fuel MAZDA 6 2002 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 124 of 909

F1–36

CONTROL SYSTEM

*1: Calculated value; differs from terminal voltage

*2: Refrigerant pressure switch (middle) turns on when the refrigerant pressure is 1.69—1.84 MPa {17.3—18.7

kgf/cm2, 247—265 psi}

*3: Refrigerant pressure switch (middle) turns off when the refrigerant pressure is 1.26—1.49 MPa {12.9—15.1

kgf/cm2, 184—214 psi}

*4: L3 and L8, LF (Intensely hot area) engine models

*5: Immobilizer system equipped model

*6: Immobilizer system not equipped

*7: L3 engine model only

*8: MTX model only

•Following PIDs are for the ATX models. If inspects for following PIDs, see K2–180 PID/DATA MONITOR

INSPECTION.

PIDs for the ATX models

—GEAR, LINEDES, LPS, OP_SW_B, SSA/SS1, SSB/SS2, SSC/SS3, TCS, TFT, TFTV, THOP, TR,

TR_SENS, TSS

RO2FT1 (Rear oxygen

sensor fuel trim)—Idle (after warm up): approx. –

0.03—0.03Perform applicable DTC

troubleshooting.—

RPM (Engine speed) rpm

LF Unleaded fuel (RON 90 or

above) model

No load: 600—700 rpm

E/L operating: 650—750 rpm

P/S operating: 650—750 rpm

A/C ON: 700—800 rpm

L3 4WD ATX model

No load: 650—750 rpm

E/L operating: 650—750 rpm

P/S operating: 650—750 rpm

A/C ON: 650—750 rpm*

2, 700—

800 rpm*3

Inspect CKP sensor. 2D, 2G

SEGRP (EGR valve

(stepping motor)

position)StepIgnition switch ON: 0 step

Idle: 0 step

Cranking: 0—60 stepsInspect following PIDs: MAF, TP,

ECT, RPM, VSS.

Inspect EGR valve.4E, 4H,

4K, 4N

SHRTFT1 (Short term

fuel trim)%Idle (after warm up): approx.–30—

25%Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

SPARKADV (Ignition

timing)°Ignition switch ON: BTDC 0°

Idle: BTDC approx. 10°Inspect following PIDs: MAF, TP,

ECT, RPM, INGEAR, TR, PSP,

ACSW, VPWR.

Inspect ignition timing.2J, 2M

TEST (Test mode) ON/OFF———

TP (TP)%CTP: 13—23%

WOT: 86—96%

Inspect TP sensor. 2A

VCTP: 0.65—1.15 V

WOT: 4.3—4.8 V

TPCT

(TP sensor voltage at

CTP )V0.65—1.15 V Inspect TP sensor. 2A

VPWR (Battery positive

voltage)V Ignition switch ON: B+Inspect main relay.

Inspect battery.2Y, 2Z

VSS (Vehicle speed) kph, mphVehicle speed 20 kph {12 mph}:

20 kph {12 mph}

Vehicle speed 40 kph {25 mph}:

20 kph {12 mph}Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

VT DUTY1*

7% Idle: 0%Inspect following PIDs: TP, ECT,

RPM.

