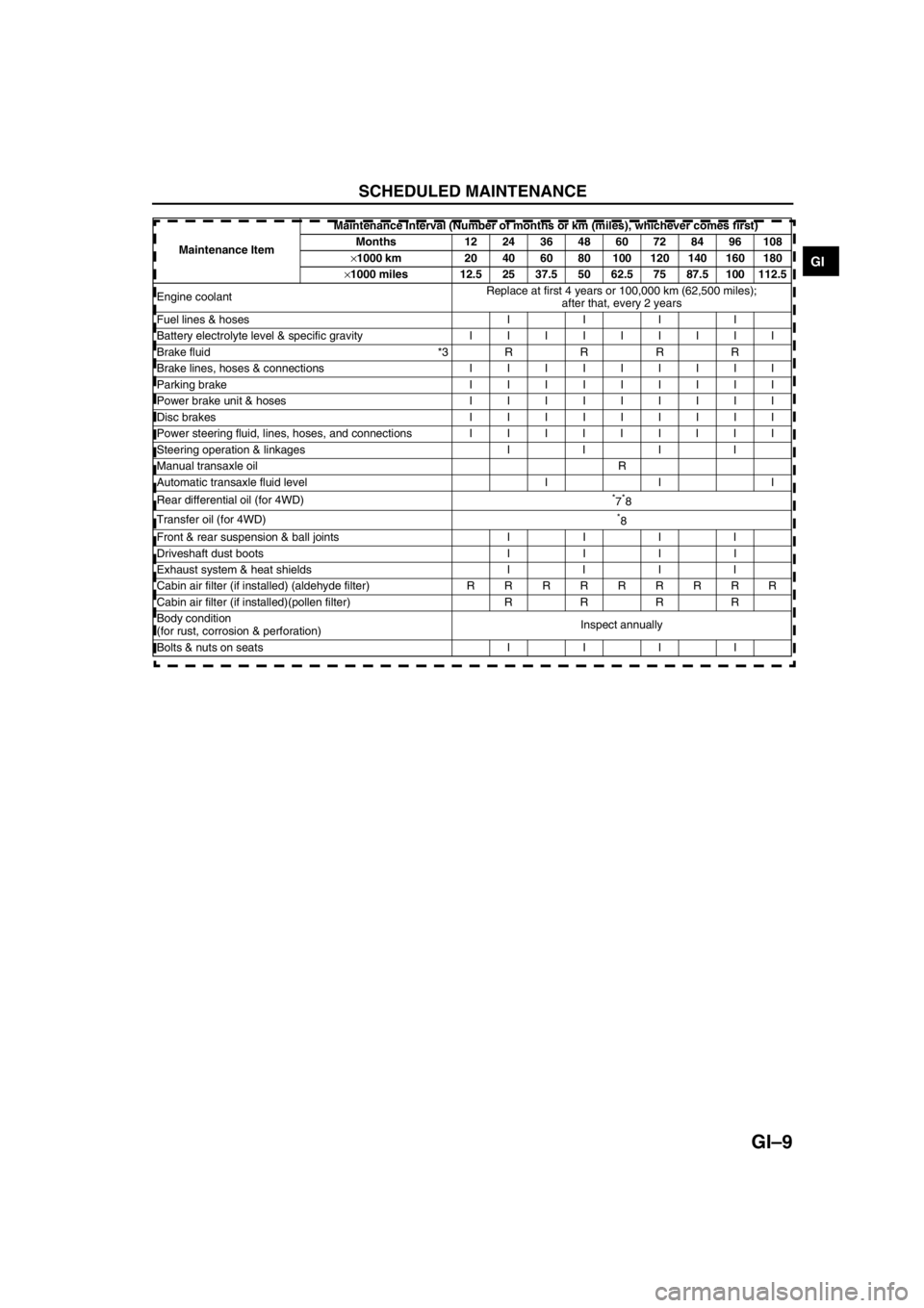

SCHEDULED MAINTENANCE

GI–9

GI

Engine coolantReplace at first 4 years or 100,000 km (62,500 miles);

after that, every 2 years

Fuel lines & hoses I I I I

Battery electrolyte level & specific gravity I I I I I I I I I

Brake fluid *3 R R R R

Brake lines, hoses & connections I I I I I I I I I

Parking brake I I I I I I I I I

Power brake unit & hoses I I I I I I I I I

Disc brakes IIIIIIIII

Power steering fluid, lines, hoses, and connections I I I I I I I I I

Steering operation & linkages I I I I

Manual transaxle oil R

Automatic transaxle fluid level I I I

Rear differential oil (for 4WD)

*7*8

Transfer oil (for 4WD)

*8

Front & rear suspension & ball joints I I I I

Driveshaft dust boots I I I I

Exhaust system & heat shields I I I I

Cabin air filter (if installed) (aldehyde filter) R R R R R R R R R

Cabin air filter (if installed)(pollen filter) R R R R

Body condition

(for rust, corrosion & perforation)Inspect annually

Bolts & nuts on seats I I I IMaintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 12 24 36 48 60 72 84 96 108

