water pump MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 328 of 909

F2–176

TROUBLESHOOTING

NO.4 HARD START/LONG CRANK/ERRATIC START/ERRATIC CRANKA6E408018881206

Diagnostic Procedure

4 HARD START/LONG CRANK/ERRATIC START/ERRATIC CRANK

DESCRIPTION•Starter cranks engine at normal speed but engine requires excessive cranking time before starting.

•Battery is in normal condition.

POSSIBLE

CAUSE•Poor fuel quality

•Intake-air system restriction or clogging

•Starting system malfunction

•Inadequate fuel pressure

•Fuel pressure limiter malfunction (built-in common rail)

•Suction control valve malfunction (built-in supply pump)

•Engine overheating

•Glow system malfunction

•Fuel filter clogging or restriction

•Fuel line clogging or restriction

•Fuel leakage

•Exhaust system and/or catalyst converter restriction or clogging

•Incorrect fuel injection timing

•Erratic signal from CKP sensor

•Erratic signal from CMP sensor

•ECT sensor or related circuit malfunction

•Accelerator position sensor or related circuit malfunction

•Accelerator position sensor misadjustment

•MAF/IAT sensor or related circuit malfunction

•Fuel pressure sensor or related circuit malfunction

•Supply pump malfunction

•Fuel injector malfunction

•Low engine compression

•IDM or related circuit malfunction

•EGR system malfunction

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before performing the fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injury or death

and damage. Fuel can also irritate skin and eyes. To prevent this, always complete “BEFORE

REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this manual.

STEP INSPECTION RESULTS ACTION

1 Inspect for following:

•Fuel quality (e.g.: include water

contamination, winter/summer blend)

•Fuel line/fuel filter clogging

•Intake-air system restriction

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 1.

2 Is engine overheating? Yes Go to symptom troubleshooting “NO.17 COOLING

SYSTEM CONCERNS-OVERHEATING”.

No Go to next step.

3 Connect WDS or equivalent to DLC-2.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to next step.

Page 338 of 909

F2–186

TROUBLESHOOTING

NO.8 ENGINE RUNS ROUGH/ROLLING IDLEA6E408018881210

Diagnostic Procedure

8 ENGINE RUNS ROUGH/ROLLING IDLE

DESCRIPTION•Engine speed fluctuates between specified idle speed and lower speed and engine shakes excessively.

•Idle speed is too slow and engine shakes excessively.

POSSIBLE

CAUSE•Poor fuel quality

•Air leakage from intake-air system

•Intake-air system restriction

•Incorrect idle speed

•Engine overheating

•Cooling fan No.1 system malfunction

•A/C system improper operation

•EGR system improper operation

•EGR water cooler malfunction

•Fuel leakage

•Inadequate fuel pressure

•Fuel pressure sensor or related circuit malfunction

•Suction control valve malfunction (built-in supply pump)

•Fuel pressure limiter malfunction (built-in common rail)

•Fuel filter clogging

•Fuel line restriction

•Incorrect fuel injection timing

•Erratic signal from CKP sensor

•Erratic signal from CMP sensor

•ECT sensor or related circuit malfunction

•Idle switch misadjustment

•Idle switch or related circuit malfunction

•Accelerator position sensor misadjustment

•Accelerator position sensor or related circuit malfunction

•MAF/IAT sensor malfunction

•Neutral switch or related circuit malfunction

•Supply pump malfunction

•Fuel injector malfunction

•Low engine compression

•Improper valve timing

•Engine compression excessive unbalance for each cylinder

•Unbalanced fuel injection amount for each cylinder

•IDM or related circuit malfunction

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before performing the fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injury or death

and damage. Fuel can also irritate skin and eyes. To prevent this, always complete “BEFORE

REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this manual.

STEP INSPECTION RESULTS ACTION

1 Inspect for following:

•Fuel quality (e.g.: including water

contamination, winter/summer blend)

•Fuel line/fuel filter clogging

•Loose bands on intake-air system

•Cracks on intake-air system parts

•Intake-air system restriction

•Vacuum leakage

•Cooling fan No.1 system operation

Are all items okay?Yes Go to next step.

No Service as necessary

Repeat Step 1.

2 Is engine overheating? Yes Go to symptom troubleshooting “NO.17 COOLING

SYSTEM CONCERNS—OVERHEATING.”