Inspect OCV.2I, 2L Monitor item

(Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

Page 130 of 909

F1–42

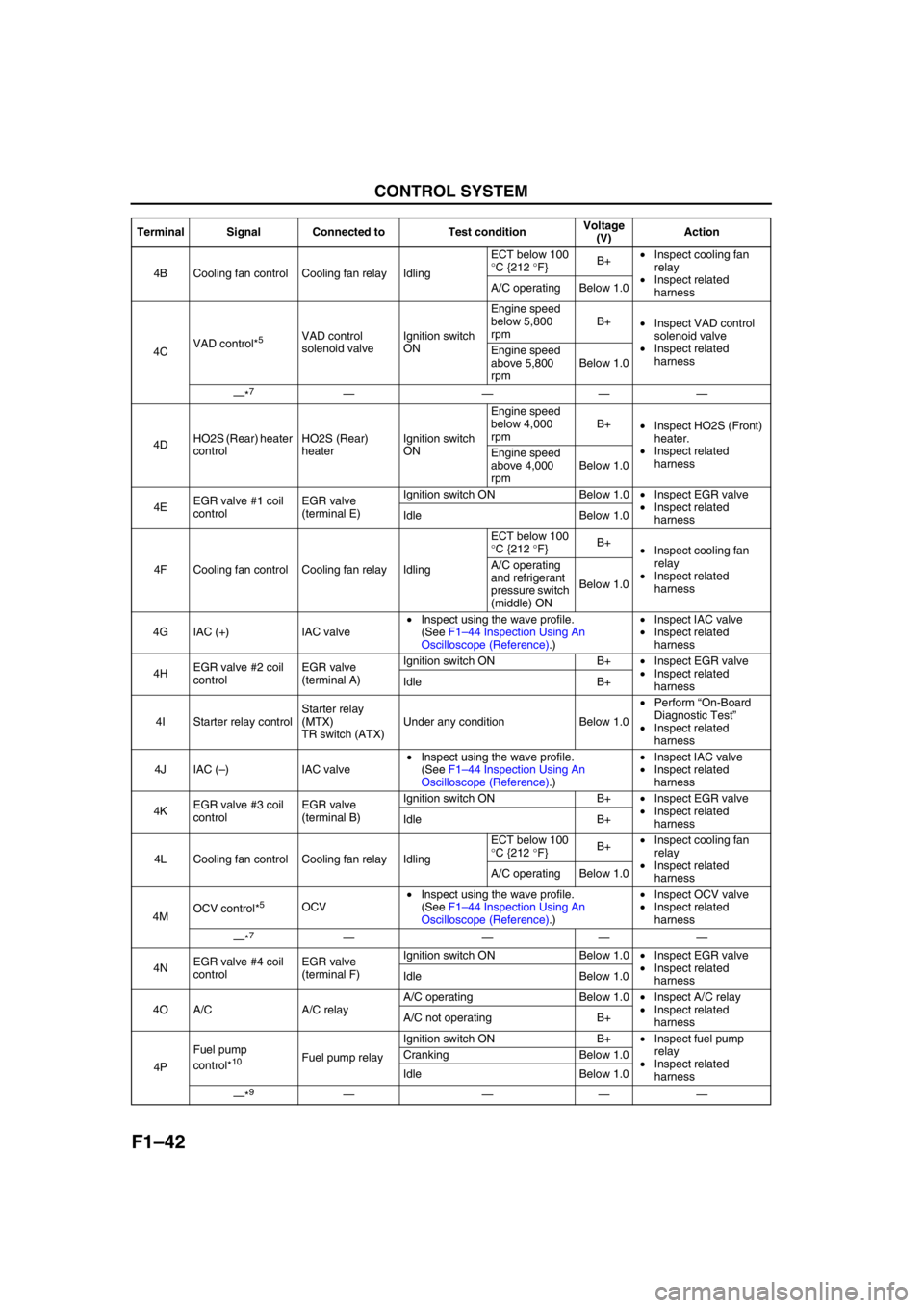

CONTROL SYSTEM

4B Cooling fan control Cooling fan relay IdlingECT below 100

°C {212 °F}B+•Inspect cooling fan

relay

•Inspect related

harness A/C operating Below 1.0

4CVAD control*

5VAD control

solenoid valveIgnition switch

ONEngine speed

below 5,800

rpmB+

•Inspect VAD control

solenoid valve

•Inspect related

harness Engine speed

above 5,800

rpmBelow 1.0

—*

7————

4DHO2S (Rear) heater

controlHO2S (Rear)

heaterIgnition switch

ONEngine speed

below 4,000

rpmB+

•Inspect HO2S (Front)

heater.

•Inspect related

harness Engine speed

above 4,000

rpmBelow 1.0

4EEGR valve #1 coil

controlEGR valve

(terminal E)Ignition switch ON Below 1.0•Inspect EGR valve

•Inspect related

harness Idle Below 1.0

4F Cooling fan control Cooling fan relay IdlingECT below 100

°C {212 °F}B+

•Inspect cooling fan

relay

•Inspect related

harness A/C operating

and refrigerant

pressure switch

(middle) ONBelow 1.0

4G IAC (+) IAC valve•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect IAC valve

•Inspect related

harness

4HEGR valve #2 coil

controlEGR valve

(terminal A)Ignition switch ON B+•Inspect EGR valve

•Inspect related

harness Idle B+

4I Starter relay controlStarter relay

(MTX)

TR switch (ATX)Under any condition Below 1.0•Perform “On-Board

Diagnostic Test”

•Inspect related

harness

4J IAC (–)IAC valve•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect IAC valve

•Inspect related

harness

4KEGR valve #3 coil

controlEGR valve

(terminal B)Ignition switch ON B+•Inspect EGR valve

•Inspect related

harness Idle B+

4L Cooling fan control Cooling fan relay IdlingECT below 100

°C {212 °F}B+•Inspect cooling fan

relay

•Inspect related

harness A/C operating Below 1.0

4MOCV control*

5OCV•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect OCV valve

•Inspect related

harness

—*

7————

4NEGR valve #4 coil

controlEGR valve

(terminal F)Ignition switch ON Below 1.0•Inspect EGR valve

•Inspect related

harness Idle Below 1.0

4O A/C A/C relayA/C operating Below 1.0•Inspect A/C relay

•Inspect related

harness A/C not operating B+

4PFuel pump

control*

10Fuel pump relayIgnition switch ON B+•Inspect fuel pump

relay

•Inspect related

harness Cranking Below 1.0

Idle Below 1.0

—*

9———— Terminal Signal Connected to Test conditionVoltage

(V)Action

Page 131 of 909

CONTROL SYSTEM

F1–43

F1

*1: Calculated value; differs from terminal voltage

*2: MTX models

*3: ATX models

*4: LF engine models

*5: L3 engine models

4QFuel pump control*

9Fuel pump relayIgnition switch ON B+•Inspect fuel pump

relay

•Inspect related

harness Cranking Below 1.0

Idle Below 1.0

—*

10————

4RVIC control*

5VIC control

solenoid valveEngine speed: above 4,500 rpm B+•Inspect VIC solenoid

valve

•Inspect related

harness Engine speed: below 4,500 rpm Below 1.0

—*

7————

4S—— — ——

4TVariable tumble

controlVariable tumble

control solenoid

valveECT above 63 °C { 145 °F} while

idling.B+•Inspect variable

tumble control

solenoid valve

•Inspect related

harness ECT below 63 °C {145 °F} and

engine speed below 3,750 rpmBelow 1.0

4U Purge controlPurge solenoid

valve•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect purge

solenoid valve

•Inspect related

harness

4VB+*

3Main relayIgnition switch OFF Below 1.0•Inspect battery

•Inspect related

harness Ignition switch ON B+

—— — ——

4W Fuel injection (#2) Fuel injector No.2•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect fuel injector

No.2

•Inspect related

harness

4X GND GND Under any condition Below 1.0•Inspect related

harness

4YShift solenoid C

control*

11Shift solenoid C•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect shift solenoid

C

•Inspect related

harness

—*

14————

4Z Fuel injection (#1) Fuel injector No.1•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect fuel injector

No.1

•Inspect related

harness

4AA Fuel injection (#4) Fuel injector No.4•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect fuel injector

No.4

•Inspect related

harness

4ABShift solenoid A

control*

11Shift solenoid A•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect shift solenoid

A

•Inspect related

harness

—*

14————

4ACShift solenoid B

control*

11Shift solenoid B•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect shift solenoid

B

•Inspect related

harness

—*

14————

4AD Fuel injection (#3) Fuel injector No.3•Inspect using the wave profile.

