check engine light MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 13 of 909

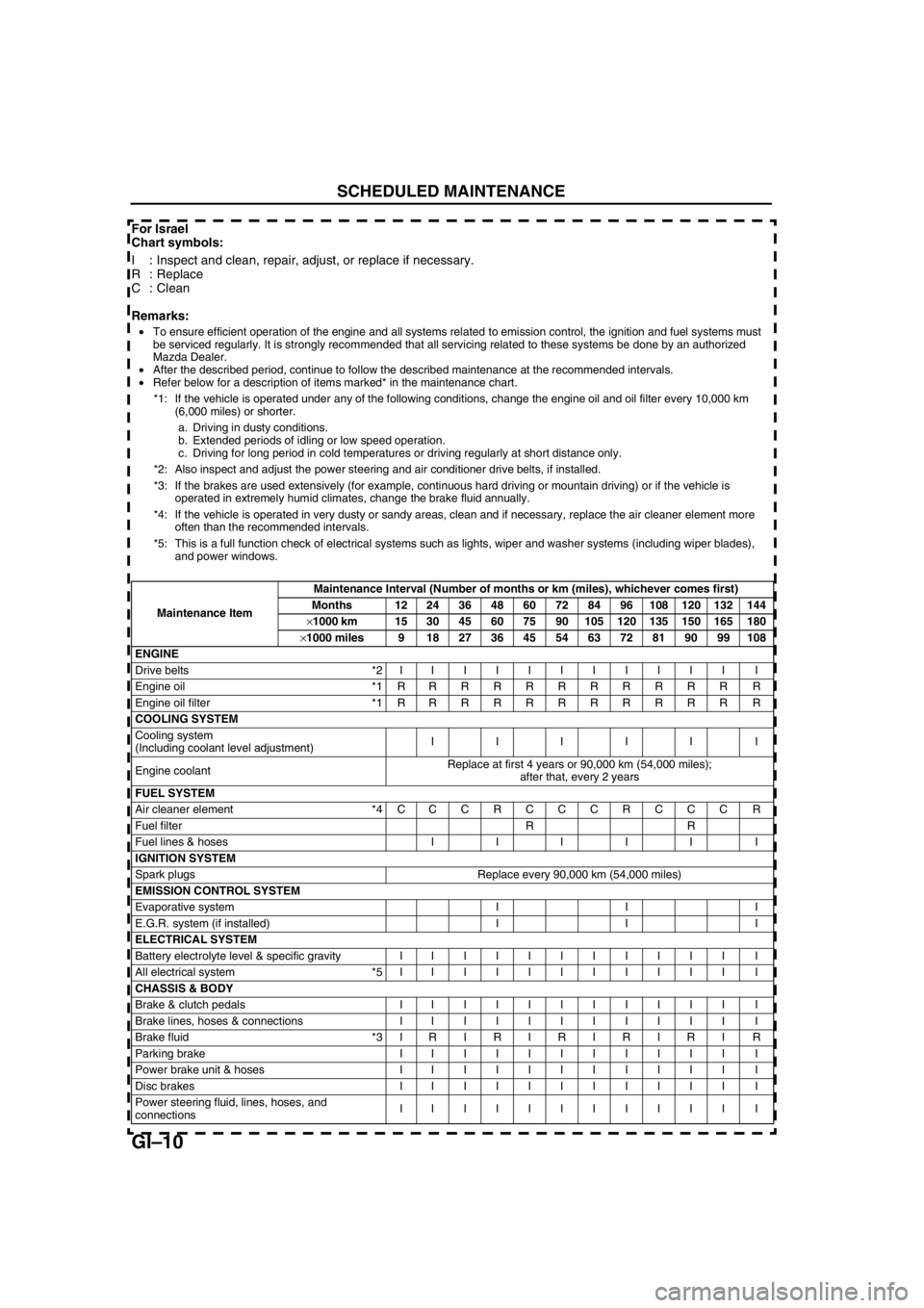

GI–10

SCHEDULED MAINTENANCE

For Israel

Chart symbols:

I : Inspect and clean, repair, adjust, or replace if necessary.

R:Replace

C : Clean

Remarks:

•To ensure efficient operation of the engine and all systems related to emission control, the ignition and fuel systems must

be serviced regularly. It is strongly recommended that all servicing related to these systems be done by an authorized

Mazda Dealer.

•After the described period, continue to follow the described maintenance at the recommended intervals.

•Refer below for a description of items marked* in the maintenance chart.

*1: If the vehicle is operated under any of the following conditions, change the engine oil and oil filter every 10,000 km

(6,000 miles) or shorter.

a. Driving in dusty conditions.

b. Extended periods of idling or low speed operation.

c. Driving for long period in cold temperatures or driving regularly at short distance only.

*2: Also inspect and adjust the power steering and air conditioner drive belts, if installed.

*3: If the brakes are used extensively (for example, continuous hard driving or mountain driving) or if the vehicle is

operated in extremely humid climates, change the brake fluid annually.

*4: If the vehicle is operated in very dusty or sandy areas, clean and if necessary, replace the air cleaner element more

often than the recommended intervals.

*5: This is a full function check of electrical systems such as lights, wiper and washer systems (including wiper blades),

and power windows.

Maintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 12 24 36 48 60 72 84 96 108 120 132 144

×1000 km 15 30 45 60 75 90 105 120 135 150 165 180

×1000 miles 9 18 27 36 45 54 63 72 81 90 99 108

ENGINE

Drive belts *2IIIIIIIIIII I

Engine oil *1RRRRRRRRRRR R

Engine oil filter *1RRRRRRRRRRR R

COOLING SYSTEM

Cooling system

(Including coolant level adjustment)IIIII I

Engine coolantReplace at first 4 years or 90,000 km (54,000 miles);

after that, every 2 years

FUEL SYSTEM

Air cleaner element *4CCCRCCCRCCC R

Fuel filter R R

Fuel lines & hoses IIIII I

IGNITION SYSTEM

Spark plugs Replace every 90,000 km (54,000 miles)