×1000 km 20 40 60 80 100 120 140 160 180

×1000 miles 12.5 25 37.5 50 62.5 75 87.5 100 112.5

Page 14 of 909

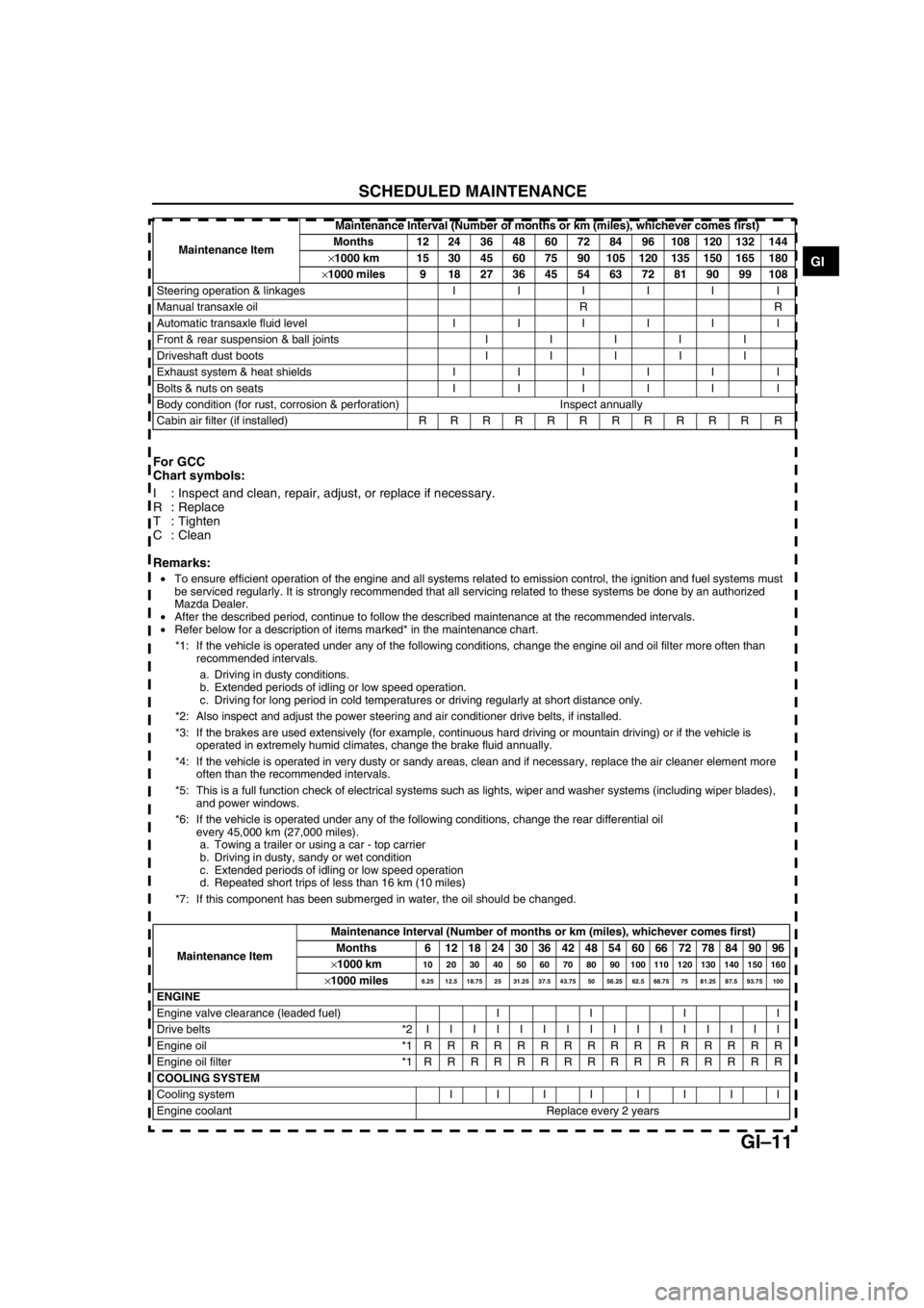

SCHEDULED MAINTENANCE

GI–11

GI

For GCC

Chart symbols:

I : Inspect and clean, repair, adjust, or replace if necessary.

R : Replace

T:Tighten

C : Clean

Remarks:

End Of Sie

Steering operation & linkages IIIII I

Manual transaxle oil R R

Automatic transaxle fluid level IIIII I

Front & rear suspension & ball joints IIIII

Driveshaft dust boots IIIII

Exhaust system & heat shields IIIII I

Bolts & nuts on seats IIIII I

Body condition (for rust, corrosion & perforation) Inspect annually

Cabin air filter (if installed) R R R R R R R R R R R RMaintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 12 24 36 48 60 72 84 96 108 120 132 144

×1000 km 15 30 45 60 75 90 105 120 135 150 165 180

×1000 miles 9 18 27 36 45 54 63 72 81 90 99 108

•To ensure efficient operation of the engine and all systems related to emission control, the ignition and fuel systems must

be serviced regularly. It is strongly recommended that all servicing related to these systems be done by an authorized

Mazda Dealer.

•After the described period, continue to follow the described maintenance at the recommended intervals.

•Refer below for a description of items marked* in the maintenance chart.

*1: If the vehicle is operated under any of the following conditions, change the engine oil and oil filter more often than

recommended intervals.

a. Driving in dusty conditions.

b. Extended periods of idling or low speed operation.

c. Driving for long period in cold temperatures or driving regularly at short distance only.

*2: Also inspect and adjust the power steering and air conditioner drive belts, if installed.

*3: If the brakes are used extensively (for example, continuous hard driving or mountain driving) or if the vehicle is

operated in extremely humid climates, change the brake fluid annually.

*4: If the vehicle is operated in very dusty or sandy areas, clean and if necessary, replace the air cleaner element more

often than the recommended intervals.

*5: This is a full function check of electrical systems such as lights, wiper and washer systems (including wiper blades),

and power windows.

*6: If the vehicle is operated under any of the following conditions, change the rear differential oil

every 45,000 km (27,000 miles).

a. Towing a trailer or using a car - top carrier

b. Driving in dusty, sandy or wet condition

c. Extended periods of idling or low speed operation

d. Repeated short trips of less than 16 km (10 miles)

*7: If this component has been submerged in water, the oil should be changed.

Maintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 6 121824303642485460667278849096

×1000 km

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

×1000 miles6.25 12.5 18.75 25 31.25 37.5 43.75 50 56.25 62.5 68.75 75 81.25 87.5 93.75 100