(See F1–44 Inspection Using An

Oscilloscope (Reference).)•Inspect fuel injector

No.3

•Inspect related

harness Terminal Signal Connected to Test conditionVoltage

(V)Action

Page 132 of 909

F1–44

CONTROL SYSTEM

*6: Unleaded fuel (RON 90 or above) models

*7: Exclude L3 engine models

*8: MTX, without ABS models

*9: Immobilizer system equipped

*10: Immobilizer system not equipped

*11: 2WD ATX models

*12: 4WD ATX models

*13: Exclude MTX models without ABS

*14: Exclude 2WD ATX models

Inspection Using An Oscilloscope (Reference)

IGT1, IGT2 control signals

PCM terminals

•IGT1(No.1 and No.4): 1A(+)—1D(–)

•IGT2(No.2 and No.3): 1B(+)—1C(–)

Oscilloscope setting

•4 V/DIV (Y), 0.01 ms/DIV (X), DC range

Vehicle condition

•Idle after warm up (engine speed approx. 650

rpm [MTX] or 700 rpm [ATX], no load, P/S off, A/C

off)

Generator output voltage signal

PCM terminals

•1AA(+)—2AC(–)

Oscilloscope setting

•2 V/DIV (Y), 2 ms/DIV (X), DC range

Vehicle condition

•Idle after warm up (engine speed approx. 650

rpm [MTX] or 700 rpm [ATX], no load, P/S off, A/C

off)

HO2S (front) signal

PCM terminals

•1AB(+)—2H(–)

Oscilloscope setting

•0.1 V/DIV (Y), 400 ms/DIV (X), DC range

Vehicle condition

•Idle after warm up (engine speed approx. 650

rpm [MTX], 700 rpm [ATX], no load, P/S off, A/C

off)

0 V

A6A3940W003

0 V

A6A3940W004

0 V

A6A3940W005

Page 137 of 909

CONTROL SYSTEM

F1–49

F1

Fuel injection control

PCM terminals

•Fuel Injection No.1: 4Z(+)—1C(–)

•Fuel Injection No.1: 4W(+)—1C(–)

•Fuel Injection No.1: 4AD(+)—1C(–)

•Fuel Injection No.1: 4AA(+)—1C(–)

Oscilloscope setting

•4 V/DIV (Y), 10 ms/DIV (X), DC range

Vehicle condition

•Idle after warm up (engine speed approx. 650

rpm [MTX] or 700 rpm [ATX], no load, P/S off, A/C

off)

Shift solenoid C control

PCM terminals

•4Y(+)—1C(–)

Oscilloscope setting

•5 V/DIV (Y), 5 ms/DIV (X), DC range

Vehicle condition

•Idle after warm up (engine speed approx. 650

rpm [MTX] or 700 rpm [ATX], no load, P/S off, A/C

off)

Shift solenoid A control

PCM terminals

•4AB(+)—1C(–)

Oscilloscope setting

•5 V/DIV (Y), 5 ms/DIV (X), DC range

Vehicle condition

•Idle after warm up (engine speed approx. 650

rpm [MTX] or 700 rpm [ATX], no load, P/S off, A/C

off)

Shift solenoid B control

PCM terminals

•4AC(+)—1C(–)

Oscilloscope setting

•5 V/DIV (Y), 5 ms/DIV (X), DC range

Vehicle condition

•Idle after warm up (engine speed approx. 650

rpm [MTX] or 700 rpm [ATX], no load, P/S off, A/C

off)

