fuel pump MAZDA 6 2002 Suplement Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 151 of 909

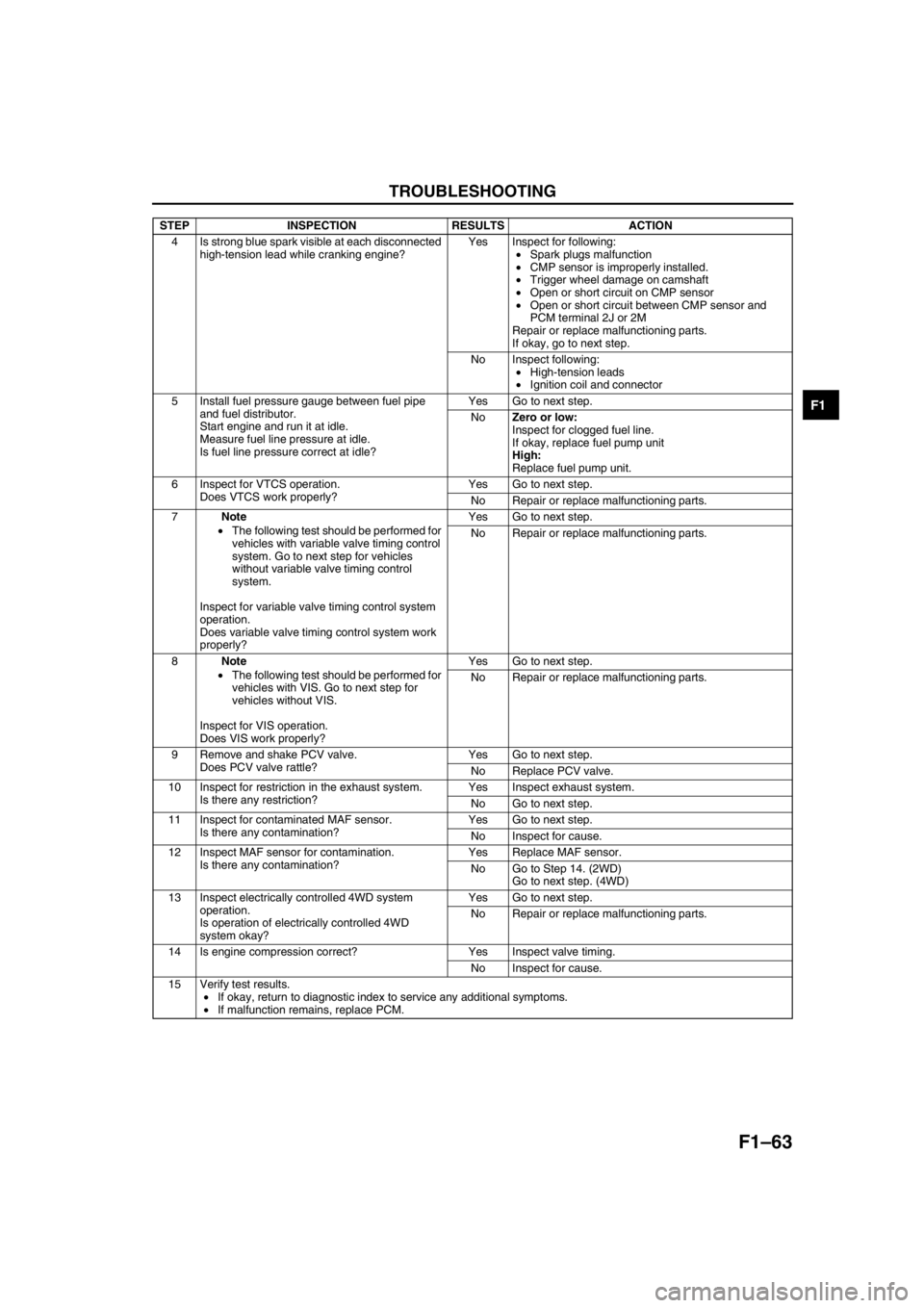

TROUBLESHOOTING

F1–63

F1

End Of Sie

4 Is strong blue spark visible at each disconnected

high-tension lead while cranking engine?Yes Inspect for following:

•Spark plugs malfunction

•CMP sensor is improperly installed.

