wiring MAZDA 6 2002 Suplement Manual PDF

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 382 of 909

F2–230

TROUBLESHOOTING

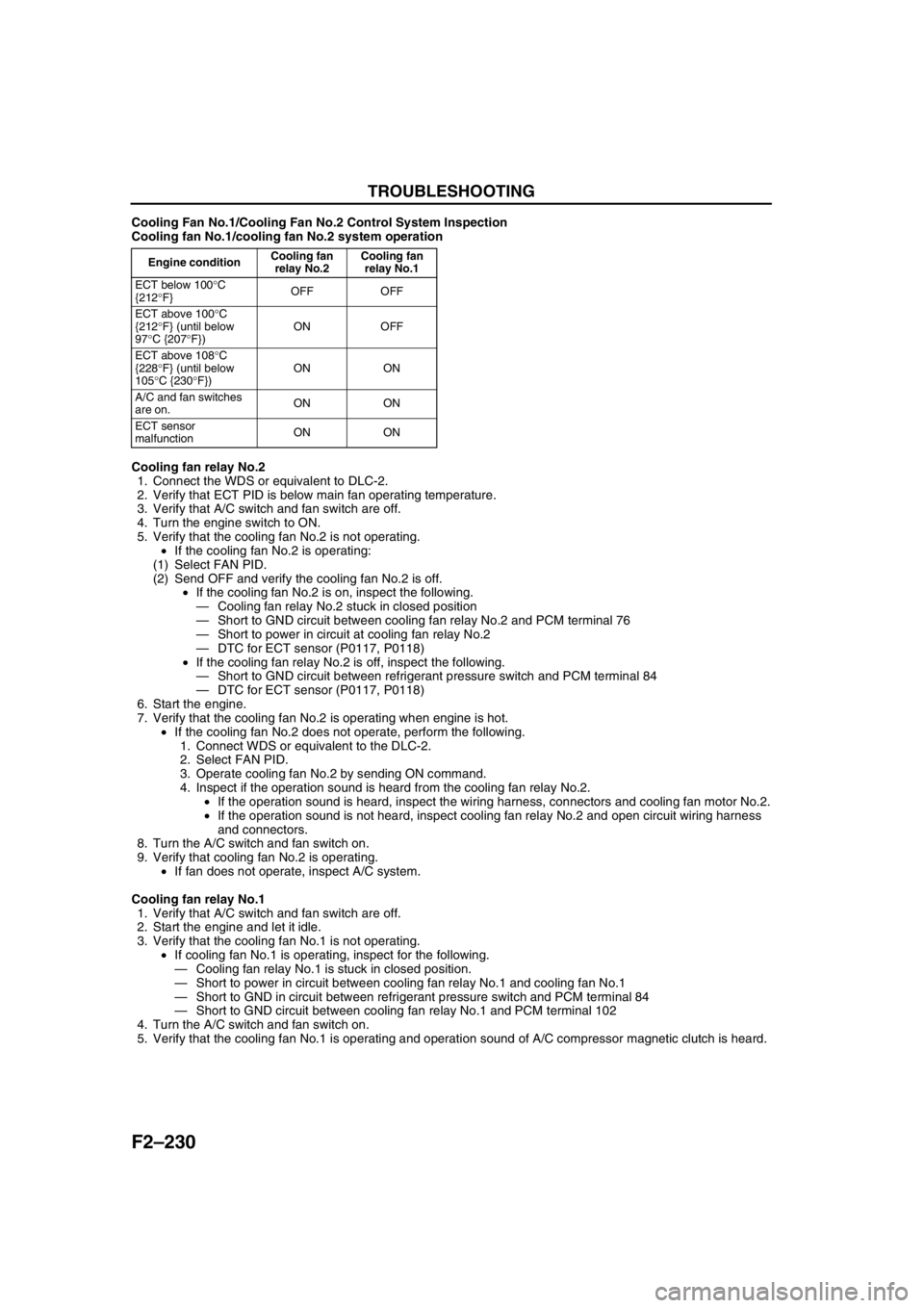

Cooling Fan No.1/Cooling Fan No.2 Control System Inspection

Cooling fan No.1/cooling fan No.2 system operation

Cooling fan relay No.2

1. Connect the WDS or equivalent to DLC-2.

2. Verify that ECT PID is below main fan operating temperature.

3. Verify that A/C switch and fan switch are off.

4. Turn the engine switch to ON.

5. Verify that the cooling fan No.2 is not operating.

•If the cooling fan No.2 is operating:

(1) Select FAN PID.

(2) Send OFF and verify the cooling fan No.2 is off.

•If the cooling fan No.2 is on, inspect the following.

—Cooling fan relay No.2 stuck in closed position

—Short to GND circuit between cooling fan relay No.2 and PCM terminal 76

—Short to power in circuit at cooling fan relay No.2

—DTC for ECT sensor (P0117, P0118)

•If the cooling fan relay No.2 is off, inspect the following.

—Short to GND circuit between refrigerant pressure switch and PCM terminal 84

—DTC for ECT sensor (P0117, P0118)

6. Start the engine.

7. Verify that the cooling fan No.2 is operating when engine is hot.

•If the cooling fan No.2 does not operate, perform the following.

1. Connect WDS or equivalent to the DLC-2.

2. Select FAN PID.

3. Operate cooling fan No.2 by sending ON command.

4. Inspect if the operation sound is heard from the cooling fan relay No.2.

•If the operation sound is heard, inspect the wiring harness, connectors and cooling fan motor No.2.

•If the operation sound is not heard, inspect cooling fan relay No.2 and open circuit wiring harness

and connectors.

8. Turn the A/C switch and fan switch on.

9. Verify that cooling fan No.2 is operating.

•If fan does not operate, inspect A/C system.

Cooling fan relay No.1

1. Verify that A/C switch and fan switch are off.

2. Start the engine and let it idle.

3. Verify that the cooling fan No.1 is not operating.

•If cooling fan No.1 is operating, inspect for the following.

—Cooling fan relay No.1 is stuck in closed position.