End Of Sie

0 V

A6A3940W024

0 V

A6A3940W025

0 V

A6A3940W026

0 V

A6A3940W027

Page 138 of 909

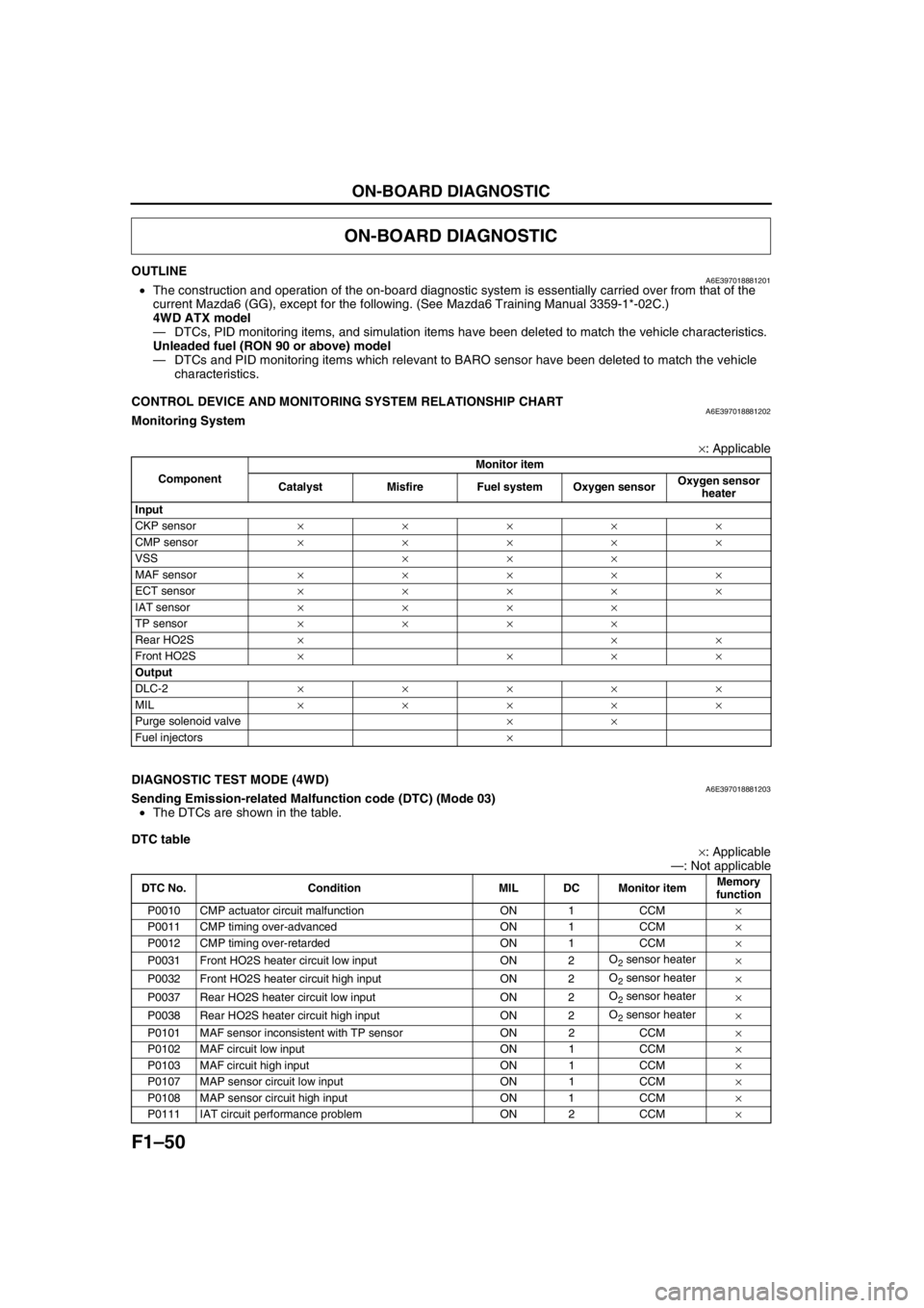

F1–50

ON-BOARD DIAGNOSTIC

OUTLINEA6E397018881201•The construction and operation of the on-board diagnostic system is essentially carried over from that of the

current Mazda6 (GG), except for the following. (See Mazda6 Training Manual 3359-1*-02C.)

4WD ATX model

—DTCs, PID monitoring items, and simulation items have been deleted to match the vehicle characteristics.

Unleaded fuel (RON 90 or above) model

—DTCs and PID monitoring items which relevant to BARO sensor have been deleted to match the vehicle

characteristics.

End Of Sie

CONTROL DEVICE AND MONITORING SYSTEM RELATIONSHIP CHARTA6E397018881202Monitoring System

×: Applicable

End Of Sie

DIAGNOSTIC TEST MODE (4WD)A6E397018881203Sending Emission-related Malfunction code (DTC) (Mode 03)

•The DTCs are shown in the table.

