water pump MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 81 of 909

E–6

OUTLINE

SUPPLEMENTAL SERVICE INFORMATIONA6E360202000208•The following changes and/or additions have been made since publication of the Mazda6 Workshop Manual

(1730-1*-02C).

Radiator cap

•Inspection procedure has been added. (MZR-CD (RF Turbo) engine model)

Thermostat

•Removal/Installation procedure has been added. (MZR-CD (RF Turbo) engine model)

•Inspection procedure has been added. (MZR-CD (RF Turbo) engine model)

Water pump

•Removal/Installation procedure has been added. (MZR-CD (RF Turbo) engine model)

Fan motor

•Removal/Installation procedure has been added. (MZR-CD (RF Turbo) engine model)

•Inspection procedure has been added. (MZR-CD (RF Turbo) engine model)

End Of Sie

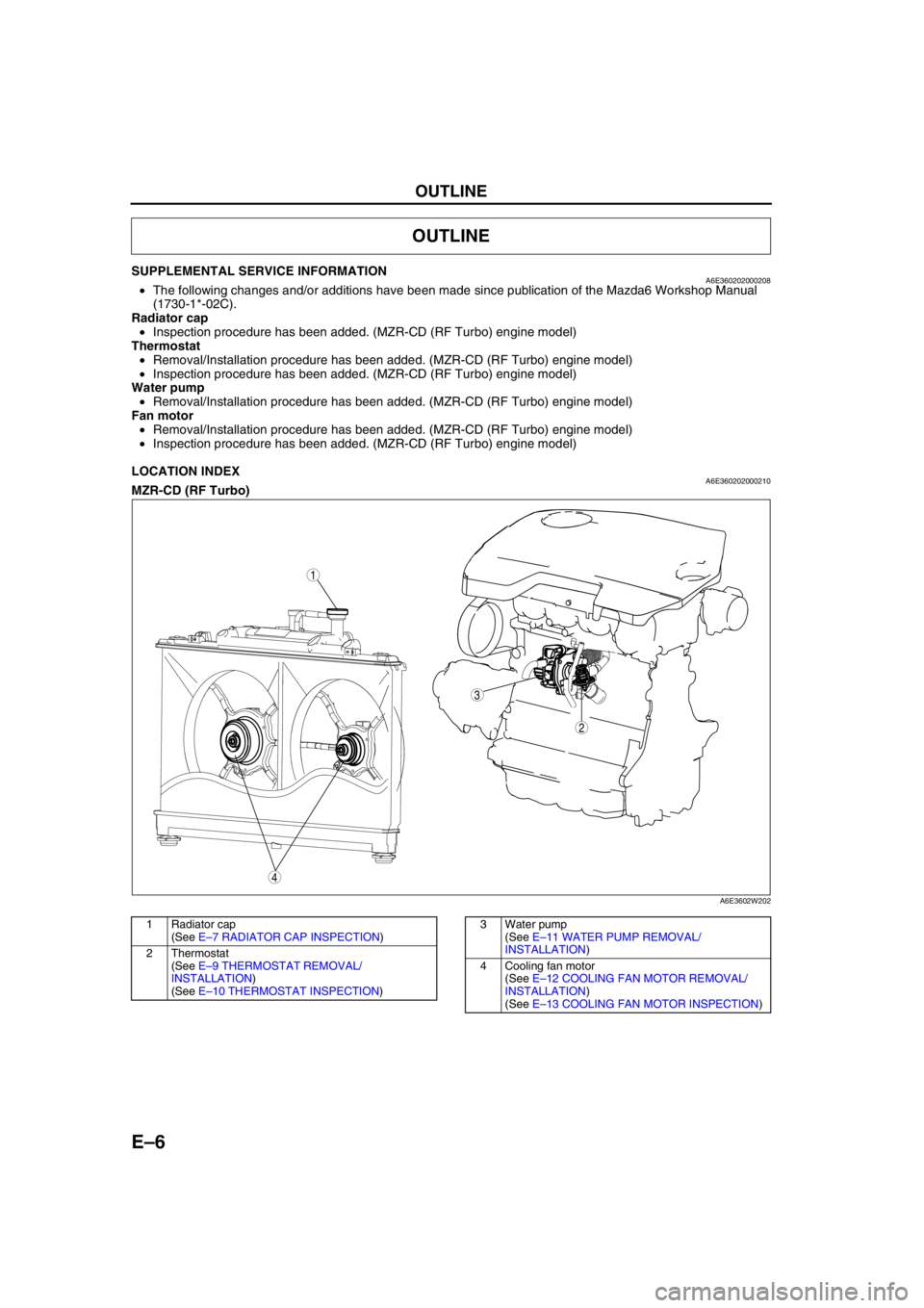

LOCATION INDEXA6E360202000210MZR-CD (RF Turbo)

.

End Of Sie

OUTLINE

4

3

1

2

A6E3602W202

1 Radiator cap

(See E–7 RADIATOR CAP INSPECTION)

2Thermostat

(See E–9 THERMOSTAT REMOVAL/

INSTALLATION)

(See E–10 THERMOSTAT INSPECTION)3 Water pump

(See E–11 WATER PUMP REMOVAL/

INSTALLATION)

4 Cooling fan motor

(See E–12 COOLING FAN MOTOR REMOVAL/

INSTALLATION)

(See E–13 COOLING FAN MOTOR INSPECTION)

Page 86 of 909

WATER PUMP

E–11

E

WATER PUMP REMOVAL/INSTALLATIONA6E362015010201MZR-CD (RF Turbo)

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Drain the engine coolant.