ENGINE

Engine valve clearance (leaded fuel) I I I I

Drive belts *2IIIIIIIIIIIIIIII

Engine oil *1RRRRRRRRRRRRRRRR

Engine oil filter *1RRRRRRRRRRRRRRRR

COOLING SYSTEM

Cooling system IIIIIIII

Engine coolant Replace every 2 years

Page 15 of 909

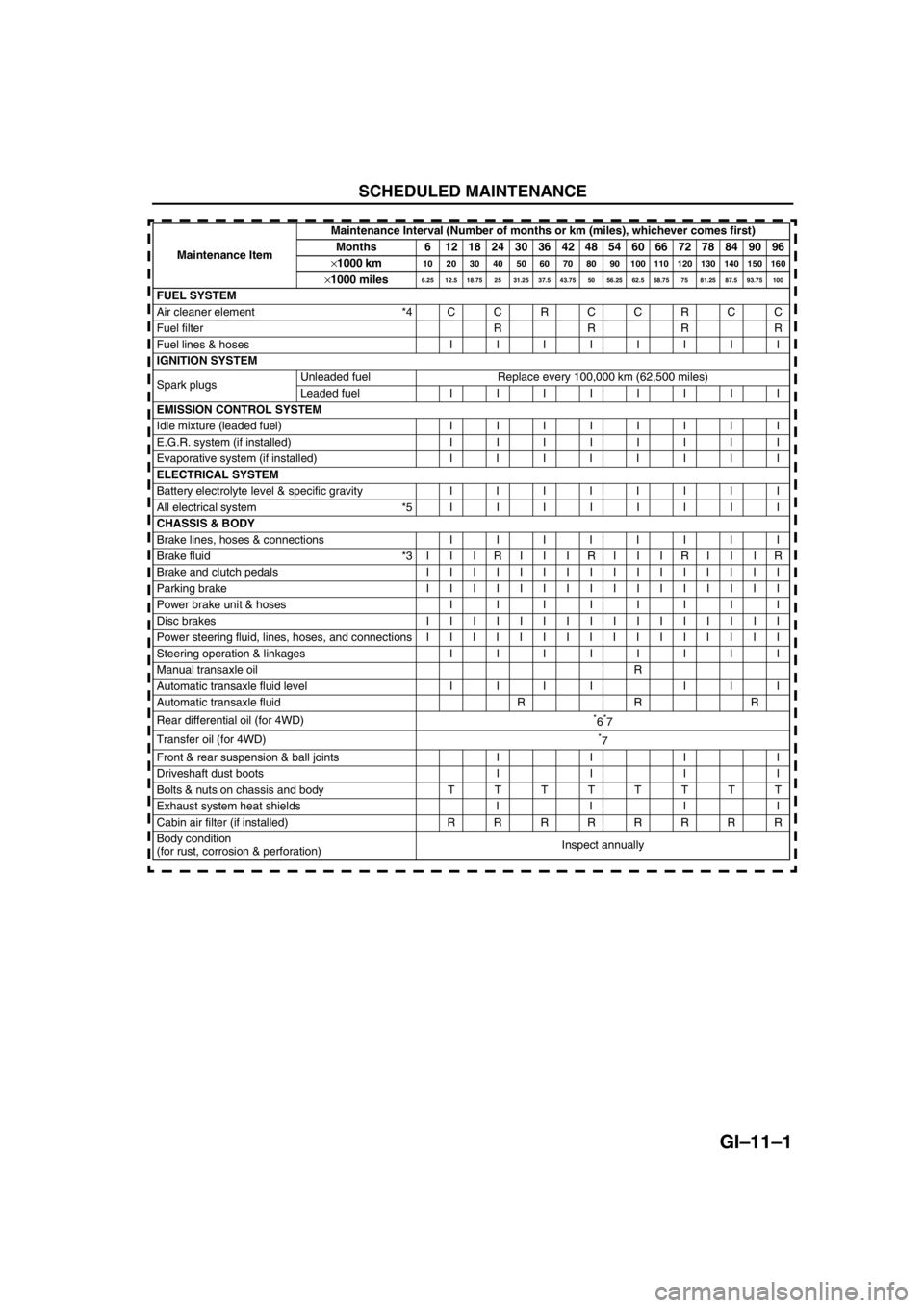

SCHEDULED MAINTENANCE

GI–11–1

GI–11GE NERAL INFORMATION

End Of Sie

SCHEDU LED MAINTENANCE

Maintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 6 121824303642485460667278849096

×1000 km10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

×1000 miles6.25 12.5 18.75 25 31.25 37.5 43.75 50 56.25 62.5 68.75 75 81.25 87.5 93.75 100

FUEL SYSTEM

Air cleaner element *4CCRCCRCC

Fuel filter R R R R

Fuel lines & hoses IIIIIIII

IGNITION SYSTEM

Spark plugs Unleaded fuel Replace every 100,000 km (62,500 miles)

Leaded fuel IIIIIIII

EMISSION CONTROL SYSTEM

Idle mixture (leaded fuel) IIIIIIII

E.G.R. system (if installed) IIIIIIII

Evaporative system (if installed) IIIIIIII

ELECTRICAL SYSTEM

Battery electrolyte level & specific gravity IIIIIIII

All electrical system *5IIIIIIII

CHASSIS & BODY

Brake lines, hoses & connections IIIIIIII

Brake fluid *3 I I I R I I I R I I I R I I I R

Brake and clutch pedals IIIIIIIIIIIIIIII

Parking brake IIIIIIIIIIIIIIII

Power brake unit & hosesIIIIIIII

Disc brakes IIIIIIIIIIIIIIII

Power steering fluid, lines, hoses, and connections I I I I I I I I I I I I I I I I

Steering operation & linkages IIIIIIII

Manual transaxle oilR

Automatic transaxle fluid level IIII III

Automatic transaxle fluid R R R

Rear differential oil (for 4WD)

*6*7

Transfer oil (for 4WD)