DTC table

×: Applicable

—: Not applicable

ON-BOARD DIAGNOSTIC

ComponentMonitor item

Catalyst Misfire Fuel system Oxygen sensor Oxygen sensor

heater

Input

CKP sensor×××××

CMP sensor×××××

VSS×××

MAF sensor×××××

ECT sensor×××××

IAT sensor××××

TP sensor××××

Rear HO2S×××

Front HO2S××××

Output

DLC-2×××××

MIL×××××

Purge solenoid valve××

Fuel injectors×

DTC No. Condition MIL DC Monitor itemMemory

function

P0010 CMP actuator circuit malfunction ON 1 CCM×

P0011 CMP timing over-advanced ON 1 CCM×

P0012 CMP timing over-retarded ON 1 CCM×

P0031 Front HO2S heater circuit low input ON 2O

2 sensor heater

×

P0032 Front HO2S heater circuit high input ON 2O

2 sensor heater

×

P0037 Rear HO2S heater circuit low input ON 2O

2 sensor heater

×

P0038 Rear HO2S heater circuit high input ON 2O

2 sensor heater

×

P0101 MAF sensor inconsistent with TP sensor ON 2 CCM×

P0102 MAF circuit low input ON 1 CCM×

P0103 MAF circuit high input ON 1 CCM×

P0107 MAP sensor circuit low input ON 1 CCM×

P0108 MAP sensor circuit high input ON 1 CCM×

P0111 IAT circuit performance problem ON 2 CCM×

Page 139 of 909

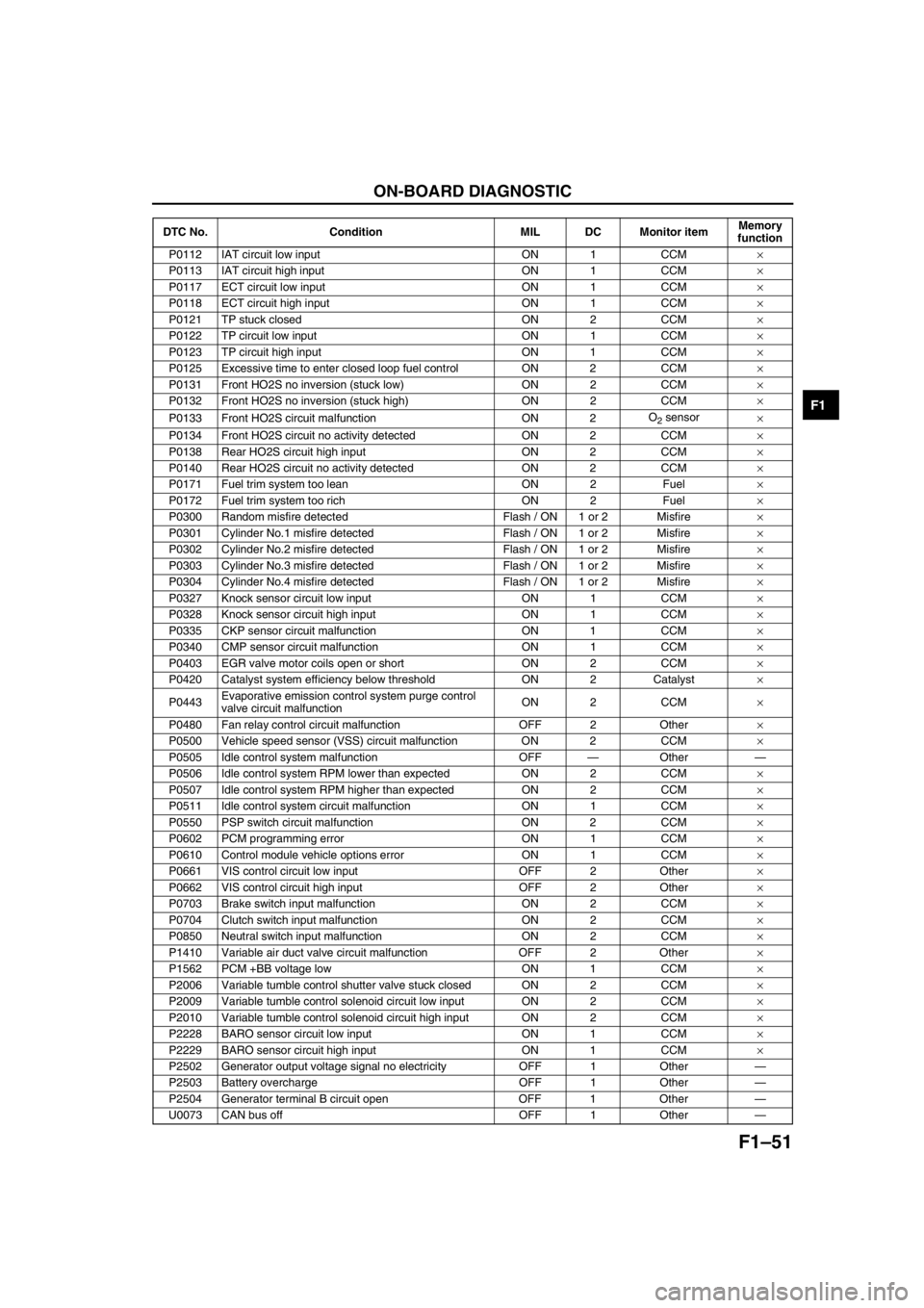

ON-BOARD DIAGNOSTIC

F1–51

F1

P0112 IAT circuit low input ON 1 CCM×

P0113 IAT circuit high input ON 1 CCM×

P0117 ECT circuit low input ON 1 CCM×

P0118 ECT circuit high input ON 1 CCM×

P0121 TP stuck closed ON 2 CCM×

P0122 TP circuit low input ON 1 CCM×

P0123 TP circuit high input ON 1 CCM×

P0125 Excessive time to enter closed loop fuel control ON 2 CCM×

P0131 Front HO2S no inversion (stuck low) ON 2 CCM×

P0132 Front HO2S no inversion (stuck high) ON 2 CCM×

P0133 Front HO2S circuit malfunction ON 2O

2 sensor

×

P0134 Front HO2S circuit no activity detected ON 2 CCM×

P0138 Rear HO2S circuit high input ON 2 CCM×

P0140 Rear HO2S circuit no activity detected ON 2 CCM×

P0171 Fuel trim system too lean ON 2 Fuel×

P0172 Fuel trim system too rich ON 2 Fuel×

P0300 Random misfire detected Flash / ON 1 or 2 Misfire×

P0301 Cylinder No.1 misfire detected Flash / ON 1 or 2 Misfire×

P0302 Cylinder No.2 misfire detected Flash / ON 1 or 2 Misfire×

P0303 Cylinder No.3 misfire detected Flash / ON 1 or 2 Misfire×

P0304 Cylinder No.4 misfire detected Flash / ON 1 or 2 Misfire×

P0327 Knock sensor circuit low input ON 1 CCM×

P0328 Knock sensor circuit high input ON 1 CCM×