4. Remove the timing belt. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

5. Remove the thermostat. (See E–9 THERMOSTAT REMOVAL/INSTALLATION.)

6. Remove in the order indicated in the table.

7. Install in the reverse order of removal.

8. Insect the drive belt. (See B2–4 DRIVE BELT INSPECTION.)

9. Fill the radiator with the specified amount and type of engine coolant.

10. Inspect the engine coolant leakage. (See E–8 ENGINE COOLANT LEAKAGE INSPECTION.)

End Of Sie

WATER PUMP

3

1

2

1

19—25

{1.9—2.6, 14—18}

N·m {kgf·m, ft·lbf} 38—51

{3.8—5.3, 28—38}

7.9—10.7 N·m

{80—110 kgf·cm, 69.5—95.4 in·lbf} 38—51

{3.8—5.3, 28—38}

R

R

A6E3620W100

1Hose

2 Water pump

3 Thermostat case

Page 153 of 909

![MAZDA 6 2002 Suplement User Guide F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATUR MAZDA 6 2002 Suplement User Guide F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATUR](/img/28/57057/w960_57057-152.png)

F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATURES ........................................................ F2-3

SPECIFICATIONS ............................................. F2-3

CONTROL SYSTEM DIAGRAM ........................ F2-4

CONTROL SYSTEM WIRING DIAGRAM.......... F2-5

INTAKE-AIR SYSTEM.......................................... F2-8

OUTLINE ........................................................... F2-8

STRUCTURAL VIEW......................................... F2-9

FUEL SYSTEM................................................... F2-10

OUTLINE ......................................................... F2-10

STRUCTURAL VIEW....................................... F2-11

EXHAUST SYSTEM........................................... F2-13

OUTLINE ......................................................... F2-13

STRUCTURAL VIEW....................................... F2-13

EMISSION SYSTEM........................................... F2-14

OUTLINE ......................................................... F2-14

STRUCTURAL VIEW....................................... F2-15

WARM UP OXIDATION CATALYTIC

CONVERTER DESCRIPTION ...................... F2-16

CONTROL SYSTEM........................................... F2-16

OUTLINE ......................................................... F2-16

STRUCTURAL VIEW....................................... F2-18

BLOCK DIAGRAM ........................................... F2-20

CONTROL DEVICE AND CONTROL

RELATIONSHIP CHART .............................. F2-22

CRUISE CONTROL SYSTEM ......................... F2-23

CONTROLLER AREA NETWORK (CAN) ....... F2-24

ON-BOARD DIAGNOSTIC................................. F2-24

OUTLINE ......................................................... F2-24

DTC.................................................................. F2-24

KOEO/KOER SELF-TEST ............................... F2-26

PID/DATA MONITOR AND RECORD ............. F2-27

SIMULATION TEST ......................................... F2-27

LOCATION INDEX............................................. F2-28

INTAKE-AIR SYSTEM ..................................... F2-28

FUEL SYSTEM ................................................ F2-29

EMISSION SYSTEM........................................ F2-31

CONTROL SYSTEM........................................ F2-32

ENGINE TUNE-UP............................................. F2-34

ENGINE TUNE-UP PREPARATION ............... F2-34

IDLE SPEED INSPECTION ............................. F2-34

CORRECTION PROCEDURE ......................... F2-34

INTAKE-AIR SYSTEM........................................ F2-35

VACUUM TUBE ROUTING DIAGRAM............ F2-35

INTAKE-AIR SYSTEM

REMOVAL/INSTALLATION .......................... F2-36

AIR CLEANER ELEMENT INSPECTION ........ F2-37

TURBOCHARGER INSPECTION ................... F2-38

GUIDE BLADE ACTUATOR INSPECTION ..... F2-39

VARIABLE BOOST CONTROL (VBC)

SOLENOID VALVE INSPECTION ................ F2-40VARIABLE BOOST CONTROL (VBC)

CHECK VALVE INSPECTION ...................... F2-41

VARIABLE SWIRL CONTROL (VSC)

VALVE ACTUATOR INSPECTION ............... F2-41

VARIABLE SWIRL CONTROL (VSC)

SOLENOID VALVE INSPECTION ................ F2-42

GLOW PLUG REMOVAL/INSTALLATION ...... F2-42

GLOW PLUG INSPECTION ............................ F2-43

GLOW PLUG LEAD INSPECTION .................. F2-43

ACCELERATOR PEDAL COMPONENT

REMOVAL/INSTALLATION .......................... F2-44

ACCELERATOR PEDAL COMPONENT

DISASSEMBLY/ASSEMBLY ........................ F2-44

FUEL SYSTEM................................................... F2-45

BEFORE REPAIR PROCEDURE .................... F2-45

AFTER REPAIR PROCEDURE ....................... F2-45

FUEL TANK REMOVAL/INSTALLATION ........ F2-45

FUEL TANK INSPECTION .............................. F2-49

NONRETURN VALVE INSPECTION............... F2-50

FUEL FILTER COMPONENT

REMOVAL/INSTALLATION .......................... F2-50

FUEL FILTER COMPONENT

DISASSEMBLY/ASSEMBLY ........................ F2-51

FUEL WARMER INSPECTION........................ F2-51

SEDIMENTOR WATER DRAINING................. F2-52

SEDIMENTOR SWITCH INSPECTION ........... F2-52

SUPPLY PUMP REMOVAL/INSTALLATION .. F2-53

SUPPLY PUMP INSPECTION......................... F2-54

SUCTION CONTROL VALVE INSPECTION ... F2-54

COMMON RAIL INSPECTION ........................ F2-54

FUEL INJECTOR REMOVAL/INSTALLATION F2-55

FUEL INJECTOR INSPECTION ...................... F2-56

EXHAUST SYSTEM........................................... F2-57

EXHAUST SYSTEM INSPECTION ................. F2-57

EXHAUST SYSTEM

REMOVAL/INSTALLATION .......................... F2-57

EMISSION SYSTEM........................................... F2-59

EGR VALVE REMOVAL/INSTALLATION........ F2-59

EGR VALVE INSPECTION .............................. F2-59

EGR SOLENOID VALVE (VACUUM)

