fuel MAZDA 6 2002 Suplement Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 99 of 909

FUEL SYSTEM

F1–11

F1

Operation

•The fuel jet pump (venturi) is installed in the return passage from the pressure regulator, and fuel in the fuel

tank is pumped to the left side from the right side using the vacuum generated in the passage.

•When the return fuel pressure exceeds a specified value, the relief valve is opened. The relief valve delivers the

return fuel directly to the fuel tank. In this way, pressure of the return fuel passing through the fuel jet pump is

kept constantly below the specified value.

.

End Of Sie

9

8

7

54

3

10

14

13

11

12

6

1

2

:

:

2

15

A6E39122003

1 Fuel pump unit

2 Fuel pump (transfer)

3 Fuel injector

4 Fuel tank (left side)

5 Fuel tank (right side)

6 Relief valve

7 Discharge outlet

8 From pressure regulator9 From fuel tank (right side)

10 Fuel jet pump

11 To fuel tank (left side)

12 Fuel jet pump

13 From fuel tank (left side)

14 Fuel flow

15 Pumped fuel flow

Page 100 of 909

F1–12

FUEL SYSTEM

QUICK RELEASE CONNECTOR (FUEL TANK SIDE, TRANSFER HOSE PART)A6E391242692201Function

•The quick release connector makes disconnecting and connecting of fuel hoses and fuel pipes easy.

Structure

•The quick release connector is adopted for the transfer hose part of the fuel tank side.

•The quick release connector is composed of a retainer, O-ring and other parts. The quick release connector

and plastic fuel hose are integrated and cannot be disconnected.

•The retainer and quick release connector are integrated and cannot be disconnected.

•An SST is not required to uncouple this type of quick release connector.

.

Operation

•Squeeze the tabs of the retainer to unlock and disconnect the quick release connector from the fuel pipe.

•A click is heard when the tabs of the retainer are pushed correctly into the lock point of the quick release

connector.

.

End Of Sie

3

1

2

A6E39122010

1Tab

2 Quick release connector3 Disconnect

7

5

4

3

6

1

21

A6E39122011

1 O-ring

2 Lock point

3 Disconnect

4Fuel hose5 Quick release connector

6 Retainer

7 Fuel pipe

Page 102 of 909

F1–14

CONTROL SYSTEM

OUTLINEA6E394018880201•The control system is essentially carried over from the current Mazda6 (GG), except for the following. (See

Mazda6 Training Manual 3359-1*-02C.)

Vehicle Adoption

4WD ATX model

•TCM has been adopted. Due to this the PCM terminal of ATX device has been replaced to TCM. The ATX

device information which is needed by the fuel and emission control systems is communicated to the PCM by

the controller area network (CAN).

Unleaded (RON 90 or above) model

•BARO sensor has been eliminated. Due to this the BARO factor for purge control has been eliminated.

Input Device

×:Applicable

—: Not applicable

*

1: For MTX model

*2: With Immobilizer system

CONTROL SYSTEM

Item SignalMazda6 (GG, GY)

Remark for new model

4WD ATX Unleaded

(RON 90 or

above)Current

model

MAF/IAT sensor MAF and IAT×Same as current model

TP sensor TP×Same as current model

MAP sensor MAP×Same as current model

ECT sensor ECT×Same as current model

CMP sensorCylinder

identification×Same as current model

CKP sensor Engine revolution×Same as current model

Knock sensor Knocking×Same as current model

HO2S (Front, Rear)Oxygen

concentration×Same as current model

BARO sensor BARO×—×Same as current model

Neutral switch*

1Load/no load

distinction×Same as current model

Clutch switch*

1Load/no load

distinction×Same as current model

Brake switchBrake pedal

condition×Same as current model

PSP switchP/S oil pump load

condition×Same as current model

VSS Vehicle speed—×—

A/C switch, refrigerant

pressure switch (high,

low pressure)A/C operational×Same as current model

Refrigerant pressure

switch (middle

pressure)A/C compressor load×—×Same as current model

Battery Battery voltage×Same as current model

Generation voltage

(Generator terminal P)Generation voltage×Same as current model

Immobilizer unit*

2Immobilizer system

communication×—×Same as current model

Page 103 of 909

CONTROL SYSTEM

F1–15

F1

Output Device

×:Applied

—: Not applied

* : For L3 engine only

End Of Sie

Item SignalMazda6 (GG, GY)