•Trigger wheel damage on camshaft

•Open or short circuit on CMP sensor

•Open or short circuit between CMP sensor and

PCM terminal 2J or 2M

Repair or replace malfunctioning parts.

If okay, go to next step.

No Inspect following:

•High-tension leads

•Ignition coil and connector

5 Install fuel pressure gauge between fuel pipe

and fuel distributor.

Start engine and run it at idle.

Measure fuel line pressure at idle.

Is fuel line pressure correct at idle?Yes Go to next step.

NoZero or low:

Inspect for clogged fuel line.

If okay, replace fuel pump unit

High:

Replace fuel pump unit.

6 Inspect for VTCS operation.

Does VTCS work properly?Yes Go to next step.

No Repair or replace malfunctioning parts.

7Note

•The following test should be performed for

vehicles with variable valve timing control

system. Go to next step for vehicles

without variable valve timing control

system.

Inspect for variable valve timing control system

operation.

Does variable valve timing control system work

properly?Yes Go to next step.

No Repair or replace malfunctioning parts.

8Note

•The following test should be performed for

vehicles with VIS. Go to next step for

vehicles without VIS.

Inspect for VIS operation.

Does VIS work properly?Yes Go to next step.

No Repair or replace malfunctioning parts.

9 Remove and shake PCV valve.

Does PCV valve rattle?Yes Go to next step.

No Replace PCV valve.

10 Inspect for restriction in the exhaust system.

Is there any restriction?Yes Inspect exhaust system.

No Go to next step.

11 Inspect for contaminated MAF sensor.

Is there any contamination?Yes Go to next step.

No Inspect for cause.

12 Inspect MAF sensor for contamination.

Is there any contamination?Yes Replace MAF sensor.

No Go to Step 14. (2WD)

Go to next step. (4WD)

13 Inspect electrically controlled 4WD system

operation.

Is operation of electrically controlled 4WD

system okay?Yes Go to next step.

No Repair or replace malfunctioning parts.

14 Is engine compression correct? Yes Inspect valve timing.

No Inspect for cause.

15 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. STEP INSPECTION RESULTS ACTION

Page 153 of 909

![MAZDA 6 2002 Suplement Owners Guide F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATUR MAZDA 6 2002 Suplement Owners Guide F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATUR](/img/28/57057/w960_57057-152.png)

F2–1

F2

F2FUEL AND EMISSION CONTROL SYSTEMS

[MZR-CD (RF Turbo)]