No Go to next step.

Page 340 of 909

F2–188

TROUBLESHOOTING

End Of Sie

13 Is engine compression correct?

(See B2–8 COMPRESSION INSPECTION)Yes Go to next step.

No Inspect for following:

•Damaged valve seat

•Worn valve stem and valve guide

•Worn or stuck piston ring

•Worn piston, piston ring or cylinder

•Improper valve timing

Service as necessary.

14 Inspect fuel injector.

(See F2–56 FUEL INJECTOR INSPECTION)

Is fuel injector okay?Yes Go to next step.

No Repair or replace as necessary.

15 Inspect EGR system operation.

Is EGR system operation normal?Yes Go to next step.

No Repair or replace malfunctioning part according to

EGR system operation results.

16 Inspect EGR water cooler for following:

•Coolant passage clogging/restriction

•Exhaust gas clogging/restriction

Is EGR water cooler okay?Yes Go to next step.

No Service as necessary.

17 Inspect IDM.

(See F2–84 INJECTOR DRIVER MODULE

(IDM) INSPECTION)

Is IDM okay?Yes Remove and inspect supply pump and common rail.

No Repair or replace as necessary.

18 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. (See F2–64 PCM REMOVAL/INSTALLATION) STEP INSPECTION RESULTS ACTION

Page 342 of 909

F2–190

TROUBLESHOOTING

NO.10 LOW IDLE/STALLS DURING DECELERATIONA6E408018881212

Diagnostic Procedure

10 LOW IDLE/STALLS DURING DECELERATION

DESCRIPTION•Engine stops unexpectedly at beginning of deceleration or recovery from deceleration.

POSSIBLE

CAUSE•Intake-air system restriction or clogging

•Poor fuel quality

•A/C system improper operation

•Inadequate fuel pressure

•Suction control valve malfunction (built-in supply pump)

•Fuel pressure limiter malfunction (built-in common rail)

•Fuel leakage

•Fuel line restriction or clogging

•Fuel filter restriction or clogging

•Incorrect fuel injection timing

•Incorrect idle speed

•Erratic signal from CKP sensor

•Erratic signal from CMP sensor

•Supply pump malfunction

•Fuel injector malfunction

•Low engine compression

•Improper valve timing

•Glow system malfunction

•EGR system malfunction

•MAF/IAT sensor or related circuit malfunction

•ECT sensor or related circuit malfunction

•Fuel pressure sensor or related circuit malfunction

•Neutral switch malfunction or related circuit malfunction

•Accelerator position sensor or related circuit malfunction

•Idle switch or related circuit malfunction

•Incorrect adjustment accelerator position sensor and/or idle switch

•IDM or related circuit malfunction

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before performing the fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injury or death

and damage. Fuel can also irritate skin and eyes. To prevent this, always complete “BEFORE

REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this manual.

STEP INSPECTION RESULTS ACTION

1 Does engine idle rough? Yes Go to symptom troubleshooting “NO.8 ENGINE RUNS

ROUGH/ROLLING IDLE”.

No Go to next step.

2 Inspect for following:

•Fuel line/fuel filter clogging or restriction

•Intake-air system restriction or clogging

•Fuel quality (e.g.: include water

contamination, winter/summer blend)

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 2.

3 Perform self-test function using WDS or

equivalent.

Turn engine switch to ON.

Retrieve any DTC.

Is DTC displayed?YesDTC is displayed:

Go to appropriate DTC test.

Communication error message is displayed:

Inspect for following:

•Open circuit between PCM control relay and PCM

terminal 53 or 79

•Open circuit PCM control relay and PCM terminal

69

•PCM control relay stuck open

•Open or poor GND circuit (PCM terminal 65, 85,

103 or 104)

•Poor connection vehicle body GND

NoNo DTC is displayed:

Go to next step.

4 Inspect idle speed.

(See F2–34 IDLE SPEED INSPECTION)

Is idle speed correct?Yes Go to next step.

No Repair or replace malfunctioning part according to idle

speed inspection results.

Page 351 of 909

TROUBLESHOOTING

F2–199

F2

NO.13 KNOCKING/PINGINGA6E408018881215

Diagnostic Procedure

13 KNOCKING/PINGING

DESCRIPTION•Excessive shrilly knocking sound from engine.