Remark for new model

4WD ATX Unleaded

(RON 90

or above)Current

model

IAC valve IAC×Same as current model

VIC solenoid valve* VIC×—×Same as current model

Variable tumble control

solenoid valveVTCS×Same as current model

Oil control valve (OCV)*Variable valve

timing control×—×Same as current model

Fuel injectorFuel injection

control×Same as current model

Fuel pump relayFuel pump

control×Same as current model

Ignition coil ESA control×Same as current model

EGR valve EGR control×Same as current model

Purge solenoid valve Purge control×Same as current model

BARO factor for Purge control has been

eliminated.

Heated oxygen sensor

heater

(Front, rear)O2S heater

control×Same as current model

Field coil

(Generator terminal D)Generator

control×Same as current model

Cooling fan relayElectric fan

control×Same as current model

A/C relayA/C cut-off

control×Same as current model

Controller area network

(CAN)Information

function×Same as current model

TCM (ATX) information have been

adopted for 4WD ATX model.

Page 104 of 909

F1–16

CONTROL SYSTEM

STRUCTURAL VIEW (4WD)A6E394018880202

.

End Of Sie

9

8

7

5

4

3

10

1817

15

16

14

13

11

12

20

25

24

23

21

22

6

1

2

19

A6E39402000

1 MAF/IAT sensor

2 TP sensor

3 MAP sensor

4 CMP sensor

5 CKP sensor

6 ECT sensor

7 Knock sensor

8 HO2S (front)

9 HO2S (rear)

10 PSP switch

11 Brake switch

12 VAD control solenoid valve

13 IAC valve14 VIC solenoid valve

15 Variable tumble control solenoid valve

16 OCV

17 Fuel injector

18 Ignition coil

19 Purge solenoid valve

20 EGR valve

21 BARO sensor

22 PCM (R.H.D.)

23 TCM (R.H.D)

24 PCM (L.H.D.)

25 TCM (L.H.D)

Page 106 of 909

F1–18

CONTROL SYSTEM

*1: For MTX model

*2: For 2WD ATX model

*3: For L3 engine

End Of Sie

1 MAF/IAT sensor

2 TP sensor

3 MAP sensor

4 CMP sensor

5 CKP sensor

6 ECT sensor

7 Knock sensor

8 HO2S (front, rear)

9 PSP switch