OUTLINE.............................................................. F2-3

OUTLINE OF CONSTRUCTION ....................... F2-3

FEATURES ........................................................ F2-3

SPECIFICATIONS ............................................. F2-3

CONTROL SYSTEM DIAGRAM ........................ F2-4

CONTROL SYSTEM WIRING DIAGRAM.......... F2-5

INTAKE-AIR SYSTEM.......................................... F2-8

OUTLINE ........................................................... F2-8

STRUCTURAL VIEW......................................... F2-9

FUEL SYSTEM................................................... F2-10

OUTLINE ......................................................... F2-10

STRUCTURAL VIEW....................................... F2-11

EXHAUST SYSTEM........................................... F2-13

OUTLINE ......................................................... F2-13

STRUCTURAL VIEW....................................... F2-13

EMISSION SYSTEM........................................... F2-14

OUTLINE ......................................................... F2-14

STRUCTURAL VIEW....................................... F2-15

WARM UP OXIDATION CATALYTIC

CONVERTER DESCRIPTION ...................... F2-16

CONTROL SYSTEM........................................... F2-16

OUTLINE ......................................................... F2-16

STRUCTURAL VIEW....................................... F2-18

BLOCK DIAGRAM ........................................... F2-20

CONTROL DEVICE AND CONTROL

RELATIONSHIP CHART .............................. F2-22

CRUISE CONTROL SYSTEM ......................... F2-23

CONTROLLER AREA NETWORK (CAN) ....... F2-24

ON-BOARD DIAGNOSTIC................................. F2-24

OUTLINE ......................................................... F2-24

DTC.................................................................. F2-24

KOEO/KOER SELF-TEST ............................... F2-26

PID/DATA MONITOR AND RECORD ............. F2-27

SIMULATION TEST ......................................... F2-27

LOCATION INDEX............................................. F2-28

INTAKE-AIR SYSTEM ..................................... F2-28

FUEL SYSTEM ................................................ F2-29

EMISSION SYSTEM........................................ F2-31

CONTROL SYSTEM........................................ F2-32

ENGINE TUNE-UP............................................. F2-34

ENGINE TUNE-UP PREPARATION ............... F2-34

IDLE SPEED INSPECTION ............................. F2-34

CORRECTION PROCEDURE ......................... F2-34

INTAKE-AIR SYSTEM........................................ F2-35

VACUUM TUBE ROUTING DIAGRAM............ F2-35

INTAKE-AIR SYSTEM

REMOVAL/INSTALLATION .......................... F2-36

AIR CLEANER ELEMENT INSPECTION ........ F2-37

TURBOCHARGER INSPECTION ................... F2-38

GUIDE BLADE ACTUATOR INSPECTION ..... F2-39

VARIABLE BOOST CONTROL (VBC)

SOLENOID VALVE INSPECTION ................ F2-40VARIABLE BOOST CONTROL (VBC)

CHECK VALVE INSPECTION ...................... F2-41

VARIABLE SWIRL CONTROL (VSC)

VALVE ACTUATOR INSPECTION ............... F2-41

VARIABLE SWIRL CONTROL (VSC)

SOLENOID VALVE INSPECTION ................ F2-42

GLOW PLUG REMOVAL/INSTALLATION ...... F2-42

GLOW PLUG INSPECTION ............................ F2-43

GLOW PLUG LEAD INSPECTION .................. F2-43

ACCELERATOR PEDAL COMPONENT

REMOVAL/INSTALLATION .......................... F2-44

ACCELERATOR PEDAL COMPONENT

DISASSEMBLY/ASSEMBLY ........................ F2-44

FUEL SYSTEM................................................... F2-45

BEFORE REPAIR PROCEDURE .................... F2-45

AFTER REPAIR PROCEDURE ....................... F2-45

FUEL TANK REMOVAL/INSTALLATION ........ F2-45

FUEL TANK INSPECTION .............................. F2-49

NONRETURN VALVE INSPECTION............... F2-50

FUEL FILTER COMPONENT

REMOVAL/INSTALLATION .......................... F2-50

FUEL FILTER COMPONENT

DISASSEMBLY/ASSEMBLY ........................ F2-51

FUEL WARMER INSPECTION........................ F2-51

SEDIMENTOR WATER DRAINING................. F2-52

SEDIMENTOR SWITCH INSPECTION ........... F2-52

SUPPLY PUMP REMOVAL/INSTALLATION .. F2-53

SUPPLY PUMP INSPECTION......................... F2-54

SUCTION CONTROL VALVE INSPECTION ... F2-54

COMMON RAIL INSPECTION ........................ F2-54

FUEL INJECTOR REMOVAL/INSTALLATION F2-55

FUEL INJECTOR INSPECTION ...................... F2-56

EXHAUST SYSTEM........................................... F2-57

EXHAUST SYSTEM INSPECTION ................. F2-57

EXHAUST SYSTEM

REMOVAL/INSTALLATION .......................... F2-57

EMISSION SYSTEM........................................... F2-59

EGR VALVE REMOVAL/INSTALLATION........ F2-59

EGR VALVE INSPECTION .............................. F2-59

EGR SOLENOID VALVE (VACUUM)

INSPECTION ................................................ F2-60

EGR SOLENOID VALVE (VENT)

