cruise control MAZDA 6 2002 Suplement Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 428 of 909

AUTOMATIC TRANSAXLE

K2–13

K2

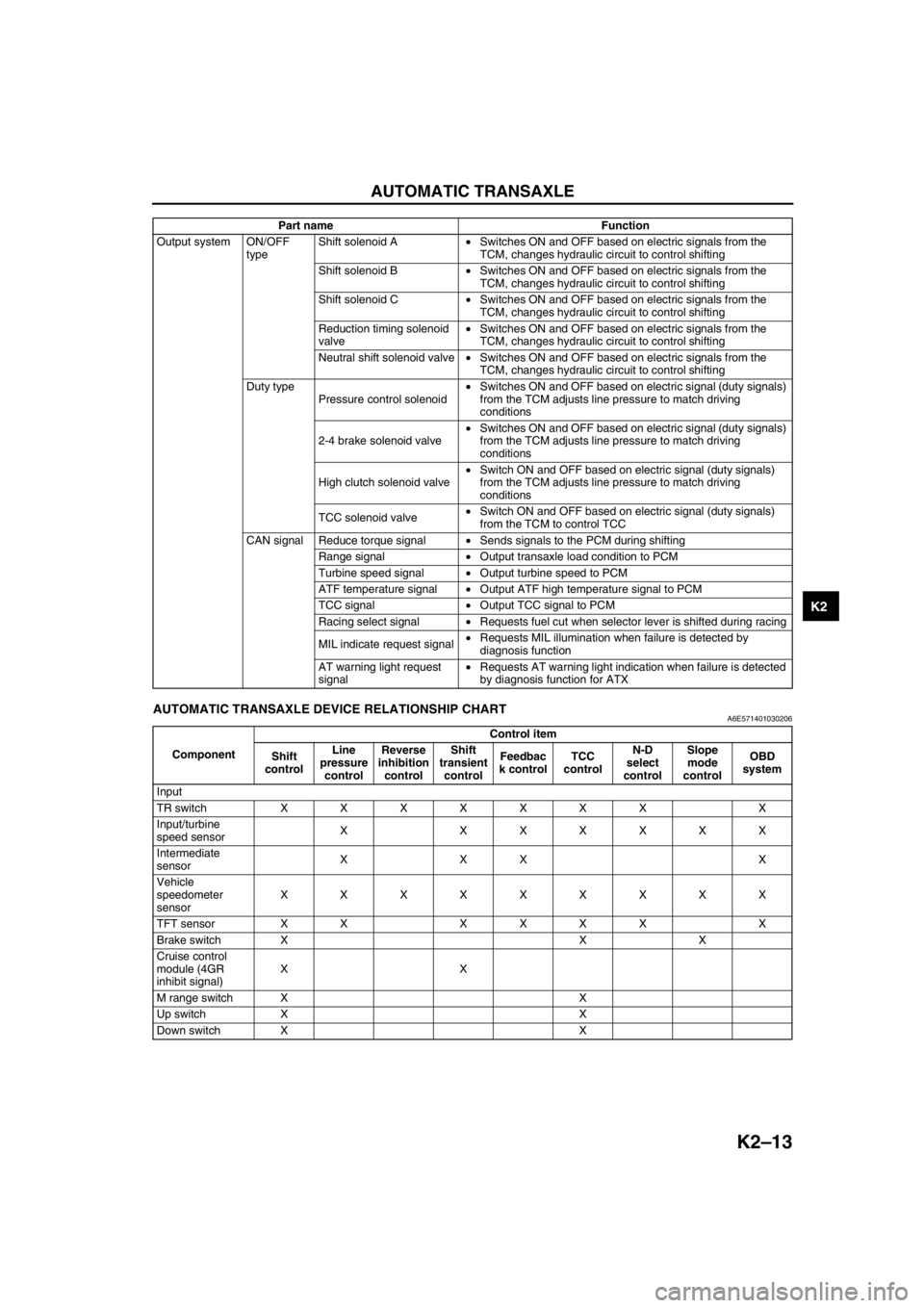

End Of SieAUTOMATIC TRANSAXLE DEVICE RELATIONSHIP CHARTA6E571401030206

Output system ON/OFF

typeShift solenoid A•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Shift solenoid B•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Shift solenoid C•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Reduction timing solenoid

valve•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Neutral shift solenoid valve•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Duty type

Pressure control solenoid•Switches ON and OFF based on electric signal (duty signals)

from the TCM adjusts line pressure to match driving

conditions

2-4 brake solenoid valve•Switches ON and OFF based on electric signal (duty signals)

from the TCM adjusts line pressure to match driving

conditions

High clutch solenoid valve•Switch ON and OFF based on electric signal (duty signals)

from the TCM adjusts line pressure to match driving

conditions

TCC solenoid valve•Switch ON and OFF based on electric signal (duty signals)

from the TCM to control TCC

CAN signal Reduce torque signal•Sends signals to the PCM during shifting

Range signal•Output transaxle load condition to PCM

Turbine speed signal•Output turbine speed to PCM

ATF temperature signal•Output ATF high temperature signal to PCM

TCC signal•Output TCC signal to PCM

Racing select signal•Requests fuel cut when selector lever is shifted during racing