—Short to power in circuit between cooling fan relay No.1 and cooling fan No.1

—Short to GND in circuit between refrigerant pressure switch and PCM terminal 84

—Short to GND circuit between cooling fan relay No.1 and PCM terminal 102

4. Turn the A/C switch and fan switch on.

5. Verify that the cooling fan No.1 is operating and operation sound of A/C compressor magnetic clutch is heard.

Engine conditionCooling fan

relay No.2Cooling fan

relay No.1

ECT below 100°C

{212°F}OFF OFF

ECT above 100°C

{212°F} (until below

97°C {207°F})ON OFF

ECT above 108°C

{228°F} (until below

105°C {230°F})ON ON

A/C and fan switches

are on.ON ON

ECT sensor

malfunctionON ON

Page 390 of 909

CHARGING SYSTEM

G–7

G

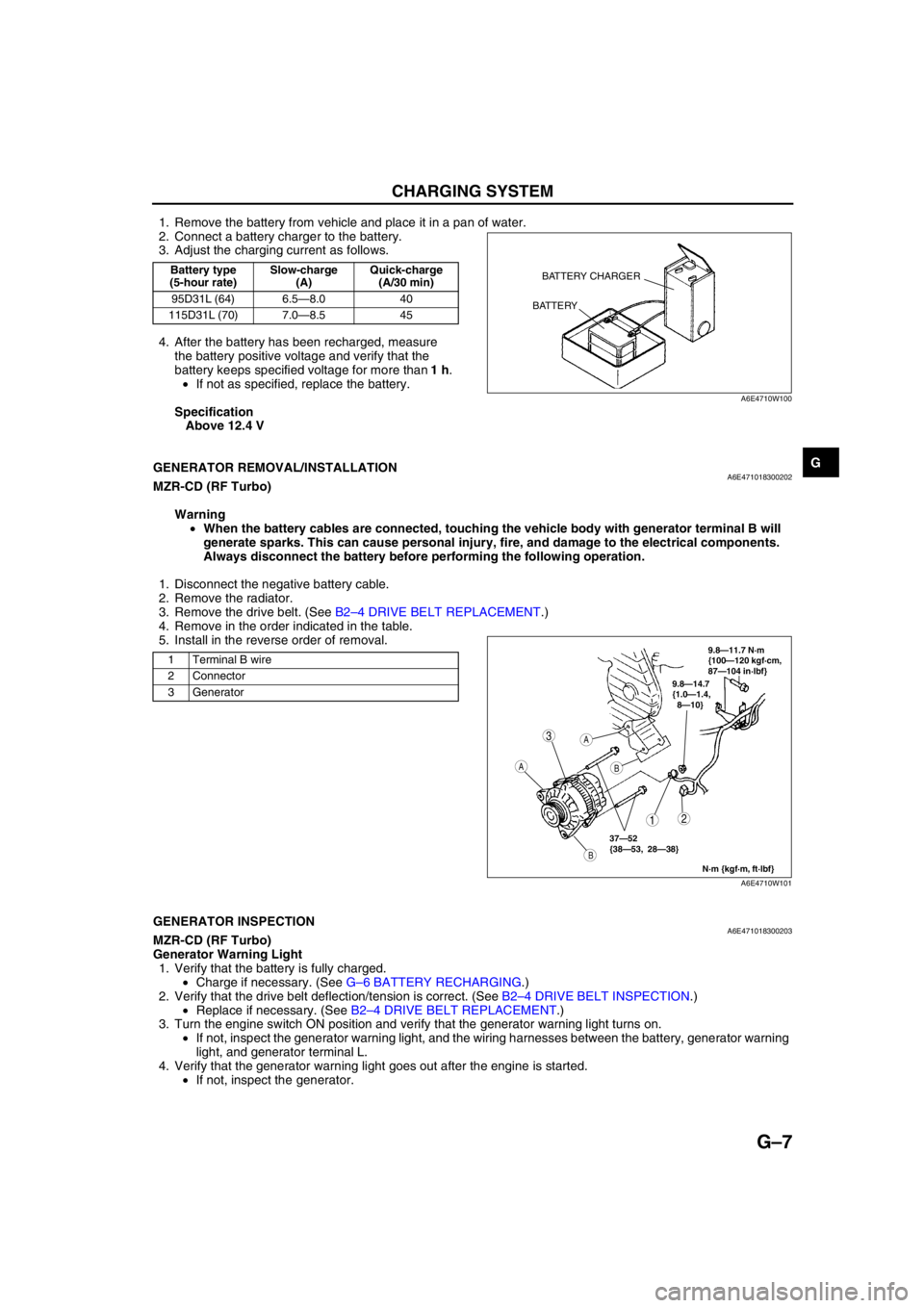

1. Remove the battery from vehicle and place it in a pan of water.

2. Connect a battery charger to the battery.

3. Adjust the charging current as follows.

4. After the battery has been recharged, measure

the battery positive voltage and verify that the

battery keeps specified voltage for more than 1 h.

•If not as specified, replace the battery.

Specification

Above 12.4 V

End Of Sie

GENERATOR REMOVAL/INSTALLATIONA6E471018300202MZR-CD (RF Turbo)

Warning

•When the battery cables are connected, touching the vehicle body with generator terminal B will

generate sparks. This can cause personal injury, fire, and damage to the electrical components.

Always disconnect the battery before performing the following operation.

1. Disconnect the negative battery cable.

2. Remove the radiator.

3. Remove the drive belt. (See B2–4 DRIVE BELT REPLACEMENT.)

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

End Of SieGENERATOR INSPECTIONA6E471018300203MZR-CD (RF Turbo)

Generator Warning Light

1. Verify that the battery is fully charged.

•Charge if necessary. (See G–6 BATTERY RECHARGING.)

2. Verify that the drive belt deflection/tension is correct. (See B2–4 DRIVE BELT INSPECTION.)

•Replace if necessary. (See B2–4 DRIVE BELT REPLACEMENT.)

3. Turn the engine switch ON position and verify that the generator warning light turns on.

•If not, inspect the generator warning light, and the wiring harnesses between the battery, generator warning

light, and generator terminal L.