EMISSION CONTROL SYSTEM

Evaporative system I I I

E.G.R. system (if installed) I I I

ELECTRICAL SYSTEM

Battery electrolyte level & specific gravity I I I I I I I I I I I I

All electrical system *5IIIIIIIIIII I

CHASSIS & BODY

Brake & clutch pedals IIIIIIIIIII I

Brake lines, hoses & connections I I I I I I I I I I I I

Brake fluid *3IRIRIRIRIRI R

Parking brake IIIIIIIIIII I

Power brake unit & hoses IIIIIIIIIII I

Disc brakes IIIIIIIIIII I

Power steering fluid, lines, hoses, and

connectionsIIIIIIIIIII I

Page 14 of 909

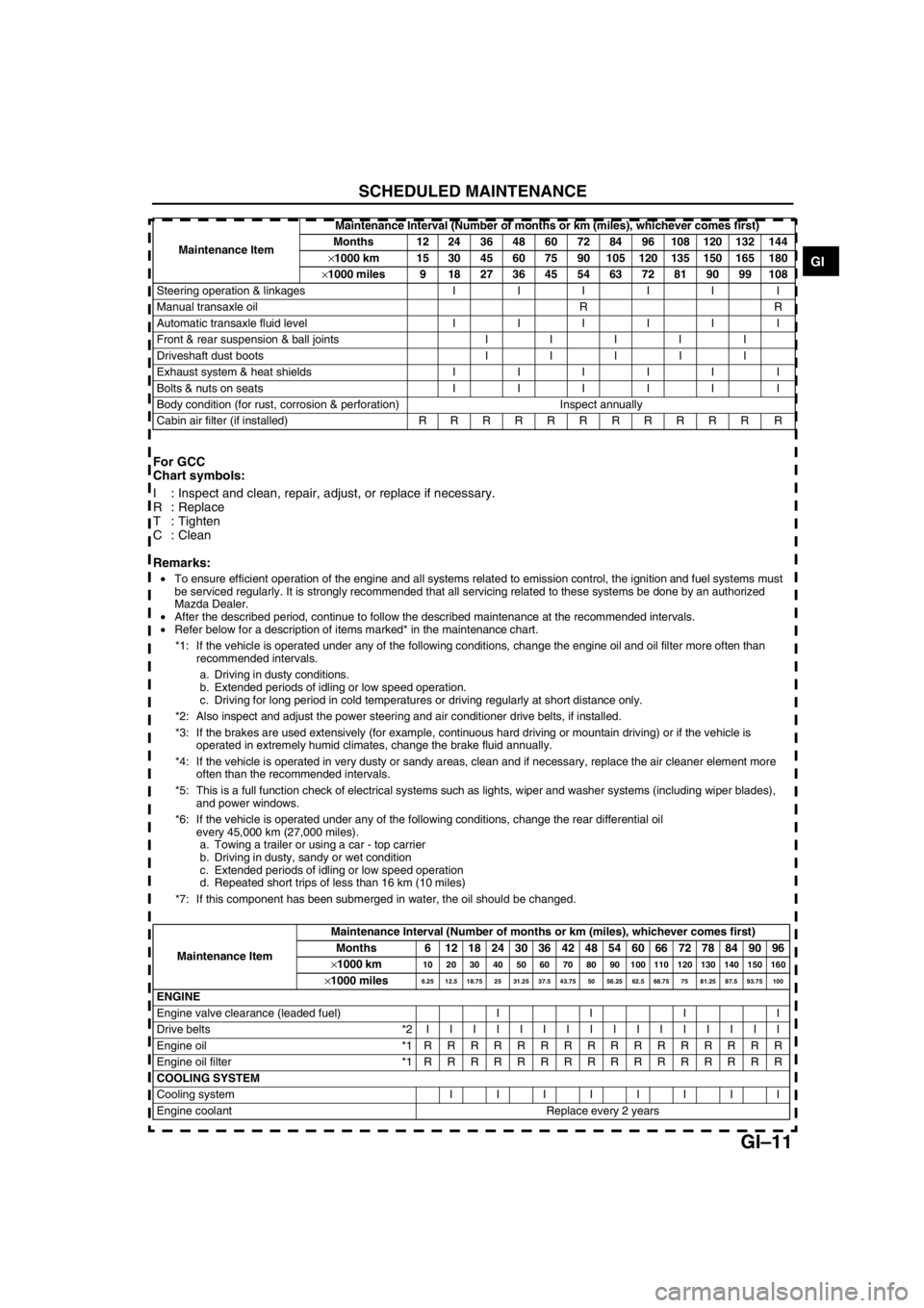

SCHEDULED MAINTENANCE

GI–11

GI

For GCC

Chart symbols:

I : Inspect and clean, repair, adjust, or replace if necessary.

R : Replace

T:Tighten

C : Clean

Remarks:

End Of Sie

Steering operation & linkages IIIII I

Manual transaxle oil R R

Automatic transaxle fluid level IIIII I

Front & rear suspension & ball joints IIIII

Driveshaft dust boots IIIII

Exhaust system & heat shields IIIII I

Bolts & nuts on seats IIIII I

Body condition (for rust, corrosion & perforation) Inspect annually

Cabin air filter (if installed) R R R R R R R R R R R RMaintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 12 24 36 48 60 72 84 96 108 120 132 144

×1000 km 15 30 45 60 75 90 105 120 135 150 165 180

×1000 miles 9 18 27 36 45 54 63 72 81 90 99 108

•To ensure efficient operation of the engine and all systems related to emission control, the ignition and fuel systems must

be serviced regularly. It is strongly recommended that all servicing related to these systems be done by an authorized

Mazda Dealer.

•After the described period, continue to follow the described maintenance at the recommended intervals.

•Refer below for a description of items marked* in the maintenance chart.

*1: If the vehicle is operated under any of the following conditions, change the engine oil and oil filter more often than

recommended intervals.

a. Driving in dusty conditions.

b. Extended periods of idling or low speed operation.

c. Driving for long period in cold temperatures or driving regularly at short distance only.

*2: Also inspect and adjust the power steering and air conditioner drive belts, if installed.

*3: If the brakes are used extensively (for example, continuous hard driving or mountain driving) or if the vehicle is

operated in extremely humid climates, change the brake fluid annually.

*4: If the vehicle is operated in very dusty or sandy areas, clean and if necessary, replace the air cleaner element more

often than the recommended intervals.

*5: This is a full function check of electrical systems such as lights, wiper and washer systems (including wiper blades),

and power windows.

*6: If the vehicle is operated under any of the following conditions, change the rear differential oil

every 45,000 km (27,000 miles).

a. Towing a trailer or using a car - top carrier

b. Driving in dusty, sandy or wet condition

c. Extended periods of idling or low speed operation

d. Repeated short trips of less than 16 km (10 miles)

*7: If this component has been submerged in water, the oil should be changed.

Maintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 6 121824303642485460667278849096

×1000 km

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

×1000 miles6.25 12.5 18.75 25 31.25 37.5 43.75 50 56.25 62.5 68.75 75 81.25 87.5 93.75 100