INSPECTION ................................................ F2-60

EGR SOLENOID VALVE (VENT)

INSPECTION ................................................ F2-60

EGR CONTROL SOLENOID VALVE

INSPECTION ................................................ F2-61

INTAKE SHUTTER VALVE ACTUATOR

INSPECTION ................................................ F2-62

INTAKE SHUTTER SOLENOID VALVE

INSPECTION ................................................ F2-63

CONTROL SYSTEM........................................... F2-64

PCM REMOVAL/INSTALLATION .................... F2-64

PCM INSPECTION .......................................... F2-65

PCM CONFIGURATION .................................. F2-68

CLUTCH SWITCH INSPECTION .................... F2-68

NEUTRAL SWITCH INSPECTION .................. F2-69

IDLE SWITCH INSPECTION ........................... F2-70

IDLE SWITCH ADJUSTMENT ......................... F2-71

ACCELERATOR POSITION SENSOR

INSPECTION ................................................ F2-72

ACCELERATOR POSITION SENSOR

ADJUSTMENT .............................................. F2-73 FEATURES

SERVICE

Page 156 of 909

F2–4

OUTLINE

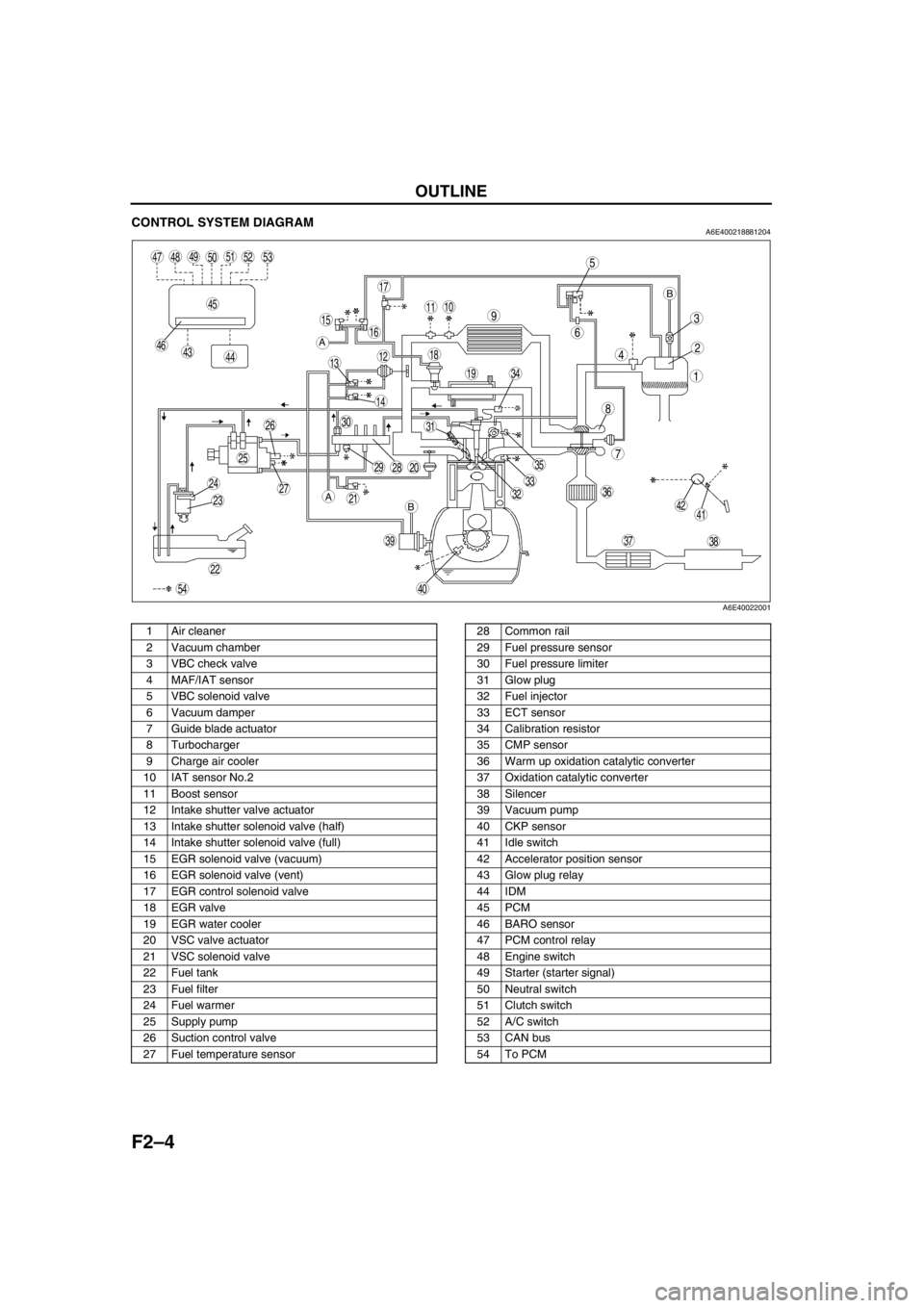

CONTROL SYSTEM DIAGRAMA6E400218881204

.