4. Verify that the generator warning light goes out after the engine is started.

•If not, inspect the generator.

Battery type

(5-hour rate)Slow-charge

(A)Quick-charge

(A/30 min)

95D31L (64) 6.5—8.0 40

115D31L (70) 7.0—8.5 45BATTERY CHARGER

BATTERY

A6E4710W100

1 Terminal B wire

2 Connector

3 Generator

3

12

A

B

A

B

9.8—14.7

{1.0—1.4,

8—10}

N·m {kgf·m, ft·lbf}

37—52

{38—53, 28—38}

9.8—11.7 N·m

{100—120 kgf·cm,

87—104 in·lbf}

A6E4710W101

Page 391 of 909

G–8

CHARGING SYSTEM

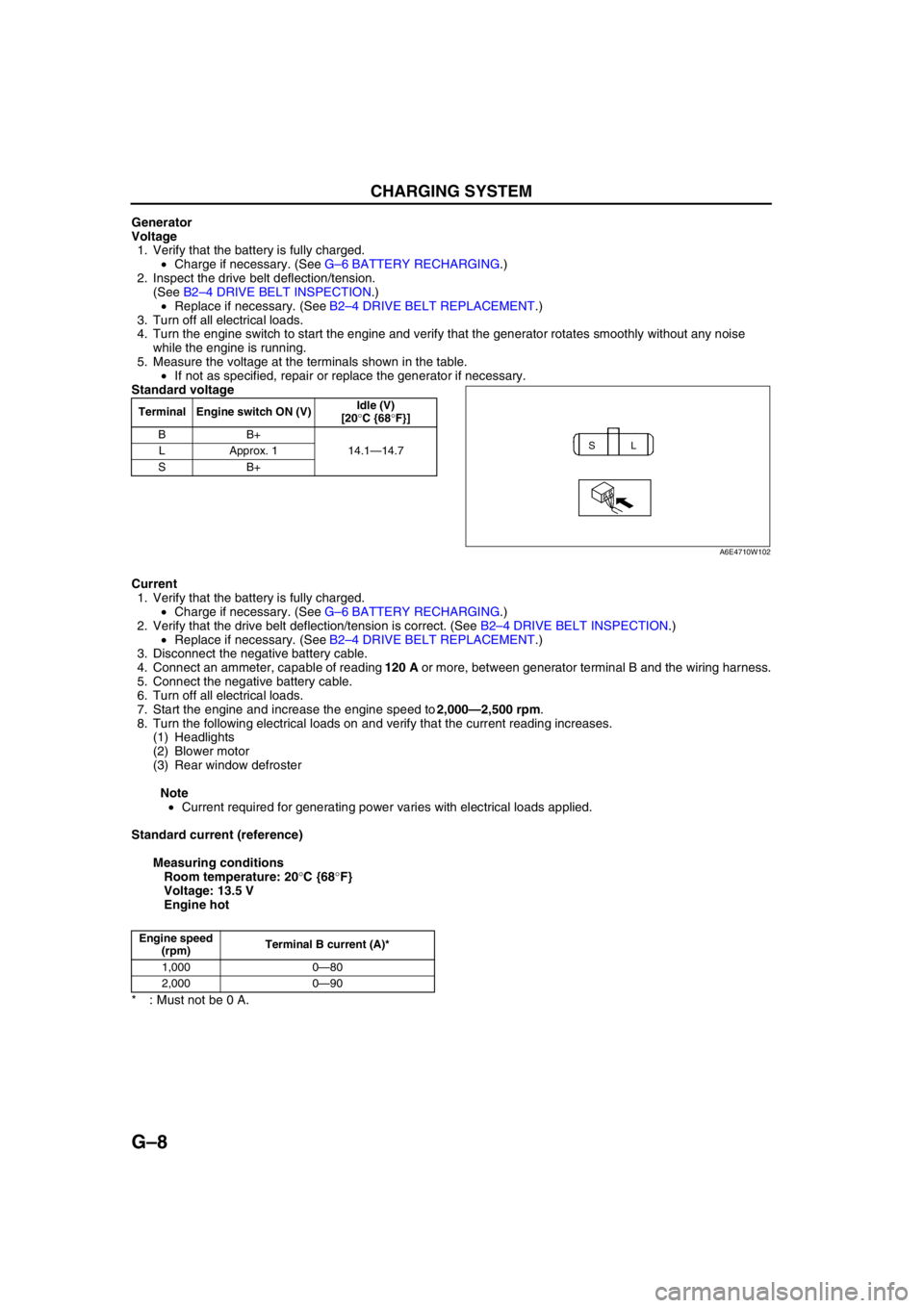

Generator

Voltage

1. Verify that the battery is fully charged.

•Charge if necessary. (See G–6 BATTERY RECHARGING.)

2. Inspect the drive belt deflection/tension.

(See B2–4 DRIVE BELT INSPECTION.)

•Replace if necessary. (See B2–4 DRIVE BELT REPLACEMENT.)

3. Turn off all electrical loads.

4. Turn the engine switch to start the engine and verify that the generator rotates smoothly without any noise

while the engine is running.

5. Measure the voltage at the terminals shown in the table.

•If not as specified, repair or replace the generator if necessary.

Standard voltage

Current

1. Verify that the battery is fully charged.

•Charge if necessary. (See G–6 BATTERY RECHARGING.)

2. Verify that the drive belt deflection/tension is correct. (See B2–4 DRIVE BELT INSPECTION.)

•Replace if necessary. (See B2–4 DRIVE BELT REPLACEMENT.)

3. Disconnect the negative battery cable.

4. Connect an ammeter, capable of reading 120 A or more, between generator terminal B and the wiring harness.

5. Connect the negative battery cable.

6. Turn off all electrical loads.

7. Start the engine and increase the engine speed to 2,000—2,500 rpm.

8. Turn the following electrical loads on and verify that the current reading increases.

(1) Headlights

(2) Blower motor

(3) Rear window defroster

Note

•Current required for generating power varies with electrical loads applied.

Standard current (reference)

Measuring conditions

Room temperature: 20°C {68°F}

Voltage: 13.5 V

Engine hot

* : Must not be 0 A.