ENGINE

Engine valve clearance (leaded fuel) I I I I

Drive belts *2IIIIIIIIIIIIIIII

Engine oil *1RRRRRRRRRRRRRRRR

Engine oil filter *1RRRRRRRRRRRRRRRR

COOLING SYSTEM

Cooling system IIIIIIII

Engine coolant Replace every 2 years

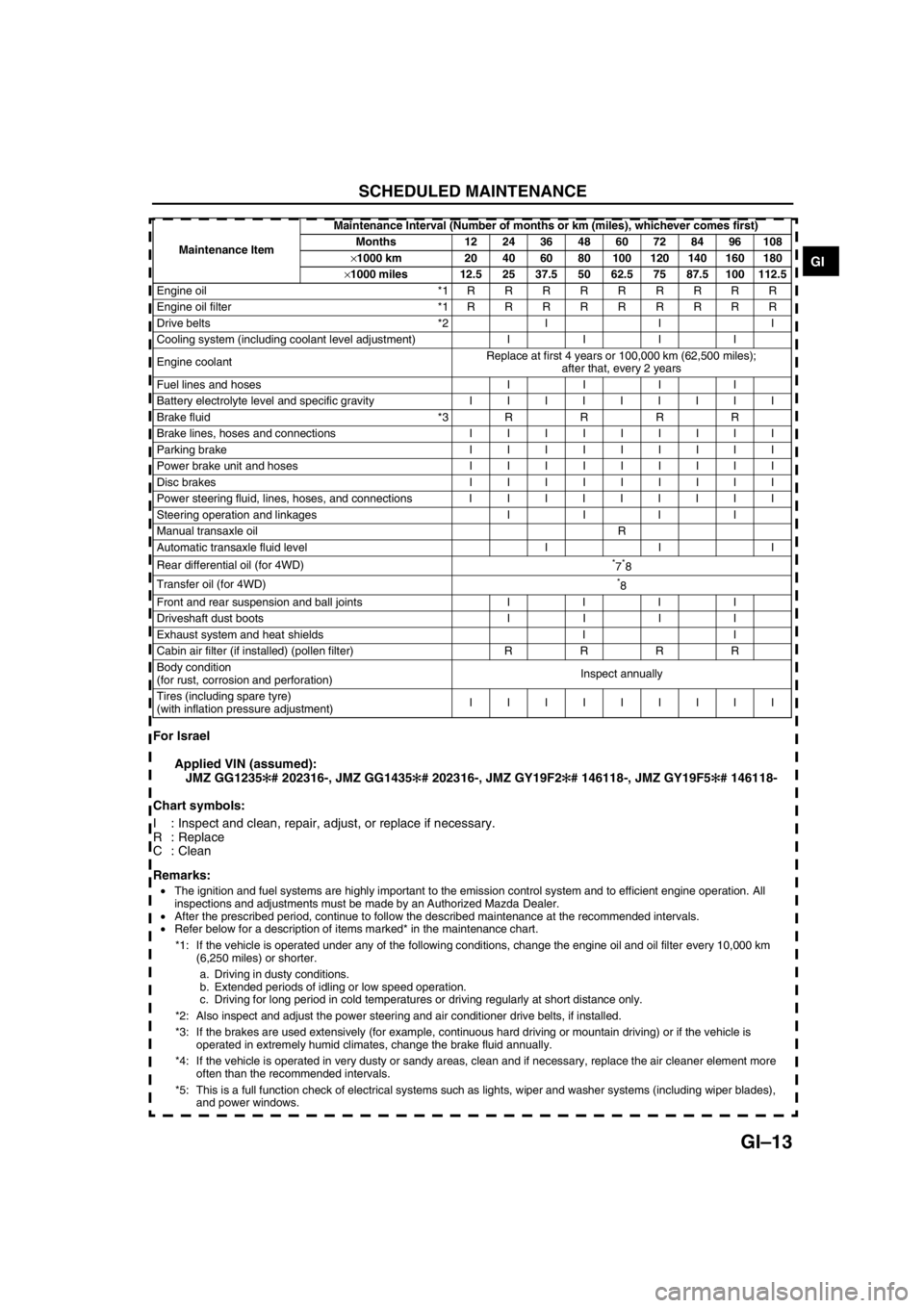

Page 17 of 909

SCHEDULED MAINTENANCE

GI–13

GI

For Israel

Applied VIN (assumed):

JMZ GG1235✻

✻✻ ✻

# 202316-, JMZ GG1435✻

✻✻ ✻

# 202316-, JMZ GY19F2✻

✻✻ ✻

# 146118-, JMZ GY19F5✻

✻✻ ✻

# 146118-

Chart symbols:

I : Inspect and clean, repair, adjust, or replace if necessary.

R : Replace

C : Clean

Remarks:

Engine oil *1 R R R R R R R R R

Engine oil filter *1RRRRRRRRR

Drive belts *2 I I I

Cooling system (including coolant level adjustment) I I I I

Engine coolantReplace at first 4 years or 100,000 km (62,500 miles);

after that, every 2 years

Fuel lines and hoses I I I I

Battery electrolyte level and specific gravity IIIIIIIII

Brake fluid *3 R R R R

Brake lines, hoses and connections IIIIIIIII

Parking brake IIIIIIIII

Power brake unit and hoses IIIIIIIII

Disc brakes IIIIIIIII

Power steering fluid, lines, hoses, and connections IIIIIIIII

Steering operation and linkages I I I I

Manual transaxle oil R

Automatic transaxle fluid level I I I

Rear differential oil (for 4WD)

*7*8

Transfer oil (for 4WD)

*8

Front and rear suspension and ball joints I I I I

Driveshaft dust boots I I I I

Exhaust system and heat shields I I

Cabin air filter (if installed) (pollen filter) R R R R

Body condition

(for rust, corrosion and perforation)Inspect annually

Tires (including spare tyre)

(with inflation pressure adjustment)IIIIIIIII Maintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 12 24 36 48 60 72 84 96 108

×1000 km 20 40 60 80 100 120 140 160 180

×1000 miles 12.5 25 37.5 50 62.5 75 87.5 100 112.5

•The ignition and fuel systems are highly important to the emission control system and to efficient engine operation. All

inspections and adjustments must be made by an Authorized Mazda Dealer.

•After the prescribed period, continue to follow the described maintenance at the recommended intervals.

•Refer below for a description of items marked* in the maintenance chart.

*1: If the vehicle is operated under any of the following conditions, change the engine oil and oil filter every 10,000 km

(6,250 miles) or shorter.

a. Driving in dusty conditions.

b. Extended periods of idling or low speed operation.

c. Driving for long period in cold temperatures or driving regularly at short distance only.

*2: Also inspect and adjust the power steering and air conditioner drive belts, if installed.

*3: If the brakes are used extensively (for example, continuous hard driving or mountain driving) or if the vehicle is

operated in extremely humid climates, change the brake fluid annually.

*4: If the vehicle is operated in very dusty or sandy areas, clean and if necessary, replace the air cleaner element more

often than the recommended intervals.

*5: This is a full function check of electrical systems such as lights, wiper and washer systems (including wiper blades),

and power windows.