P0335 CKP sensor circuit malfunction ON 1 CCM×

P0340 CMP sensor circuit malfunction ON 1 CCM×

P0403 EGR valve motor coils open or short ON 2 CCM×

P0420 Catalyst system efficiency below threshold ON 2 Catalyst×

P0443Evaporative emission control system purge control

valve circuit malfunctionON 2 CCM×

P0480 Fan relay control circuit malfunction OFF 2 Other×

P0500 Vehicle speed sensor (VSS) circuit malfunction ON 2 CCM×

P0505 Idle control system malfunction OFF—Other—

P0506 Idle control system RPM lower than expected ON 2 CCM×

P0507 Idle control system RPM higher than expected ON 2 CCM×

P0511 Idle control system circuit malfunction ON 1 CCM×

P0550 PSP switch circuit malfunction ON 2 CCM×

P0602 PCM programming error ON 1 CCM×

P0610 Control module vehicle options error ON 1 CCM×

P0661 VIS control circuit low input OFF 2 Other×

P0662 VIS control circuit high input OFF 2 Other×

P0703 Brake switch input malfunction ON 2 CCM×

P0704 Clutch switch input malfunction ON 2 CCM×

P0850 Neutral switch input malfunction ON 2 CCM×

P1410 Variable air duct valve circuit malfunction OFF 2 Other×

P1562 PCM +BB voltage low ON 1 CCM×

P2006 Variable tumble control shutter valve stuck closed ON 2 CCM×

P2009 Variable tumble control solenoid circuit low input ON 2 CCM×

P2010 Variable tumble control solenoid circuit high input ON 2 CCM×

P2228 BARO sensor circuit low input ON 1 CCM×

P2229 BARO sensor circuit high input ON 1 CCM×

P2502 Generator output voltage signal no electricity OFF 1 Other—

P2503 Battery overcharge OFF 1 Other—

P2504 Generator terminal B circuit open OFF 1 Other—

U0073 CAN bus off OFF 1 Other— DTC No. Condition MIL DC Monitor itemMemory

function

Page 142 of 909

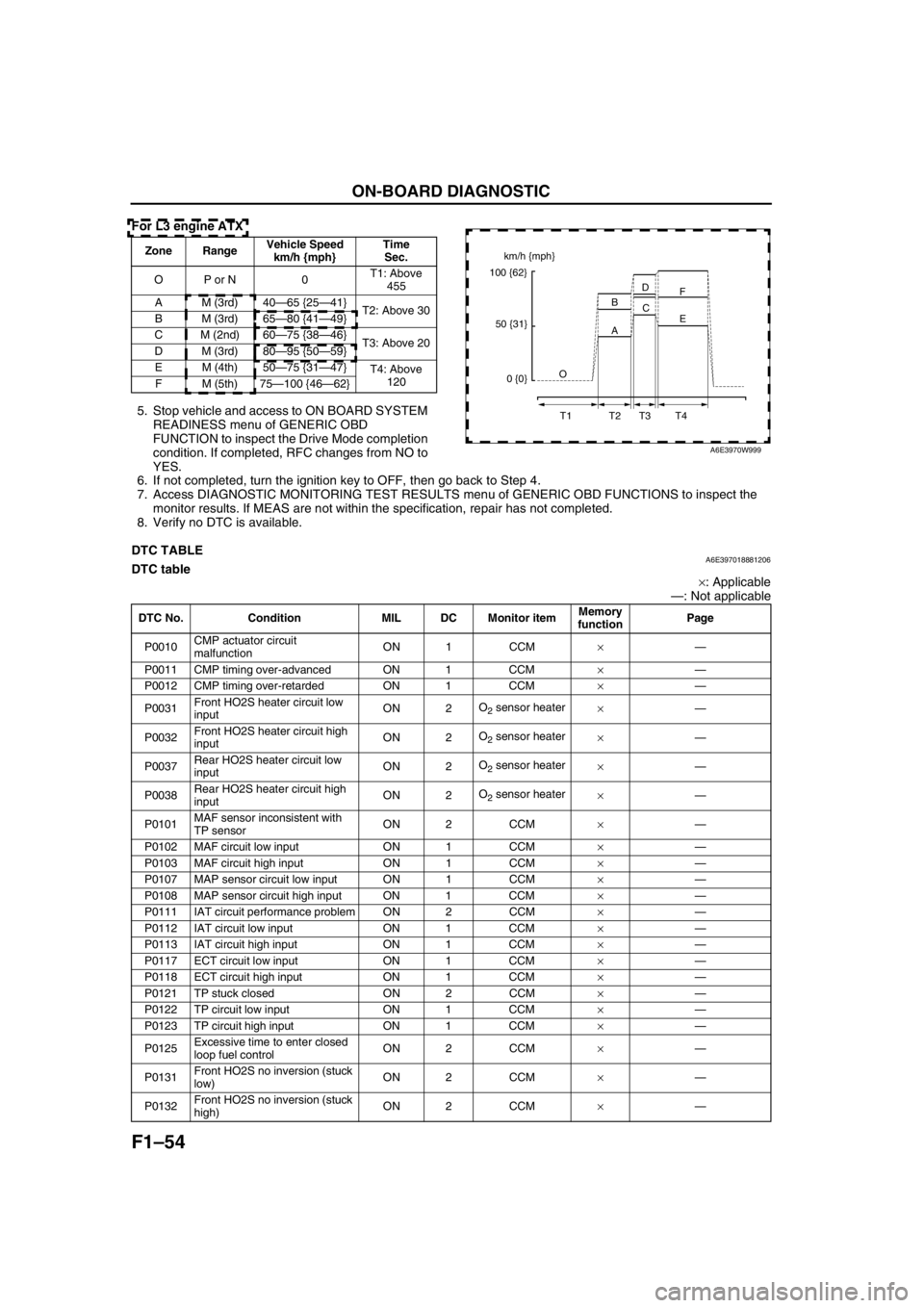

F1–54

ON-BOARD DIAGNOSTIC

For L3 engine ATX

5. Stop vehicle and access to ON BOARD SYSTEM

READINESS menu of GENERIC OBD

FUNCTION to inspect the Drive Mode completion

condition. If completed, RFC changes from NO to

YES.

6. If not completed, turn the ignition key to OFF, then go back to Step 4.

7. Access DIAGNOSTIC MONITORING TEST RESULTS menu of GENERIC OBD FUNCTIONS to inspect the

monitor results. If MEAS are not within the specification, repair has not completed.

8. Verify no DTC is available.

End Of Sie

DTC TABLEA6E397018881206DTC table

×: Applicable

—: Not applicable

Zone RangeVehicle Speed

km/h {mph}Time

Sec.