MIL indicate request signal•Requests MIL illumination when failure is detected by

diagnosis function

AT warning light request

signal•Requests AT warning light indication when failure is detected

by diagnosis function for ATX Part name Function

ComponentControl item

Shift

controlLine

pressure

controlReverse

inhibition

controlShift

transient

controlFeedbac

k controlTCC

controlN-D

select

controlSlope

mode

controlOBD

system

Input

TR switch XXXXXXX X

Input/turbine

speed sensorX XXXXXX

Intermediate

sensorXXX X

Vehicle

speedometer

sensorXXXXXXXXX

TFT sensor XX XXXX X

Brake switch X X X

Cruise control

module (4GR

inhibit signal)XX

M range switch X X

Up switch X X

Down switch X X

Page 470 of 909

AUTOMATIC TRANSAXLE

K2–55

K2

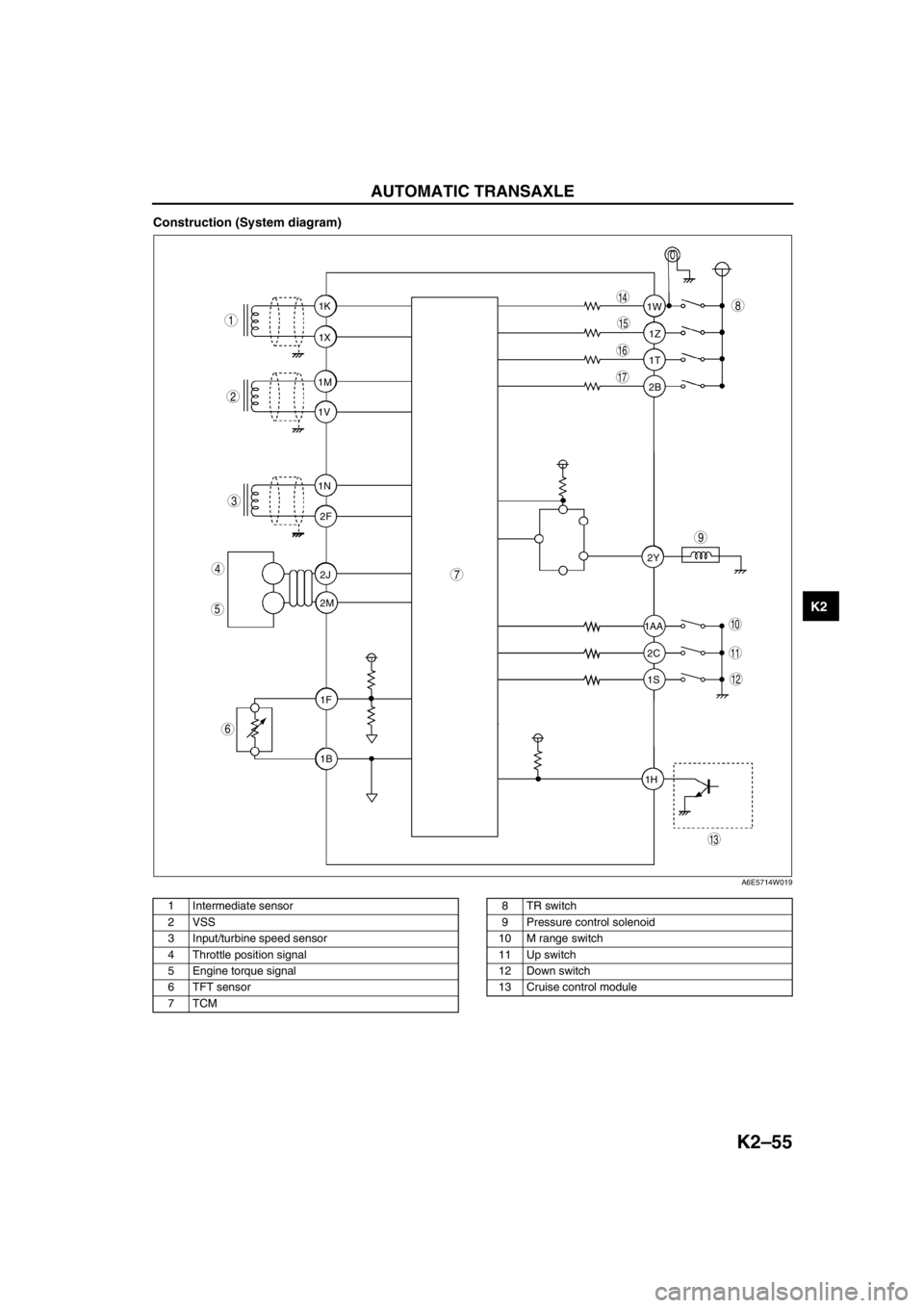

Construction (System diagram)

.