Page 19 of 909

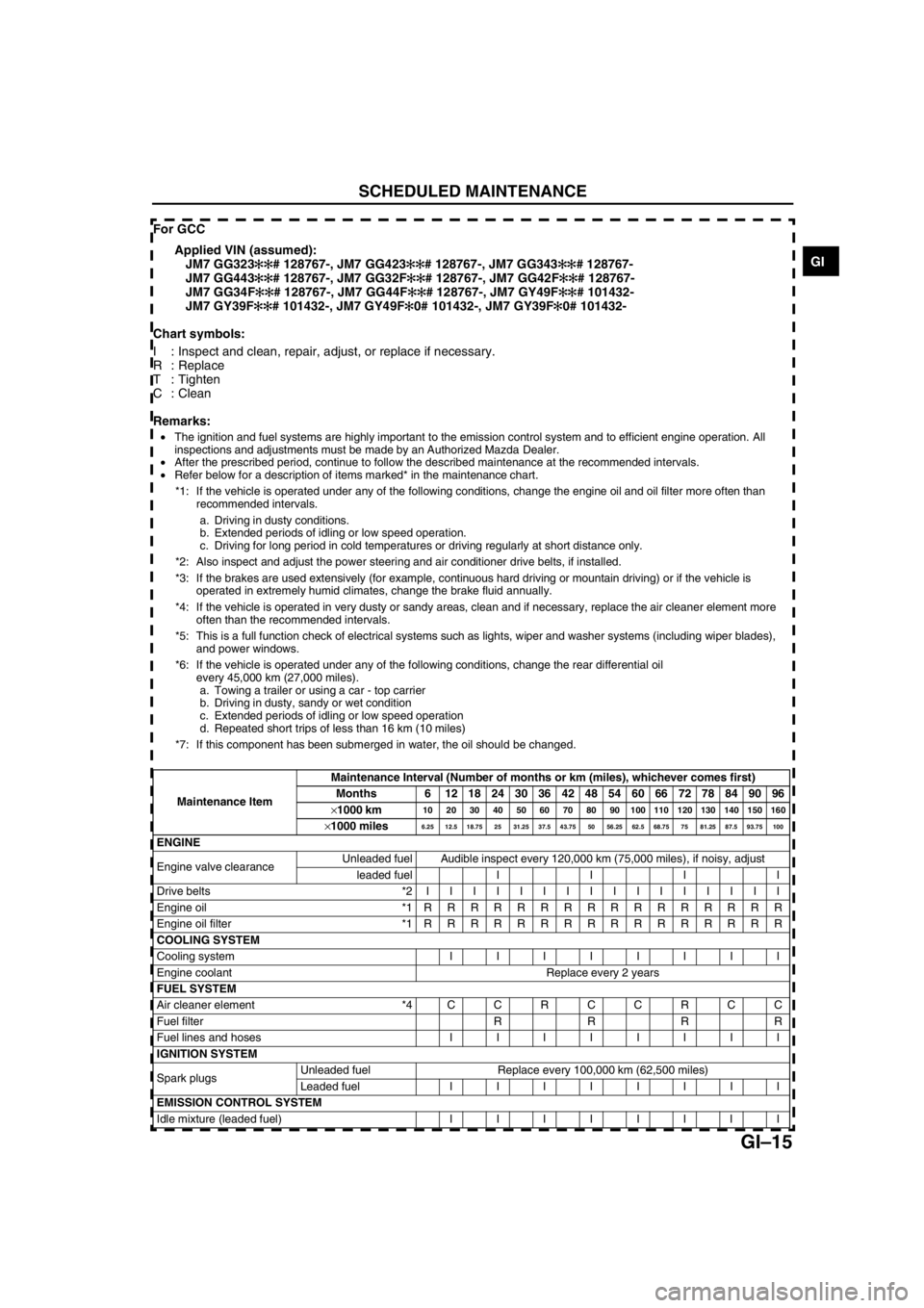

SCHEDULED MAINTENANCE

GI–15

GI

For GCC

Applied VIN (assumed):

JM7 GG323✻✻

✻✻✻✻ ✻✻

# 128767-, JM7 GG423✻✻

✻✻✻✻ ✻✻

# 128767-, JM7 GG343✻✻

✻✻✻✻ ✻✻

# 128767-

JM7 GG443✻✻

✻✻✻✻ ✻✻

# 128767-, JM7 GG32F✻✻

✻✻✻✻ ✻✻

# 128767-, JM7 GG42F✻✻

✻✻✻✻ ✻✻

# 128767-

JM7 GG34F✻

✻✻ ✻✻

✻✻ ✻

# 128767-, JM7 GG44F✻

✻✻ ✻✻

✻✻ ✻

# 128767-, JM7 GY49F✻✻

✻✻✻✻ ✻✻

# 101432-

JM7 GY39F✻✻

✻✻✻✻ ✻✻

# 101432-, JM7 GY49F✻

✻✻ ✻

0# 101432-, JM7 GY39F✻

✻✻ ✻

0# 101432-

Chart symbols:

I : Inspect and clean, repair, adjust, or replace if necessary.

R : Replace

T:Tighten

C : Clean

Remarks:

•The ignition and fuel systems are highly important to the emission control system and to efficient engine operation. All

inspections and adjustments must be made by an Authorized Mazda Dealer.

•After the prescribed period, continue to follow the described maintenance at the recommended intervals.

•Refer below for a description of items marked* in the maintenance chart.

*1: If the vehicle is operated under any of the following conditions, change the engine oil and oil filter more often than

recommended intervals.

a. Driving in dusty conditions.

b. Extended periods of idling or low speed operation.

c. Driving for long period in cold temperatures or driving regularly at short distance only.

*2: Also inspect and adjust the power steering and air conditioner drive belts, if installed.

*3: If the brakes are used extensively (for example, continuous hard driving or mountain driving) or if the vehicle is

operated in extremely humid climates, change the brake fluid annually.

*4: If the vehicle is operated in very dusty or sandy areas, clean and if necessary, replace the air cleaner element more

often than the recommended intervals.

*5: This is a full function check of electrical systems such as lights, wiper and washer systems (including wiper blades),

and power windows.

*6: If the vehicle is operated under any of the following conditions, change the rear differential oil

every 45,000 km (27,000 miles).

a. Towing a trailer or using a car - top carrier

b. Driving in dusty, sandy or wet condition

c. Extended periods of idling or low speed operation

d. Repeated short trips of less than 16 km (10 miles)

*7: If this component has been submerged in water, the oil should be changed.

Maintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 6 121824303642485460667278849096

×1000 km

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

×1000 miles6.25 12.5 18.75 25 31.25 37.5 43.75 50 56.25 62.5 68.75 75 81.25 87.5 93.75 100

ENGINE

Engine valve clearance Unleaded fuel Audible inspect every 120,000 km (75,000 miles), if noisy, adjust

leaded fuel I I I I

Drive belts *2IIIIIIIIIIIIIIII

Engine oil *1RRRRRRRRRRRRRRRR

Engine oil filter *1RRRRRRRRRRRRRRRR

COOLING SYSTEM

Cooling system IIIIIIII

Engine coolant Replace every 2 years

FUEL SYSTEM

Air cleaner element *4CCRCCRCC

Fuel filter R R R R

Fuel lines and hoses IIIIIIII

IGNITION SYSTEM

Spark plugs Unleaded fuel Replace every 100,000 km (62,500 miles)