End Of Sie

Terminal Engine switch ON (V)Idle (V)

[20°C {68°F}]

BB+

14.1—14.7 LApprox. 1

SB+

SL

A6E4710W102

Engine speed

(rpm)Terminal B current (A)*

1,000 0—80

2,000 0—90

Page 394 of 909

STARTING SYSTEM

G–11

G

STARTER INSPECTIONA6E471418400203MZR-CD (RF Turbo)

On-vehicle Inspection

1. Verify that the battery is fully charged.

•Charge if necessary. (See G–6 BATTERY RECHARGING.)

2. Crank the engine and verify that the starter rotates smoothly without any noise.

•If not as specified, inspect the following:

—Remove the starter, and inspect the magnetic switch and the starter.

—Inspect the related wiring harness and the engine switch.

No Load Test

1. Verify that the battery is fully charged.

•Charge if necessary. (See G–6 BATTERY RECHARGING.)

2. Connect the starter, battery, voltmeter and

ammeter as shown.

3. Operate the starter and verify that it rotates

smoothly.

4. Measure the voltage and current while the starter

is operating.

•If not as specified, replace the starter.

Specification

End Of Sie

Voltage (V)11

Current (A)Below 130

ENGINE

SWITCH

TERMINAL SB

M

STARTERVA

VOLTMETER

BATTERY

AMMETER

A6E4714W101

Page 416 of 909

![MAZDA 6 2002 Suplement Manual PDF K2–1

K2

K2AUTOMATIC TRANSAXLE [JA5AX-EL]

OUTLINE.............................................................. K2-3

FEATURES ........................................................ K2-3

SPECIFICATI MAZDA 6 2002 Suplement Manual PDF K2–1

K2

K2AUTOMATIC TRANSAXLE [JA5AX-EL]

OUTLINE.............................................................. K2-3

FEATURES ........................................................ K2-3

SPECIFICATI](/img/28/57057/w960_57057-415.png)

K2–1

K2

K2AUTOMATIC TRANSAXLE [JA5AX-EL]

OUTLINE.............................................................. K2-3

FEATURES ........................................................ K2-3

SPECIFICATIONS ............................................. K2-3

AUTOMATIC TRANSAXLE.................................. K2-4

OUTLINE ........................................................... K2-4

CROSS-SECTIONAL VIEW .............................. K2-6

ELECTRONIC CONTROL SYSTEM

STRUCTURAL VIEW...................................... K2-8

AUTOMATIC TRANSAXLE CONTROL SYSTEM

WIRING DIAGRAM ....................................... K2-10

AUTOMATIC TRANSAXLE BLOCK

DIAGRAM ..................................................... K2-11

AUTOMATIC TRANSAXLE DEVICE

RELATIONSHIP CHART .............................. K2-13

POWERTRAIN DESCRIPTION ....................... K2-15

TORQUE CONVERTER DESCRIPTION......... K2-40

OIL PUMP DESCRIPTION .............................. K2-41

CENTRIFUGAL BALANCE CLUTCH

DESCRIPTION ............................................. K2-42

CONTROL VALVE BODY DESCRIPTION ...... K2-43

TRANSAXLE FLUID TEMPERATURE

(TFT) SENSOR DESCRIPTION ................... K2-45

INPUT/TURBINE SPEED SENSOR

DESCRIPTION ............................................. K2-45

INTERMEDIATE SENSOR DESCRIPTION..... K2-46

VEHICLE SPEEDOMETER SENSOR

DESCRIPTION ............................................. K2-46

SOLENOID VALVE DESCRIPTION ................ K2-47

CONTROLLER AREA NETWORK (CAN)

DESCRIPTION ............................................. K2-50

TRANSAXLE CONTROL MODULE

(TCM) DESCRIPTION .................................. K2-51

SHIFT CONTROL DESCRIPTION .................. K2-51

MANUAL MODE SHIFT CONTROL

DESCRIPTION ............................................. K2-52

LINE PRESSURE CONTROL DESCRIPTION K2-54

FEEDBACK CONTROL DESCRIPTION ......... K2-57

N-D SELECT CONTROL DESCRIPTION........ K2-59

TORQUE CONVERTER CLUTCH

(TCC) CONTROL DESCRIPTION ................ K2-59

SLOPE MODE CONTROL DESCRIPTION ..... K2-63

ON-BOARD DIAGNOSTIC (OBD)