INSPECTION ................................................ F2-60

EGR CONTROL SOLENOID VALVE

INSPECTION ................................................ F2-61

INTAKE SHUTTER VALVE ACTUATOR

INSPECTION ................................................ F2-62

INTAKE SHUTTER SOLENOID VALVE

INSPECTION ................................................ F2-63

CONTROL SYSTEM........................................... F2-64

PCM REMOVAL/INSTALLATION .................... F2-64

PCM INSPECTION .......................................... F2-65

PCM CONFIGURATION .................................. F2-68

CLUTCH SWITCH INSPECTION .................... F2-68

NEUTRAL SWITCH INSPECTION .................. F2-69

IDLE SWITCH INSPECTION ........................... F2-70

IDLE SWITCH ADJUSTMENT ......................... F2-71

ACCELERATOR POSITION SENSOR

INSPECTION ................................................ F2-72

ACCELERATOR POSITION SENSOR

ADJUSTMENT .............................................. F2-73 FEATURES

SERVICE

Page 155 of 909

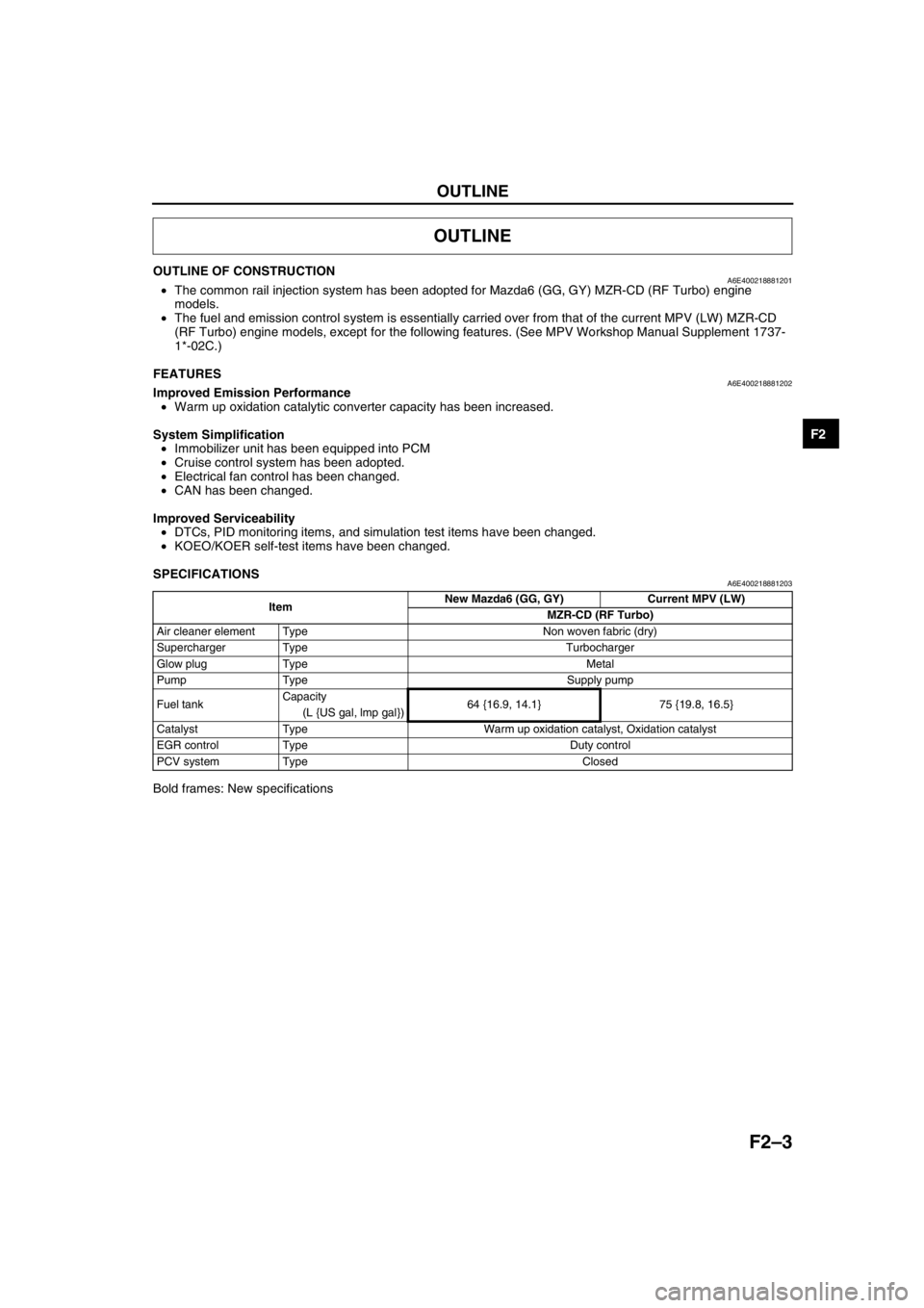

OUTLINE

F2–3

F2

OUTLINE OF CONSTRUCTIONA6E400218881201•The common rail injection system has been adopted for Mazda6 (GG, GY) MZR-CD (RF Turbo) engine

models.

•The fuel and emission control system is essentially carried over from that of the current MPV (LW) MZR-CD

(RF Turbo) engine models, except for the following features. (See MPV Workshop Manual Supplement 1737-

1*-02C.)

End Of Sie

FEATURESA6E400218881202Improved Emission Performance

•Warm up oxidation catalytic converter capacity has been increased.

System Simplification

•Immobilizer unit has been equipped into PCM

•Cruise control system has been adopted.

•Electrical fan control has been changed.

•CAN has been changed.

Improved Serviceability

•DTCs, PID monitoring items, and simulation test items have been changed.

•KOEO/KOER self-test items have been changed.

End Of Sie

SPECIFICATIONSA6E400218881203

Bold frames: New specifications

End Of Sie

OUTLINE

ItemNew Mazda6 (GG, GY) Current MPV (LW)

MZR-CD (RF Turbo)

Air cleaner element Type Non woven fabric (dry)

Supercharger Type Turbocharger

Glow plug Type Metal

Pump Type Supply pump

Fuel tankCapacity

64 {16.9, 14.1} 75 {19.8, 16.5}

(L {US gal, lmp gal})