POSSIBLE

CAUSE•Poor fuel quality

•Air leakage from intake-air system

•Intake-air system restriction or clogging

•Variable swirl control (VSC) system malfunction

•Variable boost control (VBC) system malfunction

•Intake shutter valve stuck close

•VSC valve stuck close

•Glow system malfunction

•Low engine compression

•Improper valve timing

•Low coolant temperature

•Incorrect fuel injection timing

•Erratic signal from CKP sensor

•Erratic signal from CMP sensor

•ECT sensor or related circuit malfunction

•MAF/IAT sensor or related circuit malfunction

•IAT sensor No.2 or related circuit malfunction

•Boost sensor or related malfunction

•Fuel pressure sensor or related circuit malfunction

•Accelerator position sensor or related circuit malfunction

•Excessive fuel pressure

•Fuel return line clogging or restriction

•EGR system malfunction

•Exhaust system and/or catalyst converter restriction

•Turbocharger malfunction

•Charge air cooler malfunction

•Suction control valve malfunction (built-in supply pump)

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before performing the fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injury or death

and damage. Fuel can also irritate skin and eyes. To prevent this, always complete “BEFORE

REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this manual.

STEP INSPECTION RESULTS ACTION

1 Does engine run cold? Yes Go to symptom troubleshooting “NO.18 COOLING

SYSTEM CONCERNS—RUNS COLD”.

No Go to next step.

2 Inspect for following:

•Fuel quality (e.g.: including water

contamination, winter/summer blend)

•Fuel return line clogging and/or restriction

•Intake-air system restriction or clogging

•Exhaust system and/or catalyst converter

restriction or clogging

•Charge air cooler condition (restriction or

damaged)

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 2.

3 Connect WDS or equivalent to DLC-2.

Access ECT PID.

Verify ECT PID is above 80 °C {176 °F}?Yes Go to next step.

No Inspect ECT PID.