Leaded fuel IIIIIIII

EMISSION CONTROL SYSTEM

Idle mixture (leaded fuel) IIIIIIII

Page 116 of 909

F1–28

FUEL SYSTEM

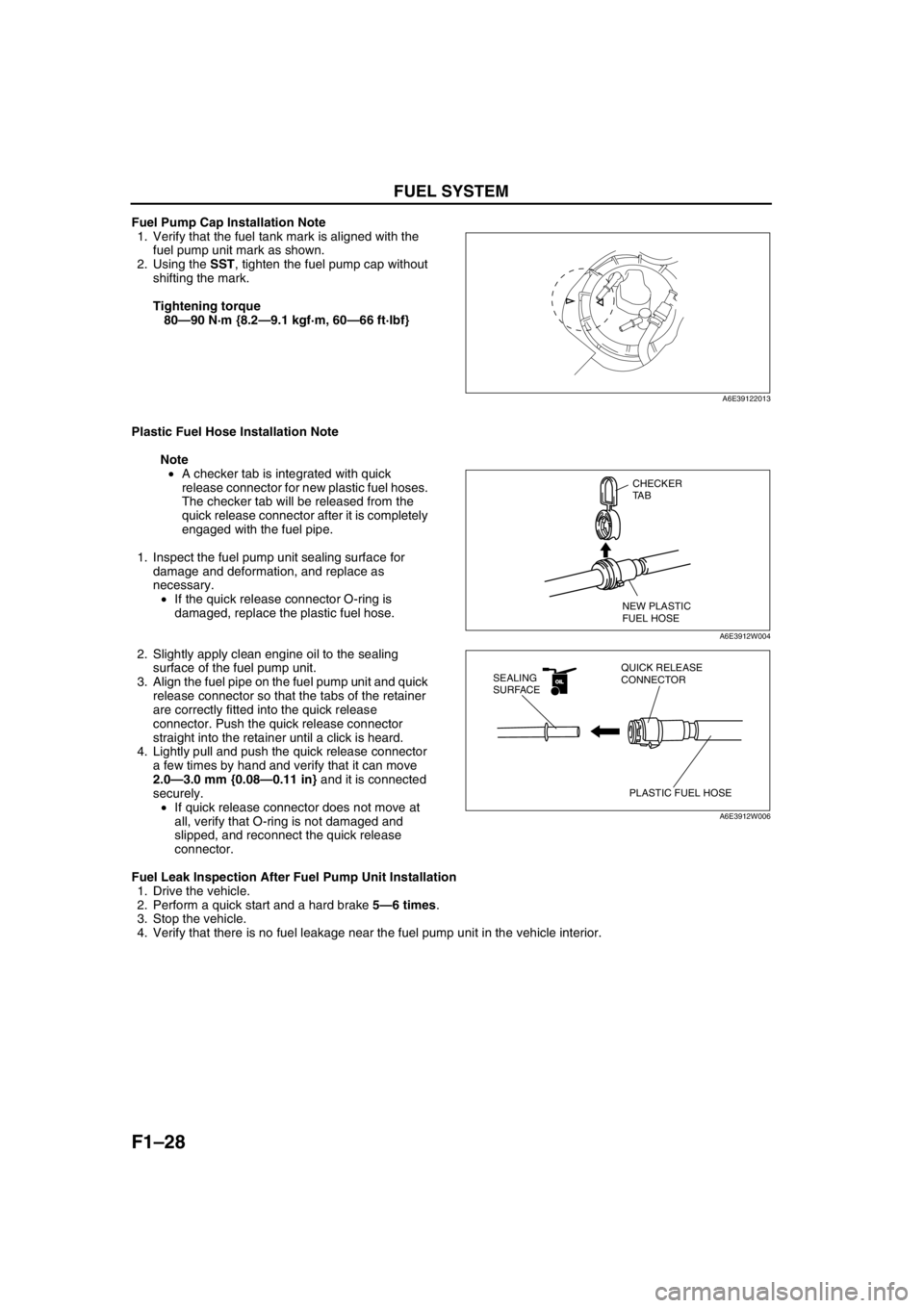

Fuel Pump Cap Installation Note

1. Verify that the fuel tank mark is aligned with the

fuel pump unit mark as shown.

2. Using the SST, tighten the fuel pump cap without

shifting the mark.

Tightening torque

80—90 N·m {8.2—9.1 kgf·m, 60—66 ft·lbf}

Plastic Fuel Hose Installation Note

Note

•A checker tab is integrated with quick

release connector for new plastic fuel hoses.

The checker tab will be released from the

quick release connector after it is completely

engaged with the fuel pipe.

1. Inspect the fuel pump unit sealing surface for

damage and deformation, and replace as

necessary.

•If the quick release connector O-ring is

damaged, replace the plastic fuel hose.

2. Slightly apply clean engine oil to the sealing

surface of the fuel pump unit.

3. Align the fuel pipe on the fuel pump unit and quick

release connector so that the tabs of the retainer

are correctly fitted into the quick release

connector. Push the quick release connector

straight into the retainer until a click is heard.

4. Lightly pull and push the quick release connector

a few times by hand and verify that it can move

2.0—3.0 mm {0.08—0.11 in} and it is connected

securely.

•If quick release connector does not move at

all, verify that O-ring is not damaged and

slipped, and reconnect the quick release

connector.

Fuel Leak Inspection After Fuel Pump Unit Installation

1. Drive the vehicle.

2. Perform a quick start and a hard brake 5—6 times.

3. Stop the vehicle.

4. Verify that there is no fuel leakage near the fuel pump unit in the vehicle interior.

End Of Sie

A6E39122013

CHECKER

TA B

NEW PLASTIC

FUEL HOSE

A6E3912W004

OILOIL

PLASTIC FUEL HOSE QUICK RELEASE

CONNECTOR SEALING

SURFACE

A6E3912W006

Page 190 of 909

F2–38

INTAKE-AIR SYSTEM

TURBOCHARGER INSPECTIONA6E401013700201

Note

•If the following problems exist, diagnosis the turbocharger using the following symptom troubleshooting

procedures.

1. Lack of power: perform “NO.12 LACK/LOSS OF POWER”. (See F2–195 NO.12 LACK/LOSS OF POWER-

ACCELERATION/CRUISE.)

2. Oil leak: perform “NO.16 HIGH OIL CONSUMPTION/LEAKAGE”. (See F2–209 NO.16 HIGH OIL

CONSUMPTION/LEAKAGE.)