End Of Sie

5

4

3

6

1

2

8

7

910

13

11

12

19

18

17

1516

14

202928

27

25

26

24

2321

22

30

393837

35

3633

31

32

40

34

494847

45

464443

4142

50

54

515253

A

A

BB

A6E40022001

1 Air cleaner

2 Vacuum chamber

3 VBC check valve

4 MAF/IAT sensor

5 VBC solenoid valve

6 Vacuum damper

7 Guide blade actuator

8 Turbocharger

9 Charge air cooler

10 IAT sensor No.2

11 Boost sensor

12 Intake shutter valve actuator

13 Intake shutter solenoid valve (half)

14 Intake shutter solenoid valve (full)

15 EGR solenoid valve (vacuum)

16 EGR solenoid valve (vent)

17 EGR control solenoid valve

18 EGR valve

19 EGR water cooler

20 VSC valve actuator

21 VSC solenoid valve

22 Fuel tank

23 Fuel filter

24 Fuel warmer

25 Supply pump

26 Suction control valve

27 Fuel temperature sensor28 Common rail

29 Fuel pressure sensor

30 Fuel pressure limiter

31 Glow plug

32 Fuel injector

33 ECT sensor

34 Calibration resistor

35 CMP sensor

36 Warm up oxidation catalytic converter

37 Oxidation catalytic converter

38 Silencer

39 Vacuum pump

40 CKP sensor

41 Idle switch

42 Accelerator position sensor

43 Glow plug relay

44 IDM

45 PCM

46 BARO sensor

47 PCM control relay

48 Engine switch

49 Starter (starter signal)

50 Neutral switch

51 Clutch switch

52 A/C switch

53 CAN bus

54 To PCM

Page 158 of 909

F2–6

OUTLINE

.

a

b

c

d

e

f

gCBD

A

CBD

ACBD

ACBD

A

3762

89 11C

BABABABABABABABABA

81 55 29 3 99 72

1017410067 77

h

i

j

k

l

m

n

oA

B

C36

10

A

BCD8831

90

A B CA

BA

B

A B 6135

87 94 93 8

A

B76

E

C

A D

M84

10273 8668

AB

C D

M

M A B

29282725262430

1

393837353633

31

3240

49

48

47454644

4341

42

50

59

58

57

55

5654

60

64

63

61

62

34

51

5253

A6E40022003

1PCM

2DLC-2

3 Water heater unit

4Fuel pump

5 Other unit6IDM

7Battery

8 Engine switch

9 Starter relay

10 Starter

Page 182 of 909

F2–30

LOCATION INDEX

Fuel tank side

.

End Of Sie

21

A6E40002004

1 Fuel tank

(See F2–45 FUEL TANK REMOVAL/

INSTALLATION)

(See F2–49 FUEL TANK INSPECTION)

2 Nonreturn valve

(See F2–50 NONRETURN VALVE INSPECTION)

3 Sedimentor switch

(See F2–52 SEDIMENTOR SWITCH INSPECTION)

4 Fuel filter

(See F2–50 FUEL FILTER COMPONENT

REMOVAL/INSTALLATION)

(See F2–51 FUEL FILTER COMPONENT

DISASSEMBLY/ASSEMBLY)

5 Fuel warmer

(See F2–51 FUEL WARMER INSPECTION)6 Priming pump

(See F2–52 SEDIMENTOR WATER DRAINING)

7 Supply pump

(See F2–53 SUPPLY PUMP REMOVAL/

INSTALLATION)

(See F2–54 SUPPLY PUMP INSPECTION)

8 Suction control valve

(See F2–54 SUCTION CONTROL VALVE

INSPECTION)

9 Common rail

(See F2–54 COMMON RAIL INSPECTION)

10 Fuel injector

(See F2–55 FUEL INJECTOR REMOVAL/

INSTALLATION)

(See F2–56 FUEL INJECTOR INSPECTION)