*7

Front & rear suspension & ball joints I I I I

Driveshaft dust boots I I I I

Bolts & nuts on chassis and body TTTTTTTT

Exhaust system heat shields I I I I

Cabin air filter (if installed) RRRRRRRR

Body condition

(for rust, corrosion & perforation)Inspect annually

Page 17 of 909

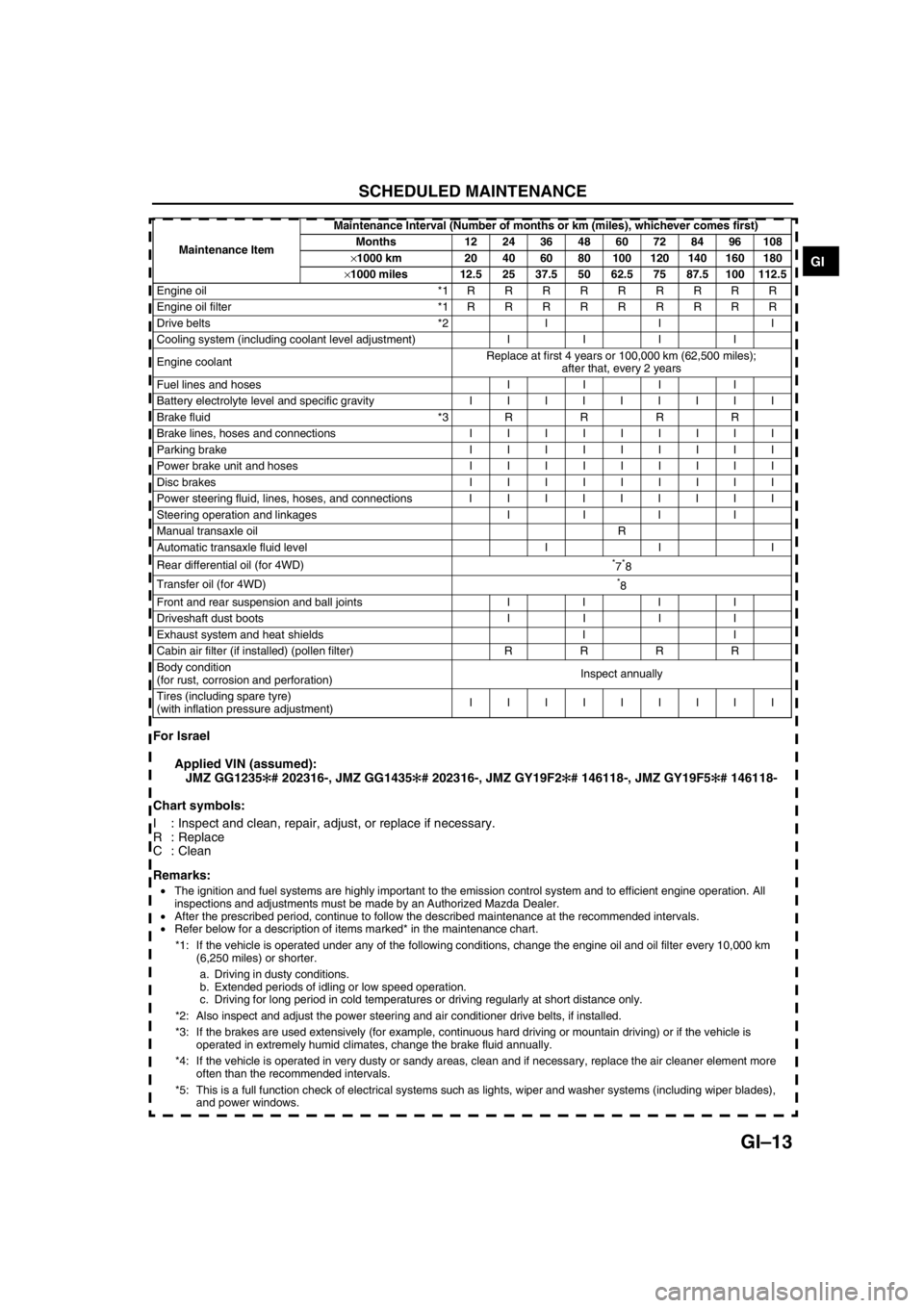

SCHEDULED MAINTENANCE

GI–13

GI

For Israel

Applied VIN (assumed):

JMZ GG1235✻

✻✻ ✻

# 202316-, JMZ GG1435✻

✻✻ ✻

# 202316-, JMZ GY19F2✻

✻✻ ✻

# 146118-, JMZ GY19F5✻

✻✻ ✻

# 146118-

Chart symbols:

I : Inspect and clean, repair, adjust, or replace if necessary.

R : Replace

C : Clean

Remarks:

Engine oil *1 R R R R R R R R R

Engine oil filter *1RRRRRRRRR

Drive belts *2 I I I

Cooling system (including coolant level adjustment) I I I I

Engine coolantReplace at first 4 years or 100,000 km (62,500 miles);

after that, every 2 years

Fuel lines and hoses I I I I

Battery electrolyte level and specific gravity IIIIIIIII

Brake fluid *3 R R R R

Brake lines, hoses and connections IIIIIIIII

Parking brake IIIIIIIII

Power brake unit and hoses IIIIIIIII

Disc brakes IIIIIIIII

Power steering fluid, lines, hoses, and connections IIIIIIIII

Steering operation and linkages I I I I

Manual transaxle oil R

Automatic transaxle fluid level I I I

Rear differential oil (for 4WD)

*7*8

Transfer oil (for 4WD)

*8

Front and rear suspension and ball joints I I I I

Driveshaft dust boots I I I I

Exhaust system and heat shields I I

Cabin air filter (if installed) (pollen filter) R R R R

Body condition

(for rust, corrosion and perforation)Inspect annually

Tires (including spare tyre)

(with inflation pressure adjustment)IIIIIIIII Maintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 12 24 36 48 60 72 84 96 108

×1000 km 20 40 60 80 100 120 140 160 180

×1000 miles 12.5 25 37.5 50 62.5 75 87.5 100 112.5

•The ignition and fuel systems are highly important to the emission control system and to efficient engine operation. All

inspections and adjustments must be made by an Authorized Mazda Dealer.

•After the prescribed period, continue to follow the described maintenance at the recommended intervals.

•Refer below for a description of items marked* in the maintenance chart.

*1: If the vehicle is operated under any of the following conditions, change the engine oil and oil filter every 10,000 km

(6,250 miles) or shorter.

a. Driving in dusty conditions.

b. Extended periods of idling or low speed operation.

c. Driving for long period in cold temperatures or driving regularly at short distance only.

*2: Also inspect and adjust the power steering and air conditioner drive belts, if installed.

*3: If the brakes are used extensively (for example, continuous hard driving or mountain driving) or if the vehicle is

operated in extremely humid climates, change the brake fluid annually.

*4: If the vehicle is operated in very dusty or sandy areas, clean and if necessary, replace the air cleaner element more

often than the recommended intervals.

*5: This is a full function check of electrical systems such as lights, wiper and washer systems (including wiper blades),

and power windows.