10 Vehicle speedometer sensor

11

Clutch switch*

1

12

Neutral switch*1

13

TR switch*2

14 Brake switch

15 A/C switch

16 Refrigerant pressure switch

17 Generator (terminal P: generation voltage)

18 Battery

19

VAD control solenoid valve*

3

20 IAC valve

21

VIC solenoid valve*

3

22 Variable tumble control solenoid valve

23

OCV*

3

24 Fuel injector

25 Fuel pump relay

26 Ignition coil

27 Purge solenoid valve

28 EGR valve

29 Oxygen sensor heater (front, rear)

30 A/C relay

31 Cooling fan relay

32 Generator (terminal D: field coil)

33

VAD control*

3

34 IAC

35

VIC*

3

36 VTCS

37

Variable valve timing control*

3

38 Fuel injection control

39 Fuel pump control

40 Electronic spark advance (ESA) control

41 Purge control

42 EGR control

43 Oxygen sensor heater control

44 A/C cut-off control

45 Electrical fan control

46 Generator control

Page 107 of 909

CONTROL SYSTEM

F1–19

F1

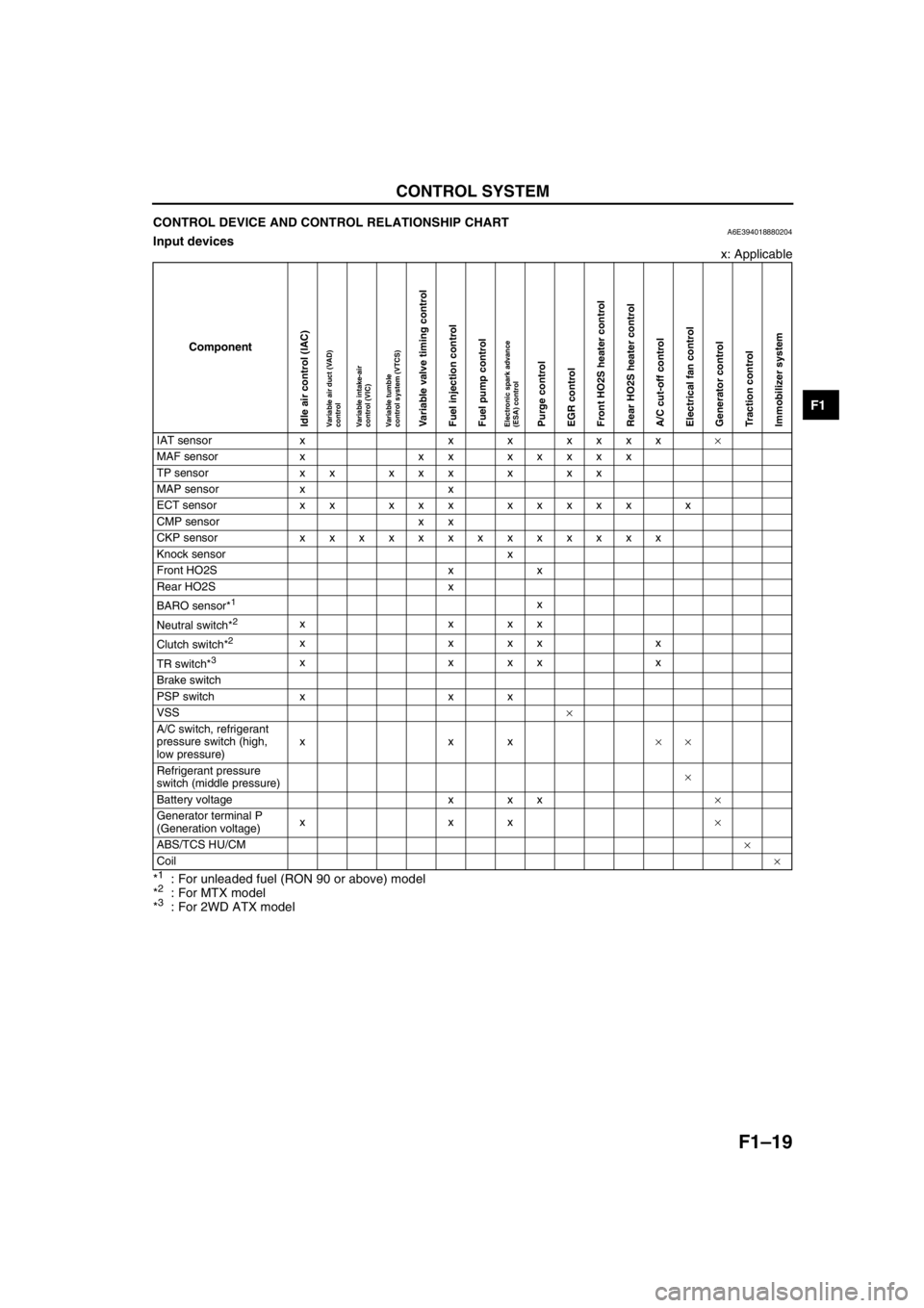

CONTROL DEVICE AND CONTROL RELATIONSHIP CHARTA6E394018880204Input devices

x: Applicable

*

1: For unleaded fuel (RON 90 or above) model

*2: For MTX model

*3: For 2WD ATX model

Component

IAT sensor x x x xxxx×

MAF sensor x xx xxxxx

TP sensor x x x x x x x x

MAP sensor x x

ECT sensor xx xxx xxxxx x

CMP sensor x x

CKP sensor xxxxxxxxxxxxx

Knock sensor x

Front HO2S x x

Rear HO2S x

BARO sensor*

1x

Neutral switch*

2xxxx

Clutch switch*

2xxxxx

TR switch*

3xxxxx

Brake switch

PSP switch x x x

VSS×

A/C switch, refrigerant

pressure switch (high,

low pressure)xxx××

Refrigerant pressure

switch (middle pressure)×

Battery voltage x x x×

Generator terminal P

(Generation voltage)xxx×

ABS/TCS HU/CM×

Coil×

Idle air control (IAC)Variable air duct (VAD)

controlVariable intake-air

control (VIC)Variable tumble

control system (VTCS)Variable valve timing controlFuel injection controlFuel pump controlElectronic spark advance