Page 354 of 909

F2–202

TROUBLESHOOTING

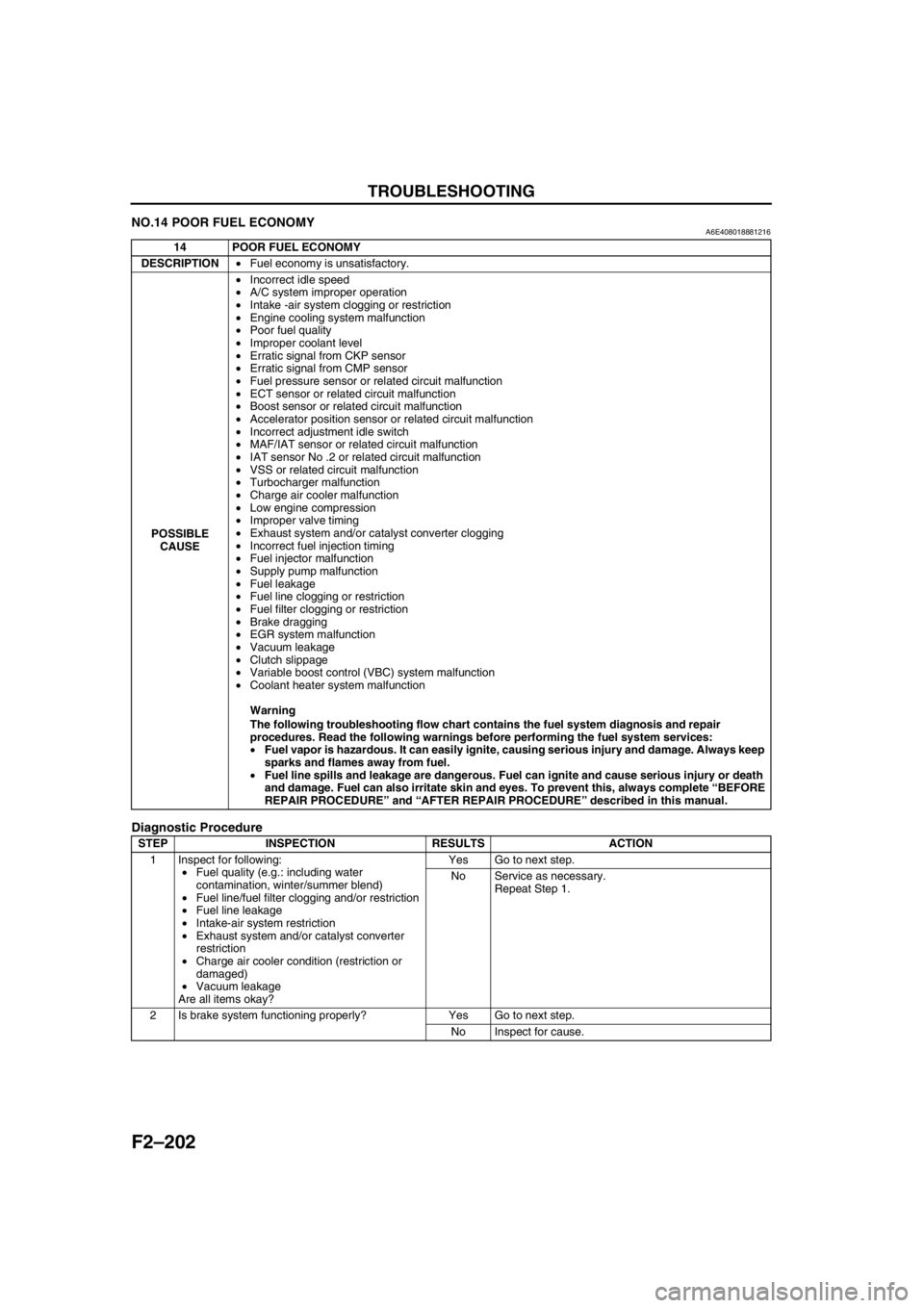

NO.14 POOR FUEL ECONOMYA6E408018881216

Diagnostic Procedure

14 POOR FUEL ECONOMY

DESCRIPTION•Fuel economy is unsatisfactory.

POSSIBLE

CAUSE•Incorrect idle speed

•A/C system improper operation

•Intake -air system clogging or restriction

•Engine cooling system malfunction

•Poor fuel quality

•Improper coolant level

•Erratic signal from CKP sensor

•Erratic signal from CMP sensor

•Fuel pressure sensor or related circuit malfunction

•ECT sensor or related circuit malfunction

•Boost sensor or related circuit malfunction

•Accelerator position sensor or related circuit malfunction

•Incorrect adjustment idle switch

•MAF/IAT sensor or related circuit malfunction

•IAT sensor No .2 or related circuit malfunction

•VSS or related circuit malfunction

•Turbocharger malfunction

•Charge air cooler malfunction

•Low engine compression

•Improper valve timing

•Exhaust system and/or catalyst converter clogging

•Incorrect fuel injection timing

•Fuel injector malfunction

•Supply pump malfunction

•Fuel leakage

•Fuel line clogging or restriction

•Fuel filter clogging or restriction

•Brake dragging

•EGR system malfunction

•Vacuum leakage

•Clutch slippage

•Variable boost control (VBC) system malfunction

•Coolant heater system malfunction

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before performing the fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injury or death

and damage. Fuel can also irritate skin and eyes. To prevent this, always complete “BEFORE

REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this manual.

STEP INSPECTION RESULTS ACTION

1 Inspect for following:

•Fuel quality (e.g.: including water

contamination, winter/summer blend)

•Fuel line/fuel filter clogging and/or restriction

•Fuel line leakage

•Intake-air system restriction

•Exhaust system and/or catalyst converter

restriction

•Charge air cooler condition (restriction or

damaged)

•Vacuum leakage

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 1.

2 Is brake system functioning properly? Yes Go to next step.

No Inspect for cause.

Page 357 of 909

TROUBLESHOOTING

F2–205

F2

NO.15 EMISSION COMPLIANCEA6E408018881217

Diagnostic Procedure

15 EMISSION COMPLIANCE

DESCRIPTION•Fails emissions test.