SYSTEM DESCRIPTION.............................. K2-64

COOLING SYSTEM DESCRIPTION ............... K2-69

LOCATION INDEX............................................. K2-70

AUTOMATIC TRANSAXLE LOCATION

INDEX ........................................................... K2-70

AUTOMATIC TRANSAXLE................................ K2-72

MECHANICAL SYSTEM TEST ....................... K2-72

ROAD TEST .................................................... K2-75AUTOMATIC TRANSAXLE FLUID

(ATF) INSPECTION ...................................... K2-78

AUTOMATIC TRANSAXLE FLUID

(ATF) REPLACEMENT ................................. K2-80

TRANSAXLE RANGE (TR) SWITCH

INSPECTION ................................................ K2-80

TRANSAXLE RANGE (TR) SWITCH

REMOVAL/INSTALLATION .......................... K2-81

TRANSAXLE RANGE (TR) SWITCH

ADJUSTMENT .............................................. K2-83

TRANSAXLE FLUID TEMPERATURE

(TFT) SENSOR INSPECTION ...................... K2-84

TRANSAXLE FLUID TEMPERATURE

(TFT) SENSOR REMOVAL/INSTALLATION K2-85

INPUT/TURBINE SPEED SENSOR

INSPECTION ................................................ K2-85

INPUT/TURBINE SPEED SENSOR

REMOVAL/INSTALLATION .......................... K2-86

INTERMEDIATE SENSOR INSPECTION ....... K2-86

INTERMEDIATE SENSOR

REMOVAL/INSTALLATION .......................... K2-86

VEHICLE SPEEDOMETER SENSOR

(VSS) INSPECTION...................................... K2-87

VEHICLE SPEEDOMETER SENSOR

(VSS) REMOVAL/INSTALLATION ............... K2-87

SOLENOID VALVE INSPECTION ................... K2-88

SOLENOID VALVE

REMOVAL/INSTALLATION .......................... K2-90

TCM INSPECTION .......................................... K2-90

TCM REMOVAL/INSTALLATION .................... K2-96

AUTOMATIC TRANSAXLE AND

TRANSFER REMOVAL/INSTALLATION...... K2-99

OIL SEAL REMOVAL/INSTALLATION .......... K2-104

CONTROL VALVE BODY

REMOVAL/INSTALLATION ........................ K2-105

OIL COOLER FLUSHING .............................. K2-106

OIL COOLER REMOVAL/INSTALLATION .... K2-108

OIL COOLER DISASSEMBLY/ASSEMBLY .. K2-110

DRIVE PLATE REMOVAL/INSTALLATION... K2-112

TRANSFER....................................................... K2-114

TRANSFER OIL INSPECTION ...................... K2-114

TRANSFER OIL REPLACEMENT ................. K2-114

TRANSFER REMOVAL/INSTALLATION....... K2-115

BREATHER PLUG

REMOVAL/INSTALLATION ........................ K2-116

AUTOMATIC TRANSAXLE SHIFT

MECHANISM................................................. K2-117

SELECTOR LEVER INSPECTION ................ K2-117

SELECTOR LEVER COMPONENT

INSPECTION .............................................. K2-117

SELECTOR CABLE ADJUSTMENT .............. K2-118

SELECTOR LEVER

REMOVAL/INSTALLATION ........................ K2-119

SELECTOR LEVER

DISASSEMBLY/ASSEMBLY ...................... K2-122

ON-BOARD DIAGNOSTIC............................... K2-123

FOREWORD .................................................. K2-123 FEATURES

SERVICE

Page 425 of 909

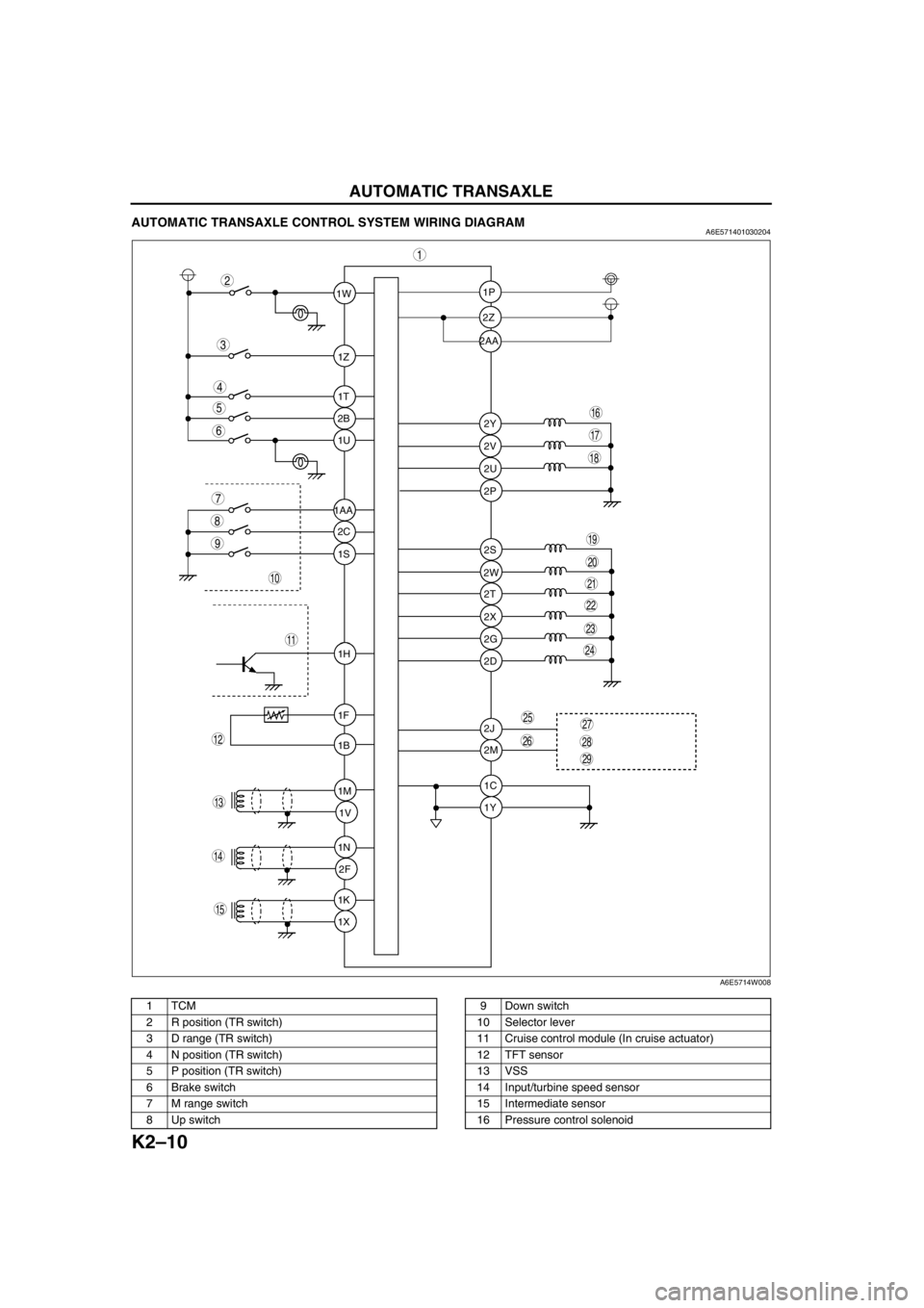

K2–10

AUTOMATIC TRANSAXLE

AUTOMATIC TRANSAXLE CONTROL SYSTEM WIRING DIAGRAMA6E571401030204

.