1T 1Z 1W

1AA

2C 2Y

1S

1H2B 1K

1X

1M

1V

1N

2F

2J

2M

1F

1B

9

8

7

5

4

3

1

2

10

17

15

16

14

13

11

12

6

A6E5714W019

1 Intermediate sensor

2 VSS

3 Input/turbine speed sensor

4 Throttle position signal

5 Engine torque signal

6 TFT sensor

7TCM8TR switch

9 Pressure control solenoid

10 M range switch

11 Up switch

12 Down switch

13 Cruise control module

Page 506 of 909

AUTOMATIC TRANSAXLE

K2–91

K2

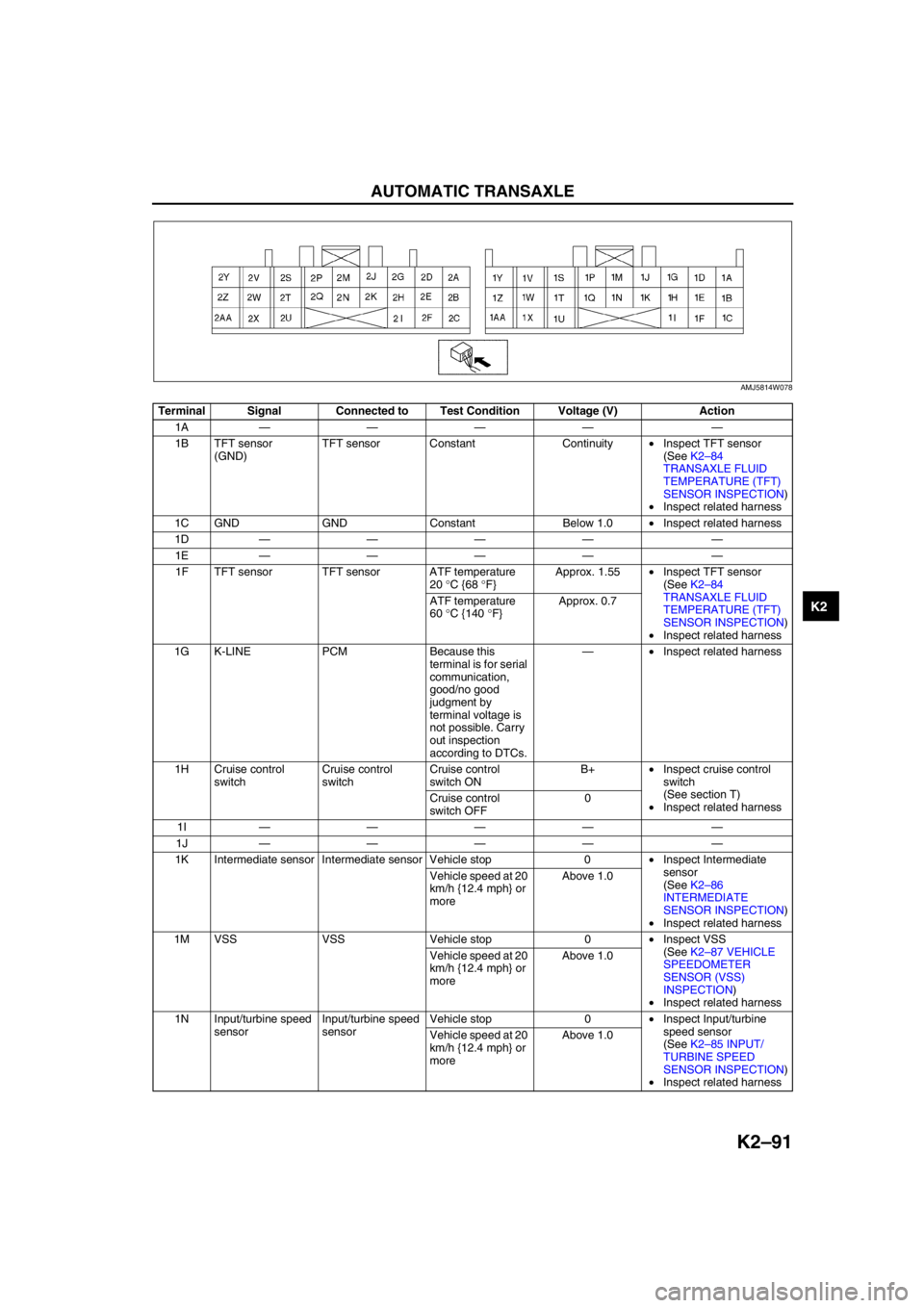

Terminal Signal Connected to Test Condition Voltage (V) Action

1A———— —

1B TFT sensor

(GND)TFT sensor Constant Continuity•Inspect TFT sensor

(See K2–84

TRANSAXLE FLUID

TEMPERATURE (TFT)

SENSOR INSPECTION)