3. Noise: perform “NO. 21 ENGINE NOISE”. (See F2–217 NO.21 ENGINE NOISE.)

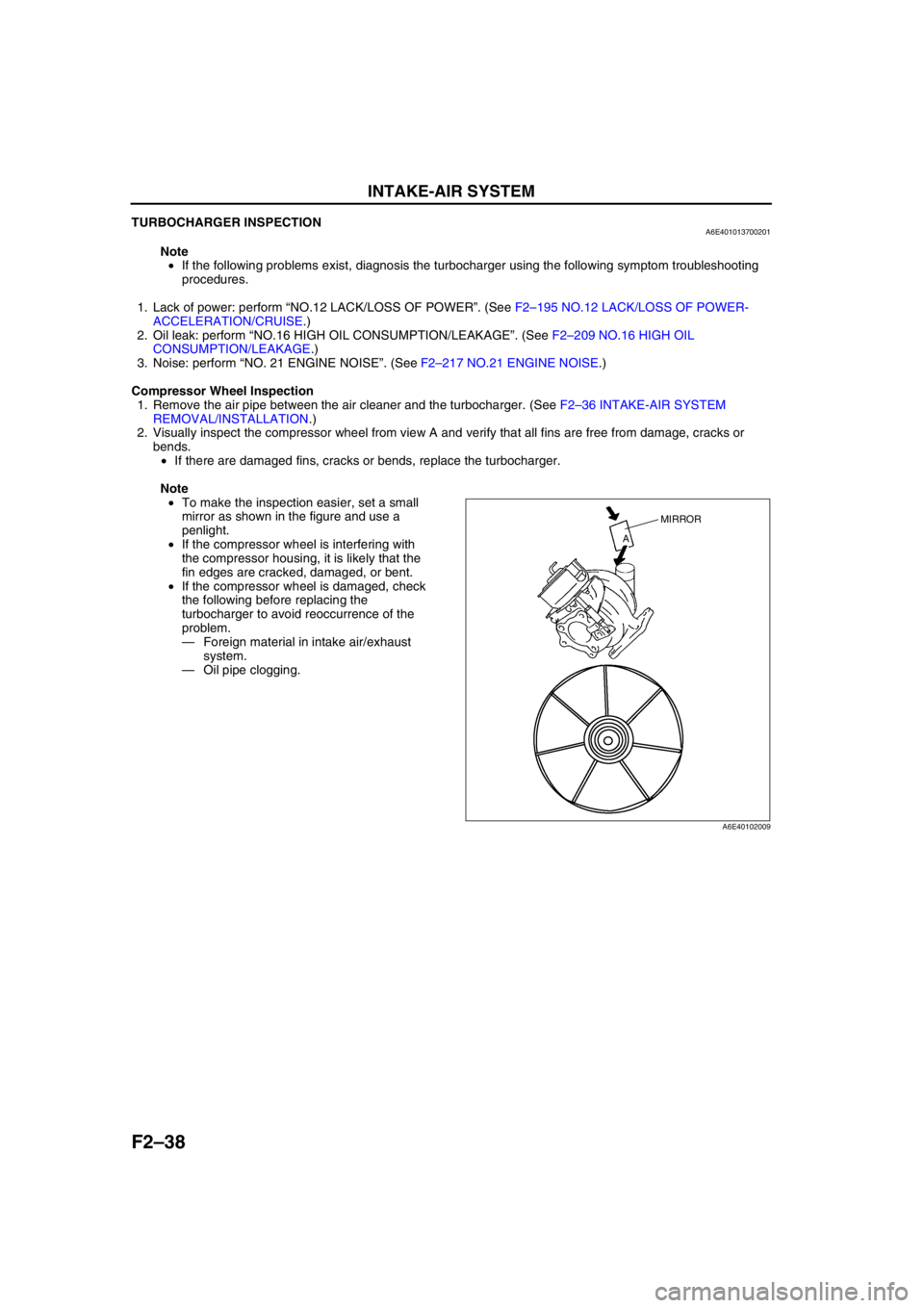

Compressor Wheel Inspection

1. Remove the air pipe between the air cleaner and the turbocharger. (See F2–36 INTAKE-AIR SYSTEM

REMOVAL/INSTALLATION.)

2. Visually inspect the compressor wheel from view A and verify that all fins are free from damage, cracks or

bends.

•If there are damaged fins, cracks or bends, replace the turbocharger.

Note

•To make the inspection easier, set a small

mirror as shown in the figure and use a

penlight.

•If the compressor wheel is interfering with

the compressor housing, it is likely that the

fin edges are cracked, damaged, or bent.

•If the compressor wheel is damaged, check

the following before replacing the

turbocharger to avoid reoccurrence of the

problem.

—Foreign material in intake air/exhaust

system.

—Oil pipe clogging.

MIRROR

A

A6E40102009

Page 201 of 909

FUEL SYSTEM

F2–49

F2

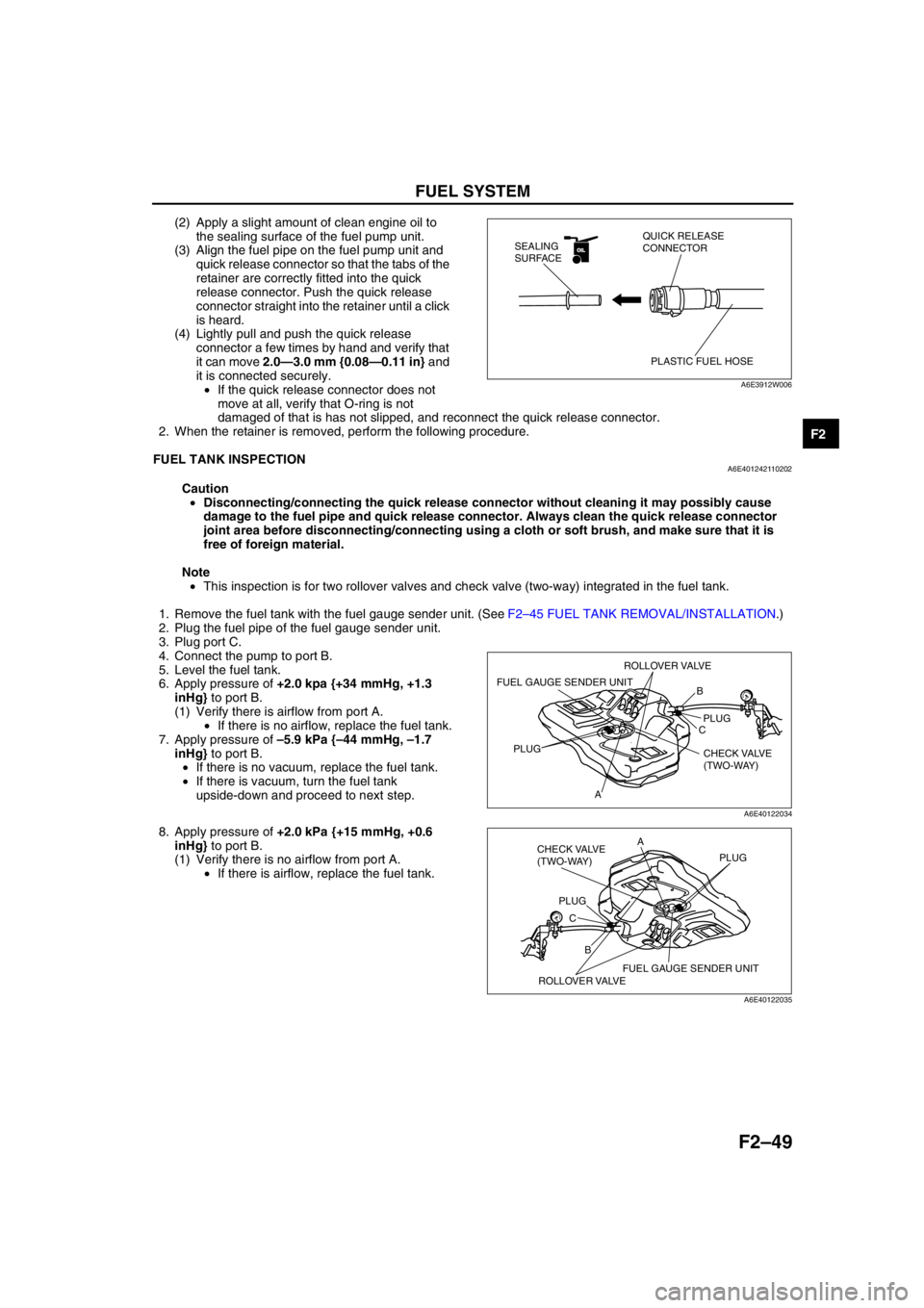

(2) Apply a slight amount of clean engine oil to

the sealing surface of the fuel pump unit.

(3) Align the fuel pipe on the fuel pump unit and

quick release connector so that the tabs of the

retainer are correctly fitted into the quick

release connector. Push the quick release

connector straight into the retainer until a click

is heard.

(4) Lightly pull and push the quick release

connector a few times by hand and verify that

it can move 2.0—3.0 mm {0.08—0.11 in} and

it is connected securely.

•If the quick release connector does not

move at all, verify that O-ring is not

damaged of that is has not slipped, and reconnect the quick release connector.

2. When the retainer is removed, perform the following procedure.

End Of Sie

FUEL TANK INSPECTIONA6E401242110202

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

Note

•This inspection is for two rollover valves and check valve (two-way) integrated in the fuel tank.