(ESA) controlPurge controlEGR controlFront HO2S heater controlRear HO2S heater controlA/C cut-off controlElectrical fan controlGenerator controlTraction controlImmobilizer system

Page 108 of 909

F1–20

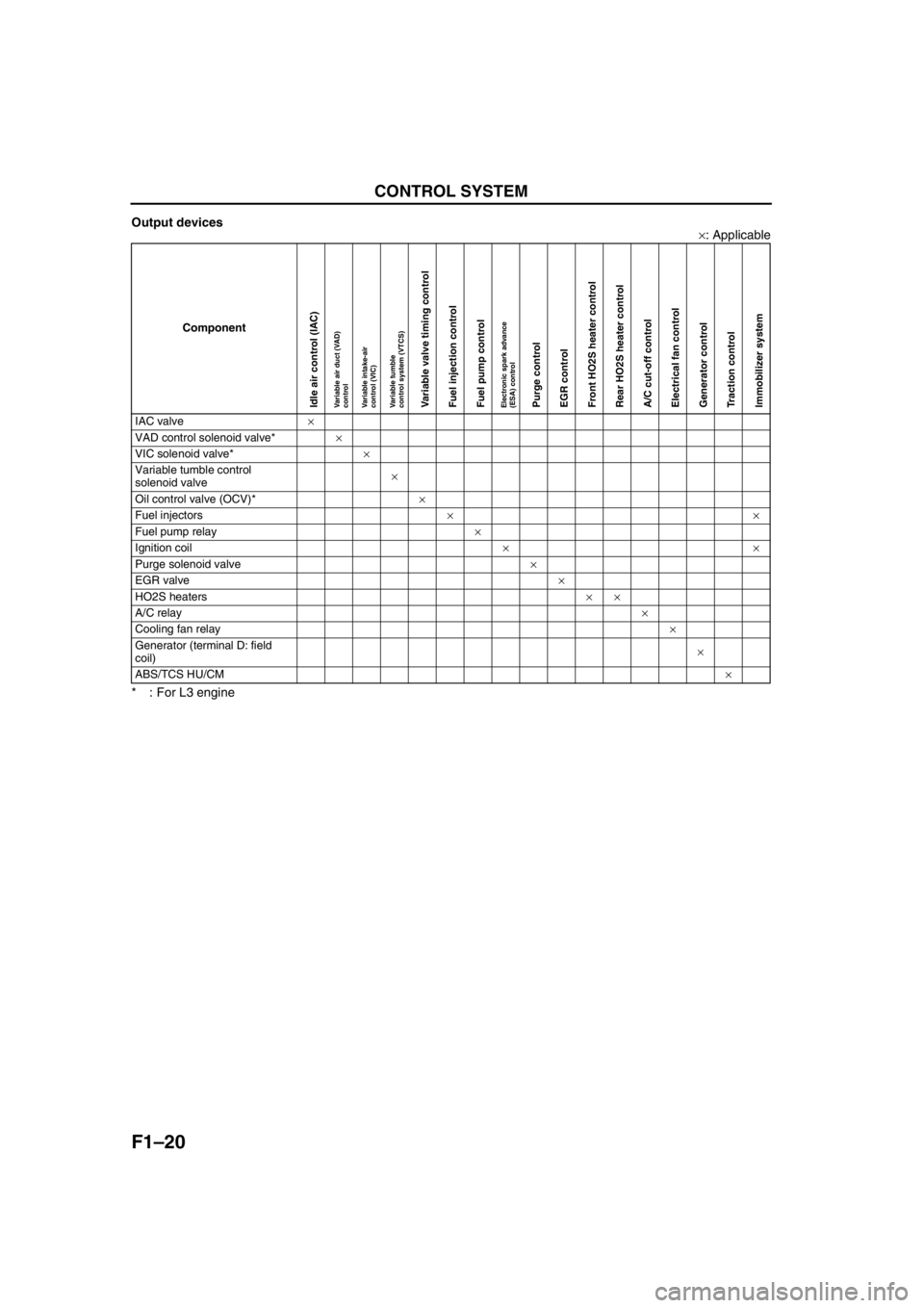

CONTROL SYSTEM

Output devices

×: Applicable

* : For L3 engine

End Of Sie

Component

IAC valve×

VAD control solenoid valve*×

VIC solenoid valve*×

Variable tumble control

solenoid valve×

Oil control valve (OCV)*×

Fuel injectors××

Fuel pump relay×

Ignition coil××

Purge solenoid valve×

EGR valve×

HO2S heaters××

A/C relay×

Cooling fan relay×

Generator (terminal D: field

coil)×

ABS/TCS HU/CM×

Idle air control (IAC)Variable air duct (VAD)

controlVariable intake-air

control (VIC)Variable tumble

control system (VTCS)Variable valve timing controlFuel injection controlFuel pump controlElectronic spark advance

(ESA) controlPurge controlEGR controlFront HO2S heater controlRear HO2S heater controlA/C cut-off controlElectrical fan controlGenerator controlTraction controlImmobilizer system

Page 109 of 909

CONTROL SYSTEM

F1–21

F1

CONTROLLER AREA NETWORK (CAN)A6E394018880205•PCM transmit/received the information in the CAN. For detail information of the CAN, see the “MULTIPLEX

COMMUNICATION SYSTEM.” (See T–3 OUTLINE.)

Transmit Information (4WD ATX Model)

•Engine control condition

•Torque reduction inhibit

•Engine speed

•Vehicle Speed

•TP

•Engine torque (without torque reduction)

•Engine torque (with torque reduction)

•Battery reconnection

•Engine loss torque

•ECT