OP or N 0T1: Above

455

A M (3rd) 40—65 {25—41}

T2: Above 30

B M (3rd) 65—80 {41—49}

C M (2nd) 60—75 {38—46}

T3: Above 20

D M (3rd) 80—95 {50—59}

EM (4th)50—75 {31—47}

T4: Above

120

FM (5th)75—100 {46—62}km/h {mph}

100 {62}

50 {31}

0 {0}O

T1 T2 T3 T4A BD

C

E F

A6E3970W999

DTC No. Condition MIL DC Monitor itemMemory

functionPage

P0010CMP actuator circuit

malfunctionON 1 CCM×—

P0011 CMP timing over-advanced ON 1 CCM×—

P0012 CMP timing over-retarded ON 1 CCM×—

P0031Front HO2S heater circuit low

inputON 2O

2 sensor heater

×—

P0032Front HO2S heater circuit high

inputON 2O

2 sensor heater

×—

P0037Rear HO2S heater circuit low

inputON 2O

2 sensor heater

×—

P0038Rear HO2S heater circuit high

inputON 2O

2 sensor heater

×—

P0101MAF sensor inconsistent with

TP sensorON 2 CCM×—

P0102 MAF circuit low input ON 1 CCM×—

P0103 MAF circuit high input ON 1 CCM×—

P0107 MAP sensor circuit low input ON 1 CCM×—

P0108 MAP sensor circuit high input ON 1 CCM×—

P0111 IAT circuit performance problem ON 2 CCM×—

P0112 IAT circuit low input ON 1 CCM×—

P0113 IAT circuit high input ON 1 CCM×—

P0117 ECT circuit low input ON 1 CCM×—

P0118 ECT circuit high input ON 1 CCM×—

P0121 TP stuck closed ON 2 CCM×—

P0122 TP circuit low input ON 1 CCM×—

P0123 TP circuit high input ON 1 CCM×—

P0125Excessive time to enter closed

loop fuel controlON 2 CCM×—

P0131Front HO2S no inversion (stuck

low)ON 2 CCM×—

P0132Front HO2S no inversion (stuck

high)ON 2 CCM×—

Page 143 of 909

ON-BOARD DIAGNOSTIC

F1–55

F1

P0133 Front HO2S circuit malfunction ON 2O2 sensor

×—

P0134Front HO2S circuit no activity

detectedON 2 CCM×—

P0138 Rear HO2S circuit high input ON 2 CCM×—

P0140Rear HO2S circuit no activity

detectedON 2 CCM×—

P0171 Fuel trim system too lean ON 2 Fuel×—

P0172 Fuel trim system too rich ON 2 Fuel×—

P0300 Random misfire detected Flash / ON 1 or 2 Misfire×—

P0301 Cylinder No.1 misfire detected Flash / ON 1 or 2 Misfire×—

P0302 Cylinder No.2 misfire detected Flash / ON 1 or 2 Misfire×—

P0303 Cylinder No.3 misfire detected Flash / ON 1 or 2 Misfire×—

P0304 Cylinder No.4 misfire detected Flash / ON 1 or 2 Misfire×—

P0327 Knock sensor circuit low input ON 1 CCM×—

P0328 Knock sensor circuit high input ON 1 CCM×—

P0335 CKP sensor circuit malfunction ON 1 CCM×—

P0340 CMP sensor circuit malfunction ON 1 CCM×—

P0403EGR valve motor coils open or

shortON 2 CCM×—

P0420Catalyst system efficiency

below thresholdON 2 Catalyst×—

P0443Evaporative emission control

system purge control valve

circuit malfunctionON 2 CCM×—

P0480Fan relay control circuit

malfunctionOFF 2 Other×—

P0500Vehicle speed sensor (VSS)

circuit malfunction (MTX)ON 2 CCM×—

P0505 Idle control system malfunction OFF—Other——

P0506Idle control system RPM lower

than expectedON 2 CCM×—

P0507Idle control system RPM higher

than expectedON 2 CCM×—

P0511Idle control system circuit

malfunctionON 1 CCM×—

P0550 PSP switch circuit malfunction ON 2 CCM×—

P0602 PCM programming error ON 1 CCM×—

P0610Control module vehicle options

errorON 1 CCM×—

P0661 VIS control circuit low input OFF 2 Other×—

P0662 VIS control circuit high input OFF 2 Other×—

P0703 Brake switch input malfunction ON 2 CCM×—

P0704 Clutch switch input malfunction ON 2 CCM×—

P0850 Neutral switch input malfunction ON 2 CCM×—

P1410Variable air duct valve circuit

malfunctionOFF 2 Other×—

P1562 PCM +BB voltage low ON 1 CCM×—

P2006Variable tumble control system

shutter valve stuck closedON 2 CCM×—

P2009Variable tumble control solenoid

valve circuit low inputON 2 CCM×—

P2010Variable tumble control solenoid

valve circuit high inputON 2 CCM×—

P2228 BARO sensor circuit low input ON 1 CCM×—

P2229 BARO sensor circuit high input ON 1 CCM×—

P2502Generator output voltage signal

no electricityOFF 1 Other——

P2503 Battery overcharge OFF 1 Other—— DTC No. Condition MIL DC Monitor itemMemory