Page 189 of 909

INTAKE-AIR SYSTEM

F2–37

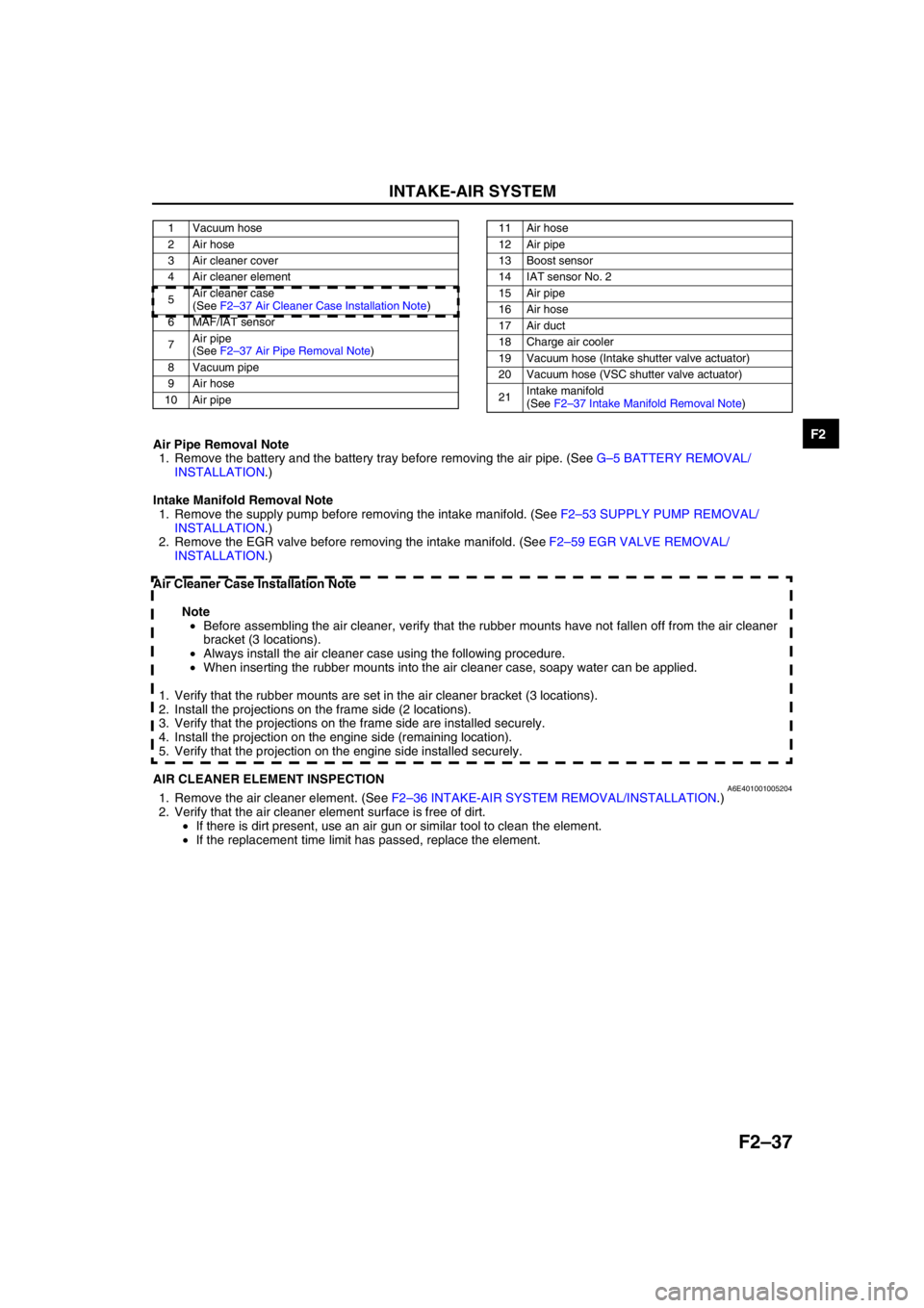

F2Air Pipe Removal Note

1. Remove the battery and the battery tray before removing the air pipe. (See G–5 BATTERY REMOVAL/

INSTALLATION.)

Intake Manifold Removal Note

1. Remove the supply pump before removing the intake manifold. (See F2–53 SUPPLY PUMP REMOVAL/

INSTALLATION.)

2. Remove the EGR valve before removing the intake manifold. (See F2–59 EGR VALVE REMOVAL/

INSTALLATION.)

Air Cleaner Case Installation Note

Note

•Before assembling the air cleaner, verify that the rubber mounts have not fallen off from the air cleaner

bracket (3 locations).

•Always install the air cleaner case using the following procedure.

•When inserting the rubber mounts into the air cleaner case, soapy water can be applied.

1. Verify that the rubber mounts are set in the air cleaner bracket (3 locations).

2. Install the projections on the frame side (2 locations).

3. Verify that the projections on the frame side are installed securely.

4. Install the projection on the engine side (remaining location).

5. Verify that the projection on the engine side installed securely.

End Of Sie

AIR CLEANER ELEMENT INSPECTIONA6E4010010052041. Remove the air cleaner element. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

2. Verify that the air cleaner element surface is free of dirt.

•If there is dirt present, use an air gun or similar tool to clean the element.

•If the replacement time limit has passed, replace the element.

End Of Sie

1 Vacuum hose

2 Air hose

3 Air cleaner cover

4 Air cleaner element

5Air cleaner case

(See F2–37 Air Cleaner Case Installation Note)

6 MAF/IAT sensor

7Air pipe

(See F2–37 Air Pipe Removal Note)

8 Vacuum pipe

9 Air hose

10 Air pipe11 Air hose

12 Air pipe

13 Boost sensor

14 IAT sensor No. 2

15 Air pipe

16 Air hose

17 Air duct

18 Charge air cooler

19 Vacuum hose (Intake shutter valve actuator)

20 Vacuum hose (VSC shutter valve actuator)

21Intake manifold

(See F2–37 Intake Manifold Removal Note)

Page 204 of 909

F2–52

FUEL SYSTEM

SEDIMENTOR WATER DRAININGA6E4012348022041. Disconnect the negative battery cable.