Catalyst Type Warm up oxidation catalyst, Oxidation catalyst

EGR control Type Duty control

PCV system Type Closed

Page 156 of 909

F2–4

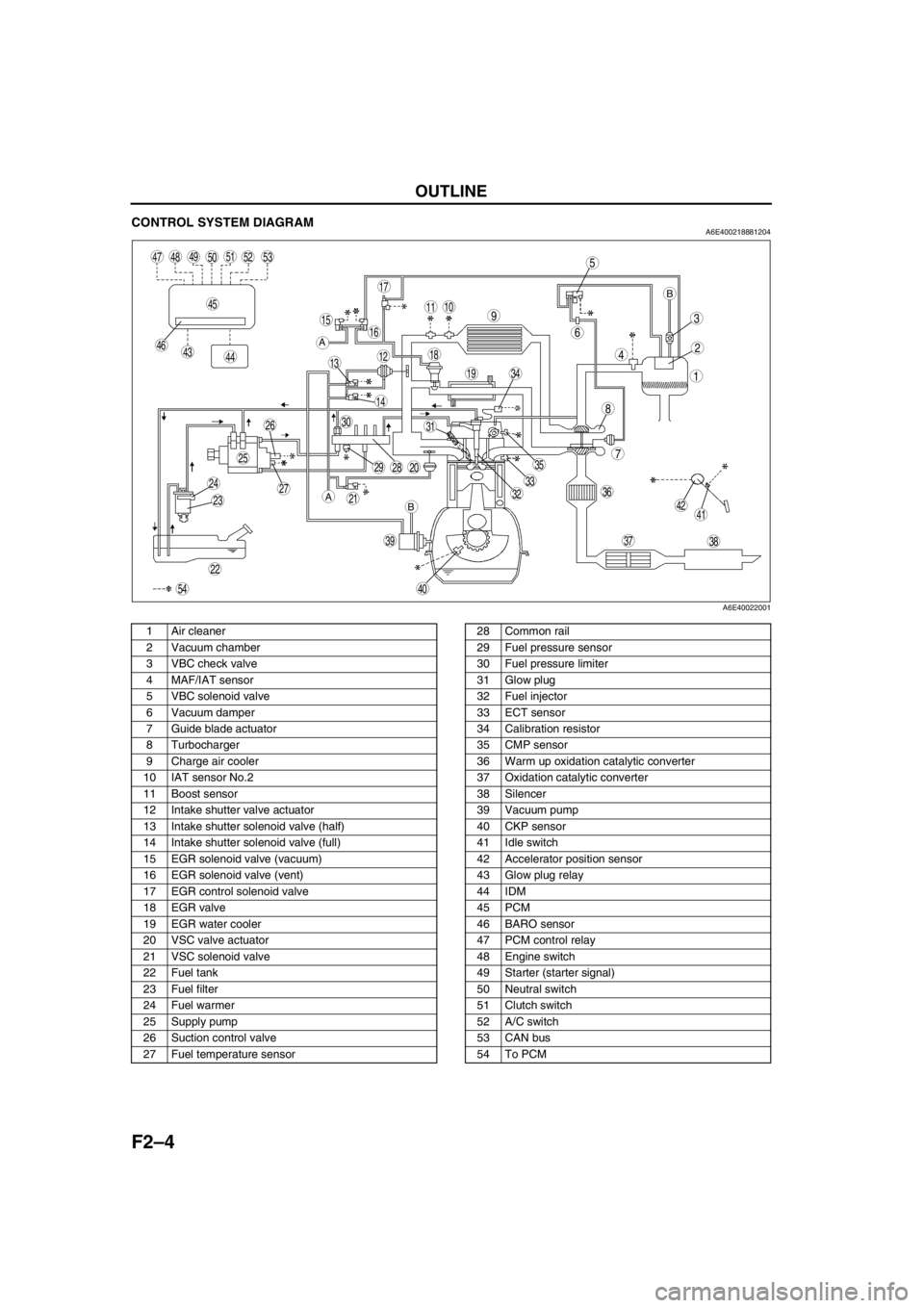

OUTLINE

CONTROL SYSTEM DIAGRAMA6E400218881204

.

End Of Sie

5

4

3

6

1

2

8

7

910

13

11

12

19

18

17

1516

14

202928

27

25

26

24

2321

22

30

393837

35

3633

31

32

40

34

494847

45

464443

4142

50

54

515253

A

A

BB

A6E40022001

1 Air cleaner

2 Vacuum chamber

3 VBC check valve

4 MAF/IAT sensor

5 VBC solenoid valve

6 Vacuum damper

7 Guide blade actuator

8 Turbocharger

9 Charge air cooler

10 IAT sensor No.2

11 Boost sensor

12 Intake shutter valve actuator

13 Intake shutter solenoid valve (half)

14 Intake shutter solenoid valve (full)

15 EGR solenoid valve (vacuum)

16 EGR solenoid valve (vent)

17 EGR control solenoid valve

18 EGR valve

19 EGR water cooler

20 VSC valve actuator

21 VSC solenoid valve

22 Fuel tank

23 Fuel filter

24 Fuel warmer

25 Supply pump

26 Suction control valve

27 Fuel temperature sensor28 Common rail

29 Fuel pressure sensor

30 Fuel pressure limiter

31 Glow plug

32 Fuel injector

33 ECT sensor

34 Calibration resistor