•Inspect related harness

1C GND GND Constant Below 1.0•Inspect related harness

1D———— —

1E———— —

1F TFT sensor TFT sensor ATF temperature

20 °C {68 °F}Approx. 1.55•Inspect TFT sensor

(See K2–84

TRANSAXLE FLUID

TEMPERATURE (TFT)

SENSOR INSPECTION)

•Inspect related harness ATF temperature

60 °C {140 °F}Approx. 0.7

1G K-LINE PCM Because this

terminal is for serial

communication,

good/no good

judgment by

terminal voltage is

not possible. Carry

out inspection

according to DTCs.—•Inspect related harness

1H Cruise control

switchCruise control

switchCruise control

switch ONB+•Inspect cruise control

switch

(See section T)

•Inspect related harness Cruise control

switch OFF0

1I———— —

1J———— —

1K Intermediate sensor Intermediate sensor Vehicle stop 0•Inspect Intermediate

sensor

(See K2–86

INTERMEDIATE

SENSOR INSPECTION)

•Inspect related harness Vehicle speed at 20

km/h {12.4 mph} or

moreAbove 1.0

1M VSS VSS Vehicle stop 0•Inspect VSS

(See K2–87 VEHICLE

SPEEDOMETER

SENSOR (VSS)

INSPECTION)

•Inspect related harness Vehicle speed at 20

km/h {12.4 mph} or

moreAbove 1.0

1N Input/turbine speed

sensorInput/turbine speed

sensorVehicle stop 0•Inspect Input/turbine

speed sensor

(See K2–85 INPUT/

TURBINE SPEED

SENSOR INSPECTION)