Page 18 of 909

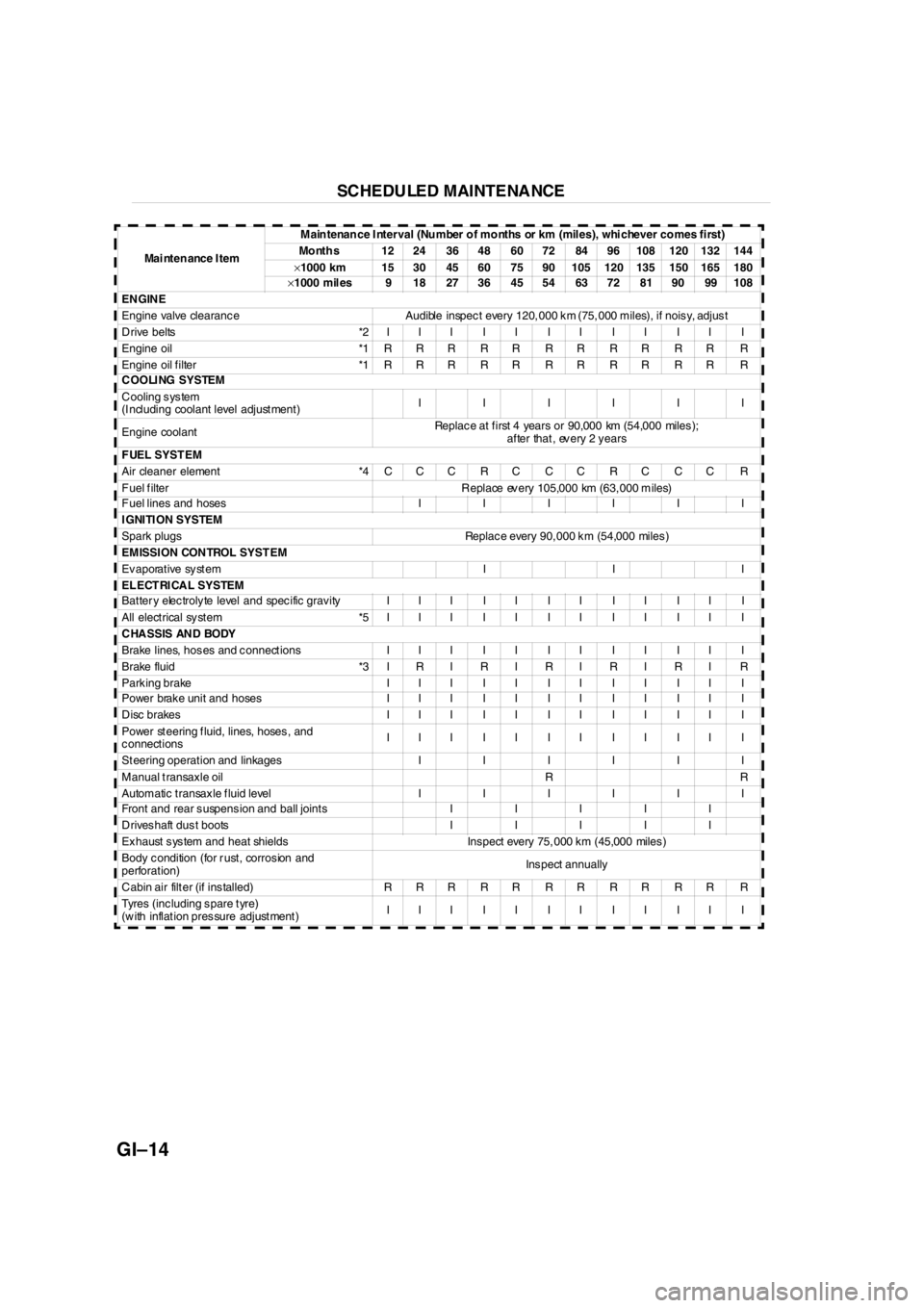

GI–14

SC HE DU LE D MAI NTE NA NCE

Mai nten ance I temM ain tenan ce I nter val (Nu mber o f mo nths or km (mil es), whi chever co mes fi rst)

Mo nth s 12 24 36 48 60 72 84 96 108 120 132 144

×1000 km 15 30 45 60 75 90 105 120 135 150 165 180

×1000 mil es 9 18 27 36 45 54 63 72 81 90 99 108

EN GIN E

Engine valve clearanc e Audible inspec t every 120, 000 k m (75, 000 m iles), if nois y, adjus t

Drive belts *2III II II II II I

Engine oil *1RRR RR RR RR RR R

Engine oil filter *1RRR RR RR RR RR R

C OOLI NG SYSTEM

C ooling s ys tem

(I ncluding coolant level adjust ment )IIIIII

Engine coolantReplac e at f irst 4 years or 90,000 km (54,000 miles );

af ter that , ev ery 2 y ears

F UEL SYST EM

Air cleaner element *4 C C C R C C C R C C C R

F uel f ilter R eplace ev ery 105,000 km (63, 000 m iles)

F uel lines and hosesIIIIII

I GNI TI ON SYSTEM

Spark plugs Replac e every 90, 000 k m (54,000 miles )

EM ISSI ON CON TROL SYST EM

Ev aporat ive sy st em I I I

EL ECT RI CA L SYSTEM

Bat ter y elec troly te level and spec ific grav ity I I I I I I I I I I I I

All electrical system *5III II II II II I

C HA S S IS AN D BO DY

Brake lines, hos es and c onnect ions I I I I I I I I I I I I

Brake fluid *3IRI RI RI RI RI R

Parking brake III II II II II I

Power brak e unit and hoses I I I I I I I I I I I I

Disc brakes III II II II II I

Power st eering f luid, lines, hoses , and

c onnect ionsIII II II II II I

St eering operat ion and linkagesIIIIII

M anual t ransax le oil R R

Automatic transaxle fluid level IIIIII

Front and rear s uspens ion and ball joint s I I I I I

D rives haft dus t boots I I I I I

Ex haust s ys tem and heat shields Ins pect every 75, 000 k m (45,000 miles )

Body c ondition (for r ust , corros ion and

perforat ion)Ins pect annually

C abin air filt er (if ins talled) R R R R R R R R R R R R

Tyres (inc luding s pare t yre)