2. Complete the “BEFORE REPAIR PROCEDURE”. (See F2–45 BEFORE REPAIR PROCEDURE.)

3. Loosen the drain plug located at the bottom of the fuel filter.

4. Pump the priming pump and drain the water.

5. After all the water has been drained, tighten the drain plug.

6. Complete the “AFTER REPAIR PROCEDURE”. (See F2–45 AFTER REPAIR PROCEDURE.)

7. Reconnect the negative battery cable.

End Of Sie

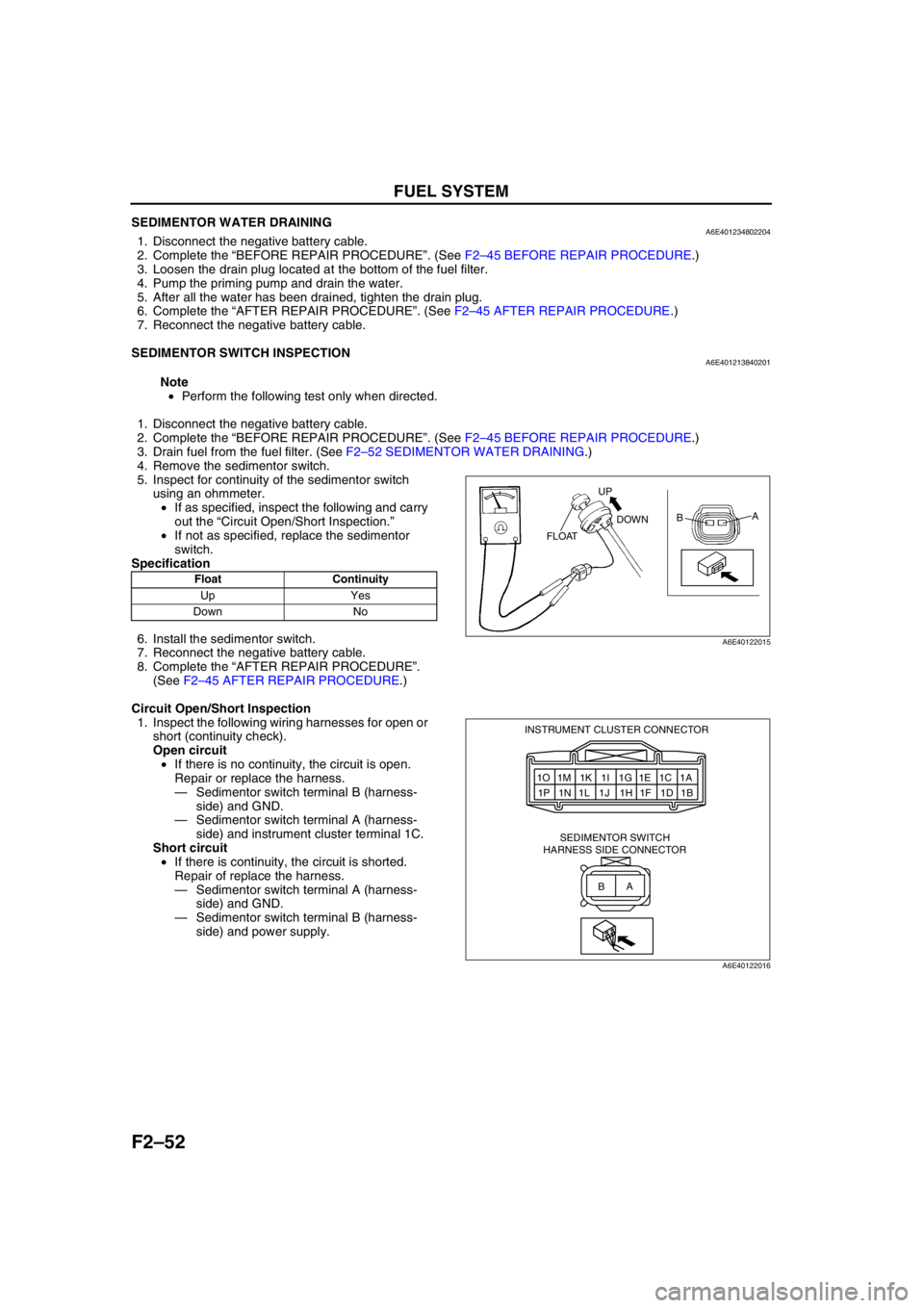

SEDIMENTOR SWITCH INSPECTIONA6E401213840201

Note

•Perform the following test only when directed.

1. Disconnect the negative battery cable.

2. Complete the “BEFORE REPAIR PROCEDURE”. (See F2–45 BEFORE REPAIR PROCEDURE.)

3. Drain fuel from the fuel filter. (See F2–52 SEDIMENTOR WATER DRAINING.)

4. Remove the sedimentor switch.

5. Inspect for continuity of the sedimentor switch

using an ohmmeter.

•If as specified, inspect the following and carry

out the “Circuit Open/Short Inspection.”

•If not as specified, replace the sedimentor

switch.

Specification

6. Install the sedimentor switch.

7. Reconnect the negative battery cable.

8. Complete the “AFTER REPAIR PROCEDURE”.

(See F2–45 AFTER REPAIR PROCEDURE.)

Circuit Open/Short Inspection

1. Inspect the following wiring harnesses for open or

short (continuity check).

Open circuit

•If there is no continuity, the circuit is open.

Repair or replace the harness.

—Sedimentor switch terminal B (harness-

side) and GND.

—Sedimentor switch terminal A (harness-

side) and instrument cluster terminal 1C.

Short circuit

•If there is continuity, the circuit is shorted.

Repair of replace the harness.

—Sedimentor switch terminal A (harness-

side) and GND.

—Sedimentor switch terminal B (harness-

side) and power supply.