•Inspect related harness Vehicle speed at 20

km/h {12.4 mph} or

moreAbove 1.0

AMJ5814W078

Page 605 of 909

K2–190

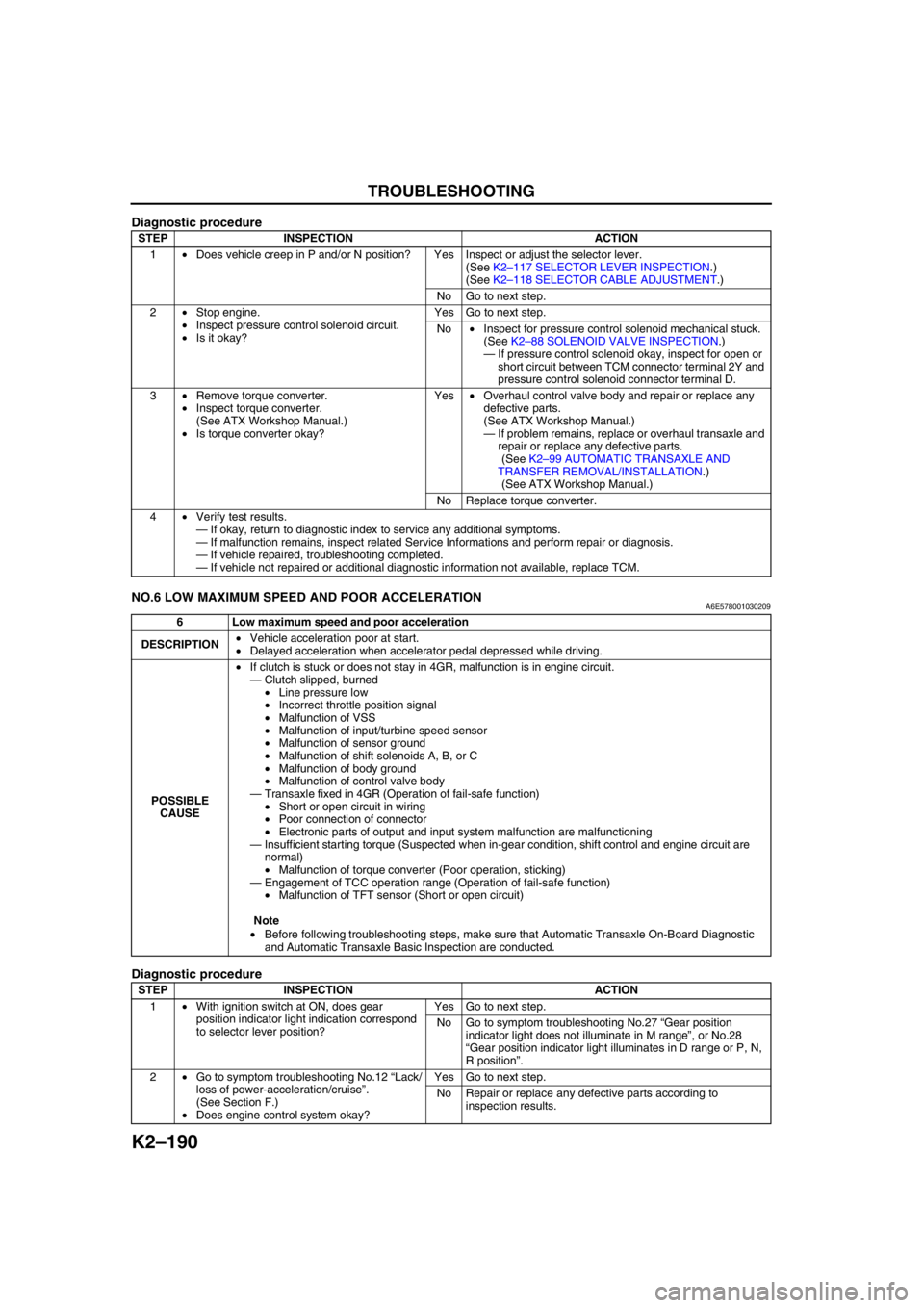

TROUBLESHOOTING

Diagnostic procedure

End Of SieNO.6 LOW MAXIMUM SPEED AND POOR ACCELERATIONA6E578001030209

Diagnostic procedure

STEP INSPECTION ACTION

1•Does vehicle creep in P and/or N position? Yes Inspect or adjust the selector lever.

(See K2–117 SELECTOR LEVER INSPECTION.)

(See K2–118 SELECTOR CABLE ADJUSTMENT.)

No Go to next step.

2•Stop engine.

•Inspect pressure control solenoid circuit.

•Is it okay?Yes Go to next step.

No•Inspect for pressure control solenoid mechanical stuck.

(See K2–88 SOLENOID VALVE INSPECTION.)

—If pressure control solenoid okay, inspect for open or

short circuit between TCM connector terminal 2Y and

pressure control solenoid connector terminal D.

3•Remove torque converter.

•Inspect torque converter.

(See ATX Workshop Manual.)

•Is torque converter okay?Yes•Overhaul control valve body and repair or replace any

defective parts.

(See ATX Workshop Manual.)

—If problem remains, replace or overhaul transaxle and

repair or replace any defective parts.

(See K2–99 AUTOMATIC TRANSAXLE AND

TRANSFER REMOVAL/INSTALLATION.)

(See ATX Workshop Manual.)

No Replace torque converter.

4•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

6 Low maximum speed and poor acceleration

DESCRIPTION•Vehicle acceleration poor at start.

•Delayed acceleration when accelerator pedal depressed while driving.

POSSIBLE

CAUSE•If clutch is stuck or does not stay in 4GR, malfunction is in engine circuit.

—Clutch slipped, burned

•Line pressure low

•Incorrect throttle position signal

•Malfunction of VSS

•Malfunction of input/turbine speed sensor

•Malfunction of sensor ground

•Malfunction of shift solenoids A, B, or C

•Malfunction of body ground

•Malfunction of control valve body

—Transaxle fixed in 4GR (Operation of fail-safe function)

•Short or open circuit in wiring

•Poor connection of connector

•Electronic parts of output and input system malfunction are malfunctioning

—Insufficient starting torque (Suspected when in-gear condition, shift control and engine circuit are

normal)

•Malfunction of torque converter (Poor operation, sticking)

—Engagement of TCC operation range (Operation of fail-safe function)

•Malfunction of TFT sensor (Short or open circuit)

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•With ignition switch at ON, does gear

position indicator light indication correspond

to selector lever position?Yes Go to next step.

No Go to symptom troubleshooting No.27 “Gear position

indicator light does not illuminate in M range”, or No.28

“Gear position indicator light illuminates in D range or P, N,

R position”.

2•Go to symptom troubleshooting No.12 “Lack/

loss of power-acceleration/cruise”.

(See Section F.)

•Does engine control system okay?Yes Go to next step.

No Repair or replace any defective parts according to

inspection results.

Page 738 of 909

ABS/TCS

P–5

P

System Diagram

.

End Of Sie

9

9

8

7

5

43

12

6

18

17

15

16

14

13

11

12

RF

FL

RR

RL

PCMG

E

FI Z

U

D

A

B

C

Y

AC

X

V O

R ADAB AA

ABS/TCS HU/CM

pP

9

10

19

920

A6E6921W201

1 IG switch

2SUS 15 A fuse

3 ABS 60 A fuse

4 Meter

5 ABS warning light

6 Brake system warning light

7 TCS OFF light

8 TCS indicator light

9CAN driver

10 Brake light11 Cruise actuator

12 TCS OFF switch

13 DLC-2

14 CAN-H

15 CAN-L

16 ABS Wheel-speed sensor

17 Battery

18 Brake switch

19 Audio unit, Wiper and washer switch, Car-navigation

unit, Auto leveling control unit

20 TCM, 4WD CM

Page 740 of 909

DYNAMIC STABILITY CONTROL

P–7

P

Wiring Diagram

.