(w ith inflat ion pres sure adjust ment )III II II II II I

Page 20 of 909

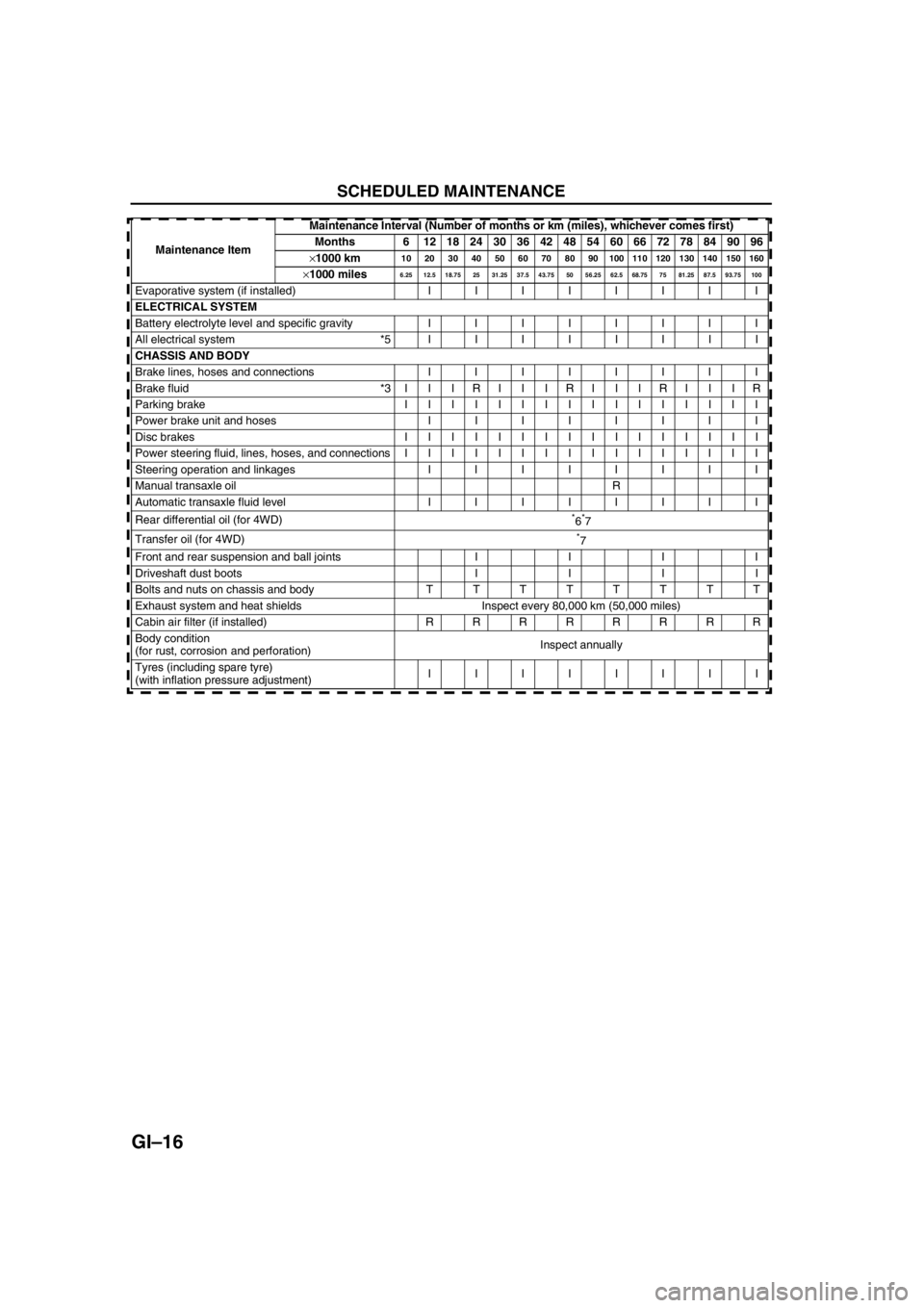

GI–16

SCHEDULED MAINTENANCE

Evaporative system (if installed) IIIIIIII

ELECTRICAL SYSTEM

Battery electrolyte level and specific gravity IIIIIIII

All electrical system *5IIIIIIII

CHASSIS AND BODY

Brake lines, hoses and connections IIIIIIII

Brake fluid *3IIIRIIIRIIIRIIIR

Parking brake IIIIIIIIIIIIIIII

Power brake unit and hoses IIIIIIII

Disc brakes IIIIIIIIIIIIIIII

Power steering fluid, lines, hoses, and connections I I I I I I I I I I I I I I I I

Steering operation and linkages IIIIIIII

Manual transaxle oilR

Automatic transaxle fluid level IIIIIIII

Rear differential oil (for 4WD)

*6*7

Transfer oil (for 4WD)

*7

Front and rear suspension and ball joints I I I I

Driveshaft dust boots I I I I

Bolts and nuts on chassis and body TTTTTTTT

Exhaust system and heat shields Inspect every 80,000 km (50,000 miles)

Cabin air filter (if installed) RRRRRRRR

Body condition

(for rust, corrosion and perforation)Inspect annually

Tyres (including spare tyre)

(with inflation pressure adjustment)IIIIIIII Maintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 6 121824303642485460667278849096

×1000 km

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

×1000 miles6.25 12.5 18.75 25 31.25 37.5 43.75 50 56.25 62.5 68.75 75 81.25 87.5 93.75 100