End Of Sie

Float Continuity

Up Yes

Down No

UP

DOWN

FLOATA

B

A6E40122015

1O 1M 1K 1I 1G 1E 1C 1A

1P 1N 1L 1J 1H 1F 1D 1B INSTRUMENT CLUSTER CONNECTOR

SEDIMENTOR SWITCH

HARNESS SIDE CONNECTOR

A

B

A6E40122016

Page 211 of 909

EMISSION SYSTEM

F2

F2–59

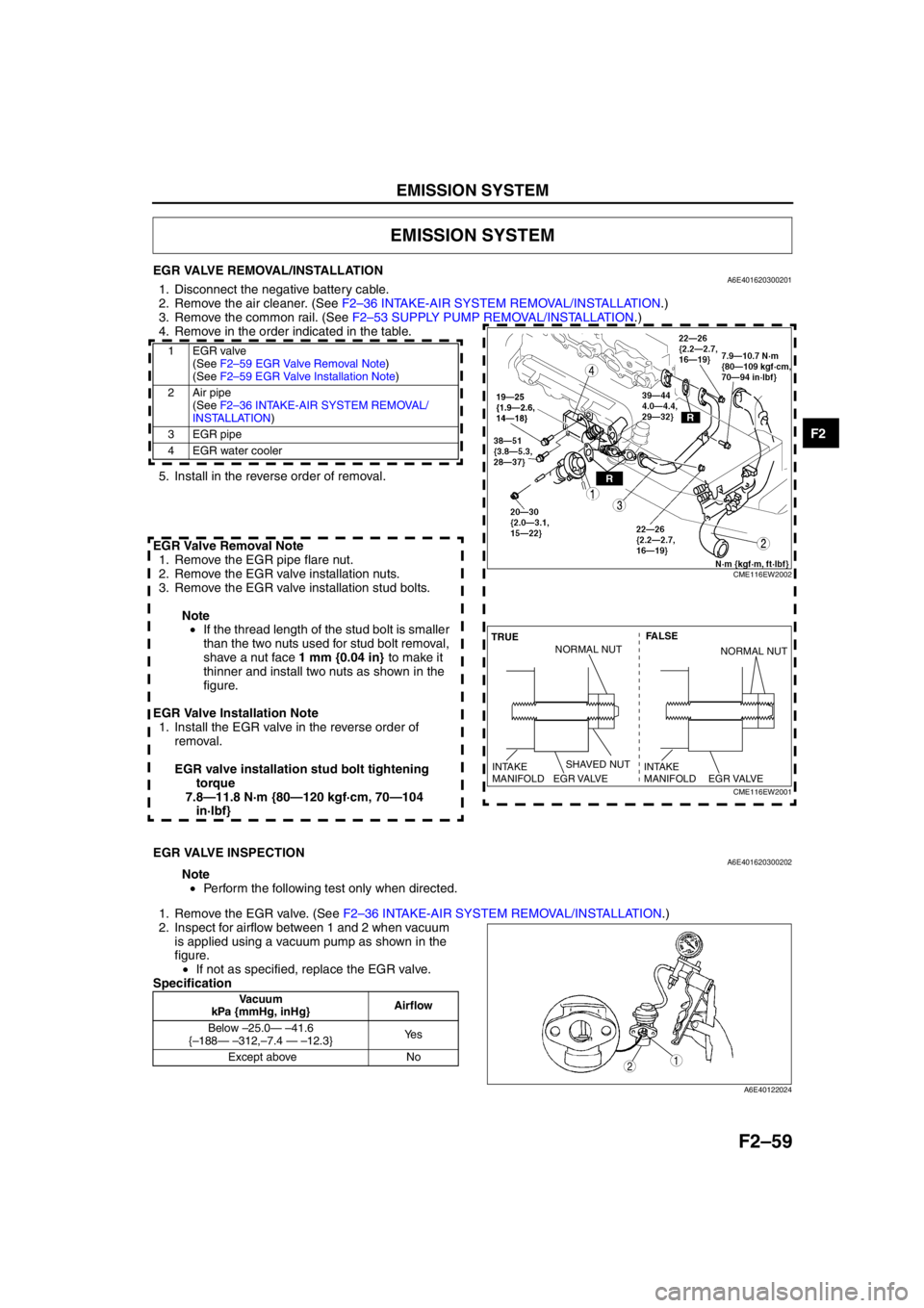

EGR VALVE REMOVAL/INSTALLATIONA6E4016203002011. Disconnect the negative battery cable.

2. R em ove t he a ir c le a ne r. (S ee F 2–36 IN TA K E-A IR SYS TEM RE MOVA L/I NSTA LL AT IO N.)

3 . R em ove t he co m mon r ai l. (S ee F 2–53 SUPPLY PU MP R EM OVA L/IN STA LLAT IO N.)

4. Remove in the order indicated in the table.

.

5. Install in the reverse order of removal.

EGR Valve Removal Note 1. Remove the EGR pipe flare nut.

2. Remove the EGR valve installation nuts.

3. Remove the EGR valve installation stud bolts.

Note• If the thread length of the stud bolt is smaller

than the two nuts used for stud bolt removal,

shave a nut face 1 mm {0.04 in} to make it

thinner and install two nuts as shown in the

figure.

EGR Valve Installation Note 1. Install the EGR valve in the reverse order of removal.

EGR valve installation stud bolt tightening torque

7.8—11.8 N·m {80—120 kgf·cm, 70—104 in·lbf}

End Of Sie

EGR VALVE INSPECTIONA6E401620300202

Note

• Perform the following test only when directed.

1 . R em ove t h e EG R va lv e . ( See F 2–36 IN TA K E-A IR SYS TEM RE MOVA L/I NSTA LL AT IO N.)

2. Inspect for airflow between 1 and 2 when vacuum is applied using a vacuum pump as shown in the

figure.• If not as specified, replace the EGR valve.

Specification

End Of Sie

EMISSION SYSTEM

1EGR valve (See F 2–5 9 EG R V alv e R em oval N ote )

(See F2 –5 9 E G R V alv e In sta llat ion Not e)

2Air pipe (See F2 –3 6 IN TAKE-AIR SYSTEM RE MOVAL/

INS TA LL ATION )