9

RF

FL

RR

RL

PCM

G

E

M

I

F

K

H

Q

NJ

P

S

T

V

O

Y

X

W

U

R

L

Z

AC

D

B

AG

AF

AE

AC

AA

AB

C

F

D

A

B

EDSC HU/CM

A

B

C

D

F

1

3

2

8

7

5

4

6

9

9

9

10

11

13

12

15

14

18

17

16

1920

2122

24

23

A6E6921W203

1 IG switch

2SUS 15A fuse

3 ABS 60 A fuse

4 Meter

5 ABS warning light

6 Brake system warning light

7 DSC OFF light

8 DSC indicator light

9CAN driver

10 Battery

11 Cruise actuator

12 DSC OFF switch13 DLC-2

14 CAN-H

15 CAN-L

16 Wheel-speed sensor

17 Combine sensor

18 Steering angle sensor

19 Brake switch

20 Brake light

21 Back-up light switch (MTX only)

22 Back-up light (MTX only)

23 Audio unit, Wiper and washer switch, Car-navigation

unit, Auto leveling control unit

24 TCM, 4WD CM

Page 752 of 909

DYNAMIC STABILITY CONTROL

P–19

P

*: Used for vehicle manufacturing, not used for DSC.

Inspection Using An Oscilloscope (Reference)

Steering angle (steering angle signal 1 and 2)

•DSC HU/CM terminal:

Steering angle signal 2: W (+) — R (-)

Steering angle signal 1: X (+) — R (-)

•Oscilloscope setting:

1 V/DIV (Y), 25 ms/DIV (X), DC range

•Vehicle condition: Rotating steering wheel at one

revolution per second

Note

•As steering wheel rotation speed increases,

period of wave shortens.

•As for shape of steering angle signals 1 and

2, the phase is different.

Wheel speed

•DSC HU/CM terminal:

RF: M (+) — I (-)

RR: K (+) — H (-)

LF: F (+) — J (-)

LR: Q (+) — N (-)

•Oscilloscope setting:

1 V/DIV (Y), 2 ms/DIV (X), AC range

•Vehicle condition: Driving 30 km/h (18.6 mph)

Note

•As vehicle speed increases, period of wave

shortens.

•If there is malfunctioning in the sensor rotor,

wave profile warps.

ACAuto cruise set

signal outputAuto cruise unitWhen auto cruise is ON Below 1.0

•Inspect related harness

•Inspect DSC HU/CM

When auto cruise is OFF B+

AD—— — — —

AEVehicle speed

output•Audio unit

•Wiper and

washer

switch

•Car-navigatio

n unit

•Auto

leveling

control unit

•Cruise

actuatorVehicle is stopped 0

•Inspect related harness

•Inspect front wheel-speed

sensor •Inspect using the wave profile.

(See P–19 Inspection Using An

Oscilloscope (Reference))