1W1P

2P

2S

2T

2X

2G

2D

2J

2M

1C

1Y 2W 2Z

2Y

2V

2U 1Z

1T

2B

1U

2C

1S

1H

1F

1B

1M

1V

1N

2F

1K

1X 1AA2AA

9

8

7

5

4

3

1

2

10

19

18

17

15

16

14

13

11

12

20

6

29

28

2725

26

24

23

21

22

A6E5714W008

1TCM

2 R position (TR switch)

3 D range (TR switch)

4 N position (TR switch)

5 P position (TR switch)

6 Brake switch

7 M range switch

8 Up switch9 Down switch

10 Selector lever

11 Cruise control module (In cruise actuator)

12 TFT sensor

13 VSS

14 Input/turbine speed sensor

15 Intermediate sensor

16 Pressure control solenoid

Page 465 of 909

K2–50

AUTOMATIC TRANSAXLE

CONTROLLER AREA NETWORK (CAN) DESCRIPTIONA6E571418901201Outline

•The TCM transmits/receives information using the CAN system. See Section T for detailed information

regarding the CAN system.

Structure/Operation

•The PCM inputs throttle opening angle, engine speed, engine torque, engine coolant temperature. to the TCM.

•The TCM operates shift and TCC controls based on the throttle opening angle, and controls line pressure and

other based on the throttle opening angle and the engine torque.

•The TCM outputs reduce torque signal, range signal, turbine speed, ATF temperature signal, and TCC signal to

the PCM.

•If there is an open or short circuit in the CAN wiring, the system determines that the CAN is abnormal and

switches to fail-safe mode.

Input

•Throttle position

•Engine torque (without torque down)

•Engine torque (with torque down)

•Engine torque (loss torque)

•Torque reduction request

•ECT

•Engine speed

•Buttery reconnection

Output

•Range position

•Turbine speed

•ATF temperature

•TCC

•Racing select

•Gear position

•Desired torque

•Desired gear position

•Upper torque limit

•Traveled distance

•MIL indicate request

•AT warning light indicate request

End Of Sie

Page 543 of 909

K2–128

ON-BOARD DIAGNOSTIC

End Of Sie

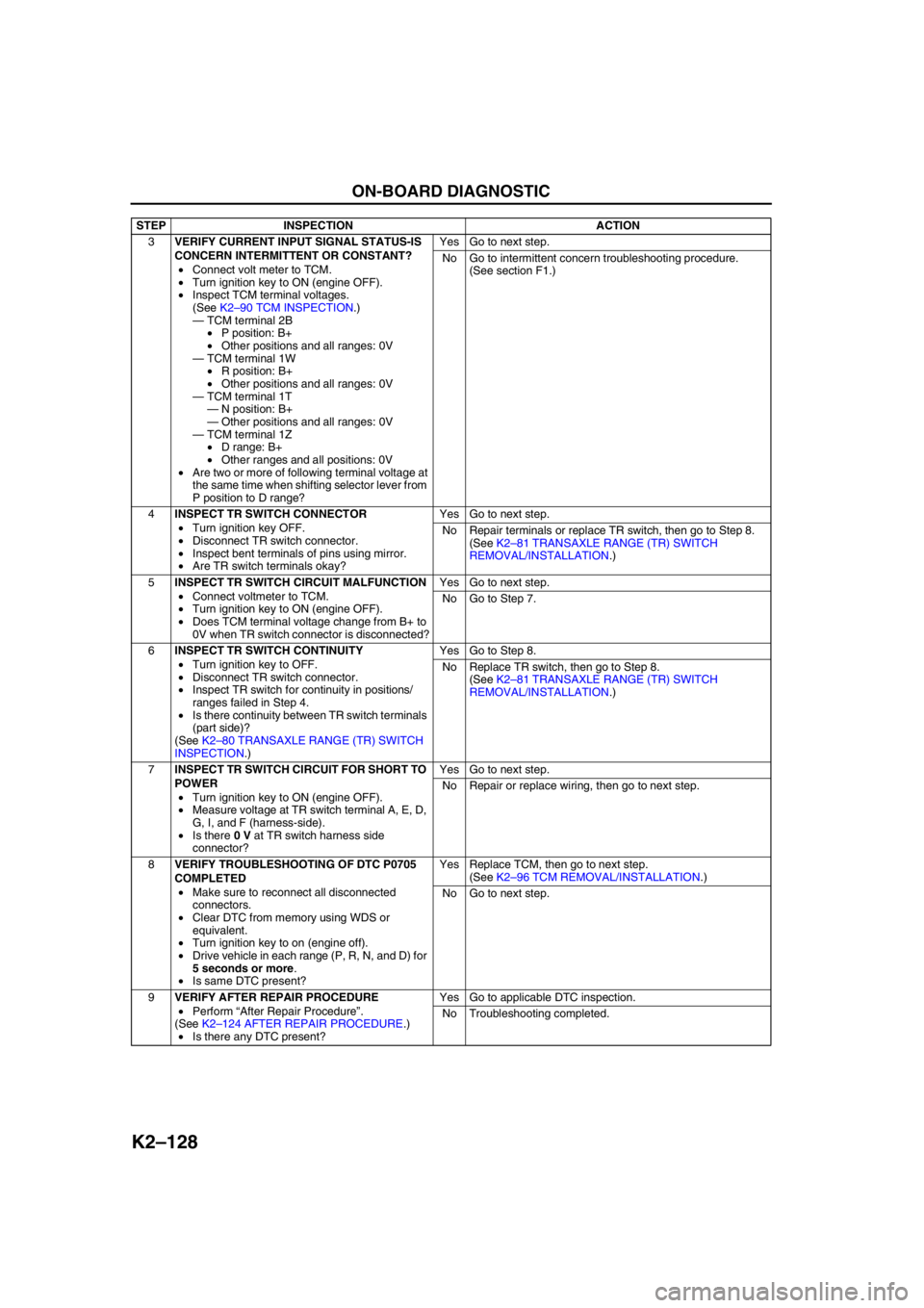

3VERIFY CURRENT INPUT SIGNAL STATUS-IS

CONCERN INTERMITTENT OR CONSTANT?

•Connect volt meter to TCM.

•Turn ignition key to ON (engine OFF).

•Inspect TCM terminal voltages.