functionPage

Page 145 of 909

TROUBLESHOOTING

F1–57

F1

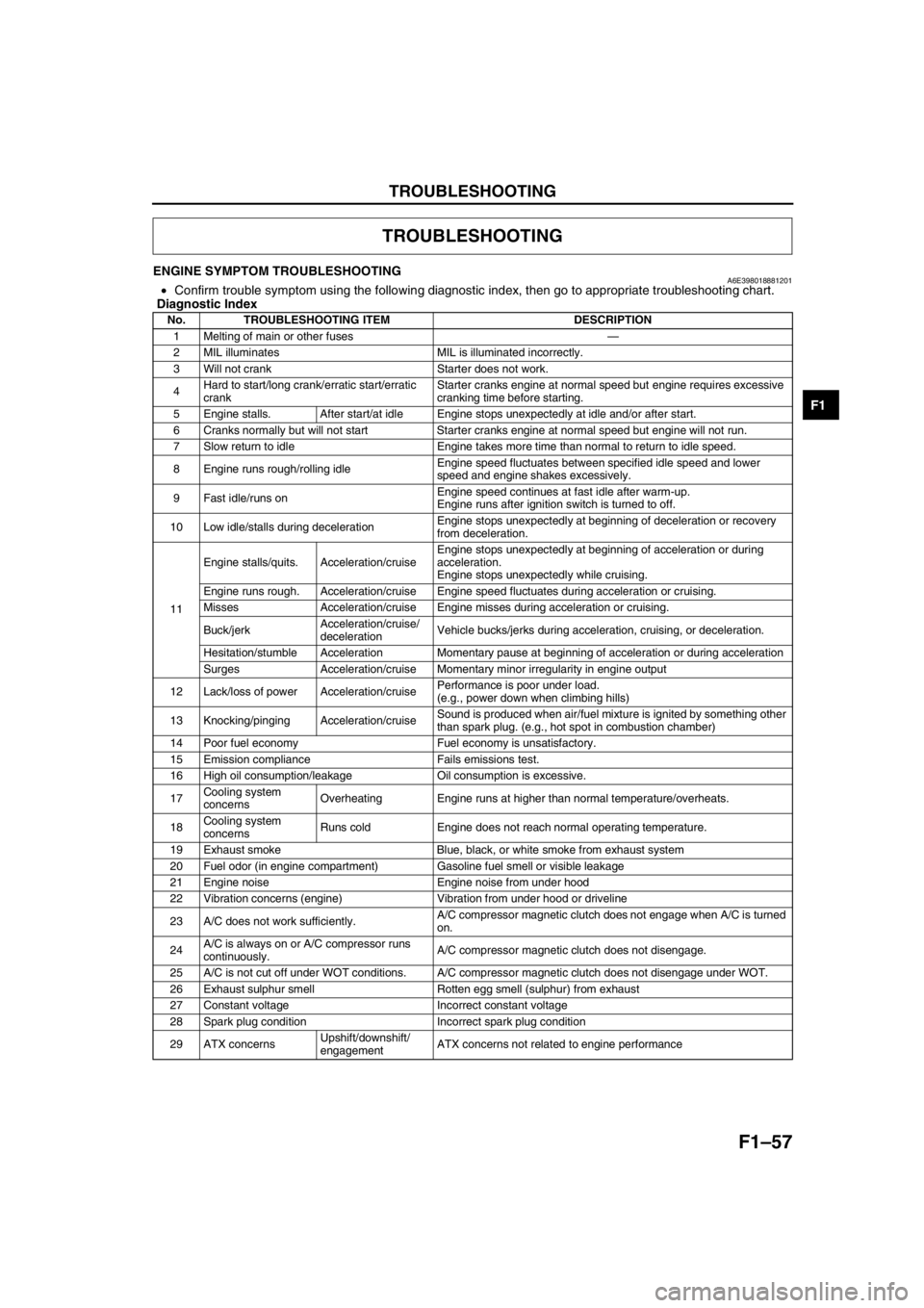

ENGINE SYMPTOM TROUBLESHOOTINGA6E398018881201•Confirm trouble symptom using the following diagnostic index, then go to appropriate troubleshooting chart.

Diagnostic Index

End Of Sie

TROUBLESHOOTING

No. TROUBLESHOOTING ITEM DESCRIPTION

1 Melting of main or other fuses—

2 MIL illuminates MIL is illuminated incorrectly.

3 Will not crank Starter does not work.

4Hard to start/long crank/erratic start/erratic

crankStarter cranks engine at normal speed but engine requires excessive

cranking time before starting.

5 Engine stalls. After start/at idle Engine stops unexpectedly at idle and/or after start.

6 Cranks normally but will not start Starter cranks engine at normal speed but engine will not run.

7 Slow return to idle Engine takes more time than normal to return to idle speed.

8 Engine runs rough/rolling idleEngine speed fluctuates between specified idle speed and lower

speed and engine shakes excessively.

9 Fast idle/runs onEngine speed continues at fast idle after warm-up.

Engine runs after ignition switch is turned to off.

10 Low idle/stalls during decelerationEngine stops unexpectedly at beginning of deceleration or recovery

from deceleration.

11Engine stalls/quits. Acceleration/cruiseEngine stops unexpectedly at beginning of acceleration or during

acceleration.

Engine stops unexpectedly while cruising.

Engine runs rough. Acceleration/cruise Engine speed fluctuates during acceleration or cruising.

Misses Acceleration/cruise Engine misses during acceleration or cruising.

Buck/jerkAcceleration/cruise/

decelerationVehicle bucks/jerks during acceleration, cruising, or deceleration.

Hesitation/stumble Acceleration Momentary pause at beginning of acceleration or during acceleration

Surges Acceleration/cruise Momentary minor irregularity in engine output

12 Lack/loss of power Acceleration/cruisePerformance is poor under load.

(e.g., power down when climbing hills)

13 Knocking/pinging Acceleration/cruiseSound is produced when air/fuel mixture is ignited by something other

than spark plug. (e.g., hot spot in combustion chamber)

14 Poor fuel economy Fuel economy is unsatisfactory.

15 Emission compliance Fails emissions test.

16 High oil consumption/leakage Oil consumption is excessive.

17Cooling system

concernsOverheating Engine runs at higher than normal temperature/overheats.

18Cooling system

concernsRuns cold Engine does not reach normal operating temperature.

19 Exhaust smoke Blue, black, or white smoke from exhaust system

20 Fuel odor (in engine compartment) Gasoline fuel smell or visible leakage

21 Engine noise Engine noise from under hood

22 Vibration concerns (engine) Vibration from under hood or driveline

23 A/C does not work sufficiently.A/C compressor magnetic clutch does not engage when A/C is turned

on.

24A/C is always on or A/C compressor runs

continuously.A/C compressor magnetic clutch does not disengage.

25 A/C is not cut off under WOT conditions. A/C compressor magnetic clutch does not disengage under WOT.

26 Exhaust sulphur smell Rotten egg smell (sulphur) from exhaust

27 Constant voltage Incorrect constant voltage

28 Spark plug condition Incorrect spark plug condition

29 ATX concernsUpshift/downshift/

engagementATX concerns not related to engine performance