35 CMP sensor

36 Warm up oxidation catalytic converter

37 Oxidation catalytic converter

38 Silencer

39 Vacuum pump

40 CKP sensor

41 Idle switch

42 Accelerator position sensor

43 Glow plug relay

44 IDM

45 PCM

46 BARO sensor

47 PCM control relay

48 Engine switch

49 Starter (starter signal)

50 Neutral switch

51 Clutch switch

52 A/C switch

53 CAN bus

54 To PCM

Page 158 of 909

F2–6

OUTLINE

.

a

b

c

d

e

f

gCBD

A

CBD

ACBD

ACBD

A

3762

89 11C

BABABABABABABABABA

81 55 29 3 99 72

1017410067 77

h

i

j

k

l

m

n

oA

B

C36

10

A

BCD8831

90

A B CA

BA

B

A B 6135

87 94 93 8

A

B76

E

C

A D

M84

10273 8668

AB

C D

M

M A B

29282725262430

1

393837353633

31

3240

49

48

47454644

4341

42

50

59

58

57

55

5654

60

64

63

61

62

34

51

5253

A6E40022003

1PCM

2DLC-2

3 Water heater unit

4Fuel pump

5 Other unit6IDM

7Battery

8 Engine switch

9 Starter relay

10 Starter

Page 162 of 909

F2–10

FUEL SYSTEM

End Of Sie

OUTLINEA6E401201006201•The fuel system is essentially carried over from that of the current MPV (LW) MZR-CD (RF Turbo) engine

model. (See MPV Wordshop Manual Supplement 1737-1*-02D.)