POSSIBLE

CAUSE•Poor fuel quality

•Vacuum leakage

•Air leakage from intake-air system

•Intake-air system restriction or clogging

•Variable swirl control (VSC) system malfunction

•Variable boost control (VBC) system malfunction

•Intake shutter valve stuck close

•VSC valve stuck close

•Turbocharger malfunction

•Guide blade valve malfunction

•Charge air cooler malfunction

•Glow system malfunction

•EGR system malfunction

•EGR water cooler malfunction

•Low coolant temperature

•Engine overheating

•Inadequate fuel pressure

•Fuel pressure limiter malfunction (built-in common rail)

•Suction control valve inspection (built-in supply pump)

•ECT sensor or related circuit malfunction

•MAF/IAT sensor related circuit malfunction

•IAT sensor No.2 or related circuit malfunction

•Fuel pressure sensor or related circuit malfunction

•Incorrect adjustment accelerator position sensor and/or idle switch

•Accelerator position sensor or related circuit malfunction

•Idle switch or related circuit malfunction

•Fuel line rclogging or restriction

•Supply pump malfunction

•Fuel injector malfunction

•Incorrect fuel injection timing

•Incorrect idle speed

•Erratic signal from CKP sensor

•Erratic signal from CMP sensor

•Boost sensor or related circuit malfunction

•Neutral switch or related circuit malfunction

•VSS or related circuit malfunction

•Low engine compression

•Improper valve timing

•Base engine malfunction

•Exhaust system and/or catalyst converter restriction

•Catalyst converter malfunction

•IDM or related circuit malfunction

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before performing the fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injury or death

and damage. Fuel can also irritate skin and eyes. To prevent this, always complete “BEFORE

REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this manual.

STEP INSPECTION RESULTS ACTION

1 Is engine overheating? Yes Go to symptom troubleshooting “NO.17 COOLING

SYSTEM CONCERNS—OVERHEATING”.

No Go to next step.

2 Does engine run cold? Yes Go to symptom troubleshooting “NO.18 COOLING

SYSTEM CONCERNS—RUNS COLD”.

No Go to next step.

Page 359 of 909

TROUBLESHOOTING

F2–207

F2

12 Inspect if turbocharger compressor wheel

locknut is loose or has fallen down inside

turbocharger.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

13 Inspect turbocharger compressor wheel by

hand.

Does wheel turn easily and smoothly?Yes Go to next step.

No Replace turbocharger.

14 Inspect if turbocharger turbine wheel is

damaged, cracked or interfering with housing on

vehicle.

Note

•Inspect all fins on each turbine wheel.

Is there any problem?Yes Replace turbocharger.

No Go to next step.

15 Is any engine oil found inside turbocharger

turbine housing?YesExcessive amount of oil is found:

Replace turbocharger.

Small amount of oil is found:

Wipe oil off of vehicle, then go to next step.

No Go to next step.

16 Is any engine oil found inside turbocharger

compressor hosing?Yes Wipe oil off of vehicle and install all removed parts in

Step 10. Then, go to next step.

No Turbocharger is okay.

Install all parts removed in Step10.

Then, go to next step.

17 Perform EGR system inspection.

Is EGR system okay?Yes Go to next step.

No Repair or replace malfunctioning part according to

EGR system operation results.

18 Inspect EGR water cooler for following:

•Coolant passage clogging/restriction

•Exhaust gas clogging/restriction

Is EGR water cooler okay?Yes Go to next step.

No Service as necessary.

19 Inspect glow system operation.

(See T–19 RELAY INSPECTION)

Is glow system operation normal?Yes Go to next step.

No Repair or replace malfunctioning part according to

glow system operation results.

20 Visually inspect CKP sensor and teeth of pulse

wheel.

Are CKP sensor and teeth of pulse wheel okay?Yes Go to next step.

No Replace malfunctioning parts.

21 Measure gap between CKP sensor and teeth of

pulse wheel.

Specification

1.5—2.5 mm {0.059—0.098 in}

Is gap within specification?Yes Go to next step.

No Adjust CKP sensor position.

22 Visually inspect CMP sensor and teeth of pulse

wheel.

Are CMP sensor and teeth of pulse wheel okay?Yes Inspect following PIDs:

(See F2–65 PCM INSPECTION)

•ECT

•IAT

•MAF

•MAP

•RPM

•VSS

If PID value is not as specified, repair or replace

malfunctioning parts.

If PID value is okay, go to next step.

No Replace malfunctioning parts.

23 Inspect fuel pressure sensor.

(See F2–79 FUEL PRESSURE SENSOR

INSPECTION)

Is fuel pressure okay?Yes Go to next step.

No Replace common rail.

24 Inspect suction control valve.

(See F2–54 SUCTION CONTROL VALVE

INSPECTION)

Is suction control valve okay?Yes Go to next step.

No Repair supply pump.