3 EGR pipe

4 EGR water cooler

CME116EW2002

SHAVED NUT FALSE

TRUE

EGR VALVE

INTAKE

MANIFOLDEGR VALVE

INTAKE

MANIFOLD

NORMAL NUTNORMAL NUT

CME116EW2001

Vacuum

kPa {mmHg, inHg} Airflow

Below –25.0 — – 41.6

{ – 188 — – 312, –7.4 — – 12.3} Ye s

Except above No

12

A6E40122024

Page 228 of 909

F2–76

CONTROL SYSTEM

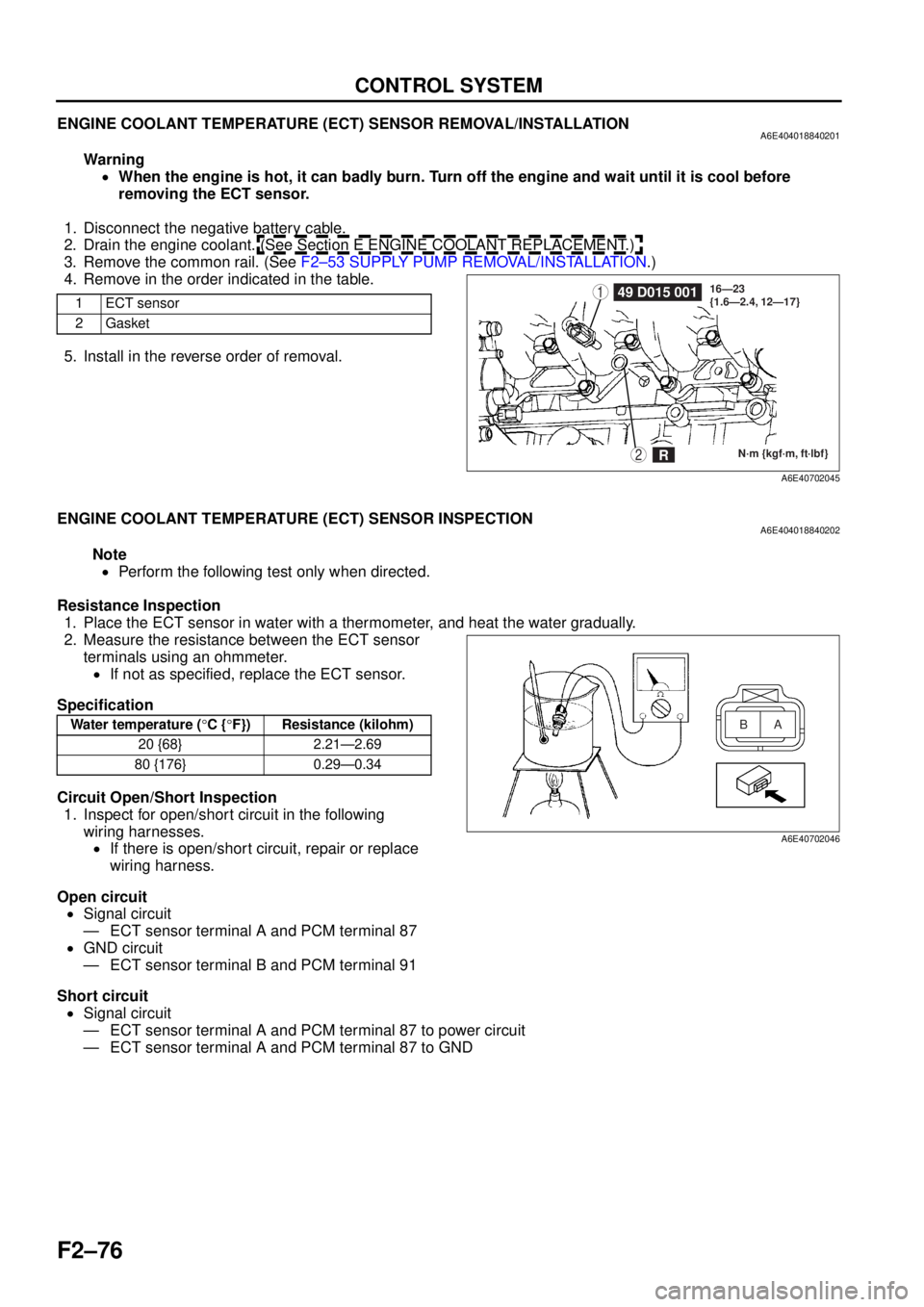

ENGINE COOLANT TEMPERATURE (ECT) SENSOR REMOVAL/INSTALLATIONA6E404018840201

Warning•When the engine is hot, it can badly burn. Turn off the engine and wait until it is cool before

removing the ECT sensor.

1. Disconnect the negative battery cable.

2. Drain the engine coolant. (See Section E ENGINE COOLANT REPLACEMENT.)

3. Remove the common rail. (See F2–53 SUPPLY PUMP REMOVAL/INSTALLATION .)

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

End Of Sie

ENGINE COOLANT TEMPERATURE (ECT) SENSOR INSPECTIONA6E404018840202

Note

• Perform the following test only when directed.

Resistance Inspection 1. Place the ECT sensor in water with a thermometer, and heat the water gradually.

2. Measure the resistance between the ECT sensor terminals using an ohmmeter.

• If not as specified, replace the ECT sensor.

Specification

Circuit Open/Short Inspection 1. Inspect for open/short circuit in the following

wiring harnesses.• If there is open/short circuit, repair or replace

wiring harness.

Open circuit • Signal circuit

— ECT sensor terminal A and PCM terminal 87

• GND circuit

— ECT sensor terminal B and PCM terminal 91

Short circuit • Signal circuit

— ECT sensor terminal A and PCM terminal 87 to power circuit

— ECT sensor terminal A and PCM terminal 87 to GND

End Of Sie

1ECT sensor

2Gasket149 D015 001

N·m {kgf·m, ft·lbf}

16—23

{1.6—2.4, 12—17}2R

A6E40702045

Water temperature (

°C { °F}) Resistance (kilohm)

20 {68} 2.21—2.69

80 {176} 0.29—0.34A

B

A6E40702046