(See K2–90 TCM INSPECTION.)

—TCM terminal 2B

•P position: B+

•Other positions and all ranges: 0V

—TCM terminal 1W

•R position: B+

•Other positions and all ranges: 0V

—TCM terminal 1T

—N position: B+

—Other positions and all ranges: 0V

—TCM terminal 1Z

•D range: B+

•Other ranges and all positions: 0V

•Are two or more of following terminal voltage at

the same time when shifting selector lever from

P position to D range?Yes Go to next step.

No Go to intermittent concern troubleshooting procedure.

(See section F1.)

4INSPECT TR SWITCH CONNECTOR

•Turn ignition key OFF.

•Disconnect TR switch connector.

•Inspect bent terminals of pins using mirror.

•Are TR switch terminals okay?Yes Go to next step.

No Repair terminals or replace TR switch, then go to Step 8.

(See K2–81 TRANSAXLE RANGE (TR) SWITCH

REMOVAL/INSTALLATION.)

5INSPECT TR SWITCH CIRCUIT MALFUNCTION

•Connect voltmeter to TCM.

•Turn ignition key to ON (engine OFF).

•Does TCM terminal voltage change from B+ to

0V when TR switch connector is disconnected?Yes Go to next step.

No Go to Step 7.

6INSPECT TR SWITCH CONTINUITY

•Turn ignition key to OFF.

•Disconnect TR switch connector.

•Inspect TR switch for continuity in positions/

ranges failed in Step 4.

•Is there continuity between TR switch terminals

(part side)?

(See K2–80 TRANSAXLE RANGE (TR) SWITCH

INSPECTION.)Yes Go to Step 8.

No Replace TR switch, then go to Step 8.

(See K2–81 TRANSAXLE RANGE (TR) SWITCH

REMOVAL/INSTALLATION.)

7INSPECT TR SWITCH CIRCUIT FOR SHORT TO

POWER

•Turn ignition key to ON (engine OFF).

•Measure voltage at TR switch terminal A, E, D,

G, I, and F (harness-side).

•Is there 0 V at TR switch harness side

connector?Yes Go to next step.

No Repair or replace wiring, then go to next step.

8VERIFY TROUBLESHOOTING OF DTC P0705

COMPLETED

•Make sure to reconnect all disconnected

connectors.

•Clear DTC from memory using WDS or

equivalent.

•Turn ignition key to on (engine off).

•Drive vehicle in each range (P, R, N, and D) for

5 seconds or more.

•Is same DTC present?Yes Replace TCM, then go to next step.

(See K2–96 TCM REMOVAL/INSTALLATION.)

No Go to next step.

9VERIFY AFTER REPAIR PROCEDURE

•Perform “After Repair Procedure”.

(See K2–124 AFTER REPAIR PROCEDURE.)

•Is there any DTC present?Yes Go to applicable DTC inspection.

No Troubleshooting completed. STEP INSPECTION ACTION

Page 545 of 909

K2–130

ON-BOARD DIAGNOSTIC

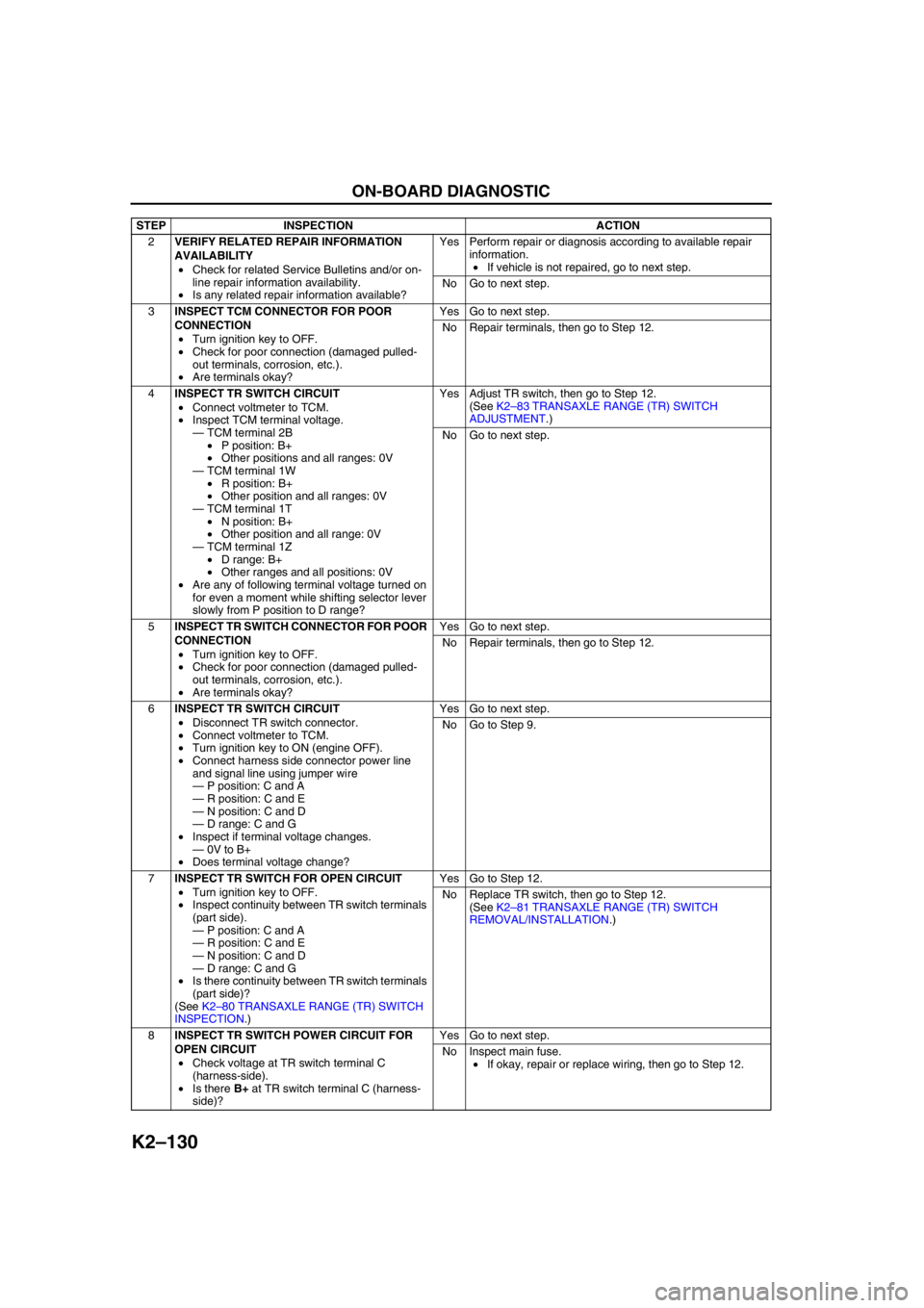

2VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

•Check for related Service Bulletins and/or on-

line repair information availability.