1. Remove the fuel tank with the fuel gauge sender unit. (See F2–45 FUEL TANK REMOVAL/INSTALLATION.)

2. Plug the fuel pipe of the fuel gauge sender unit.

3. Plug port C.

4. Connect the pump to port B.

5. Level the fuel tank.

6. Apply pressure of +2.0 kpa {+34 mmHg, +1.3

inHg} to port B.

(1) Verify there is airflow from port A.

•If there is no airflow, replace the fuel tank.

7. Apply pressure of –5.9 kPa {–44 mmHg, –1.7

inHg} to port B.

•If there is no vacuum, replace the fuel tank.

•If there is vacuum, turn the fuel tank

upside-down and proceed to next step.

8. Apply pressure of +2.0 kPa {+15 mmHg, +0.6

inHg} to port B.

(1) Verify there is no airflow from port A.

•If there is airflow, replace the fuel tank.

End Of Sie

OILOIL

PLASTIC FUEL HOSE QUICK RELEASE

CONNECTOR SEALING

SURFACE

A6E3912W006

B

C

APLUG

PLUG

CHECK VALVE

(TWO-WAY)

FUEL GAUGE SENDER UNIT

ROLLOVER VALVE

A6E40122034

B CA

PLUGPLUG

CHECK VALVE

(TWO-WAY)

FUEL GAUGE SENDER UNIT

ROLLOVER VALVE

A6E40122035

Page 380 of 909

F2–228

TROUBLESHOOTING

Inspection Method for Sensors

1. Connect the WDS or equivalent to the DLC-2.

2. Turn the engine switch to ON (Engine OFF).

Note

•If the engine starts and runs, perform the following steps at idle.

3. Access PIDs for the switch you are inspecting.

4. Vibrate the sensor slightly with your finger.

•If the PID value is unstable or malfunction occurs, check for poor connection and/or poorly mounted

sensor.

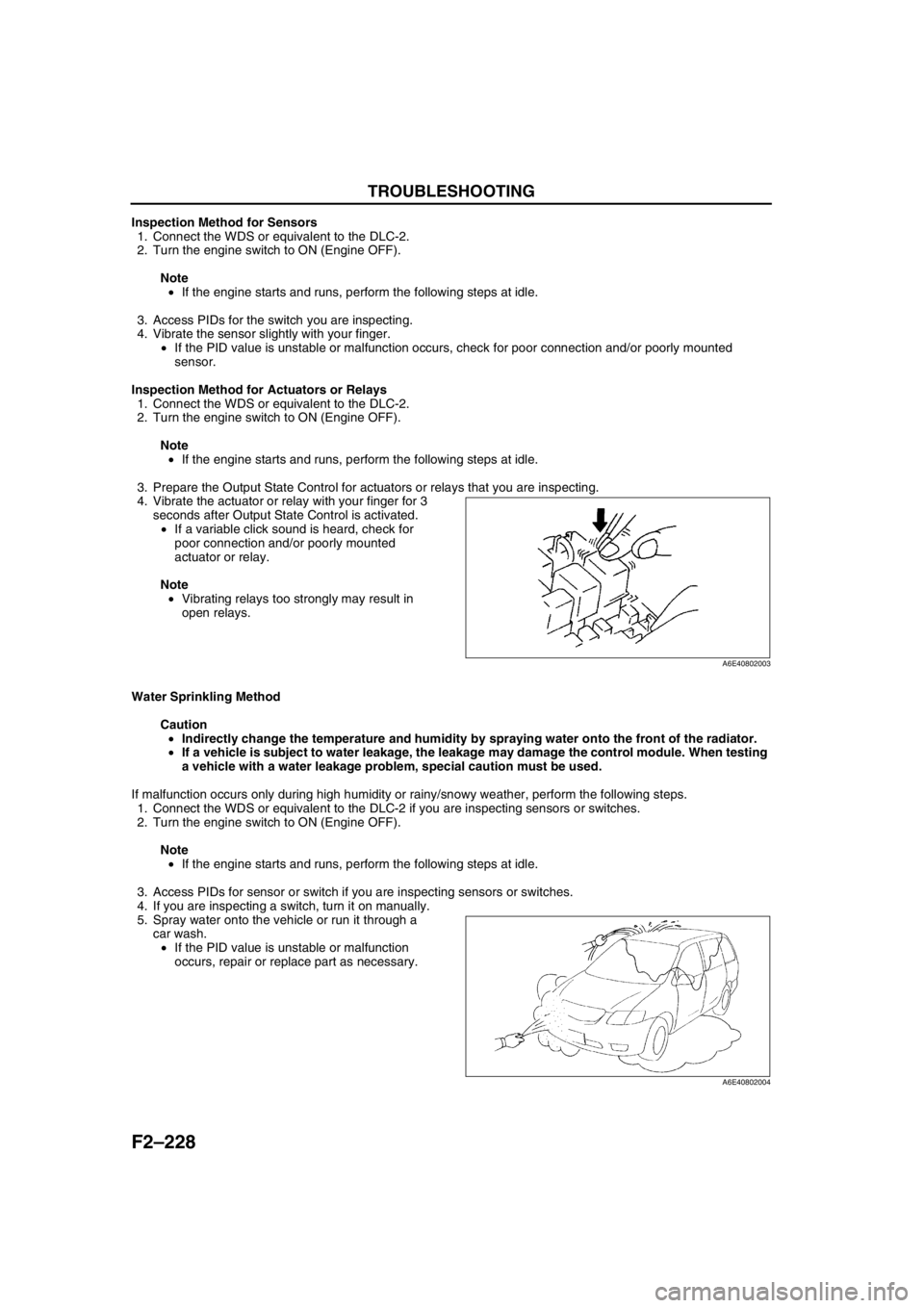

Inspection Method for Actuators or Relays

1. Connect the WDS or equivalent to the DLC-2.

2. Turn the engine switch to ON (Engine OFF).

Note

•If the engine starts and runs, perform the following steps at idle.

3. Prepare the Output State Control for actuators or relays that you are inspecting.

4. Vibrate the actuator or relay with your finger for 3

seconds after Output State Control is activated.

•If a variable click sound is heard, check for

poor connection and/or poorly mounted

actuator or relay.

Note

•Vibrating relays too strongly may result in

open relays.

Water Sprinkling Method

Caution

•Indirectly change the temperature and humidity by spraying water onto the front of the radiator.

•If a vehicle is subject to water leakage, the leakage may damage the control module. When testing

a vehicle with a water leakage problem, special caution must be used.

If malfunction occurs only during high humidity or rainy/snowy weather, perform the following steps.

1. Connect the WDS or equivalent to the DLC-2 if you are inspecting sensors or switches.

2. Turn the engine switch to ON (Engine OFF).

Note

•If the engine starts and runs, perform the following steps at idle.

3. Access PIDs for sensor or switch if you are inspecting sensors or switches.

4. If you are inspecting a switch, turn it on manually.

5. Spray water onto the vehicle or run it through a

car wash.

•If the PID value is unstable or malfunction

occurs, repair or replace part as necessary.

End Of Sie

A6E40802003

A6E40802004

Page 547 of 909

K2–132

ON-BOARD DIAGNOSTIC

DTC P0711A6E577018901207

Diagnostic procedure

End Of Sie

DTC P0711 Transaxle fluid temperature (TFT) sensor malfunction (stuck)

DETECTION

CONDITION•TFT sensor signal stays outside normal temperature range for 10 minute or more.