×:Applicable

*1: With fuel warmer

End Of Sie

FUEL SYSTEM

ItemMazda6

(GG, GY)Current

MPV (LW)

Remark for new model

MZR-CD (RF Turbo)

Fuel tank×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Shape has been changed

Fuel gauge sender unit×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Shape has been changed

Fuel filter bodyFuel filter×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Priming pump×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Fuel warmer

*1×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Common rail injection system×Same function as MPV (LW) MZR-CD (RF Turbo) engine model

Page 163 of 909

FUEL SYSTEM

F2–11

F2

STRUCTURAL VIEWA6E401201006202Engine room side

.

1

2

3

4

5

6

7

9

8

10

11

12

10

A6E40122031

1 Fuel warmer

2 Sedimentor switch

3 Supply pump

4 Suction control valve

5 Common rail

6 Priming pump7 L.H.D.

8 Fuel injector

9 Priming pump

10 Fuel filter

11 R.H.D.

12 Sedimentor switch

Page 164 of 909

F2–12

FUEL SYSTEM

Fuel tank side

.

End Of Sie

4

31

2

A6E40122032

1 Fuel tank

2Fuel pump3 Nonreturn valve

4 Fuel filler cap

Page 182 of 909

F2–30

LOCATION INDEX

Fuel tank side

.

End Of Sie

21

A6E40002004

1 Fuel tank

(See F2–45 FUEL TANK REMOVAL/

INSTALLATION)

(See F2–49 FUEL TANK INSPECTION)

2 Nonreturn valve

(See F2–50 NONRETURN VALVE INSPECTION)

3 Sedimentor switch

(See F2–52 SEDIMENTOR SWITCH INSPECTION)

4 Fuel filter

(See F2–50 FUEL FILTER COMPONENT

REMOVAL/INSTALLATION)

(See F2–51 FUEL FILTER COMPONENT

DISASSEMBLY/ASSEMBLY)

5 Fuel warmer

(See F2–51 FUEL WARMER INSPECTION)6 Priming pump

(See F2–52 SEDIMENTOR WATER DRAINING)

7 Supply pump

(See F2–53 SUPPLY PUMP REMOVAL/

INSTALLATION)

(See F2–54 SUPPLY PUMP INSPECTION)

8 Suction control valve

(See F2–54 SUCTION CONTROL VALVE

INSPECTION)

9 Common rail

(See F2–54 COMMON RAIL INSPECTION)

10 Fuel injector

(See F2–55 FUEL INJECTOR REMOVAL/

INSTALLATION)

(See F2–56 FUEL INJECTOR INSPECTION)