•Is any related repair information available?Yes Perform repair or diagnosis according to available repair

information.

•If vehicle is not repaired, go to next step.

No Go to next step.

3INSPECT TCM CONNECTOR FOR POOR

CONNECTION

•Turn ignition key to OFF.

•Check for poor connection (damaged pulled-

out terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair terminals, then go to Step 12.

4INSPECT TR SWITCH CIRCUIT

•Connect voltmeter to TCM.

•Inspect TCM terminal voltage.

—TCM terminal 2B

•P position: B+

•Other positions and all ranges: 0V

—TCM terminal 1W

•R position: B+

•Other position and all ranges: 0V

—TCM terminal 1T

•N position: B+

•Other position and all range: 0V

—TCM terminal 1Z

•D range: B+

•Other ranges and all positions: 0V

•Are any of following terminal voltage turned on

for even a moment while shifting selector lever

slowly from P position to D range?Yes Adjust TR switch, then go to Step 12.

(See K2–83 TRANSAXLE RANGE (TR) SWITCH

ADJUSTMENT.)

No Go to next step.

5INSPECT TR SWITCH CONNECTOR FOR POOR

CONNECTION

•Turn ignition key to OFF.

•Check for poor connection (damaged pulled-

out terminals, corrosion, etc.).

•Are terminals okay?Yes Go to next step.

No Repair terminals, then go to Step 12.

6INSPECT TR SWITCH CIRCUIT

•Disconnect TR switch connector.

•Connect voltmeter to TCM.

•Turn ignition key to ON (engine OFF).

•Connect harness side connector power line

and signal line using jumper wire

—P position: C and A

—R position: C and E

—N position: C and D

—D range: C and G

•Inspect if terminal voltage changes.

—0V to B+

•Does terminal voltage change?Yes Go to next step.

No Go to Step 9.

7INSPECT TR SWITCH FOR OPEN CIRCUIT

•Turn ignition key to OFF.

•Inspect continuity between TR switch terminals

(part side).

—P position: C and A

—R position: C and E

—N position: C and D

—D range: C and G

•Is there continuity between TR switch terminals

(part side)?

(See K2–80 TRANSAXLE RANGE (TR) SWITCH

INSPECTION.)Yes Go to Step 12.

No Replace TR switch, then go to Step 12.

(See K2–81 TRANSAXLE RANGE (TR) SWITCH

REMOVAL/INSTALLATION.)

8INSPECT TR SWITCH POWER CIRCUIT FOR

OPEN CIRCUIT

•Check voltage at TR switch terminal C

(harness-side).

•Is there B+ at TR switch terminal C (harness-

side)?Yes Go to next step.

No Inspect main fuse.

•If okay, repair or replace wiring, then go to Step 12. STEP INSPECTION ACTION

Page 604 of 909

TROUBLESHOOTING

K2–189

K2

Diagnostic procedure

End Of SieNO.3 VEHICLE MOVES IN P POSITION, OR PARKING GEAR DOES NOT DISENGAGE WHEN P IS

DISENGAGED

A6E578001030206

End Of SieNO.4 EXCESSIVE CREEPA6E578001030207

End Of SieNO.5 NO CREEP AT ALLA6E578001030208

STEP INSPECTION ACTION

1•Does vehicle creep when selector lever

moved slightly in N position?Yes•Overhaul control valve body and repair or replace any

defective parts.

(See ATX Workshop Manual.)

—If problem remains, replace or overhaul transaxle and

repair or replace any defective parts.

(See K2–99 AUTOMATIC TRANSAXLE AND

TRANSFER REMOVAL/INSTALLATION.)

(See ATX Workshop Manual.)

No Inspect and adjust selector lever.

(See K2–117 SELECTOR LEVER INSPECTION.)

(See K2–118 SELECTOR CABLE ADJUSTMENT.)

2•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

3 Vehicle moves in P position, or parking gear does not disengage when P is disengaged

DESCRIPTION•Vehicle rolls when on a downward slope and tires do not lock in P position.

•Tires locked when P disengaged, vehicle does not move in D range, and R position when accelerator

pedal depressed, and engine remains in stall condition.

POSSIBLE

CAUSE•Malfunction of parking mechanism (May have effect on noise or shock from transaxle)

•Improper adjustment of selector lever

•If vehicle moves in N position, perform symptom troubleshooting No.2 “Vehicle moves in N position”

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

4 Excessive creep

DESCRIPTION•Vehicle accelerates in D range, and R position without depressing accelerator pedal.

POSSIBLE

CAUSE•Engine idle speed high (transaxle system is not cause of problem)

•Go to symptom troubleshooting No.9 “Fast idle/runs on”

(See Section F.)

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

5 No creep at all

DESCRIPTION•Vehicle does not move in D range, or R position when idling on flat paved road.

POSSIBLE

CAUSE•Either engine output low or there is clutch circuit slippage.

—Clutch burned

•Line pressure low

•Malfunction of shift solenoid A, B, or C

•Malfunction of body ground

•Malfunction of control valve body

—Transaxle fixed in 4GR (Operation of fail-safe function)

•Short or open circuit in wiring

•Poor connection of connector

•Electronic parts of output and input system malfunctioning

—Engine torque is not start

•Malfunction of torque converter

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.