Diagnostic support note:

•This is a continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction conditions in two consecutive drive cycles.

•PENDING CODE is available.

•FREEZE FRAME DATA is available.

•AT warning light does not indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•TFT sensor malfunction.

•Connector corrosion.

•TCM malfunction.

STEP INSPECTION ACTION

1VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•Has FREEZE FRAME PID DATA been

recorded?Yes Go to next step.

No Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3INSPECT TFT SENSOR VOLTAGE

•Connect voltmeter to TCM terminal 1F.

•Turn ignition key to ON (engine OFF).

•Is TCM terminal voltage 1.55 V?Yes Go to next step.

No Go to Step 6.

4VERIFY CURRENT INPUT SIGNAL STATUS - IS

CONCERN INTERMITTENT OR CONSTANT?

•Start engine.

•Drive vehicle at 60 km/h {37 mph} or above

for 10 minutes or more.

—ATF 20 °C {68 °F}: 1.55 V

—ATF 60 °C {140 °F}: 0.7 V

•Does TCM terminal voltage change?Yes Go to Step 6.

No Go to next step.

5INSPECT TERMINAL CONDITION

•Turn ignition key to OFF.

•Disconnect terminal component No.2 (8-pin).

•Inspect terminals for corrosion.

•Are terminals okay?Yes Replace TFT sensor, then go to next step.

No Repair or replace terminals, then go to next step.

6VERIFY TROUBLESHOOTING OF DTC P0711

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Decrease ATF temperature to 20 °C {68 °F} or

below.

•Drive vehicle at 60 km/h {37 mph} or above

for 10 minutes or more.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

7VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed.

Page 548 of 909

ON-BOARD DIAGNOSTIC

K2–133

K2

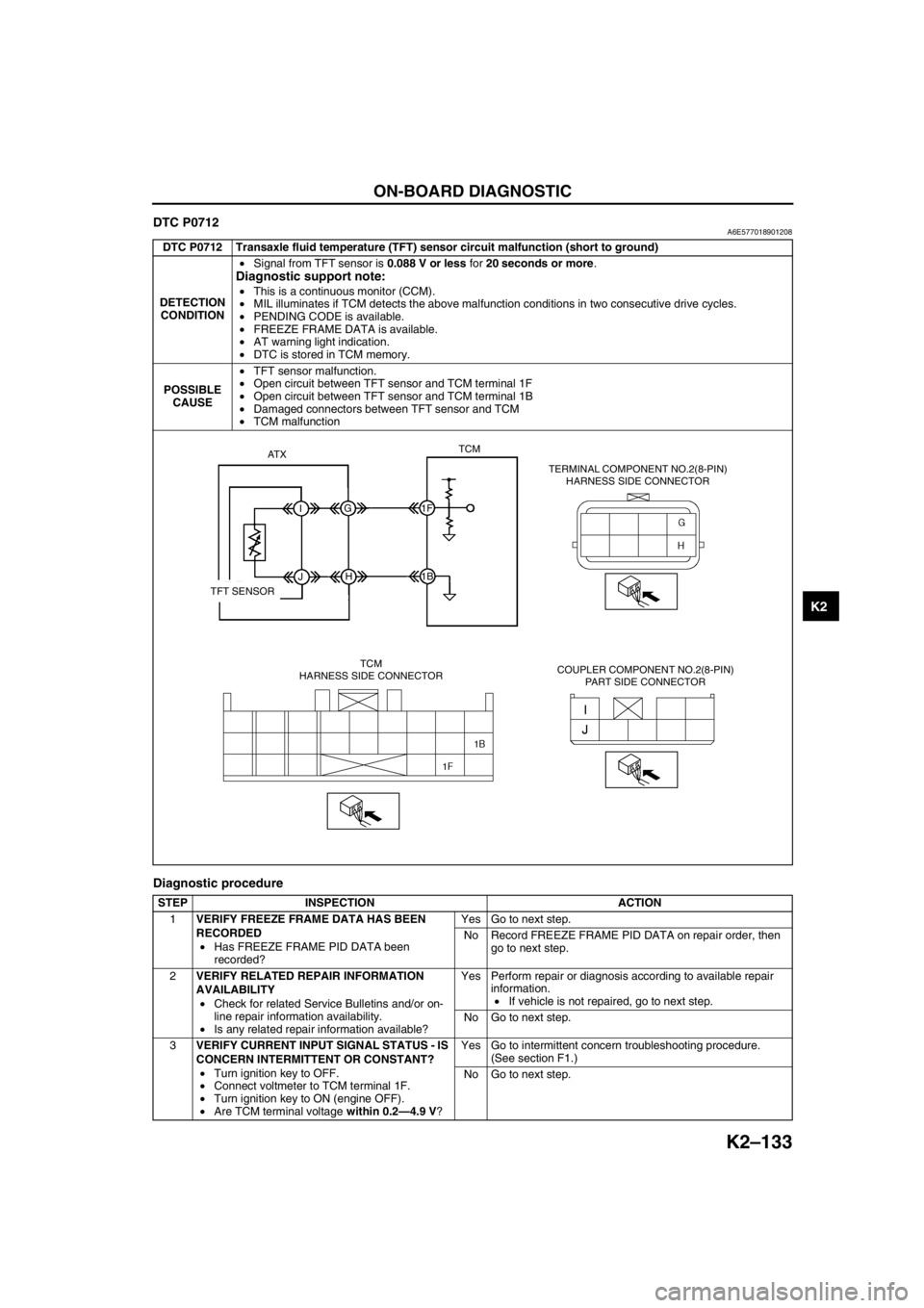

DTC P0712A6E577018901208

Diagnostic procedure

DTC P0712 Transaxle fluid temperature (TFT) sensor circuit malfunction (short to ground)

DETECTION

CONDITION•Signal from TFT sensor is 0.088 V or less for 20 seconds or more.

Diagnostic support note:

•This is a continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction conditions in two consecutive drive cycles.

•PENDING CODE is available.

•FREEZE FRAME DATA is available.

•AT warning light indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•TFT sensor malfunction.

•Open circuit between TFT sensor and TCM terminal 1F

•Open circuit between TFT sensor and TCM terminal 1B

•Damaged connectors between TFT sensor and TCM

•TCM malfunction

STEP INSPECTION ACTION

1VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•Has FREEZE FRAME PID DATA been

recorded?Yes Go to next step.

No Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3VERIFY CURRENT INPUT SIGNAL STATUS - IS

CONCERN INTERMITTENT OR CONSTANT?

•Turn ignition key to OFF.

•Connect voltmeter to TCM terminal 1F.

•Turn ignition key to ON (engine OFF).

•Are TCM terminal voltage within 0.2—4.9 V?Yes Go to intermittent concern troubleshooting procedure.

(See section F1.)

No Go to next step.

AT XTCM

IG1F

1B

JH

TFT SENSOR

TCM

HARNESS SIDE CONNECTORTERMINAL COMPONENT NO.2(8-PIN)

HARNESS SIDE CONNECTOR

COUPLER COMPONENT NO.2(8-PIN)

PART SIDE CONNECTOR