(See F2–54 SUPPLY PUMP INSPECTION) STEP INSPECTION RESULTS ACTION

Page 557 of 909

K2–142

ON-BOARD DIAGNOSTIC

End Of SieDTC P0740A6E577018901212

Diagnostic procedure

12VERIFY TROUBLESHOOTING OF DTC P0720

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Drive vehicle with vehicle speed 40 km/h {25

mph} or above for 2 second or more

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

13VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

DTC P0740 TCC system malfunction

DETECTION

CONDITION•RPM difference between crankshaft (engine speed signal) and reverse clutch drum (input/turbine speed

sensor signal) exceeds the pre-programmed value.

Diagnostic support note:

•This is continuous monitor (CCM).

•MIL illuminates if TCM detects the above malfunction conditions in two consecutive drive cycles.

•PENDING CODE is available.

•FREEZE FRAME DATA is available.

•AT warning light does not indication.

•DTC is stored in TCM memory.

POSSIBLE

CAUSE•ATF level low.

•Deteriorated ATF.

•TCC solenoid valve and pressure control solenoid stuck.

•Line pressure low.

•Oil pump malfunction.

•Control valve stuck

•Torque convert clutch malfunction

•TCM malfunction.

STEP INSPECTION ACTION

1VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

•Has FREEZE FRAME PID DATA been

recorded?Yes Go to next step.

No Record FREEZE FRAME PID DATA on repair order, then

go to next step.

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3CHECK ATF CONDITION

•Turn ignition key to OFF.

•Check ATF condition.

—Clear red: Normal

—Milky: Water mixed in fluid

—Reddish brown: Deteriorated ATF

•Is it okay?

(See K2–78 Automatic Transaxle Fluid (ATF)

Condition Inspection.)Yes Go to next step.

No If ATF color milky or reddish brown, replace ATF, then go to

Step 5.

(See K2–80 AUTOMATIC TRANSAXLE FLUID (ATF)

REPLACEMENT.)

4CHECK ATF LEVEL

•Start engine.

•Warm up ATX.

•Is ATF level within specification?

(See K2–79 Automatic Transaxle Fluid (ATF)

Level Inspection.)Yes Go to next step.

No Adjust ATF level, then go to Step 9.

(See K2–79 Automatic Transaxle Fluid (ATF) Level

Inspection.)

Page 864 of 909

U–1

U

UHEATER AND AIR CONDITIONER SYSTEMS

OUTLINE................................................................ U-2

OUTLINE OF CONSTRUCTION.......................... U-2

FEATURES .......................................................... U-2

SPECIFICATIONS ............................................... U-2

CONTROL SYSTEM............................................... U-6

WATER HEATER SYSTEM................................. U-6

OUTLINE................................................................ U-7

SUPPLEMENTAL SERVICE INFORMATION .....U-7

LOCATION INDEX.................................................U-8

BASIC SYSTEM................................................... U-8

CONTROL SYSTEM ............................................ U-9

BASIC SYSTEM................................................... U-10

A/C UNIT REMOVAL/INSTALLATION...............U-10

A/C COMPRESSOR

REMOVAL/INSTALLATION ............................U-11

CONDENSER REMOVAL/INSTALLATION ....... U-12

REFRIGERANT LINES

REMOVAL/INSTALLATION ............................U-13

CONTROL SYSTEM............................................. U-15

WATER HEATER UNIT

REMOVAL/INSTALLATION ............................U-15

FUEL PUMP (WATER HEATER SYSTEM)

INSPECTION .................................................. U-16

CLIMATE CONTROL UNIT INSPECTION.........U-16

ON-BOARD DIAGNOSTIC...................................U-22

FOREWORD ......................................................U-22

DTC TABLE ................................................... U-22-2

PID/DATA MONITOR AND RECORD ........... U-22-2

DTC B1317 .................................................... U-22-3

DTC B1318 ........................................................ U-23

DTC B1342, B2463, B2537, B2538, B2547 ....... U-23

DTC B2449, B2450 ............................................ U-24

DTC B2451, B2452 ............................................ U-24

DTC B2453, B2454 ............................................ U-25

DTC B2548 ........................................................ U-25

TROUBLESHOOTING.......................................... U-26

FOREWORD ......................................................U-26

TROUBLESHOOTING INDEX ...........................U-26 FEATURES

SERVICE