AF CAN-L——No need to

check—

AG CAN-H——No need to

check—

AH—— — — — Terminal Signal Connected to Test condition Voltage (V) Action

0 V

A6E6921W014

0 V

A6E6921W013

Page 812 of 909

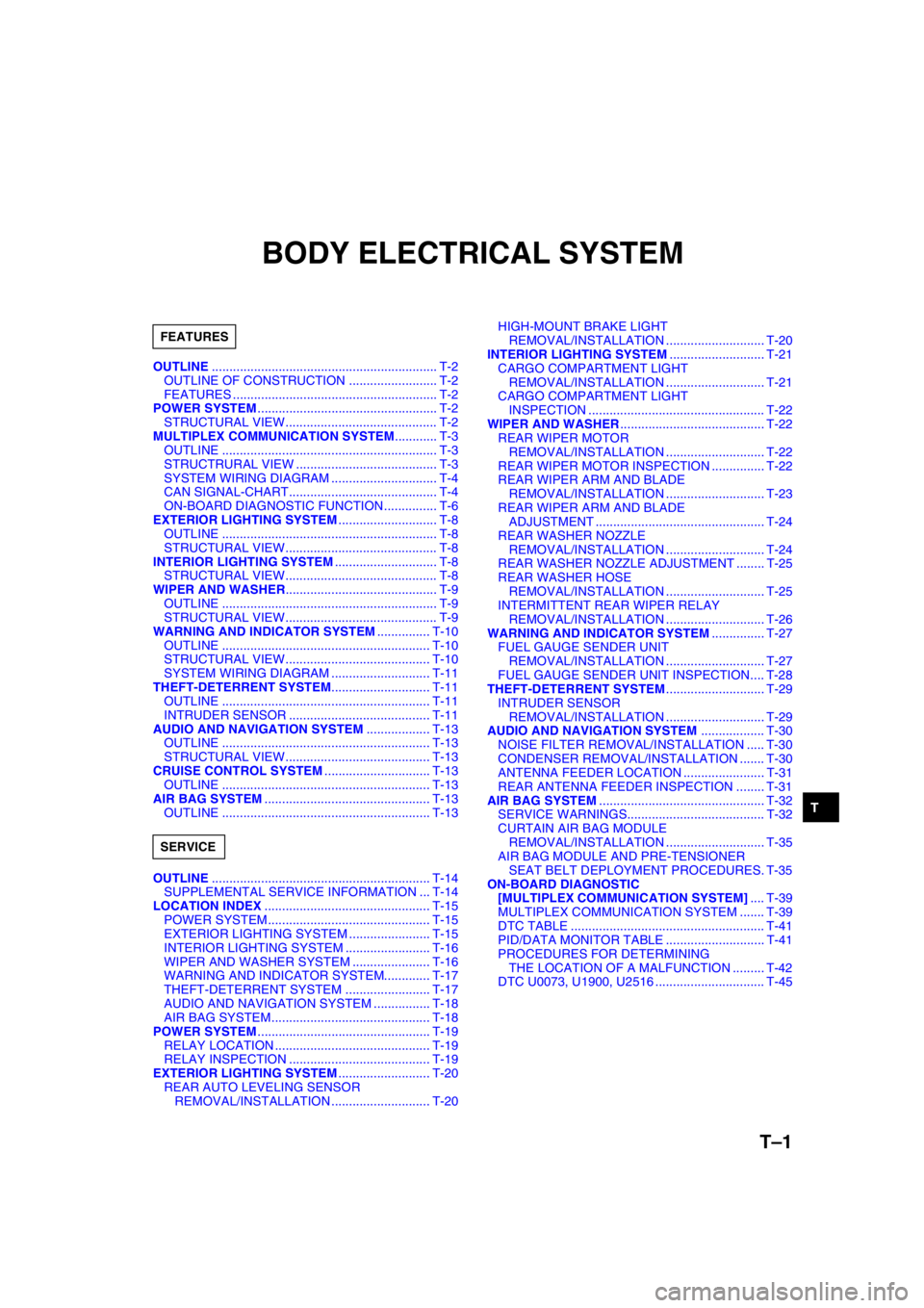

T–1

T

TBODY ELECTRICAL SYSTEM

OUTLINE................................................................ T-2

OUTLINE OF CONSTRUCTION ......................... T-2

FEATURES .......................................................... T-2

POWER SYSTEM................................................... T-2

STRUCTURAL VIEW........................................... T-2

MULTIPLEX COMMUNICATION SYSTEM............ T-3

OUTLINE ............................................................. T-3

STRUCTRURAL VIEW ........................................ T-3

SYSTEM WIRING DIAGRAM .............................. T-4

CAN SIGNAL-CHART.......................................... T-4

ON-BOARD DIAGNOSTIC FUNCTION............... T-6

EXTERIOR LIGHTING SYSTEM............................ T-8

OUTLINE ............................................................. T-8

STRUCTURAL VIEW........................................... T-8

INTERIOR LIGHTING SYSTEM............................. T-8

STRUCTURAL VIEW........................................... T-8

WIPER AND WASHER........................................... T-9

OUTLINE ............................................................. T-9

STRUCTURAL VIEW........................................... T-9

WARNING AND INDICATOR SYSTEM............... T-10

OUTLINE ........................................................... T-10

STRUCTURAL VIEW......................................... T-10

SYSTEM WIRING DIAGRAM ............................ T-11

THEFT-DETERRENT SYSTEM............................ T-11

OUTLINE ........................................................... T-11

INTRUDER SENSOR ........................................ T-11

AUDIO AND NAVIGATION SYSTEM.................. T-13

OUTLINE ........................................................... T-13

STRUCTURAL VIEW......................................... T-13

CRUISE CONTROL SYSTEM.............................. T-13

OUTLINE ........................................................... T-13

AIR BAG SYSTEM............................................... T-13

OUTLINE ........................................................... T-13

OUTLINE.............................................................. T-14

SUPPLEMENTAL SERVICE INFORMATION ... T-14

LOCATION INDEX............................................... T-15

POWER SYSTEM.............................................. T-15

EXTERIOR LIGHTING SYSTEM ....................... T-15

INTERIOR LIGHTING SYSTEM ........................ T-16

WIPER AND WASHER SYSTEM ...................... T-16

WARNING AND INDICATOR SYSTEM............. T-17

THEFT-DETERRENT SYSTEM ........................ T-17

AUDIO AND NAVIGATION SYSTEM ................ T-18

AIR BAG SYSTEM............................................. T-18

POWER SYSTEM................................................. T-19

RELAY LOCATION ............................................ T-19

RELAY INSPECTION ........................................ T-19

EXTERIOR LIGHTING SYSTEM.......................... T-20

REAR AUTO LEVELING SENSOR

REMOVAL/INSTALLATION ............................ T-20HIGH-MOUNT BRAKE LIGHT

REMOVAL/INSTALLATION ............................ T-20

INTERIOR LIGHTING SYSTEM........................... T-21

CARGO COMPARTMENT LIGHT

REMOVAL/INSTALLATION ............................ T-21

CARGO COMPARTMENT LIGHT

INSPECTION .................................................. T-22

WIPER AND WASHER......................................... T-22

REAR WIPER MOTOR

REMOVAL/INSTALLATION ............................ T-22

REAR WIPER MOTOR INSPECTION ............... T-22

REAR WIPER ARM AND BLADE

REMOVAL/INSTALLATION ............................ T-23

REAR WIPER ARM AND BLADE