Page 200 of 909

F2–48

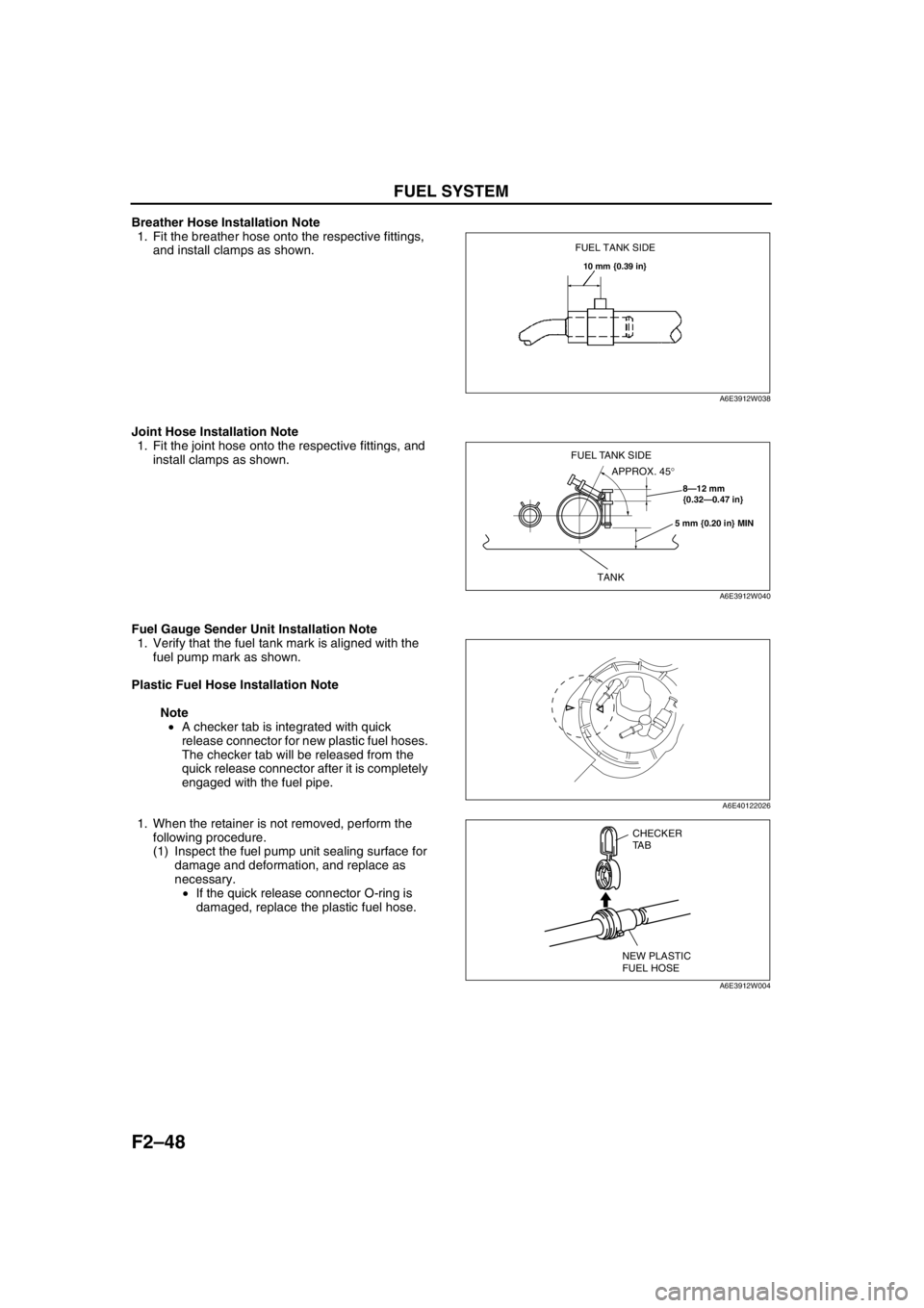

FUEL SYSTEM

Breather Hose Installation Note

1. Fit the breather hose onto the respective fittings,

and install clamps as shown.

Joint Hose Installation Note

1. Fit the joint hose onto the respective fittings, and

install clamps as shown.

Fuel Gauge Sender Unit Installation Note

1. Verify that the fuel tank mark is aligned with the

fuel pump mark as shown.

Plastic Fuel Hose Installation Note

Note

•A checker tab is integrated with quick

release connector for new plastic fuel hoses.

The checker tab will be released from the

quick release connector after it is completely

engaged with the fuel pipe.

1. When the retainer is not removed, perform the

following procedure.

(1) Inspect the fuel pump unit sealing surface for

damage and deformation, and replace as

necessary.

•If the quick release connector O-ring is

damaged, replace the plastic fuel hose.

FUEL TANK SIDE

10 mm {0.39 in}

A6E3912W038

8—12 mm

{0.32—0.47 in}

5 mm {0.20 in} MIN

TANK

APPROX. 45° FUEL TANK SIDE

A6E3912W040

A6E40122026

CHECKER

TA B

NEW PLASTIC

FUEL HOSE

A6E3912W004