•Travelled distance

•Fuel injection information

•MIL condition

•Generator warning light conditions

•Engine displacement

•Number of cylinders

•Air induction type

•Fuel type and delivery

•Country

•Transmission/axle type

•Tire circumference (front/rear)

Received Information (4WD ATX Model)

From ABS HU/CM, ABS/TCS HU/CM, or DSC HU/CM

•Wheel speed

—Front left, Front right, Rear left, and Rear right

•Travelled distance

•Brake system status

•Torque reduction request

•Brake system configuration

From TCM

•Desired torque

•Upper torque limit

•Turbineshaft speed

•Vehicle speed

•Torque reduction request

•Idle speed up request

•Racing select determination

•MIL indicate request

•Desired gear/selector lever position

•AT warning indicator light condition

•TCC condition

End Of Sie

Page 110 of 909

F1–22

OUTLINE, ENGINE TUNE-UP

SUPPLEMENTAL SERVICE INFORMATIONA6E390218881206•The following changes and/or additions have been made since publication of the Mazda6 Workshop Manual

(1621-10-98E).

Idle speed

•Adjustment procedure has been modified.

Fuel tank

•Removal/installation procedure has been modified.

Fuel pump unit

•Removal/installation procedure has been modified.

Quick release connector (fuel tank side, transfer hose part)

•Removal/installation procedure has been added.

Exhaust system

•Removal/installation procedure has been modified.

PCM

•Inspection procedure has been modified.

On-board diagnostic

•Inspection procedure has been modified.

Troubleshooting

•Inspection procedure has been modified.