ADJUSTMENT ................................................ T-24

REAR WASHER NOZZLE

REMOVAL/INSTALLATION ............................ T-24

REAR WASHER NOZZLE ADJUSTMENT ........ T-25

REAR WASHER HOSE

REMOVAL/INSTALLATION ............................ T-25

INTERMITTENT REAR WIPER RELAY

REMOVAL/INSTALLATION ............................ T-26

WARNING AND INDICATOR SYSTEM............... T-27

FUEL GAUGE SENDER UNIT

REMOVAL/INSTALLATION ............................ T-27

FUEL GAUGE SENDER UNIT INSPECTION.... T-28

THEFT-DETERRENT SYSTEM............................ T-29

INTRUDER SENSOR

REMOVAL/INSTALLATION ............................ T-29

AUDIO AND NAVIGATION SYSTEM.................. T-30

NOISE FILTER REMOVAL/INSTALLATION ..... T-30

CONDENSER REMOVAL/INSTALLATION ....... T-30

ANTENNA FEEDER LOCATION ....................... T-31

REAR ANTENNA FEEDER INSPECTION ........ T-31

AIR BAG SYSTEM............................................... T-32

SERVICE WARNINGS....................................... T-32

CURTAIN AIR BAG MODULE

REMOVAL/INSTALLATION ............................ T-35

AIR BAG MODULE AND PRE-TENSIONER

SEAT BELT DEPLOYMENT PROCEDURES. T-35

ON-BOARD DIAGNOSTIC

[MULTIPLEX COMMUNICATION SYSTEM].... T-39

MULTIPLEX COMMUNICATION SYSTEM ....... T-39

DTC TABLE ....................................................... T-41

PID/DATA MONITOR TABLE ............................ T-41

PROCEDURES FOR DETERMINING

THE LOCATION OF A MALFUNCTION ......... T-42

DTC U0073, U1900, U2516 ............................... T-45 FEATURES

SERVICE

Page 816 of 909

MULTIPLEX COMMUNICATION SYSTEM

T–5

T

End Of Sie

Cruise main indicator light

conditions (MZR-CD (RF

Turbo))OUT–––IN

Cruise set indicator light

conditions (MZR-CD (RF

Turbo))OUT–––IN

Desired gear/

selector lever

positionFN4A-EL OUT–IN–IN

JA5AX-EL IN OUT IN IN IN

ECT OUT IN–IN

Engine control condition OUT–IN––

Engine displacement OUT–IN––

Engine loss torque (except

MZR-CD (RF Turbo))OUT IN–––

Engine speed OUT IN IN IN IN

Engine torque (except

MZR-CD (RF Turbo))OUT IN–––

Fuel injection information OUT–IN––

Fuel type and delivery OUT–IN––

Gear position IN OUT IN IN IN

Generator warning light

conditions (except MZR-

CD (RF Turbo))OUT–––IN

Glow indicator light

condition (MZR-CD (RF

Turbo))OUT–––IN

HOLD indicator light

conditions (FN4A-EL)OUT–––IN

Idle speed up request IN OUT–––

MIL condition (except

MZR-CD (RF Turbo))OUT–––IN

MIL indicate request IN OUT–––

Number of cylinders OUT–IN––

Racing select

determinationIN OUT–––

TCC condition IN OUT–––

Tire circumference (front/

rear)OUT–IN––

Torque reduction inhibit OUT IN IN––

TP OUTINININ–

Transmission/axle type OUT–IN––

Travelled distanceIN–OUT––

IN OUT––IN

OUT–––IN

Torque

reduction

requestJA5AX-EL IN OUT–––

except

JA5AX-ELIN–OUT––

Turbine speed IN OUT–––

Upper torque limit IN OUT–––

Vehicle speedOUT–––IN

IN OUT–––

Wheel speed (front left/

front right/rear left/rear

right)IN IN OUT IN–

OUT–––IN

4WD system operating

condition (warning light

information)–––OUT IN SignalMultiplex module

PCM TCMABS (ABS/TCS)

HU/CM or

DSC HU/CM4WD control

moduleInstrument

cluster

Page 824 of 909

AUDIO AND NAVIGATION SYSTEM, CRUISE CONTROL SYSTEM, AIR BAG SYSTEM

T–13

T

OUTLINEA6E812401052201•Due to the adoption of the WGN, the following have been changed:

—Installation positions of the condenser and the noise filter

—Antenna feeder routing

End Of Sie

STRUCTURAL VIEWA6E812401052202

.

End Of Sie

OUTLINEA6E812801052201•The PCM controls the cruise control system. Refer to Section F for details regarding PCM control. (SeeF2–23

CRUISE CONTROL SYSTEM)

End Of Sie

OUTLINEA6E813001046201•Due to the adoption of the WGN, the shape of the curtain air bag module has been modified.

End Of Sie

AUDIO AND NAVIGATION SYSTEM

1

2

3

A6E8124T101

1 Rear antenna feeder

2 Condenser3 Noise filter

CRUISE CONTROL SYSTEM

AIR BAG SYSTEM