Page 21 of 909

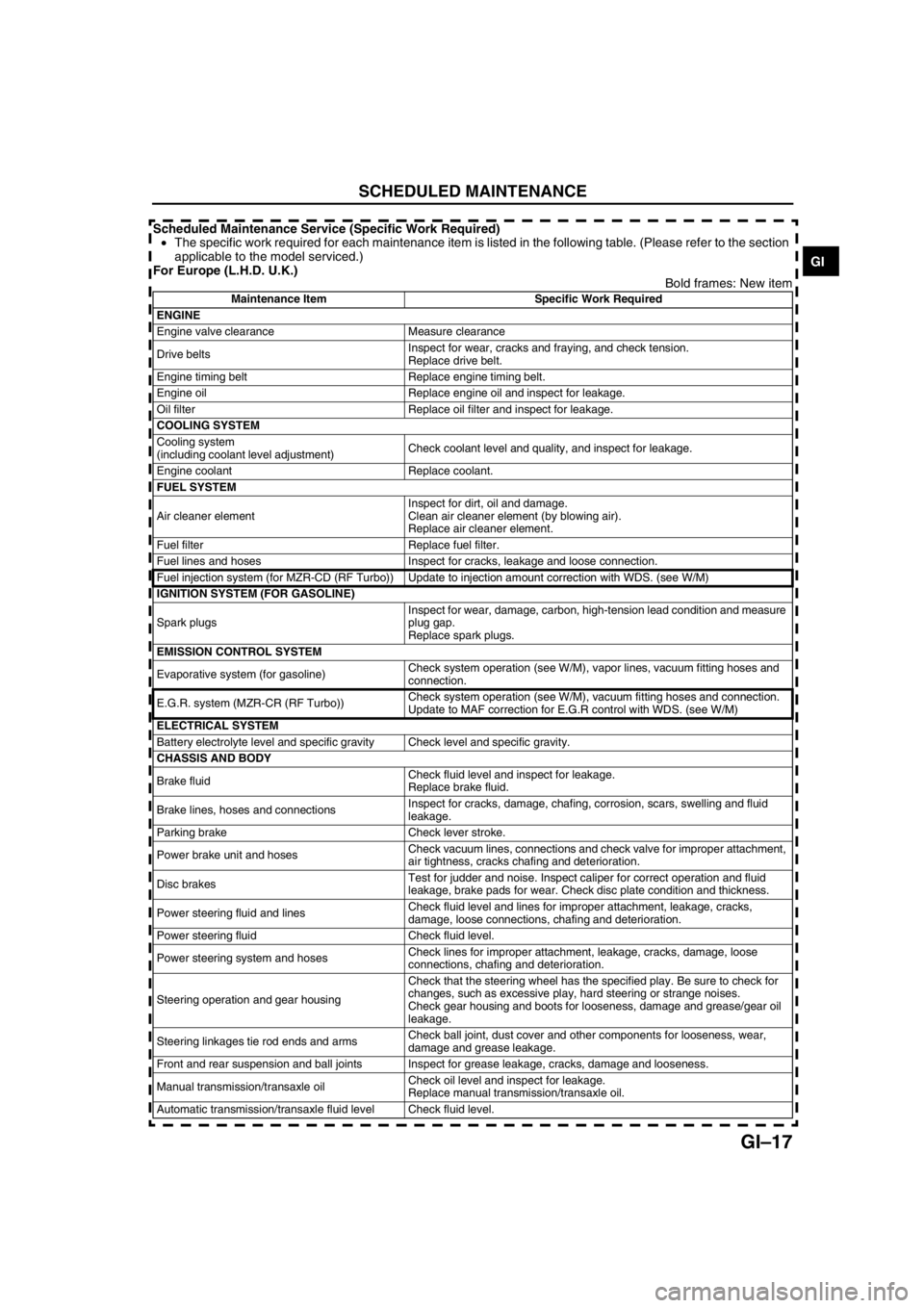

SCHEDULED MAINTENANCE

GI–17

GI

Scheduled Maintenance Service (Specific Work Required)

•The specific work required for each maintenance item is listed in the following table. (Please refer to the section

applicable to the model serviced.)

For Europe (L.H.D. U.K.)

Bold frames: New item

Maintenance Item Specific Work Required

ENGINE

Engine valve clearance Measure clearance

Drive beltsInspect for wear, cracks and fraying, and check tension.

Replace drive belt.

Engine timing belt Replace engine timing belt.

Engine oil Replace engine oil and inspect for leakage.

Oil filter Replace oil filter and inspect for leakage.

COOLING SYSTEM

Cooling system

(including coolant level adjustment)Check coolant level and quality, and inspect for leakage.

Engine coolant Replace coolant.

FUEL SYSTEM

Air cleaner elementInspect for dirt, oil and damage.

Clean air cleaner element (by blowing air).

Replace air cleaner element.

Fuel filter Replace fuel filter.

Fuel lines and hoses Inspect for cracks, leakage and loose connection.

Fuel injection system (for MZR-CD (RF Turbo)) Update to injection amount correction with WDS. (see W/M)

IGNITION SYSTEM (FOR GASOLINE)

Spark plugsInspect for wear, damage, carbon, high-tension lead condition and measure

plug gap.

Replace spark plugs.

EMISSION CONTROL SYSTEM

Evaporative system (for gasoline)Check system operation (see W/M), vapor lines, vacuum fitting hoses and

connection.

E.G.R. system (MZR-CR (RF Turbo))Check system operation (see W/M), vacuum fitting hoses and connection.

Update to MAF correction for E.G.R control with WDS. (see W/M)

ELECTRICAL SYSTEM

Battery electrolyte level and specific gravity Check level and specific gravity.

CHASSIS AND BODY

Brake fluidCheck fluid level and inspect for leakage.

Replace brake fluid.

Brake lines, hoses and connectionsInspect for cracks, damage, chafing, corrosion, scars, swelling and fluid

leakage.

Parking brake Check lever stroke.

Power brake unit and hosesCheck vacuum lines, connections and check valve for improper attachment,

air tightness, cracks chafing and deterioration.

Disc brakesTest for judder and noise. Inspect caliper for correct operation and fluid

leakage, brake pads for wear. Check disc plate condition and thickness.

Power steering fluid and linesCheck fluid level and lines for improper attachment, leakage, cracks,

damage, loose connections, chafing and deterioration.

Power steering fluid Check fluid level.

Power steering system and hosesCheck lines for improper attachment, leakage, cracks, damage, loose

connections, chafing and deterioration.

Steering operation and gear housingCheck that the steering wheel has the specified play. Be sure to check for

changes, such as excessive play, hard steering or strange noises.

Check gear housing and boots for looseness, damage and grease/gear oil

leakage.

Steering linkages tie rod ends and armsCheck ball joint, dust cover and other components for looseness, wear,

damage and grease leakage.

Front and rear suspension and ball joints Inspect for grease leakage, cracks, damage and looseness.

Manual transmission/transaxle oilCheck oil level and inspect for leakage.

Replace manual transmission/transaxle oil.

Automatic transmission/transaxle fluid level Check fluid level.