End Of Sie

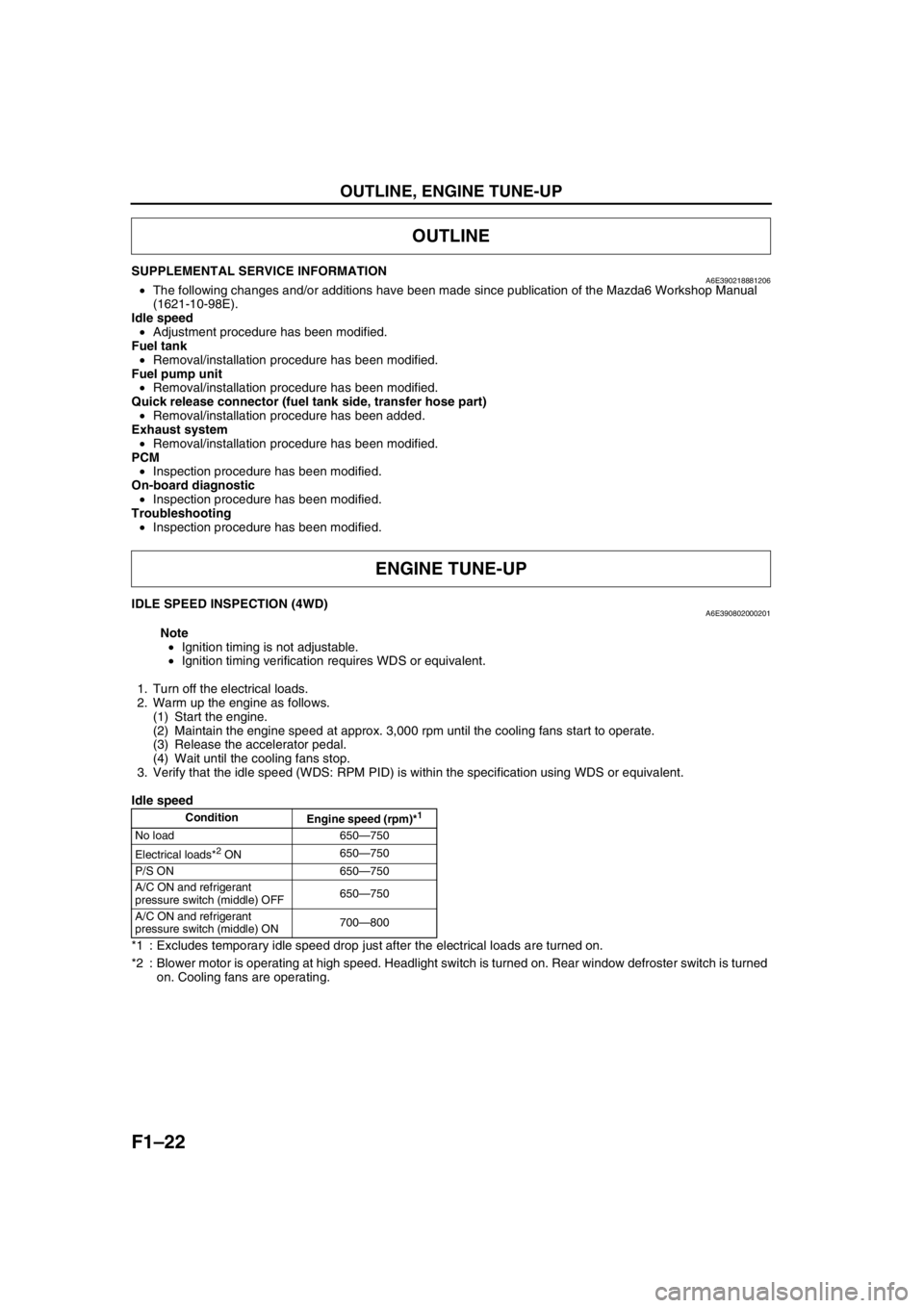

IDLE SPEED INSPECTION (4WD)A6E390802000201

Note

•Ignition timing is not adjustable.

•Ignition timing verification requires WDS or equivalent.

1. Turn off the electrical loads.

2. Warm up the engine as follows.

(1) Start the engine.

(2) Maintain the engine speed at approx. 3,000 rpm until the cooling fans start to operate.

(3) Release the accelerator pedal.

(4) Wait until the cooling fans stop.

3. Verify that the idle speed (WDS: RPM PID) is within the specification using WDS or equivalent.

Idle speed

*1 : Excludes temporary idle speed drop just after the electrical loads are turned on.

*2 : Blower motor is operating at high speed. Headlight switch is turned on. Rear window defroster switch is turned

on. Cooling fans are operating.

End Of Sie

OUTLINE

ENGINE TUNE-UP

Condition

Engine speed (rpm)*1

No load 650—750

Electrical loads*

2 ON650—750

P/S ON 650—750

A/C ON and refrigerant

pressure switch (middle) OFF650—750

A/C ON and refrigerant

pressure switch (middle) ON700—800