Page 22 of 909

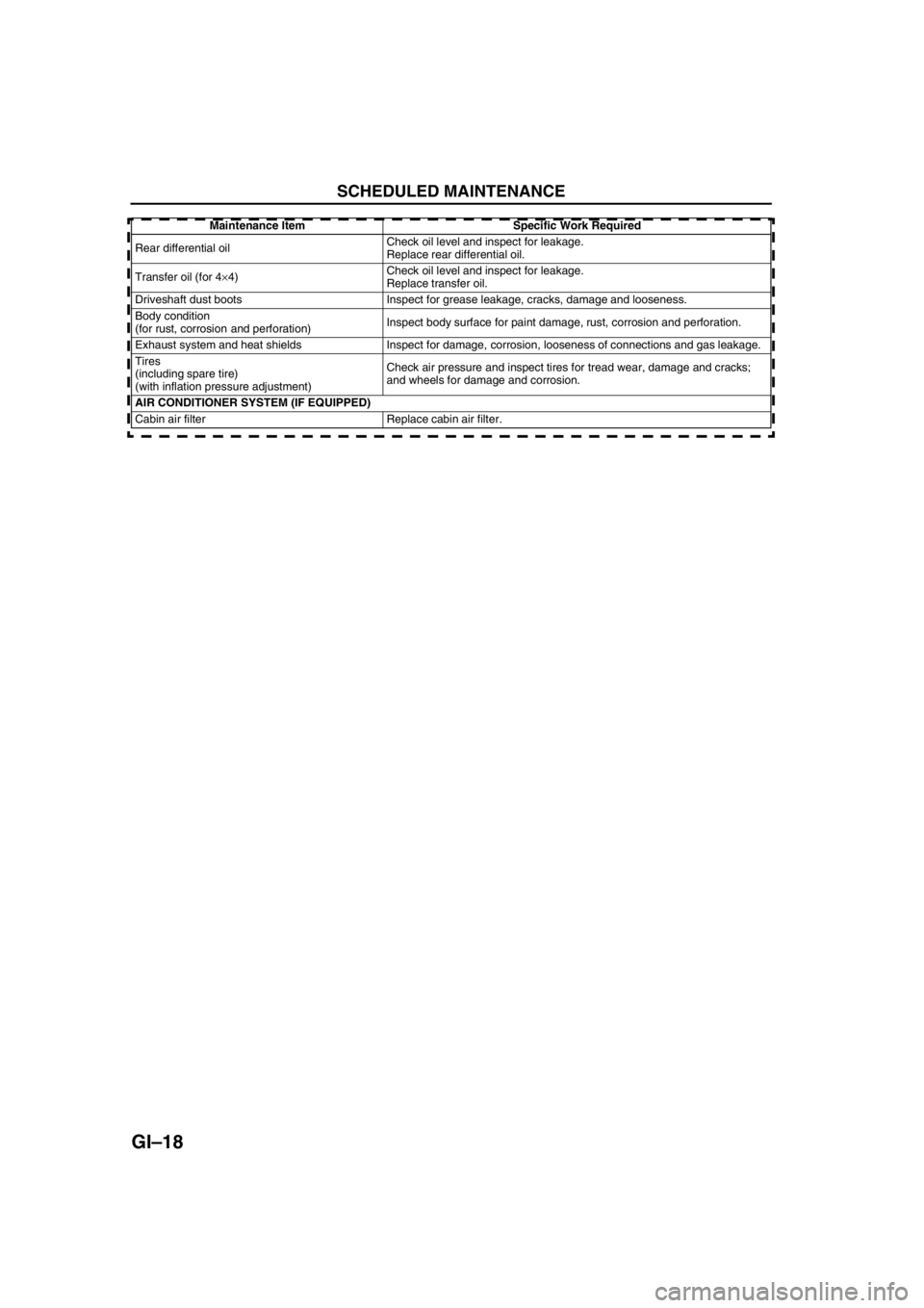

GI–18

SCHEDULED MAINTENANCE

End Of Sie

Rear differential oilCheck oil level and inspect for leakage.

Replace rear differential oil.

Transfer oil (for 4×4)Check oil level and inspect for leakage.

Replace transfer oil.

Driveshaft dust boots Inspect for grease leakage, cracks, damage and looseness.

Body condition

(for rust, corrosion and perforation)Inspect body surface for paint damage, rust, corrosion and perforation.

Exhaust system and heat shields Inspect for damage, corrosion, looseness of connections and gas leakage.

Tires

(including spare tire)

(with inflation pressure adjustment)Check air pressure and inspect tires for tread wear, damage and cracks;

and wheels for damage and corrosion.

AIR CONDITIONER SYSTEM (IF EQUIPPED)

Cabin air filter Replace cabin air filter.Maintenance Item Specific Work Required

Page 398 of 909

H–4

CLUTCH RELEASE CYLINDER

CLUTCH RELEASE CYLINDER DISASSEMBLY/ASSEMBLY (A65M-R MANUAL TRANSAXLE MODELS)A6E4918419202021. Disassemble in the order indicated in the table.

2. Assemble in the reverse order of disassembly.

.

End Of Sie

56

7

5.9—8.8 N.

m

{60—90 kgf.

cm,53—78 in.

lbf}

4

BRAKEFLUID

BRAKEFLUID3

1

2

A6E4918W011

1 Boot

2 Push rod

3 Piston and cap

4 Return spring5 Bleeder cap

6 Bleeder screw

7 Release cylinder body

Page 399 of 909

CLUTCH UNIT

H–5

H

CLUTCH UNIT REMOVAL/INSTALLATION (A65M-R MANUAL TRANSAXLE MODELS)A6E4920160002011. Remove in the order indicated in the table.

2. Install in the reverse order oremoval.

.

CLUTCH UNIT

SST

SST

SSTSEALANT

25—33

{2.6—3.3, 19—24}

151.3—161.1

{15.43—16.42, 111.6—118.8} 18.6—25.5

{1.90—2.60, 13.8—18.8}

1

GREASE

GREASE

GREASE

GREASE

GREASE

5

6

7

8

4

3

2

(MOLYBDENUM SULFIDE) TRANSAXLE SIDE ENGINE SIDE

N·m {kgf·m, ft·lbf}

A6E4920W010

1 Clutch release cylinder

2 Manual transaxle

(See J2–7 MANUAL TRANSAXLE REMOVAL/

INSTALLATION)

3Boot

4 Clutch release collar

5 Clutch release fork6 Clutch cover

(See H–6 Clutch Cover and Disc Removal Note)

(See H–7 Clutch Cover Installation Note)

7Clutch disc

(See H–6 Clutch Cover and Disc Removal Note)

(See H–7 Clutch Disc Installation Note)

8 Flywheel

(See H–6 Flywheel Removal Note)

(See H–6 Flywheel Installation Note)